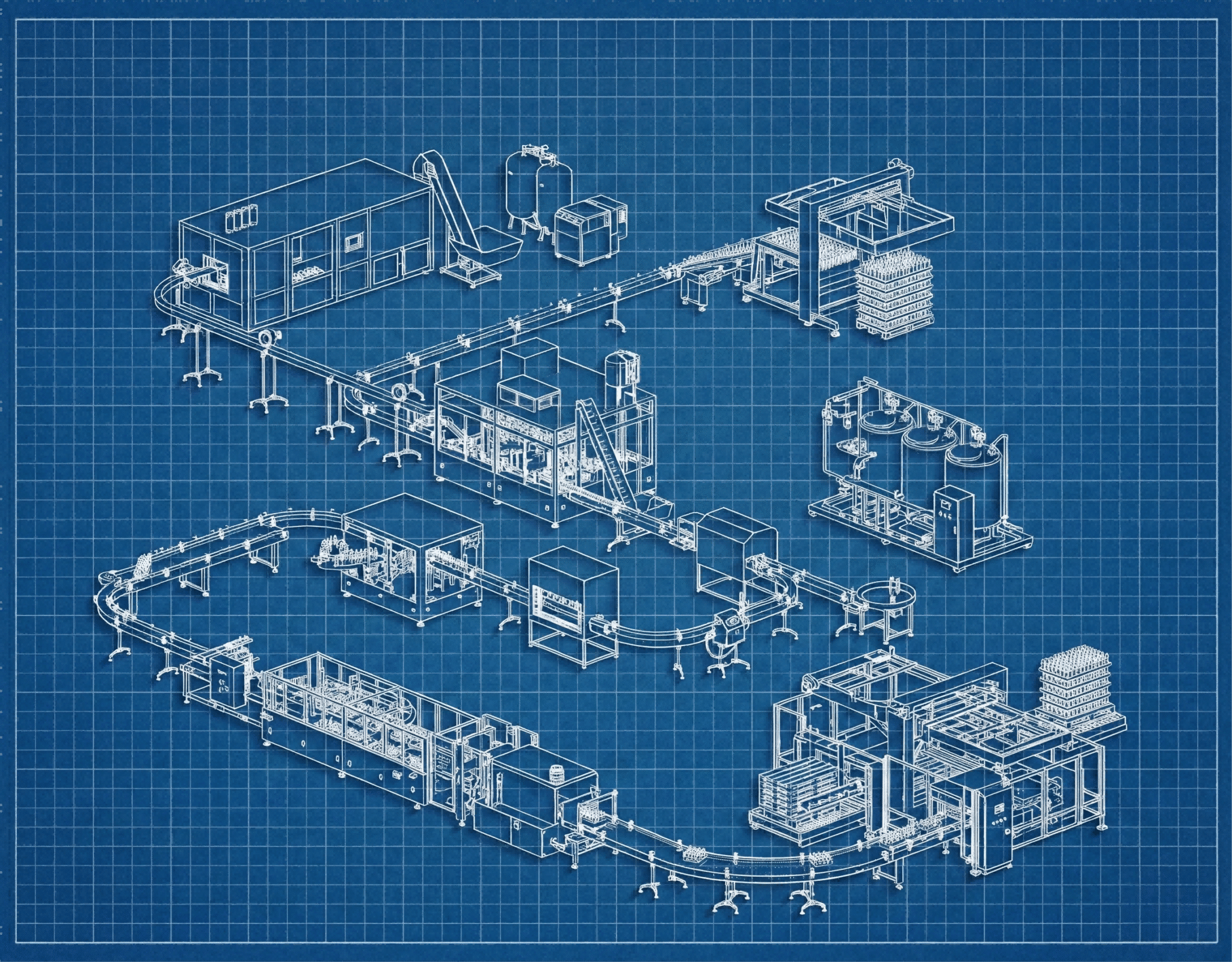

Integrated PET Bottling Solutions

Ensuring Your Project's Success

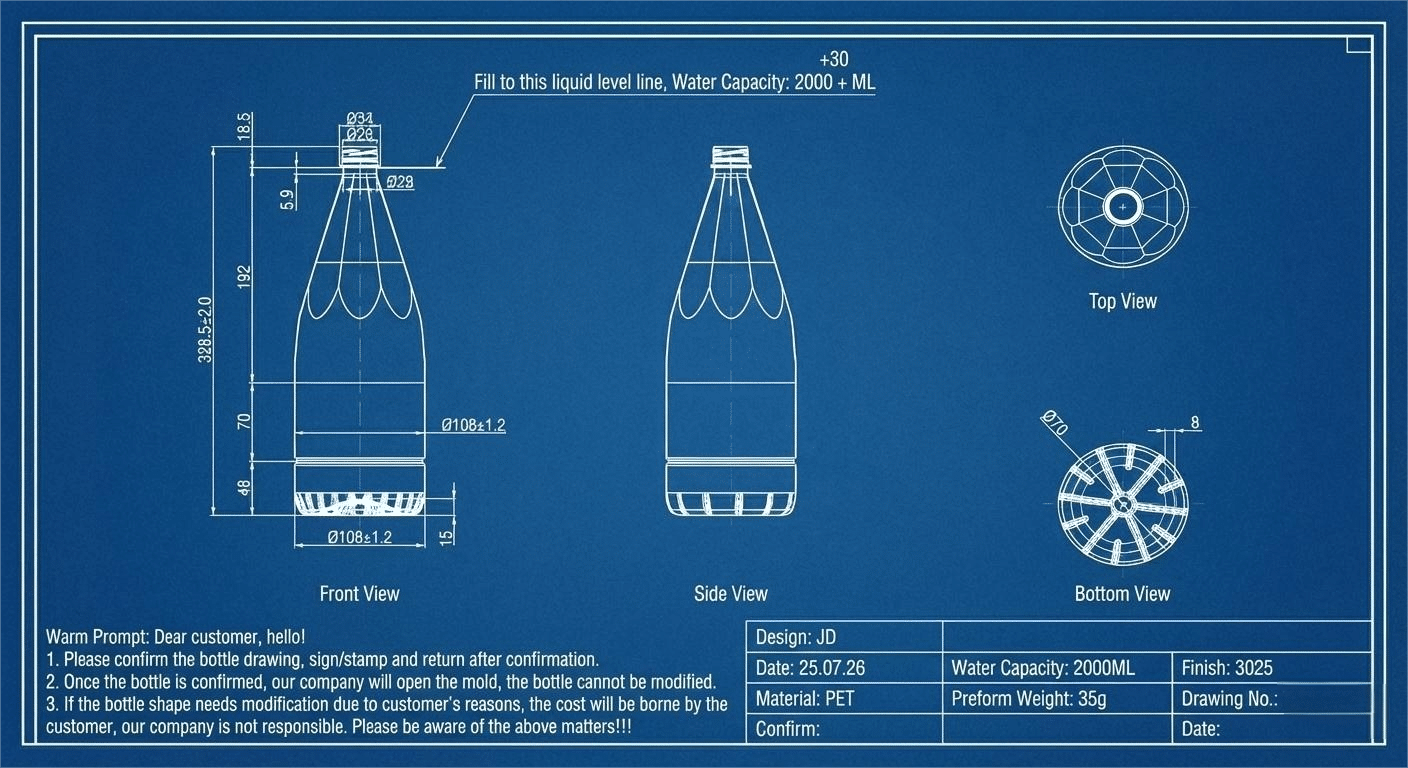

Collaborative Bottle Design

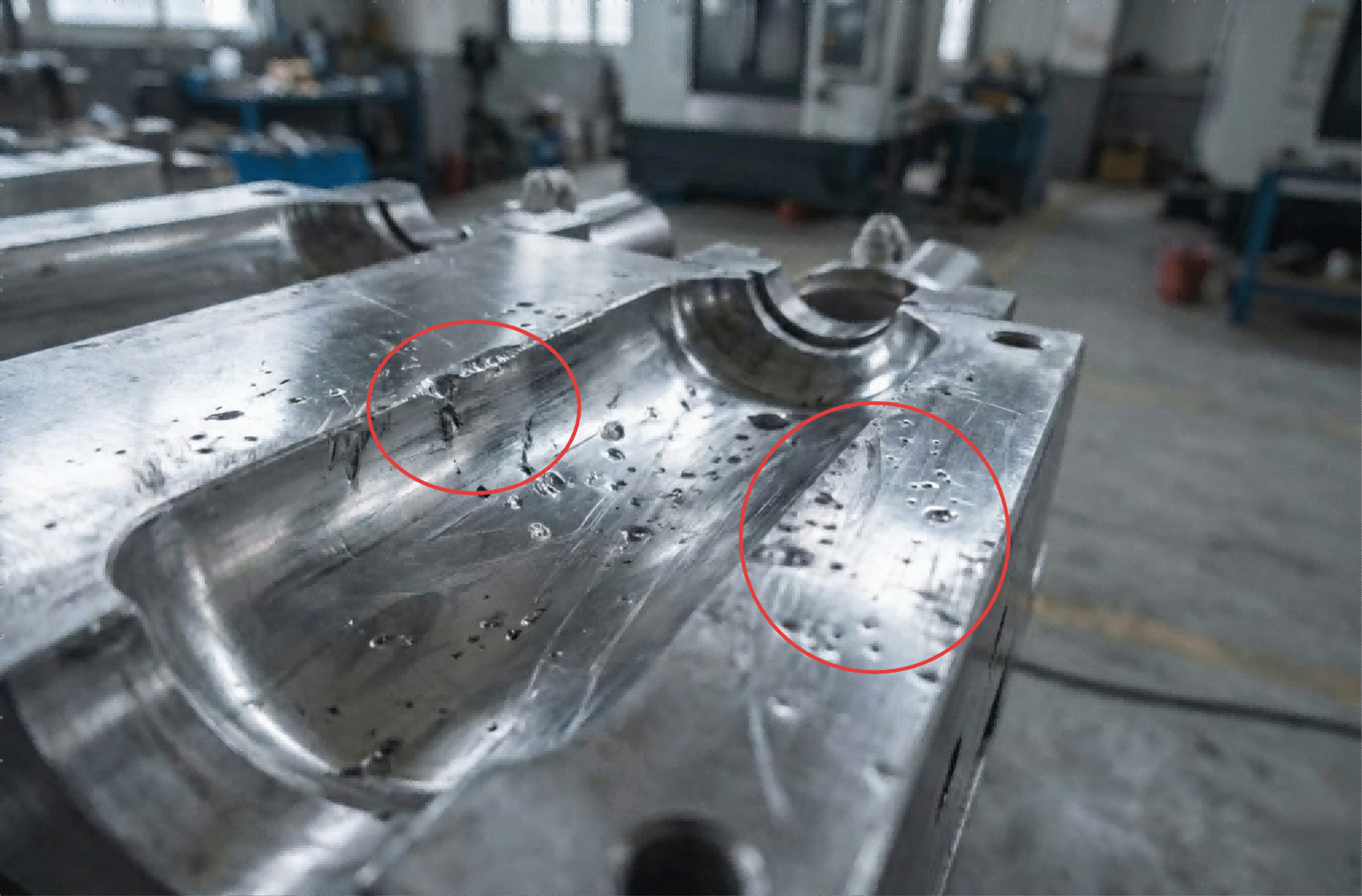

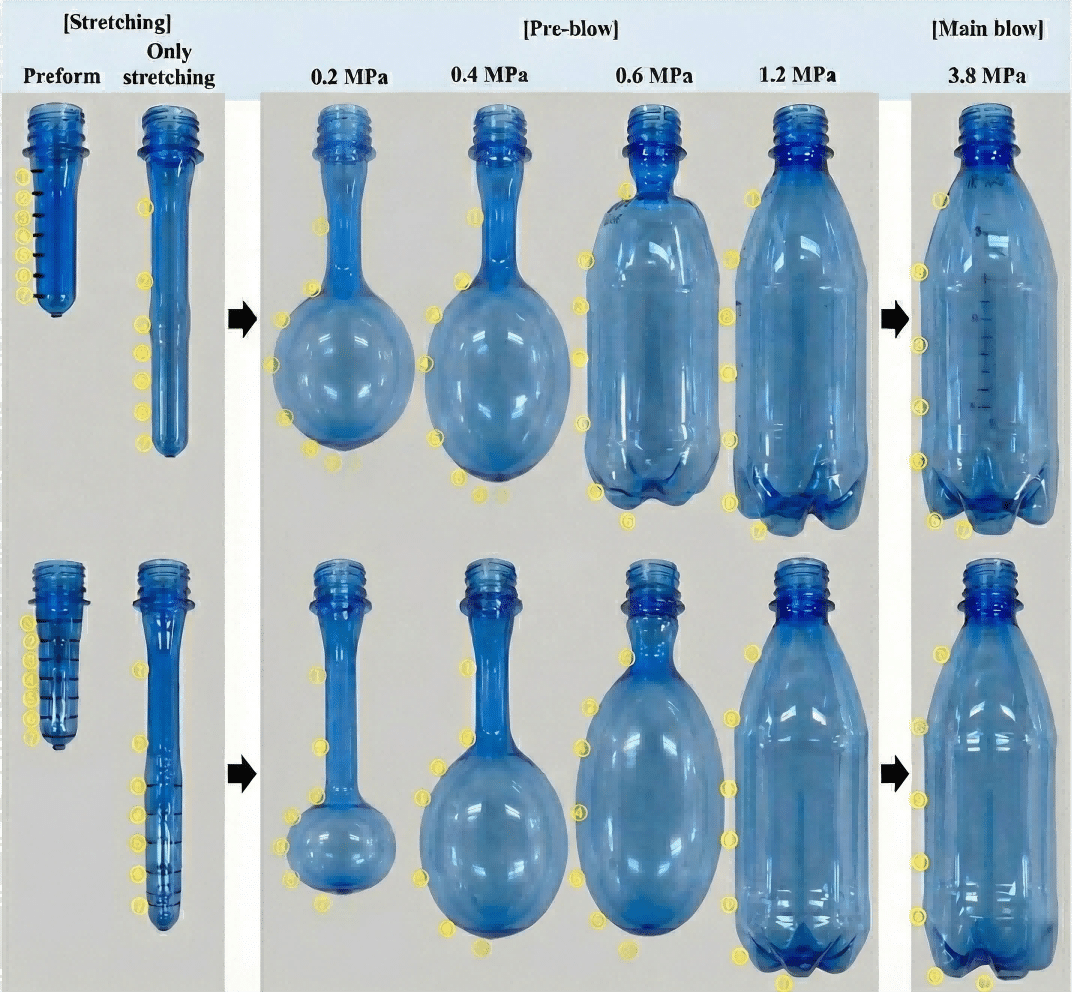

Prototype & Feasibility Approval

Real-World Performance Testing

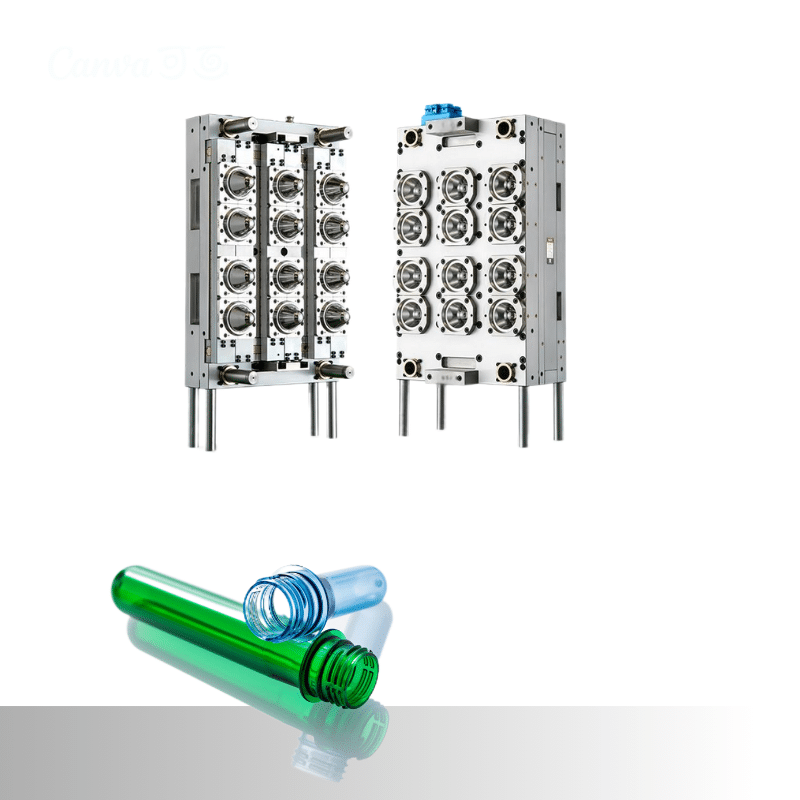

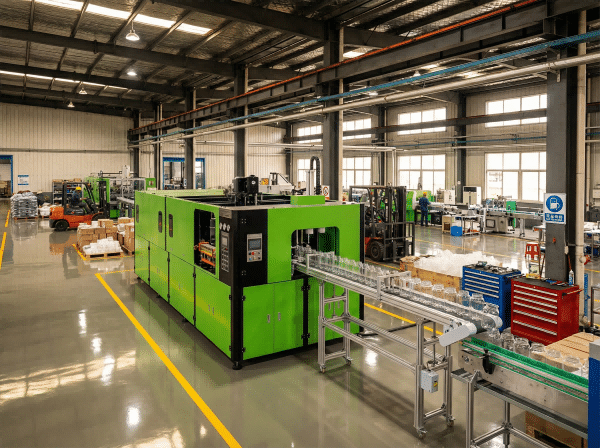

Integrated machines & molds for max speed and quality

What can we solve?

Enhance Production Stability

Reduce Production Costs

Shorten Delivery Time

Strength factory-Jindong

Helping businesses reach their goals

Never fail, learn from the experts

Friendly and efficient business coaches

-1024x576.png)

- Some partners

Leading Technology, Trusted Quality

Strength Testimony

Our Values

01

Free Design

Free bottle design service to meet personalized needs and optimize packaging.

02

Tailored Plans

Tailored production plans to ensure maximum production efficiency.

03

Fast Sampling

Fast sampling service to shorten development cycle and speed up market launch.

04

Expert Setup

Professional installation and commissioning services to ensure stable equipment operation.

05

24/7 Support

24/7 tech support for quick response and issue resolution.

06

Global After-Sales

Global after-sales network for long-term maintenance and tech support, ensuring continuous operation.

Their real feedback

Words From Clients

Why we choose Jindong Machinery?

As a long-term customer of this factory, I am deeply satisfied with their credit and service. They consistently provide high-quality PET blow molding machines and molds with excellent product quality, which gives me an advantage in the market competition. Every time we have a problem, their after-sales service responds quickly and always provides professional technical support at the first time to ensure the smooth operation of the production line. What I appreciate more is that they pay great attention to communication with customers and are willing to listen to our needs and feedback.

"Professional Team"

"Good after-sales service"

"High quality"

.png)

Solve your problems effectively

FAQ

A: Yes, we have a professional installation team with rich installation experience and can provide on-site installation service to ensure that your equipment is put into production quickly. Our engineers will provide you with detailed operation training during the installation process to help your team get started as soon as possible.

A: We value after-sales service and have a professional team on standby to provide timely remote technical support and maintenance services. In addition, we provide spare parts services to ensure the normal operation of the equipment, minimize downtime, and protect your production.

A: Of course, we have a database of more than 80% brands of blow molding machine molds, which can be well matched with your blow molding machine. Of course, we will also assist you in measuring the installation data of the mold to ensure that the installation size is correct and can be 100% produced.

A: Our blow molding machines are made with high-precision processing equipment after 20 years of factory experience. The core parts of the machine are made of high-quality materials to ensure stability and durability even under long-term production. We also provide long-term after-sales support so that you don’t have to worry about it. docking, according to your factory to provide the whole line design and planning, to product customization, installation and commissioning to produce bottled mineral water.

Vivian

Overseas Manager & Website Founder

# what are you looking for ?

a technical problem solver !

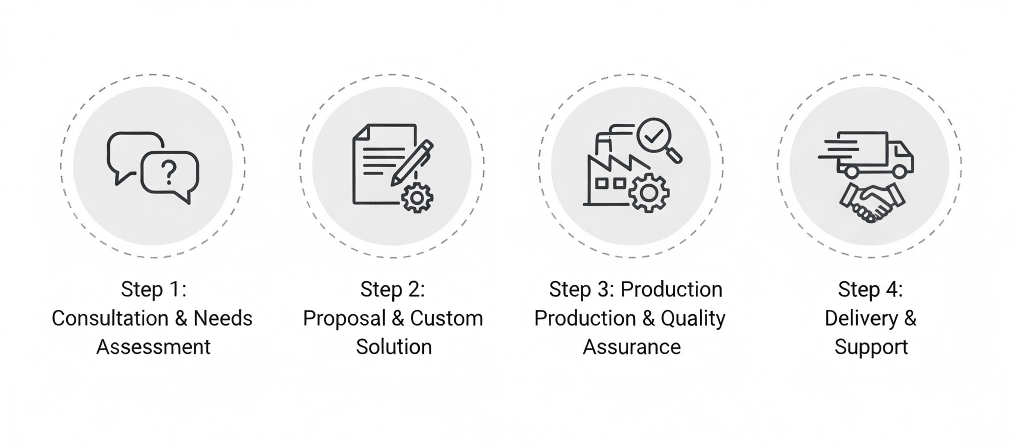

our 4 Steps: Consult, Plan, Produce, Deliver.

Quick Order, Done