Starting a PET bottle project but worried about costs and complexity? Many find this initial phase daunting. What if there was a simpler, more affordable way to begin?

A Semi-Auto Blow Molding Machine is often the perfect solution for small-scale PET bottle production. It offers a balance of affordability, ease of use, and flexibility, making it ideal for startups and businesses with smaller batch requirements.

I've seen many businesses thrive by starting smart. If you're venturing into PET bottle production, especially on a smaller scale, understanding your machinery options is key. Let's explore why a Semi-Auto Blow Molding Machine might be exactly what you need to kickstart your project efficiently and effectively. This approach could save you headaches and resources down the line.

Why Do Small PET Bottle Projects Prefer Semi-Auto Machines?

Feeling overwhelmed by the choices for PET bottle production? Many small projects face tight budgets and need a practical start. How can you get started without a huge upfront investment?

Semi-auto machines are favored by small PET bottle projects because they offer a lower initial investment, simpler operation, and easier maintenance. This makes them accessible and manageable for new businesses.

Over my 16 years in the PET packaging machinery industry, I've noticed a strong trend, especially among my clients in Southeast Asia. They often choose a Semi-Auto Blow Molding Machine. The reason is straightforward: these machines hit a sweet spot. They don't require the massive capital of fully automatic lines, and the learning curve is much gentler. For businesses testing the waters or serving niche markets, this is a game-changer. They want to see returns without betting the entire farm.

Key Advantages for Small Scale Operations

Small projects have unique needs. A Semi-Auto Blow Molding Machine addresses these perfectly.

- Reduced Initial Capital: The most obvious benefit. Less money tied up in machinery means more for raw materials, marketing, or other startup costs.

- Manual Control Benefits: While "automatic" sounds good, manual intervention in a semi-auto process allows for more immediate adjustments and quality control, which can be crucial when you're starting out and learning the nuances of PET blow molding.

- Adaptability: Small projects often mean varied orders. These machines can often handle different bottle shapes and sizes with relatively quick mold changes, offering flexibility that larger, dedicated lines might not.

- Lower Operational Overheads: Generally, these machines consume less power and require less specialized technical staff to run compared to fully automated systems. This keeps the day-to-day running costs lower.

For instance, I remember a client just starting their bottled water business. They were hesitant about a large investment. We set them up with a two-cavity Semi-Auto Blow Molding Machine. Within a year, they had captured a decent local market share, all thanks to keeping their initial costs manageable and their operations lean. This is a common story I've seen unfold.

Is a Lower Investment Cost with High ROI Ideal for Startups?

Worried about spending too much on equipment when starting your business? Many startups need to be careful with cash. How can you ensure your machinery investment pays off quickly?

Yes, a lower investment cost with the potential for high Return on Investment (ROI) is incredibly attractive for startups. A Semi-Auto Blow Molding Machine facilitates this by minimizing initial outlay while enabling production.

When you're a startup, every dollar counts. The appeal of a Semi-Auto Blow Molding Machine is that it significantly lowers the barrier to entry into PET bottle production. This isn't just about saving money upfront; it's about smart capital allocation and achieving profitability sooner. Let's look at how this actually works for new businesses.

Breaking Down the Financial Benefits

The financial argument for a Semi-Auto Blow Molding Machine in a startup scenario is compelling. It’s not just about the sticker price.

- Minimized Upfront Cost: This is the primary draw. A semi-automatic machine can be a fraction of the cost of a fully automatic one. This frees up capital for other essential business areas like marketing, inventory, or operational cash flow.

- Faster Path to Profitability: With lower initial and operational costs, the break-even point is reached much sooner. Each bottle produced contributes more significantly to covering the investment.

- Reduced Risk: A lower investment naturally means lower financial risk. If the market takes longer to penetrate, or if product lines need to pivot, the financial burden is less severe.

- Phased Growth Potential: Startups can begin with a semi-automatic setup and, as profits grow and demand increases, they can reinvest in more machines or eventually upgrade to fully automatic systems. This staged approach is much healthier for cash flow.

I've guided many startups through this. They begin with a single Semi-Auto Blow Molding Machine, learn the ropes, build their customer base, and then, when the time is right, they expand. This prudent approach has proven successful time and again. It’s about growing sustainably, not overstretching from day one.

Does a Compact Design Save Factory Space Efficiently?

Concerned about limited factory space for your new PET bottle venture? Many small businesses operate in smaller units. Can a machine's design truly make a difference in your layout?

Absolutely. The compact design of a Semi-Auto Blow Molding Machine is a major advantage for saving factory space efficiently. This is crucial for startups or businesses with limited operational footprints.

Factory floor space is often a premium, especially for small businesses or those located in expensive urban areas. The beauty of a Semi-Auto Blow Molding Machine lies in its relatively small footprint compared to its fully automatic counterparts. This isn't just about fitting the machine in; it's about optimizing your entire production flow. Let's consider how this plays out in a real-world scenario.

Maximizing Your Operational Area

A compact machine footprint offers several practical benefits for efficient space utilization.

- Smaller Dedicated Area: A Semi-Auto Blow Molding Machine generally requires less square footage. This means you might be able to operate out of a smaller, less expensive industrial unit.

- Flexible Layout Options: Its smaller size allows for more flexibility in how you arrange your production line. You can more easily position auxiliary equipment like air compressors and chillers, and organize space for raw materials (preforms) and finished products (bottles).

- Easier Integration: If you're adding bottle blowing to an existing operation, a compact machine is easier to integrate without major reconfigurations of your current setup.

- Room for Growth: By saving space initially, you leave more room for future expansion, whether that's adding another machine or other processing equipment.

Consider this: I had a client who wanted to start a small juice bottling line in a rented workshop that was quite narrow. A fully automatic machine was out of the question due to space. We installed a Semi-Auto Blow Molding Machine, and it fit perfectly, leaving enough room for their filling and labeling stations. The compact design was the enabler for their entire project. They simply wouldn't have been able to start otherwise.

Are They Easy to Operate and Maintain, Even for Beginners?

New to PET bottle manufacturing and worried about a steep learning curve? Many entrepreneurs fear complex machinery. Can a beginner truly handle the operation and upkeep of these machines?

Yes, Semi-Auto Blow Molding Machines are generally easy to operate and maintain, even for individuals with no prior experience. Their simpler design and mechanics contribute to this accessibility.

One of the most significant advantages I've seen with a Semi-Auto Blow Molding Machine, particularly for my clients, is its user-friendliness. You don't need a team of highly specialized engineers to run or look after them. This simplicity is a huge relief for small business owners who often wear many hats. Let me share an experience that really highlights this point.

Simplicity in Action: Operation and Upkeep

The ease of use and maintenance stems from several factors inherent in their design.

- Simplified Control Systems: Unlike fully automatic machines with complex PLC programming and numerous sensors, semi-automatic machines often have more straightforward, sometimes manual, controls. This makes the learning process quicker for operators.

- Manual Preform Loading: The operator typically loads preforms manually into the heater and then transfers them to the blowing station. This direct involvement helps in understanding the process.

- Fewer Moving Parts: Generally, simpler machines mean fewer components that can break down. Troubleshooting is often more direct.

- Basic Maintenance Routines: Regular maintenance usually involves basic lubrication, checking seals, and ensuring the pneumatic and heating systems are functioning correctly. These tasks can often be learned and performed by in-house staff.

I have a client in Cambodia who started with one Semi-Auto Blow Molding Machine. Over three years, their business grew, and they bought a total of eight units from me! I suggested they could increase output with a fully automatic two-cavity machine, which is also a good choice for growing businesses. However, they preferred to stick with the semi-automatic models. Their reasoning was simple: their workers were experts at operating and performing minor repairs on the semi-auto machines. They could fix small issues themselves, avoiding production delays. Introducing a new, more complex machine would mean months of retraining and familiarization, which they felt would disrupt their production. I completely understood. Workers prefer equipment they know inside out. This firsthand experience shows how the ease of operation and maintenance of a Semi-Auto Blow Molding Machine can be a decisive factor.

Is Flexible Production Capacity Suitable for Small Batch Orders?

Do you anticipate varied order sizes or need to produce different bottles frequently? Large, fixed-output machines might not be ideal. How can you cater to small, diverse demands efficiently?

Yes, the flexible production capacity of a Semi-Auto Blow Molding Machine makes it highly suitable for businesses that handle small batch orders or require frequent product changeovers.

In today's market, especially for niche products or startups, the ability to produce small quantities of different PET bottle types without incurring huge costs or long downtimes is invaluable. A Semi-Auto Blow Molding Machine shines in this area. It’s not about massive hourly output; it’s about agility and responsiveness to market needs. Let me explain why this flexibility is a key strength.

Adapting to Diverse Production Needs

The adaptability of a Semi-Auto Blow Molding Machine comes from several operational advantages:

- Quick Mold Changes: Changing molds on a semi-automatic machine is generally faster and simpler than on large, fully automatic systems. This means you can switch from producing, say, 500ml water bottles to 250ml juice bottles with minimal downtime. This is perfect for fulfilling diverse, small-quantity orders.

- Cost-Effective for Short Runs: Because setup time is less and the operational complexity is lower, running small batches is economically viable. You don't need to produce tens of thousands of bottles to justify starting the machine.

- Ideal for Market Testing: If you're launching a new product and want to test the market with a small batch, a Semi-Auto Blow Molding Machine is perfect. You can produce a few thousand bottles without a massive commitment in resources or inventory.

- Reduced Waste During Changeovers: Simpler systems and quicker changes often result in less material wastage during the transition from one product to another.

I've worked with many clients who supply artisanal beverages, custom-branded water for events, or specialty oils. Their orders are rarely huge, but they are frequent and varied. For them, a Semi-Auto Blow Molding Machine is the workhorse that allows them to cater to this dynamic demand efficiently. They value the ability to say "yes" to different customers without worrying about the economics of small production runs.

What Bottle Types Are Best Suited for Semi-Auto Blow Molding?

Wondering if a Semi-Auto Blow Molding Machine can produce the specific PET bottles your project needs? Not all machines are versatile. What types of bottles are a good match for this technology?

Semi-Auto Blow Molding Machines are best suited for a wide range of common PET bottle types, particularly those with standard shapes and sizes, typically up to 2-5 liters, like water, juice, and CSD bottles.

While a Semi-Auto Blow Molding Machine is versatile, it's good to know its sweet spot in terms of bottle design and complexity. Generally, they handle the most common types of PET containers that small and medium businesses require. Let's look at the specifics.

Common Applications and Considerations

These machines excel at producing a variety of everyday PET bottles.

- Water Bottles: Standard still water and sparkling water bottles from 200ml up to 2 liters are very common.

- Juice and Beverage Bottles: Bottles for juices, teas, and other non-carbonated drinks are easily produced. Hot-fill bottles might require specific machine configurations or preforms.

- Carbonated Soft Drink (CSD) Bottles: Many semi-auto machines can handle the slightly thicker preforms and base designs required for CSD applications.

- Edible Oil Bottles: Smaller edible oil bottles are often produced on these machines.

- Cosmetic and Pharmaceutical Bottles: Simpler shapes for items like hand sanitizers, lotions, or basic pharmaceutical containers can be suitable.

It's important to consider:

- Complexity of Shape: While they can handle many designs, extremely intricate or non-symmetrical bottle shapes might be more challenging or require specialized molds and operator skill.

- Bottle Volume: Most standard machines are excellent for bottles up to 2 liters. Some models can go up to 5 liters or even larger, but these are less common for general-purpose small projects.

- Neck Finish: Standard PCO neck finishes (like those on water and soda bottles) are easily accommodated. Other neck types might require specific mold designs.

I often advise clients to start with standard bottle designs if they are new to the process. Once they gain experience with their Semi-Auto Blow Molding Machine, they can explore more unique shapes. The key is that for the vast majority of common PET bottle needs in small projects, these machines are more than capable.

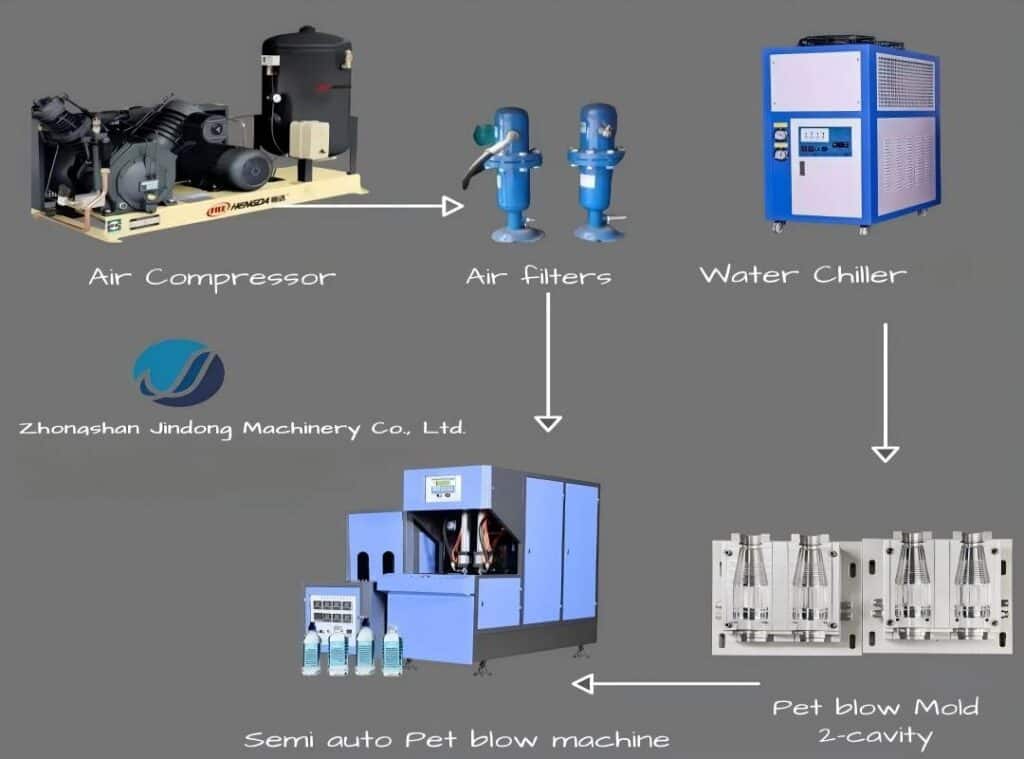

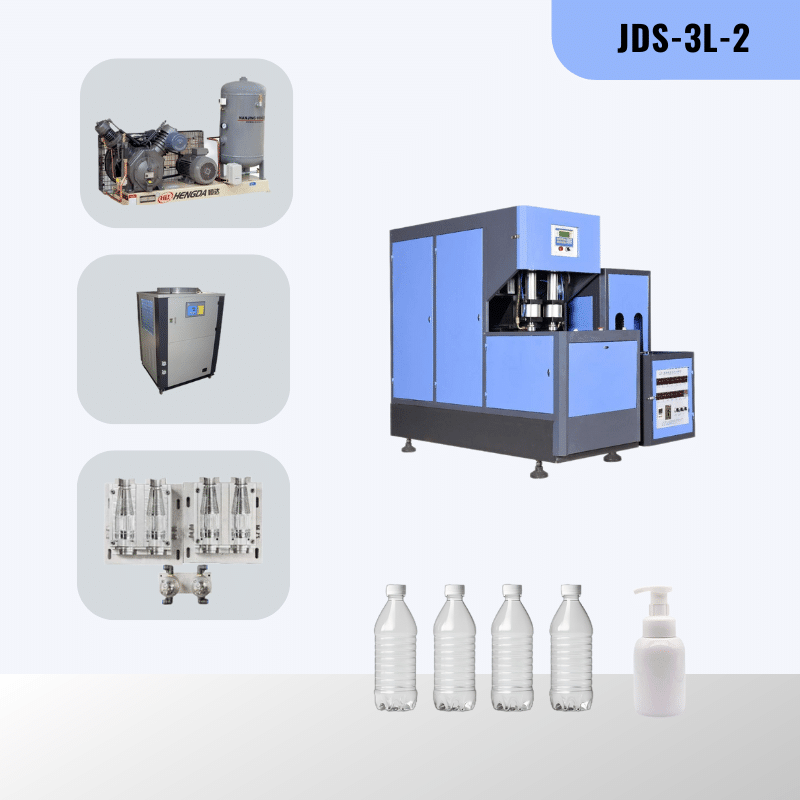

What Auxiliary Equipment Is Needed to Start Production with a Semi-Auto Blow Molding Machine?

You know you need the blow molder, but what else is essential to actually start making PET bottles? Setting up production involves more than just one machine. What supporting gear is crucial?

To start production with a Semi-Auto Blow Molding Machine, you'll need essential auxiliary equipment including an air compressor system, a water chiller, and bottle molds.

A Semi-Auto Blow Molding Machine is the heart of your PET bottle production, but it doesn't work in isolation. To get a complete production line up and running, several key pieces of auxiliary equipment are necessary. As someone who has set up countless lines, I always ensure my clients understand the full picture from the start. This avoids surprises and ensures a smooth startup.

Essential Supporting Machinery

Here’s a breakdown of the typical auxiliary equipment you will need:

| Equipment | Purpose | Key Considerations |

|---|---|---|

| High-Pressure Air Compressor | Provides high-pressure air (typically 30-40 bar) for blowing the PET preforms into bottles. | Capacity (L/min or CFM), pressure rating, oil-free options. |

| Air Receiver Tank(s) | Stores compressed air to ensure a stable supply to the blow molder. | Size (Liters/Gallons), pressure rating. |

| Air Dryer & Filters | Removes moisture and impurities from the compressed air to protect the machine and ensure bottle quality. | Type (refrigerated/desiccant), filtration level. |

| Water Chiller | Circulates chilled water to cool the bottle molds and sometimes the machine hydraulics. | Cooling capacity (kW or Tons), temperature range. |

| Bottle Molds | The custom-made tools that define the shape and size of your PET bottle. | Material (aluminum/steel), number of cavities, design complexity. |

| Preform Heater (if separate) | Heats PET preforms to the correct temperature before blowing. Many semi-auto machines have integrated heaters. | Heating capacity, type (infrared lamps). |

| (Optional) Low-Pressure Air Compressor | Provides low-pressure air (around 7-10 bar) for pneumatic machine functions if not drawn from the high-pressure system via a reducer. | Capacity, pressure. |

Getting these auxiliaries correctly sized for your Semi-Auto Blow Molding Machine and production needs is critical. For example, an undersized air compressor will lead to slow production and poor bottle quality. An inadequate chiller will result in inconsistent bottle formation and longer cycle times. I always work closely with clients to specify the right supporting gear, ensuring their entire system works harmoniously.

What Are the Utility Requirements: Electricity, Air Compressor, and Chiller?

Planning your factory setup for a Semi-Auto Blow Molding Machine involves utilities. What are the typical power, air, and water cooling needs? Knowing this helps in proper site preparation.

The primary utility requirements for a Semi-Auto Blow Molding Machine include a stable electricity supply, a high-pressure air source from an air compressor, and cooling water from a chiller.

Before your new Semi-Auto Blow Molding Machine arrives, it's crucial to prepare your facility with the necessary utilities. Proper planning here ensures a smooth installation and efficient operation from day one. Having seen many installations, I can tell you that overlooking these details can lead to frustrating delays. Let’s break down what you'll typically need.

Powering and Supporting Your Machine

Understanding the specific demands of each utility is key.

Electricity:

- Voltage & Phase: Most machines will specify their required voltage (e.g., 220V, 380V, 415V), phase (e.g., 3-phase), and frequency (50Hz or 60Hz). This must match your local supply.

- Power Consumption: This varies by machine size and type (especially the heating unit). A typical 2-cavity semi-auto machine might have a connected load of 10-25 kW, but actual consumption will be lower during operation. Always check the manufacturer's specifications.

- Stable Supply: A stable power supply, free from major fluctuations, is important for consistent heating and machine operation.

Compressed Air System:

- High-Pressure Air: This is for the actual blowing process.

- Pressure: Typically 25-40 bar (approx. 360-580 psi).

- Flow Rate: Depends on the number of cavities and bottle size. For a 2-cavity machine producing 500ml bottles, you might need 0.8-1.5 m³/min (approx. 28-53 CFM) of high-pressure air.

- Low-Pressure Air (sometimes): For pneumatic actuators on the machine.

- Pressure: Around 7-10 bar (approx. 100-145 psi).

- Flow Rate: Relatively small, often can be supplied via a pressure reducer from the high-pressure line or a separate small compressor.

- Air Quality: Air must be clean and dry. Oil, water, and particulate contamination can damage pneumatic components and affect bottle quality. Hence, air dryers and filters are essential.

- High-Pressure Air: This is for the actual blowing process.

Water Chiller (Cooling Water System):

- Purpose: To cool the bottle molds, and sometimes the preform necks or machine hydraulics, ensuring consistent bottle quality and reasonable cycle times.

- Temperature: Typically, chilled water is supplied at 7-12°C (45-54°F).

- Flow Rate & Pressure: The required flow rate and pressure will be specified by the machine and mold manufacturer. This depends on the heat load from the molds.

- Cooling Capacity: The chiller's capacity (measured in kW or Refrigeration Tons) must be sufficient to handle the heat removal needs.

I always advise my clients to have a qualified electrician and a compressed air specialist assess their site and the machine specifications. This ensures all utility connections are safe, correctly sized, and will provide reliable service for their Semi-Auto Blow Molding Machine.

What Is the Estimated Cost Breakdown for a Semi-Auto Blow Molding Machine Setup?

Budgeting is a key concern for any new project. What are the different costs involved in setting up a Semi-Auto Blow Molding Machine? A clear breakdown helps in financial planning.

The estimated cost for a Semi-Auto Blow Molding Machine setup includes the machine itself, auxiliary equipment (compressor, chiller, molds), installation, training, and initial raw materials.

Understanding the full investment picture is vital when planning for a Semi-Auto Blow Molding Machine. It's not just the price of the blowing unit itself. As someone who helps clients budget for these projects, I emphasize looking at the total cost of ownership and operation to make informed decisions. Let's outline the typical components that make up the overall project cost.

Key Elements of Your Project Budget

A comprehensive budget will typically cover the following areas:

| Cost Component | Description | Estimated % of Total (Approx.)* |

|---|---|---|

| 1. Semi-Auto Blow Molding Machine | The core blowing unit. Price varies by number of cavities, brand, features, and origin. | 30-40% |

| 2. Bottle Molds | Custom-designed for your specific bottle. Cost depends on material (aluminum, steel), cavities, complexity. | 10-20% |

| 3. High-Pressure Air Compressor System | Compressor, tank, dryer, filters. A significant investment crucial for operation. | 20-30% |

| 4. Water Chiller | For mold cooling. Cost varies with capacity. | 5-10% |

| 5. Installation & Training | Cost for technicians to install the equipment and train your staff. Might be included by some suppliers. | 3-7% |

| 6. Initial Raw Materials | First batch of PET preforms. | 5-10% |

| 7. Shipping & Handling | Cost to transport equipment to your facility. | 2-5% |

| 8. Site Preparation | Electrical wiring, plumbing for chiller, foundation if needed. Often overlooked but can add up. | Variable |

| 9. Working Capital | Funds for initial operational expenses, spare parts, unforeseen costs. | 5-10% |

*These percentages are very general estimates and can vary significantly based on specific project requirements, supplier choices, and geographic location.

Important Considerations:

- New vs. Used: Used equipment can lower initial costs but may come with higher maintenance risks and no warranty.

- Supplier Choice: Prices and included services (like installation, warranty) differ between manufacturers and distributors.

- Future Scalability: Consider if the chosen auxiliaries can support an additional Semi-Auto Blow Molding Machine if you plan to expand.

I always recommend getting detailed quotes from multiple suppliers for each component. When I work with clients, we create a comprehensive checklist to ensure no major cost item is missed. This careful planning is essential for a successful and financially sound PET bottle project using a Semi-Auto Blow Molding Machine.

Conclusion

Starting small with a Semi-Auto Blow Molding Machine can be a smart, cost-effective way to enter PET bottle production, offering flexibility and control for growing businesses.

FAQs

1. What is the typical output of a Semi-Auto Blow Molding Machine?

The output depends on the number of cavities in the mold and the bottle size. For example, a 2-cavity machine can produce around 600-900 bottles per hour for a 500ml bottle. A Semi-Auto Blow Molding Machine is designed for flexibility over sheer volume.

2. How much technical skill is needed to operate a Semi-Auto Blow Molding Machine?

Basic mechanical aptitude and proper training are usually sufficient. One of the advantages of a Semi-Auto Blow Molding Machine is its simpler operation compared to fully automatic systems. My clients often have their existing production staff trained within a few days.

3. Can I upgrade a Semi-Auto Blow Molding Machine later?

Upgrading the machine itself to a fully automatic one isn't typical. Instead, businesses usually add more semi-automatic units or purchase a separate fully automatic line when production demands significantly increase. However, some auxiliary equipment purchased for your Semi-Auto Blow Molding Machine might be usable with larger systems if sized correctly.

4. What are the common maintenance tasks for a Semi-Auto Blow Molding Machine?

Common tasks include daily checks of pneumatic systems, lubrication of moving parts, cleaning heater lamps, and inspecting seals and molds. Regular maintenance for a Semi-Auto Blow Molding Machine is straightforward and crucial for longevity and consistent bottle quality.

5. How much space do I need for a complete Semi-Auto Blow Molding Machine setup?

While the Semi-Auto Blow Molding Machine itself is compact, you also need space for the air compressor, chiller, preform storage, and finished bottle area. A small setup might fit in 30-50 square meters, but this varies greatly with the specific layout and production scale.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr