Struggling with high-volume bottle production? Traditional moulds can't keep up, causing bottlenecks and lost profits. You need a solution built for speed and precision.

Rotary blow moulds are specialized moulds designed for high-speed rotary blow moulding machines. They enable continuous, rapid production of PET bottles, making them essential for large-scale operations demanding efficiency and consistency. Understanding their intricacies is key before investing.

Key Takeaways

| Feature | Benefit | Why It Matters for You |

|---|---|---|

| High-Speed Operation | Increased output, lower per-unit cost | Meet high demand, improve profitability |

| Precision Engineering | Consistent bottle quality, reduced waste | Enhance brand image, save material costs |

| Durability (Proper Material) | Longer mould life, less downtime | Better ROI, uninterrupted production |

| Machine Compatibility | Seamless integration with specific machines | Avoid costly errors and delays |

| Supplier Experience | Optimized design, reliable performance | Ensure smooth setup and operation |

Choosing the right rotary blow moulds is a big decision. It impacts your production speed, bottle quality, and overall costs. I've spent 16 years in the PET packaging world, helping over 300 factories. I know these moulds inside out. Let's explore what makes them unique and what you need to consider before you place an order. This information will help you make a smart choice.

What Makes Rotary Blow Moulds Different from Standard Moulds?

Wondering if rotary moulds are just a fancier version of standard ones? They look similar, but the differences are critical. Understanding this helps you choose wisely.

Rotary blow moulds are engineered for continuous, high-speed operation on rotary machines, unlike standard moulds typically used on slower, linear machines. This means differences in design, materials, and precision.

Let's dive deeper into these distinctions. I've seen many clients initially underestimate these differences. Standard moulds, often called linear moulds, are great for smaller production runs or when frequent design changes are needed. They are generally simpler in construction. However, when you're talking about massive outputs – millions of bottles a day – that's where rotary blow moulds shine.

Key Differentiators: Rotary vs. Standard Moulds

| Feature | Rotary Blow Moulds | Standard (Linear) Moulds |

|---|---|---|

| Operating Speed | Very High (e.g., 1,800-2,500 bottles/hour/cavity) | Lower to Moderate (e.g., 600-1,000 bottles/hour/cavity) |

| Machine Type | Rotary blow moulding machines (continuous motion) | Linear blow moulding machines (intermittent motion) |

| Construction | More complex, precision-engineered for balance & speed | Simpler construction |

| Material | Often high-grade aluminum (e.g., 6062-T65), stainless steel for hot-fill | Typically aircraft-grade aluminum, steel |

| Cooling System | Highly optimized for rapid cycling | Efficient, but less critical than rotary |

| Cost | Higher initial investment | Lower initial investment |

| Volume Suitability | Large-scale, continuous production | Smaller runs, frequent changeovers |

The primary difference lies in their operational design. Rotary machines have multiple moulds mounted on a rotating wheel. Preforms enter, are blown, and exit in a continuous, fluid motion. This demands moulds that are perfectly balanced, can withstand high centrifugal forces, and have extremely efficient cooling. Any imperfection can lead to vibrations, inconsistent bottle quality, or even machine damage at high speeds. I remember a client who tried to adapt a standard mould concept for a rotary application; the results were far from optimal, leading to significant downtime.

Standard moulds, on the other hand, operate in a more start-stop fashion on linear machines. The stresses are different, and the speed requirements are lower. This allows for a less complex design and often a lower price point. But, if you need to produce millions of bottles consistently, rotary is the way to go. The precision required for rotary blow moulds is also much higher, directly impacting their manufacturing cost and lead time.

How Do Rotary Moulds Work in High-Speed Bottle Production?

Curious about the magic behind those incredible bottle output rates? It's not magic, but clever engineering. Understanding this helps you appreciate their value.

Rotary moulds function on a carousel system. Multiple moulds rotate continuously, each performing a blow moulding cycle in sequence, allowing for extremely high throughput of bottles.

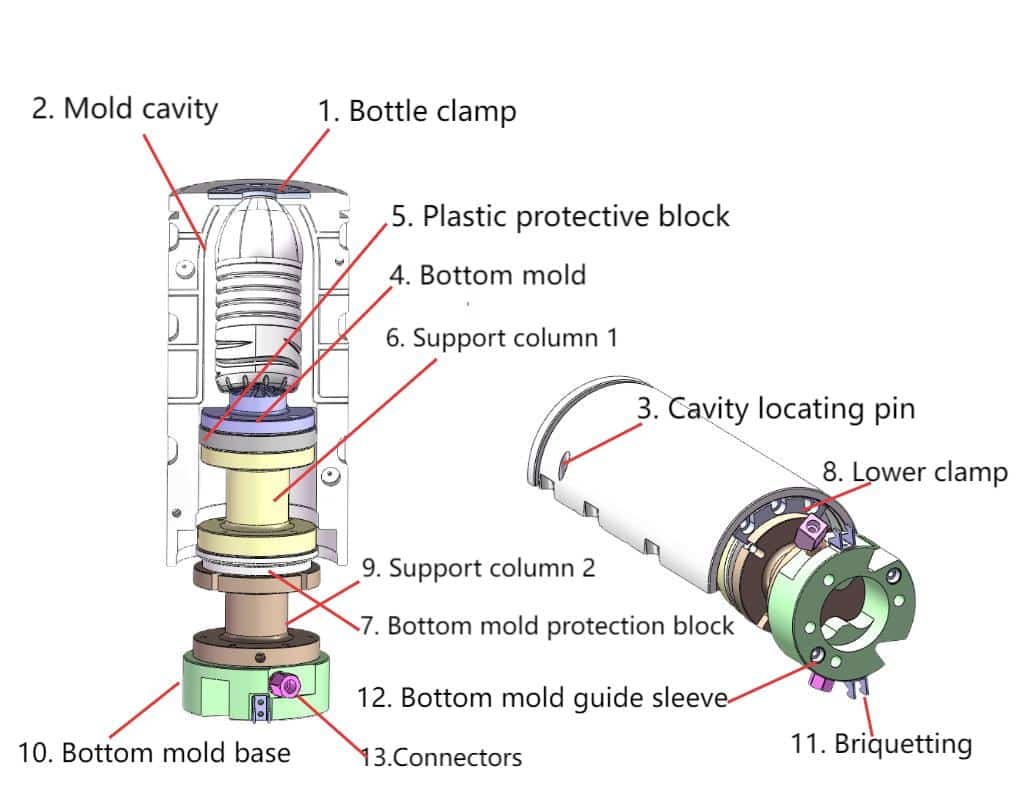

Let's look closer at this high-speed process. Imagine a large wheel, a carousel, with many rotary blow moulds mounted around its circumference. This wheel is the heart of a rotary blow moulding machine. As it turns, each mould goes through several stations in a smooth, continuous flow.

The Rotary Blow Moulding Cycle

- Preform Feeding: PET preforms are heated to the optimal temperature and then fed into the open moulds as they pass the loading station.

- Mould Closing & Sealing: The two halves of the mould close tightly around the preform. A perfect seal is critical here.

- Stretching & Blowing: A stretch rod descends into the preform, stretching it vertically. Simultaneously, high-pressure air is injected, blowing the preform outwards to take the shape of the mould cavity. This happens very quickly.

- Cooling: The newly formed bottle is held against the chilled mould walls for a brief period. Efficient cooling is vital to solidify the bottle quickly and maintain its shape. The material of the mould, typically aluminum like 6062-T65 for its thermal conductivity, plays a big role here.

- Mould Opening & Ejection: The mould opens, and the finished bottle is ejected onto a conveyor system.

- Cycle Repeat: The now-empty mould continues its rotation, ready to receive the next preform.

This entire cycle happens for each mould on the wheel, and because there are many moulds (e.g., 10 to 40 or more, depending on the machine), the output is multiplied. For example, if one mould can produce a bottle every 3 seconds, and you have 20 moulds on the wheel, you're looking at 20 bottles every 3 seconds, or 24,000 bottles per hour! This is the power of rotary systems. My work with clients using machines from Krones, SIDEL, and SIPA has shown me just how finely tuned this process must be. The synchronization, the precision of the mould clamping, and the airflow control are all critical at these speeds. It's a ballet of mechanical precision.

What Bottle Designs Are Suitable for Rotary Blow Moulds?

Got a unique bottle design in mind? Not all designs are a perfect fit for the demands of high-speed rotary production. Knowing the limitations saves headaches.

Simpler, symmetrical bottle designs with good material distribution are generally best for rotary blow moulds. Complex shapes can pose challenges at high speeds and may require design adjustments.

When you're producing bottles at such high speeds with rotary blow moulds, certain design elements become very important. It's not just about aesthetics; it's about manufacturability and performance. I've often advised clients to slightly tweak a design to make it run much more smoothly.

Design Considerations for Rotary Moulding:

- Symmetry: Symmetrical designs (round, square with rounded corners) tend to process more easily. Off-center necks or highly asymmetrical bodies can cause issues with material distribution and cooling.

- Wall Thickness Distribution: The design should allow for even wall thickness. Thin spots can lead to weak bottles, especially under pressure from carbonation or during stacking. Rotary processes are fast, so there's less time for material to flow into very intricate details perfectly.

- Base Design: The base needs to be stable and strong enough to withstand blowing pressures and subsequent handling. Petaloid bases for carbonated drinks, for instance, are common and well-suited.

- Neck Finish: The neck finish must be precise for capping. This area is formed by the preform, but the mould design must accommodate it perfectly.

- Draft Angles: Adequate draft angles (slight tapers on the bottle walls) are crucial for easy ejection of the bottle from the mould. Insufficient draft can lead to scuffing or sticking.

- Sharp Corners vs. Radii: Sharp internal or external corners can be difficult to fill consistently and can create stress points. Generous radii are preferred.

- Label Panel: If the bottle will be labeled, a smooth, consistent label panel area is important. Recessed label panels can protect labels from scuffing.

While rotary technology is advanced, extremely complex or delicate designs might be better suited for slower processes or require very specialized (and often more expensive) mould features. For example, bottles with very deep undercuts or integrated handles can be challenging. I always recommend a design review with an experienced mould manufacturer. We can often find a way to achieve the desired look while ensuring it's optimized for high-speed production. Sometimes a small change, like increasing a radius by a millimeter, can make a huge difference.

What Materials Are Used for Rotary Blow Moulds and Why It Matters?

Thinking all mould metals are the same? The material of your rotary blow moulds drastically affects performance, lifespan, and cost. This is a critical choice.

High-grade aluminum alloys like 6062-T65 are common for rotary blow moulds due to excellent thermal conductivity and light weight. For hot-fill applications, stainless steel is preferred for its durability at high temperatures.

The choice of material for your rotary blow moulds is not a minor detail; it's fundamental. As I mentioned, I've seen firsthand how material choice impacts everything from production speed to the final quality of the bottle. Let's break down why specific materials are used.

Common Rotary Blow Mould Materials and Their Properties:

| Material | Key Properties | Typical Applications | Why it's Chosen |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061-T6, 6062-T65, 7075-T6) | - Excellent thermal conductivity - Lightweight - Good machinability - Can be hard anodized for surface durability | Standard PET bottles (water, CSDs) | Fast Cooling: High thermal conductivity allows for rapid heat removal, crucial for short cycle times in rotary machines. Reduced Mass: Lighter moulds mean less stress on the rotary machine components, allowing for faster acceleration and deceleration. |

| Stainless Steel (e.g., S136, 420) | - High corrosion resistance - Excellent durability - Good polishability - Lower thermal conductivity than aluminum | Hot-fill bottles (juices, teas) PVC bottles (historically) | Temperature Resistance: Withstands the high temperatures of hot-fill products without degrading. Corrosion Resistance: Important when dealing with potentially acidic products or harsh cleaning agents. Durability: Offers a very long mould life. |

| Beryllium Copper (BeCu) | - Very high thermal conductivity - Good wear resistance | Inserts for critical cooling areas | Targeted Cooling: Used in specific parts of the mould (like base inserts) where extremely fast cooling is needed. More expensive. |

For most standard PET bottle applications (water, carbonated soft drinks), aluminum alloys like 6062-T65 are the go-to. The "T65" refers to the tempering process, which enhances its strength. Its main advantage is heat dissipation. In a rotary machine, cycles are incredibly fast, so the mould needs to cool the plastic bottle very quickly to solidify it before ejection. Aluminum does this exceptionally well. The surface of these aluminum moulds is typically hard anodized. This treatment gives them a black appearance and significantly increases surface hardness and wear resistance, protecting the precision-machined cavity. The internal cavity itself is polished to a high mirror finish – this ensures the bottles have a clear, glossy surface.

However, if you're producing hot-fill bottles, where the product is filled at high temperatures (e.g., 85-95°C), aluminum isn't suitable. The repeated exposure to high temperatures would soften the aluminum over time. In these cases, stainless steel is the material of choice. It maintains its strength and integrity at elevated temperatures. While stainless steel is more expensive and has lower thermal conductivity (meaning cooling might be slightly slower or require more aggressive cooling channel design), its durability in hot-fill scenarios is non-negotiable. I've seen clients who produce juices or teas make this switch, and their moulds last for many years despite the demanding application.

How Long Does It Take to Manufacture a Rotary Mould?

Need your moulds yesterday? Patience is key, as quality takes time. Understanding the timeline helps you plan your production schedule effectively.

Manufacturing a set of rotary blow moulds typically takes 3 to 6 weeks, depending on complexity, number of cavities, and the supplier's current workload. Precision engineering requires careful steps.

One of the first questions I always get from clients is about the lead time for rotary blow moulds. It's a fair question, as it directly impacts their project timelines. Unlike simpler components, these moulds are precision tools, and rushing the process is a recipe for problems.

Factors Influencing Mould Manufacturing Time:

- Bottle Design Complexity:

- Simple, symmetrical designs: Shorter machining and finishing time.

- Complex geometries, intricate details, or textured surfaces: Require more programming, specialized tooling, and longer machining cycles. This can add days or even weeks.

- Number of Cavities:

- A single prototype mould might be quicker.

- A full set for a 20-cavity rotary machine involves manufacturing multiple identical, high-precision components. While some work can be parallelized, it still scales the overall time.

- Mould Material:

- Aluminum alloys are generally faster to machine than stainless steel. Stainless steel's hardness means slower cutting speeds and potentially more tool wear, adding to the time.

- Mould Base and Component Standardization:

- If the mould uses standard base components readily available, it can speed things up. Custom-designed bases or components take longer.

- Approval Process:

- Design review and approval: Time for you to review and approve the final mould design drawings before manufacturing begins.

- Sample approval: If physical samples from a trial mould are required before full production, this adds a separate loop.

- Testing and Quality Control:

- Thorough testing of mould components, cooling channels, and assembly.

- For rotary moulds, balancing might also be a specific QC step.

- Supplier's Workload:

- A busy mould maker will naturally have a longer queue. It's always good to discuss lead times early.

Typical Manufacturing Stages & Estimated Time:

| Stage | Description | Estimated Duration |

|---|---|---|

| 1. Design & Approval | Finalizing bottle design, mould design, CAD modeling, customer approval. | 3-7 days |

| 2. Material Procurement | Ordering and receiving specified aluminum or stainless steel blocks. | 3-5 days |

| 3. CNC Machining | Roughing, semi-finishing, and finishing of cavities, cores, and other parts. | 2-3 weeks |

| 4. Bench Work & Polishing | Hand finishing, polishing cavities to mirror finish, fitting components. | 3-5 days |

| 5. Surface Treatment | Hard anodizing (for aluminum) or other treatments. | 3-7 days |

| 6. Assembly & QC | Assembling all parts, checking dimensions, water trials for cooling. | 2-3 days |

| 7. (Optional) Mould Trial | Producing sample bottles on a trial machine. | 1 week (incl. shipping) |

Based on my experience, a typical project for a set of aluminum rotary moulds might average around 4-6 weeks from final design approval to readiness for shipping. Stainless steel moulds can take longer, perhaps 10-14 weeks. It's crucial to have detailed discussions with your supplier. For my clients, especially those with tight launch schedules, I always emphasize building in some buffer time. Rushing a mould, particularly a high-precision rotary mould, is never a good idea.

Common Pitfalls When Ordering Rotary Moulds and How to Avoid Them?

Want to avoid costly mistakes when ordering your moulds? Being aware of common traps is the first step. This knowledge protects your investment.

Common pitfalls include unclear specifications, choosing the wrong supplier, neglecting design for manufacturability, and poor communication. Thorough planning and due diligence are key to avoidance.

Ordering rotary blow moulds is a significant investment, and mistakes can be expensive and cause major delays. Over my 16 years, I've seen companies fall into preventable traps. Let me share some common ones and how you can steer clear.

Pitfalls and How to Navigate Them:

Vague or Incomplete Specifications:

- Pitfall: Providing unclear bottle drawings, missing critical dimensions (like neck finish details), or not specifying the exact model of the rotary blow moulding machine.

- Avoidance: Provide comprehensive 2D and 3D CAD files for the bottle. Clearly define material, weight, annual volume, and the specific make and model of the machine the mould will run on. As I experienced with my Vietnamese client who had Krones and SIDEL machines, the moulds are not interchangeable. Every detail about the machine interface (mounting, connections for air/water) is vital.

- My Tip: Create a detailed checklist of all required information before approaching suppliers.

Choosing a Supplier Based Solely on Price:

- Pitfall: Opting for the cheapest quote without thoroughly vetting the supplier's experience with rotary moulds specifically. Low price can mean inferior materials, poor craftsmanship, or lack_of post-sales support.

- Avoidance: Look for suppliers with a proven track record in rotary moulds for your type of machine. Ask for references, case studies, and details about their quality control processes. Remember, a rotary blow mould is a high-precision instrument.

- My Tip: Consider the total cost of ownership, not just the upfront price. A slightly more expensive mould from a reputable supplier can save you a fortune in downtime and rejected bottles.

Ignoring Design for Manufacturability (DFM):

- Pitfall: Finalizing a bottle design without consulting the mould maker about its suitability for high-speed rotary blow moulding. This can lead to designs that are difficult or impossible to mould consistently.

- Avoidance: Involve your mould supplier early in the bottle design phase. They can provide DFM feedback, suggesting minor tweaks that improve mouldability, reduce cycle times, or enhance bottle performance without compromising aesthetics.

- My Tip: Be open to suggestions. A small radius change or a slight increase in draft angle can make a big difference.

Poor Communication and Lack of Follow-up:

- Pitfall: Not maintaining regular communication with the supplier during the manufacturing process or failing to get progress updates.

- Avoidance: Establish clear communication channels and expectations from the start. Request regular updates, photos, or even video of the manufacturing progress. Promptly respond to any queries from the supplier.

- My Tip: Schedule weekly check-ins if possible, especially for complex projects.

Not Clarifying Mould Trial and Acceptance Criteria:

- Pitfall: Failing to agree on mould trial procedures, the number of samples, and the specific criteria for accepting the moulds.

- Avoidance: Discuss and document the mould trial process. Will it be done at the supplier's facility or yours? What parameters will be checked (bottle dimensions, weight, visual defects, cycle time)? Who pays for material and shipping of samples?

- My Tip: Have clear, measurable acceptance criteria. "Looks good" is not enough.

Avoiding these pitfalls comes down to due diligence, clear communication, and partnering with an experienced and reputable mould supplier. It's an investment in a smooth production launch.

Are Rotary Blow Moulds Compatible with All Rotary Blow Machines?

Assuming any rotary mould fits any rotary machine? This is a common, and costly, misconception. Machine specificity is crucial.

No, rotary blow moulds are NOT universally compatible. They must be custom-designed for the specific make and model of the rotary blow moulding machine due to differences in mounting, kinematics, and utility connections.

This is one of the most critical points I stress to my clients. You cannot simply take a rotary blow mould designed for a SIDEL machine and expect it to work on a Krones machine, or vice-versa. It just won't fit, or worse, it could damage the machine.

Why Machine-Specific Design is Essential:

- Mounting Systems:

- Each machine manufacturer (Krones, SIDEL, SIPA, Sacmi, Newamstar, Tech-Long, etc.) has its own proprietary system for how moulds are fixed onto the rotating carousel. This includes the bolt patterns, clamping mechanisms, and overall dimensions of the mould base or shell that interfaces with the machine.

- Kinematics and Stroke:

- The way the mould halves open and close, the stroke length, and the timing are specific to the machine's design. A mould must be built to match these mechanical movements precisely.

- Utility Connections:

- Cooling water, compressed air (for blowing and potentially for actuating mould components), and vacuum lines all have specific connection points, port sizes, and locations on the machine. The mould must have perfectly aligned and compatible fittings. I remember a case with a client in Vietnam; their Krones and SIDEL machines had completely different structures and types of connectors for these utilities. We had to be incredibly meticulous, double-checking every single data point to ensure a 100% match.

- Cam Paths and Actuation:

- Some machines use cams to actuate certain mould functions (like bottom mould movement or neck orientation). The mould needs to be designed to interface correctly with these machine-specific cam paths.

- Overall Envelope and Clearance:

- The physical space available for each mould station on the carousel is limited. The mould's overall dimensions, including any protruding parts, must fit within this envelope without interfering with other moulds or machine components.

Information Needed by the Mould Maker:

To ensure compatibility, your mould maker will need very precise information about your rotary blow moulding machine:

- Machine Manufacturer: (e.g., Krones, SIDEL, SIPA)

- Machine Model & Series: (e.g., Krones Contiform S24, SIDEL SBO 20 Universal)

- Number of Stations/Cavities on the Machine

- Technical Drawings or Interface Specifications: Ideally, the machine manufacturer provides interface drawings showing mould mounting details, utility connection points, and dimensional constraints.

- Existing Mould Samples (if available): Sometimes, providing an existing, well-performing mould for that specific machine can be invaluable for the mould maker to study.

Ordering a rotary blow mould without confirming these details is like buying a custom car part without knowing the make, model, and year of your car. It's a gamble you don't want to take. Always work closely with your mould supplier and provide them with all necessary machine information.

Why Choosing an Experienced Mould Supplier Saves You Time and Money?

Tempted by a newcomer's low price? Experience in rotary moulds isn't a luxury, it's a necessity. It directly impacts your bottom line.

An experienced rotary mould supplier offers optimized designs, understands machine intricacies, anticipates problems, and provides better support, ultimately leading to faster startups, higher efficiency, and lower overall costs.

In my 16 years in this industry, I've seen the stark difference between projects handled by seasoned experts versus those by less experienced outfits, especially when it comes to complex tooling like rotary blow moulds. It might seem like you're saving money with a cheaper, less experienced supplier initially, but this can quickly turn into a costly mistake.

The Value of Experience:

Deep Understanding of Machine Specifics:

- An experienced supplier will likely have built moulds for a wide range of rotary machines (SIDEL, Krones, SIPA, etc.). They understand the nuances of each brand and model. This means they know the critical interface points, common challenges, and how to optimize the mould design for that specific machine. They won't be "learning on your dime."

- Personal Insight: I've worked on projects where a supplier's prior experience with a particular machine model saved weeks of troubleshooting because they anticipated a potential fitting issue.

Optimized Mould Design for Performance & Longevity:

- Experience brings knowledge of what works best in terms of cooling channel design for rapid cycling, material selection for durability, and structural integrity for high-speed forces. They can design moulds that not only produce good bottles but also run efficiently and last longer.

- This includes details like appropriate venting, polishing techniques for specific resins, and designing for ease of maintenance.

Problem Anticipation and Prevention:

- Seasoned mould makers have encountered a wide array of challenges over the years. They can often foresee potential issues with a bottle design or a specific application and suggest solutions before the mould is made. This proactive approach avoids costly redesigns or production problems later.

Better Material Knowledge and Sourcing:

- They have established relationships with reliable material suppliers and understand the subtle differences between grades of aluminum or stainless steel and how they perform in rotary applications. Using the correct, high-quality material (like 6062-T65 aluminum with proper hard anodizing, or specific stainless steel for hot-fill) is crucial.

Efficient Manufacturing Processes & Quality Control:

- Experienced suppliers have refined their manufacturing workflows and quality control checkpoints. This leads to more consistent quality and often more reliable delivery times. They understand the precision required for every component of a rotary mould.

Effective Troubleshooting and Post-Sales Support:

- If issues do arise during mould trials or early production, an experienced supplier is better equipped to diagnose the problem and provide effective solutions quickly. Their support doesn't just end when the mould is shipped. They understand they are providing a critical production tool.

- Personal Insight: I had a client whose new mould from an unproven supplier was causing excessive bottle flash. The supplier struggled for weeks. We brought in an experienced consultant who identified a minor venting issue in minutes, something a veteran mould maker would have likely caught in the design phase.

While the upfront cost from an experienced supplier might sometimes be higher, the savings in terms of reduced downtime, fewer rejected bottles, faster cycle times, longer mould life, and quicker problem resolution almost always result in a significantly lower total cost of ownership. Choosing a partner for your rotary blow moulds is a long-term decision. Invest in experience.

Conclusion

Rotary blow moulds are key for high-volume, quality bottle production. Understanding their specifics, from design to supplier choice, ensures you make a profitable and efficient investment.

FAQs

What is the typical lifespan of a rotary blow mould?

With proper maintenance and using the correct materials (e.g., hard-anodized 6062-T65 aluminum for standard applications), a rotary blow mould can typically produce many millions of bottles. Aluminum moulds might last for 10-30 million cycles, while stainless steel moulds, especially for hot-fill, can last even longer. Regular inspection and refurbishment can extend this life.Can existing linear blow moulds be converted for use in a rotary machine?

Generally, no. The design, construction, mounting, and precision requirements for rotary blow moulds are fundamentally different from those for linear machine moulds. Attempting a conversion is highly impractical and unlikely to yield satisfactory or safe results.What kind of maintenance do rotary blow moulds require?

Regular maintenance includes cleaning the cavities and vents, inspecting for wear or damage (especially on parting lines and neck rings), checking cooling channels for blockages, and ensuring all components are properly lubricated and tightened. The frequency depends on usage and bottle material.How critical is the cooling system design in a rotary blow mould?

Extremely critical. Efficient cooling is essential for achieving fast cycle times and consistent bottle quality in high-speed rotary operations. Poor cooling can lead to longer cycles, deformed bottles, and reduced output. Experienced suppliers pay close attention to optimizing cooling channel placement and flow.What are the signs that a rotary blow mould needs refurbishment or replacement?

Signs include a decline in bottle quality (e.g., increased flash, inconsistent wall thickness, scuff marks), difficulty in ejecting bottles, visible wear or damage to the mould surfaces, or an inability to maintain a consistent cycle time. Regular inspection will help identify these issues early.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr