Are you struggling to create a PET bottle that not only stands out on the shelf but also performs flawlessly on the production line? Perhaps you have a fantastic product, but the packaging fails to capture attention or, worse, causes a production nightmare. This guide is for you.

A successful PET bottle design begins with a deep understanding of the market and the bottle's function. This is followed by the precise definition of key parameters like the neck, volume, and shape. The concept is then transformed into a manufacturable 3D model, fully considering the blow bottle mold requirements, material selection, and finally, ensuring seamless compatibility with the filling line.

I've been in the PET bottle machinery industry for 16 years straight, and I've witnessed the birth of countless bottles. A good bottle design is far more than just drawing a pretty picture. It's a systematic engineering process, a delicate balance between branding, cost, production efficiency, and consumer experience. Many clients, especially those from overseas, come to me with wild, imaginative ideas, eager to design a bottle that consumers will fall in love with at first sight. I completely understand this passion, but they often overlook the harsh realities of manufacturing: can this shape actually be blown? Will the walls be too thin? Will the cost exceed the budget? My job is to help them bridge the gap between their dreams and reality, finding that perfect equilibrium between creativity and craftsmanship. This guide is the culmination of my 16 years of experience.

Understanding Market Requirements and Bottle Functions?

Does your meticulously designed bottle feel disconnected from the market? You're chasing aesthetics, but you're not sure if it will truly resonate with your target customers or effectively perform its "sales" duty on the shelf. This is a common problem, and its root lies in a flawed starting point for the design.

The starting point for design shouldn't be a sketchpad; it should be market research and functional analysis. You need to clearly define who your bottle is for and in what context it will be used. Is it for premium mineral water or a children's juice? A sports drink or a family-sized shareable? The positioning dictates the design direction.

Treat the Bottle Like a Product and Conduct a Requirements Analysis

In my view, the most successful designers act like product managers. Before putting pen to paper, I work with clients to create a detailed "Bottle Requirements Document," which includes at least the following:

- Consumer Persona: What is their age, gender, income, and lifestyle? The needs of a health-conscious yoga enthusiast and a truck driver needing a quick energy boost are completely different in terms of grip, opening mechanism, and volume.

- Usage Scenario Analysis: Will the bottle be opened one-handed at the gym or poured for sharing at a family dinner? Will it sit in a car's cup holder or be stuffed into a student's backpack? The scenario determines the bottle's basic form factor; for instance, a car cup holder dictates a maximum base diameter.

- Competitive Analysis: We go to the supermarket and buy every competitor's bottle off the shelf. We analyze their strengths and weaknesses: which bottle has the best grip? Which label design is most appealing? Which bottle compromised on structure to save a few cents? I'll even use a precision scale to weigh their preforms, which gives me a rough idea of their cost strategy.

- Brand Story and Value Proposition: A bottle is the brand's silent salesman. It needs to tell the brand's story through its shape, color, and texture. Take "Dongpeng Teqing," a functional beverage company I started working with in 2006. We co-designed a bottle with a unique cap and powerful, sharp lines on the body, conveying a sense of "energy" and "professionalism." It was this design that helped them stand out from a sea of beverages and capture a leading market position within just five years. This case taught me that a good blow bottle mold produces not just a container, but a brand's icon.

Key Design Parameters of a PET Bottle: Neck, Volume, and Shape?

You have a general idea for your bottle, but how do you translate it into a set of precise, executable technical parameters? The neck, volume, and shape are the three core parameters. If you get them wrong, all subsequent work will be wasted, and you could end up scrapping your entire production run.

The core of design is to "parameterize" creativity. The neck determines the seal and must meet standards; the volume determines integrity and must be accurate; the shape determines success and must balance aesthetics with physical performance. These three pillars are non-negotiable.

Constraining Creativity Within the Rules of Physics

Many initial design drafts from clients are full of artistic flair, but from my engineering perspective, they're also full of "production traps." My job is to use the bridge of technical parameters to safely guide these imaginative ideas to the shores of reality.

Neck Finish: Details Determine Success

The neck is far more than a simple opening. It's the interface between the bottle and the cap, the key to the package's entire seal integrity. We typically use international standards like PCO 1881 or PCO 1810. Why? Because a standard neck means you can easily source matching caps and that it will run smoothly on standard preform mold and filling lines. I pay special attention to the "Neck Support Ring" (NSR) below the threads. This small ring is critical for how the bottle is handled, transported, and gripped during blowing and filling. Its dimensions and strength directly impact production efficiency.Volume: Precision is the Bottom Line

Volume seems simple, but achieving accuracy is a test of skill. We must distinguish between "Nominal Volume" (e.g., the 500ml stated on the label) and "Brimful Volume." The design must leave a certain amount of "headspace" to accommodate the liquid's thermal expansion at different temperatures and any foaming during filling. I use CAD software to perform precise volume calculations, ensuring that at the standard fill level, the volume is exact. This is both a responsibility to the consumer and a cost control measure for the client.Shape: The Art of Balancing Aesthetics and Engineering

This is the most exciting part, and also the most challenging. Clients want unique ribs and elegant curves. My role is to preserve this creativity while optimizing it with an engineering mindset.- Stability: The bottle's center of gravity must be low enough, and the base stable enough, to "run" smoothly on high-speed conveyors.

- Strength: The bottle body needs designed-in ribs to resist pressure, especially for carbonated drinks and bottles that need to be stacked. I use Finite Element Analysis (FEA) software to simulate how the bottle will perform under stacking and drop stresses, optimizing the placement and shape of these ribs.

- Manufacturability: Those cool-looking sharp internal corners are often a nightmare in blow molding, easily causing uneven wall thickness or incomplete formation. I'll communicate with the client to change sharp corners to smooth radii, which preserves the design intent while guaranteeing product yield. This is a back-and-forth process of communication and optimization, and it's where I provide my value.

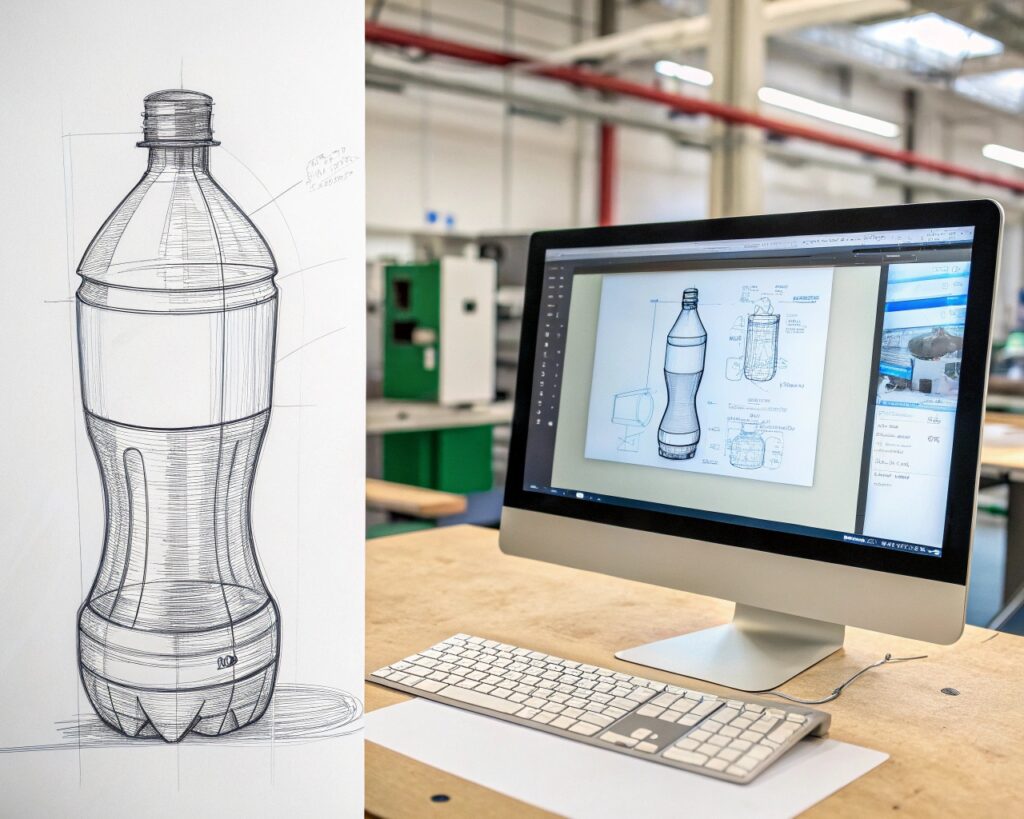

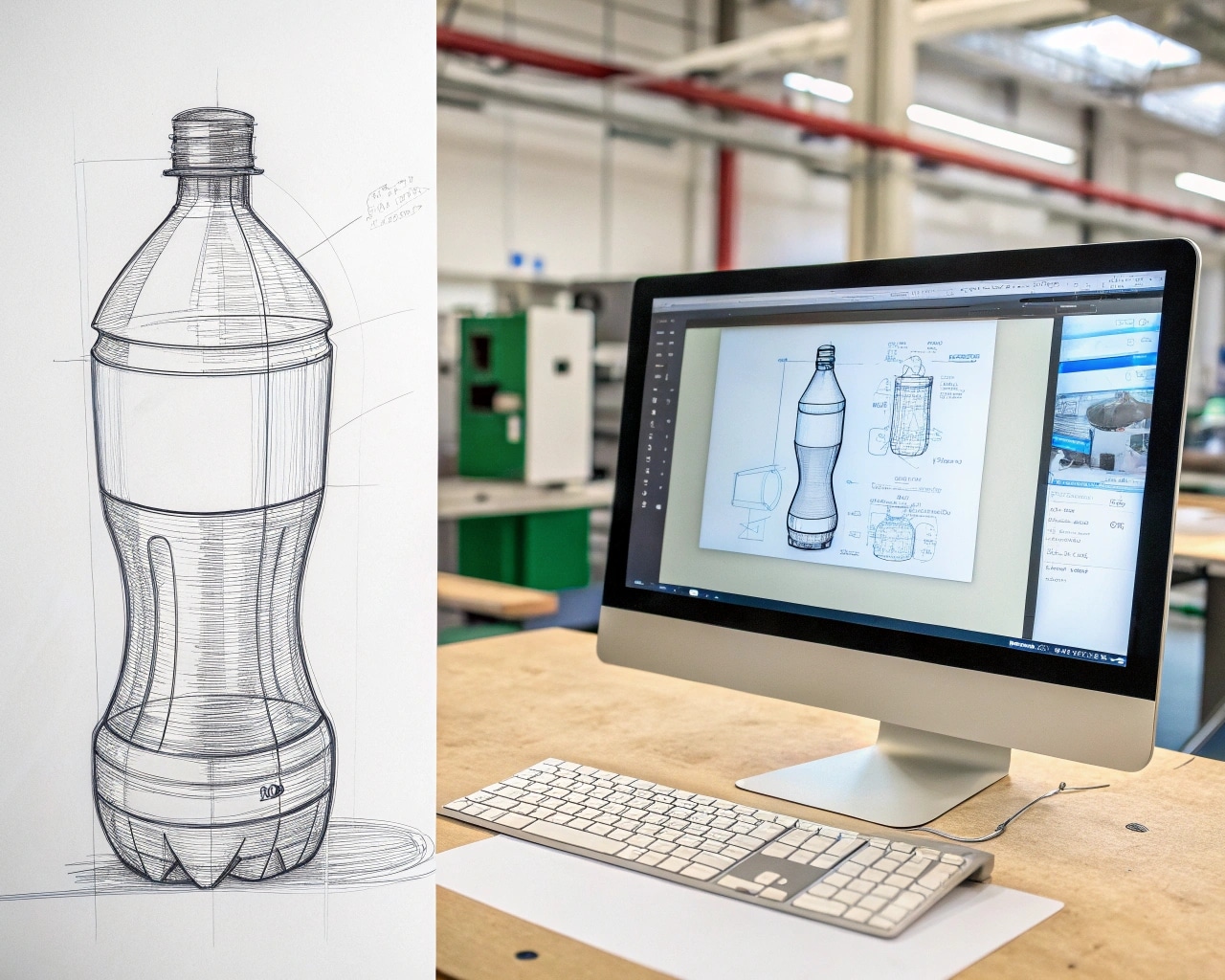

From Sketch to 3D: Turning Concepts into CAD Models?

Your bottle idea exists only as a sketch on a napkin. You don't know how to transform this 2D inspiration into a 3D digital model that engineers and mold makers can understand and use. This gap causes many great ideas to die before they are born.

The solution is to "engineer" the sketch by building a precise 3D model using Computer-Aided Design (CAD) software. This digital blueprint not only perfectly recreates your vision but also allows for repeated refinement and validation before any physical prototype is made, saving immense amounts of time and money.

A Precise Translation from Art to Mathematics

This is my favorite part of the entire workflow because it's so creative. When a client hands me a passionate sketch, I see not just lines, but their expectations for the product. My task is to translate that expectation into the language of engineering.

Profile Sketching: We don't just start drawing a 3D model. We begin in CAD software (like SolidWorks or CATIA) by drawing the key 2D cross-sectional profiles based on the sketch. This is the bottle's "skeleton," defining its basic parameters like height and maximum diameter.

Revolve & Extrude: With the 2D profile, we use a "revolve" command to generate a basic bottle body. Then, using "extrude," "sweep," and other commands, we add features like the base and neck. The process is like a digital sculptor shaping clay.

Surface Modeling: For bottles with complex curves and ergonomic shapes, we use more advanced surface modeling techniques. We need to build what's called a "Class-A Surface," a high-quality surface common in automotive design. This ensures that light and reflections flow smoothly across the bottle's surface without any blemishes, which is critical for the final mirror polish of the blow bottle mold.

Detailing and Validation: At this stage, we precisely add all the details: the neck threads, the strengthening ribs on the base, the embossed logo on the body. Then comes the most critical step: volume verification. The software instantly calculates the model's internal volume, accurate to 0.1 milliliters. If the volume is off, we go back and fine-tune the body's curves until it's perfect. I often tell clients, modifying a surface on a computer costs nothing; modifying it after the mold steel has been cut can cost thousands or even tens of thousands of dollars.

Designing for Blow Molding: Wall Thickness and Stretch Ratios?

You've designed a stunning bottle, but deep down, you're worried it won't survive the high-temperature, high-pressure ordeal of blow molding. If the design isn't optimized for the blowing process, you could end up with uneven walls, weak spots, or complete manufacturing failure.

The secret to success lies in the precise control of wall thickness and stretch ratios. A good design guides the PET material from the heated preform mold to distribute evenly as it's stretched and blown, creating a bottle that is both lightweight and strong.

You're Not Designing a Bottle; You're Designing the Material's Flow Path

When I get a 3D model, my mind immediately starts simulating its journey inside the bottle blowing machine. A heated preform is like a tiny, hot, high-pressure balloon. A stretch rod pushes it down, elongating it, and then high-pressure air inflates it. Our design must map out a perfect path for this "balloon" to expand into.

Stretch Ratios: This is the most critical concept in blow molding.

- Axial Stretch Ratio: Final bottle height / Preform body height. We typically aim for a ratio between 2.5 and 3.5.

- Hoop Stretch Ratio: Bottle's max diameter / Preform's diameter. We typically aim for a ratio between 3.5 and 4.5.

- Overall Stretch Ratio: Axial Ratio × Hoop Ratio. If this value is too high, the material's molecular chains are over-stretched, making the bottle brittle or causing stress whitening (a pearlescent appearance). If it's too low, the material flow is insufficient, and the bottle feels "fleshy" and lacks rigidity. I once had a client who designed a very slender bottle with an axial ratio over 5.0. During trials, the bottle's mid-section always had stretch marks or even burst. We ultimately solved it by optimizing the preform design, increasing the wall thickness in the preform's mid-section.

Wall Thickness Distribution: The ideal bottle has a uniform wall thickness everywhere. In reality, the corners of the base and the slope of the shoulder are "danger zones" where the material tends to thin out. Our design strategy is "pre-compensation." This means when we design the preform mold, we intentionally make the walls of the preform slightly thicker in the areas corresponding to these danger zones. This way, after being stretched and blown, they achieve the same thickness as the rest of the bottle. We use specialized wall thickness gauges (like Hall Effect gauges) to inspect every point of a sample, ensuring even the thinnest spot meets strength requirements.

Selecting Mold Materials: Aluminum vs. Stainless Steel?

You need to commission a mold for your bottle but are stuck choosing between aluminum and stainless steel. Picking the wrong material can lead to slower production cycles, lower bottle quality, or a mold that wears out prematurely, costing you dearly in the long run.

The choice hinges on your planned production volume and quality standards. Aluminum, with its fast heat transfer and lower cost, is the king of prototyping and short runs. Stainless steel, with its durability and high polish, is the only choice for long-term, high-volume production.

This Isn't a Choice Between "Good" and "Bad," but "Fit" and "Unfit"

Every time a client asks me which material is better, I ask them back: "How many bottles do you plan to produce? What is your product's life cycle?"

I once had a client launching a seasonal juice, with a planned run of only 200,000 bottles. I recommended a 7075 aircraft-grade aluminum mold without hesitation. Why?

- Fast: Aluminum machines much faster than steel, meaning his blow bottle mold could be delivered sooner, allowing him to catch the precious market window.

- Economical: Both the material and machining costs for aluminum are lower than steel, reducing the initial investment.

- Efficient: Aluminum's thermal conductivity is excellent. This means shorter cooling times after blowing, which shortens the cycle time and increases the hourly output of the bottle blowing machine.

But for another major client, like a beverage giant planning to produce hundreds of millions or even billions of a single bottle type, I would only recommend a high-quality stainless steel like S136.

- Durable: Stainless steel's hardness and wear resistance are exceptional. It can withstand tens of millions of cycles of opening, closing, and high-pressure blowing without significant wear.

- Pristine Finish: Stainless steel can be polished to a mirror finish, producing bottles that are crystal clear and have a premium, high-quality feel.

- Stable: Steel's corrosion resistance is excellent. Even in humid factory environments, it won't rust, ensuring long-term production stability.

I often use an analogy with my clients: An aluminum mold is like an F1 race car—incredibly fast, but it needs a major overhaul after just a few races. A stainless steel mold is like a heavy-duty truck—it starts a bit slower but can run reliably for decades. Your choice depends on your race.

| Feature | 7075 Aircraft Aluminum | S136 Stainless Steel | My Insight |

|---|---|---|---|

| Mold Lifespan | Lower (~1-2 million cycles) | Extremely High (10+ million cycles) | Don't use an aluminum mold to run a marathon. I've seen clients try to save money with aluminum for high-volume runs, only to have the mold wear out mid-production, forcing a costly and urgent replacement. |

| Lead Time | Short (Typically 2-4 weeks) | Long (Typically 5-8 weeks) | If you need to test a market response quickly, time is money. Aluminum is the best choice for speed-to-market. |

| Cooling Efficiency | Excellent | Good | Cooling accounts for over 60% of the entire blow molding cycle. An aluminum mold's rapid cooling can genuinely increase production efficiency by 5-10%. |

| Surface Quality | Good, but easily scratched | Excellent, can be mirror-polished | If you're selling premium water and chasing that ultimate crystal-clear look, only stainless steel will do. |

| Initial Cost | Low | High | This is an investment. You should calculate the "amortized cost per bottle," not the total price of the mold. The higher the volume, the lower the per-bottle cost of a steel mold. |

Cooling and Venting Design in Bottle Molds?

Your production line is inefficient, and your bottle quality is inconsistent. The problem may be hidden inside your mold. Poorly designed cooling and venting systems are the "invisible killers" of production efficiency and quality.

A superior mold is inevitably filled with meticulously designed water channels and microscopic vents. An optimized cooling system allows the bottle to cool down and solidify quickly and evenly, while an efficient venting system instantly evacuates trapped air, ensuring the plastic perfectly conforms to the mold.

The Devil is in the Details: Designing Waterways and Airways

In high-speed production, every second counts. The cooling phase is the longest part of the blow molding cycle. Shaving off just 0.1 seconds per cycle adds up to a massive increase in output over a year.

Cooling System: The Mold's "Arteries"

- Conformal Cooling: This is the state-of-the-art design. We no longer just drill simple, straight water lines through the mold block. Instead, we design complex cooling channels that follow the bottle's contour. This ensures the cooling water is as close as possible to the mold cavity surface, especially in "hot spots" with thicker material, like the base. This can improve cooling efficiency by over 20%.

- Flow State: We calculate the pipe diameter and pump pressure to ensure the water flow inside the channels is "turbulent," not smooth "laminar" flow. Turbulent flow is orders of magnitude more efficient at heat transfer.

Venting System: The Mold's "Lungs"

- Why Venting is Needed: When the hot preform inflates under high pressure, the air originally inside the mold cavity must be evacuated within milliseconds. If it's not removed completely, this trapped air gets compressed and superheats, burning the plastic and leaving "diesel effect" black spots on the bottle. This air cushion also prevents the plastic from making intimate contact with the mold, causing fine details like textures or logos to become blurry.

- How It's Designed: We machine extremely fine vent slots on the mold's parting lines and in corners where air tends to get trapped. These vents are typically only 0.02-0.03 mm deep—just wide enough for air molecules to escape, but small enough to block the much larger PET molecules, preventing flash. This is a job that demands extreme experience and machining precision. I once solved a tricky case where a client's bottle always had a small blurry patch. After examining it under high magnification, we determined it was a venting issue. By adding a tiny vent in that spot using Electrical Discharge Machining (EDM), the problem was solved.

From Prototype to Mass Production: Mold Trial and Tuning?

Your brand-new mold is ready, but that absolutely does not mean you can start mass production. Skipping the critical trial and tuning phase is a gamble that leads to wasted material, inconsistent products, and costly line stoppages.

The solution is a systematic first trial (T1). This process involves testing the mold with the actual preform and machine, comprehensively analyzing the resulting bottles, and then making precise micro-adjustments to both the mold and the process parameters until perfection is achieved.

A Trial is Not a Test; It's the Final Step of Co-Creation

For me, every T1 trial is like a final exam—both nerve-wracking and exciting. It's the moment when all the designs and theories on paper face their first real-world test. I insist on being on-site with the client for this process.

T1 - The First Shots: We install the new blow bottle mold into the bottle blowing machine and use the client's actual production preform. The goal is simple: to blow a "complete" bottle. The first few bottles are almost never perfect.

A Diagnostic Approach - Sample Analysis: I approach the first samples like a doctor diagnosing a patient.

- Visual Inspection: Is the shape complete? Are there black spots, bubbles, stretch lines, or a prominent parting line? I hold it up to the light to check for "pearlescence," a sign of over-stretching.

- Smell: I smell the inside of the bottle. A burnt odor could mean poor venting or excessive heating.

- Inquiry: I ask the on-site operator about the pressure, temperature, and other parameters during the process.

- Measurement & Testing: This is the most critical part. We use a professional wall thickness gauge to measure the bottle from top to bottom, 360 degrees. We also conduct a series of physical tests: top-load test, drop test, and leak test.

Tuning - A Combination of Science and Experience: Based on the analysis, we begin tuning. This is an iterative process.

- Process Parameter Adjustments: This is the first line of defense. We fine-tune the preform heating temperatures (power of different lamp zones), pre-blow pressure and time, and main-blow pressure and time. For example, if we find the base is too thin, we might slightly increase the heating temperature for the preform's base or slightly delay the main blow time.

- Mold Modifications: If process adjustments can't solve an issue—for example, a sharp detail that consistently fails to form—it means the mold itself needs a minor tweak. We might need to locally polish the mold or add a vent.

This process can take several hours or even a full day. The trial is only truly successful when we have a bottle with stable weight, uniform wall thickness, and certified performance, produced by a process with a wide operating window (meaning it can still produce good bottles despite minor parameter fluctuations).

How to Ensure Bottle Design Matches Filling Line Compatibility?

You've finally perfected your bottle. It looks great, and its strength is certified. But you've overlooked the most critical step: can it run smoothly on your high-speed filling line? An incompatible bottle will cause endless jams, spills, and operational nightmares.

To avoid this disaster, you must treat "filling line compatibility" as a core design metric from the very beginning. This means considering bottle stability, neck rigidity, and all surfaces that will interact with guide rails, star wheels, grippers, and labeling equipment.

The Bottle's Journey is Far From Over

I always emphasize one thing to my clients: "The bottle's birth in the blowing machine is just the first step of its life. Its real test is on the filling line."

I have seen too many painful lessons. One client designed an "artistic" bottle with a very small base. It constantly tipped over on the conveyor, forcing them to run the line at half its designed speed. Another client designed a bottle with a deep, concave curve in the waist, which caused the labels to wrinkle during application.

Therefore, before we finalize a design, I always ask the client for the detailed specifications of their filling line. I might even suggest they 3D-print a 1:1 dummy bottle to run on their actual line. We need to focus on these key points:

| Compatibility Checkpoint | Why It's Important | Design Strategy |

|---|---|---|

| Conveyor Stability | On high-speed conveyors, any slight wobble can cause a bottle to tip, triggering a chain reaction and a line stoppage. | Design a wide, flat base. For the five-point (petaloid) base of a carbonated bottle, ensure all five "feet" are on the same plane and provide enough support area. |

| Star Wheel & Gripper Fit | Star wheels and grippers are key to transferring the bottle between stations. A mismatch will cause jams or dropped bottles. | The bottle's diameter must be highly consistent and smooth where it contacts the star wheels. The dimensions of the neck support ring must strictly match the equipment specs. |

| Labeling Applicability | Whether using pressure-sensitive labels or sleeve labels, a flat or regular curved surface is required. | Design a dedicated "label panel" area free of interfering features. For shrink sleeves, the bottle body should avoid drastic changes in diameter to prevent wrinkles or air bubbles. |

| Top-load Strength | The bottle must withstand the force from the capping head above and, later, from warehouse stacking. | In addition to even material distribution, we can design clever reinforcing ribs in the shoulder area, like the arches of a building, to distribute pressure. This is key to ensuring the bottle doesn't buckle under pressure. |

Ultimately, a successful bottle design is a perfect symphony between the bottle blowing machine, the mold, the bottle itself, and the filling line. As the designer, my job is to conduct this complex orchestra.

Conclusion

From a sketch on a napkin to a shining product on the shelf, designing a PET bottle is a journey of balancing creativity with cost and the laws of physics. True success comes from a respect for the market and an obsessive focus on the details of manufacturing.

FAQ

1. What is the most common and costly mistake people make when designing a new PET bottle?

The most costly mistake is focusing solely on aesthetics while ignoring manufacturing and downstream processes. A beautiful design that is difficult to blow, weak, unstable on a filling line, or too expensive to produce is ultimately a failure. Practicality must be a primary consideration from day one.

2. How much does a custom PET bottle mold typically cost? What are the main cost drivers?

The cost varies widely based on cavitation (number of bottles per cycle), material, and complexity. A single-cavity aluminum prototype mold might cost a few thousand dollars, while a multi-cavity, hardened stainless steel production mold for millions of cycles can cost tens of thousands of dollars or more. The main cost drivers are: 1) Cavitation; 2) Mold Material (aluminum vs. steel); 3) Design Complexity (complex surfaces are more time-consuming to machine); and 4) Advanced Features (like a conformal cooling system).

3. How can I make my bottle stronger without making it heavier (and more expensive)?

This is achieved entirely through "structural optimization." It's like how a cylinder of paper can support much more weight than a flat sheet, using the same amount of material. We can significantly increase a bottle's top-load and side-wall rigidity without adding a single milligram of plastic by designing invisible reinforcing ribs, optimizing the petaloid base structure, and ensuring even wall material distribution. This requires extensive experience and the use of Finite Element Analysis (FEA) software.

4. How long does it typically take to go from a design sketch to a finished, production-ready mold?

The timeline is heavily influenced by the mold's complexity and material. For a simple design and a single-cavity prototype aluminum mold, the process can be as fast as 3-4 weeks. However, for a complex, multi-cavity stainless steel production mold, the entire process—from final design confirmation to manufacturing, trials, and iterative tuning—typically takes 8 to 12 weeks, or sometimes longer.

5. Why is the preform design so critical to the final bottle quality?

The preform is the bottle's "DNA"; it determines the bottle's full potential. The final wall thickness distribution is entirely dictated by the preform's wall distribution and the stretch ratios. An excellent preform mold will have different wall thicknesses at different sections of the preform, specifically designed for the final bottle shape. If the preform's "genes" are wrong, no matter how precise your blow bottle mold or how advanced your bottle blowing machine is, you will never produce a high-quality bottle.

🔗 Learn More about Blow Molding Technology

To better understand the core components of a 6-cavity automatic blow molding machine, here are some useful resources:

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr