Struggling to choose the right plastic for your bottled water brand? You want a material that is safe, cost-effective, and looks premium, but the options are confusing. Making the wrong choice can lead to higher costs and a product that doesn't appeal to customers.

The clear choice for bottled water is PET (polyethylene terephthalate) due to its superior transparency, lightweight nature, and high production efficiency. Its glass-like appearance enhances brand appeal, while its suitability for high-speed manufacturing and established recycling systems make it the most practical and sustainable option.

I've been in the PET packaging equipment business for over 16 years. During that time, a question I hear constantly, especially from startups, is: "Why are water bottles always made of PET? Can I use something else?" This question often comes from a desire to stand out. I remember a client from France who wanted to launch a luxury water brand to compete with the likes of Evian. He believed that using a different, seemingly more robust material like HDPE would justify a higher price point. He thought a heavier, opaque bottle might feel more "premium." It was a fascinating idea, and it led us down a path of exploring exactly why the beverage industry has universally landed on PET for water. I walked him through every stage, from material science to the realities of mass production and logistics. By the end of our discussion, he understood completely. This article is my attempt to share that same comprehensive breakdown with you, so you can make the most informed decision for your project.

What Exactly Are PET and HDPE, and How Do They Differ?

Are you wondering about the basic building blocks of these plastics? You know they are different, but the technical details can seem overwhelming when you're just trying to bottle water. Understanding the fundamentals is the first step to making a smart choice.

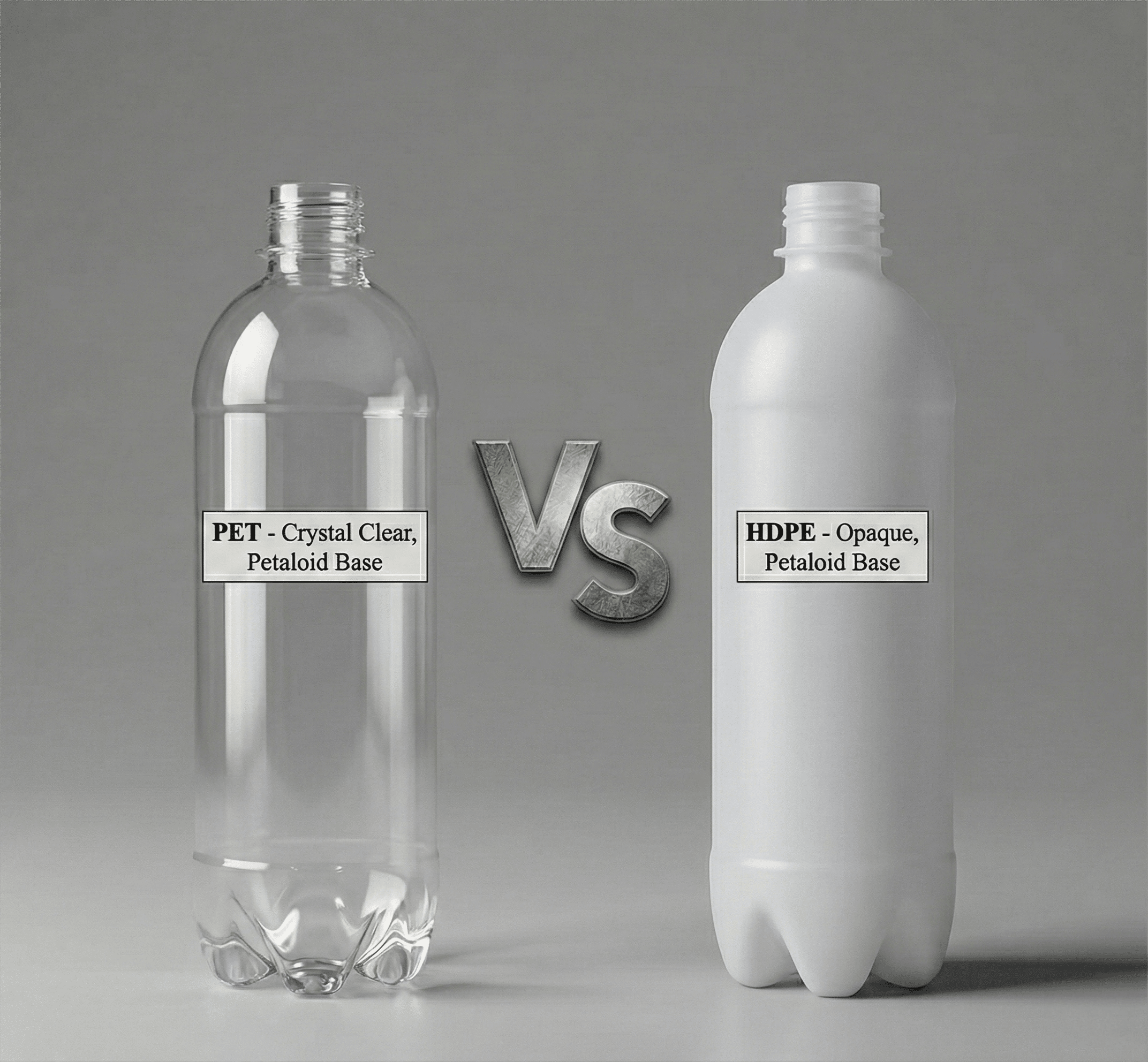

PET, or polyethylene terephthalate, is a type of polyester. It's known for being strong, lightweight, and, most importantly, clear. HDPE, or high-density polyethylene, is a different kind of polymer that is naturally milky white or opaque and is recognized for its excellent durability and chemical resistance.

To truly grasp why these two plastics serve different purposes, we need to look closer at their core characteristics. I often explain to my clients that you can't just pick a plastic based on how it feels; you have to understand how it behaves. The choice has implications for your production line, your shipping costs, and even your brand's environmental image.

A Deeper Look at the Materials

| Property | PET (Polyethylene Terephthalate) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Appearance | Crystal clear, glass-like transparency. | Naturally opaque or translucent (milky). |

| Density | Higher density, but used in thin walls. | Lower density, but requires thicker walls. |

| Common Uses | Carbonated drinks, bottled water, jars. | Milk jugs, shampoo bottles, chemical drums. |

| Feel | Rigid and strong, but lightweight. | More flexible, can feel waxy. |

The secret lies in their molecular structure. PET has a structure that allows it to be oriented, a process called biaxial stretching, which happens during stretch blow molding. This alignment of molecules is what gives a PET bottle its remarkable clarity and strength, even with very thin walls. It's like aligning the fibers in a rope to make it stronger. HDPE, on the other hand, has a more crystalline structure that scatters light, making it naturally opaque. This structure provides excellent impact resistance and a superior barrier against moisture, but it can't be made crystal clear. This fundamental difference is the starting point for why PET dominates the water aisle. For my French client, this was the first "aha" moment. He wanted his water to look pure, and you can't showcase purity if you can't see the product.

Why Is PET’s Visual Appeal a Decisive Advantage for Branding?

Worried your product won't look appealing on the shelf? The appearance of your bottle is the first handshake with your customer. A cloudy or unappealing container can kill a sale before the customer even considers the quality of the water inside.

PET's crystal-clear, glass-like appearance is its killer feature for marketing bottled water. It showcases the purity and cleanliness of the water, which is a primary selling point. HDPE's opacity makes it a non-starter for products where visual clarity is key to consumer trust.

In my experience, branding is everything in the beverage market. Think about it—when you walk down the drink aisle, you are met with a wall of options. The bottles that stand out are the ones that look the most refreshing. This is not just about the label; it's about the container itself. PET allows you to use the clarity of the water as part of your brand identity. It conveys a sense of quality that a dull, opaque bottle simply cannot match. For any new brand trying to establish a foothold, leveraging this inherent quality of PET is a massive, cost-free advantage.

The Power of Transparency in Marketing

When my French client and I discussed his vision for a luxury water brand, we spent a lot of time on the concept of "perceived value." High-end brands, whether in fashion or food, rely on presentation. He initially thought an opaque HDPE bottle would be unique, a point of differentiation. But I asked him to consider why premium spirits are almost always in clear glass bottles. It's because transparency signals purity, quality, and confidence in the product.

Here’s how PET’s clarity directly impacts branding:

- Showcases Purity: For water, "clear" equals "clean." Consumers make this association instantly and subconsciously. Using a transparent PET bottle is the easiest way to communicate that your water is pure and refreshing.

- Enhances Label Design: A clear bottle acts like a blank canvas. Your label design can pop, and you can even use the back of the label for additional branding that is visible through the bottle and the water, creating a cool 3D effect.

- Allows for Embossing: The molding process for PET is perfect for creating intricate designs and embossed logos directly on the bottle. A well-designed custom bottle feels more premium in the hand and looks more attractive. For a truly unique shape, you'll need a high-quality blow bottle mold, which is a key part of creating a premium identity.

- Consumer Trust: Ultimately, people like to see what they are buying. This is especially true for anything they are going to consume. PET provides that trust, while HDPE creates a barrier, forcing the consumer to trust the label alone.

How Does PET Improve Production Speed and Efficiency?

Are you concerned about scaling up your production? A slow, inefficient manufacturing process can cripple your business as demand grows. You need a material that supports high-speed, automated production to keep costs down and meet orders.

PET is perfect for high-speed, two-step stretch blow molding, allowing for the rapid production of millions of identical, lightweight bottles. HDPE typically uses extrusion blow molding, which is slower and offers less flexibility for complex bottle shapes, making it less suitable for mass-market beverages.

This is where the conversation gets very practical. As a business owner, you care about the final product, but you also care deeply about the bottom line. The efficiency of your production line is a major factor in your profitability. I've spent my career working with the machinery that makes these bottles, and the difference between PET and HDPE manufacturing is night and day, especially for a product like water that is sold in huge volumes. The choice of material dictates the technology you can use.

The Two-Step Advantage: Speed and Precision

The reason PET is so efficient is the "two-step" manufacturing process.

- Step One: The Preform. First, PET resin is melted and injection molded into a small, test-tube-like shape called a preform. These preforms are small, easy to ship, and can be produced in massive quantities. The neck of the bottle is fully formed and finished in this stage. This is a critical step, and the quality is determined by the preform mold. A good mold ensures every preform is perfect.

- Step Two: Stretch Blow Molding. The preforms are then reheated and placed inside a bottle blowing machine. Here, they are stretched lengthwise by a rod and inflated with high-pressure air, which forces them into the shape of the final bottle mold. This entire process is incredibly fast—a modern machine can produce tens of thousands of bottles per hour.

In contrast, HDPE usually uses extrusion blow molding. In this method, a hollow tube of molten plastic (called a parison) is extruded downwards. A mold then closes around the parison, and air is blown in to expand it. This process is generally slower and gives you less control over the final wall thickness, which is why HDPE bottles often feel heavier and less uniform. For a high-volume, low-margin product like water, the speed and material savings from the PET process are unbeatable. It’s a technology we have perfected over the years, and a high-quality bottle blowing machine is the heart of any major bottling plant.

Why Is HDPE’s Barrier a Better Fit for Chemicals, Not Water?

Do you think a stronger barrier is always better? It seems logical that more protection is a good thing. But for water, an extreme barrier is not only unnecessary, but it also comes with trade-offs that make the material unsuitable.

HDPE provides a superior barrier against moisture, chemicals, and UV light. This is crucial for protecting sensitive products like pharmaceuticals, milk, or household chemicals. However, water doesn't require this level of protection, and HDPE's opacity and production method make it a poor choice for a beverage.

This was a key point in the discussion with my French client. He thought, "If HDPE is strong enough for chemicals, it must be extra safe for my premium water." It's a common misconception. The goal of packaging is not to use the strongest material possible; it's to use the right material for the specific product. Using a material that is over-engineered for the task means you are paying for features you don't need and sacrificing features you do need, like clarity.

Matching the Barrier to the Product

The reason HDPE is the king for packaging things like milk, laundry detergent, and medicine is its chemical makeup. Its molecular chains are packed tightly, creating a formidable barrier.

Let's break down why this is important for some products but not for water:

- Moisture Barrier (WVTR): HDPE has a lower Water Vapor Transmission Rate (WVTR) than PET. This makes it excellent for powders or pills that must be kept perfectly dry. Water, obviously, doesn't need to be protected from moisture.

- Oxygen Barrier: PET actually has a better oxygen barrier than HDPE. This is critical for carbonated beverages, as it keeps the CO2 from escaping and the drink from going flat. While not essential for still water, it shows that "barrier" is a complex topic.

- UV Light Protection: HDPE is naturally opaque, which helps block UV light that can degrade sensitive products, like certain vitamins in milk or active ingredients in pharmaceuticals. Water is not sensitive to UV light in the same way.

- Chemical Resistance: HDPE is highly resistant to strong acids and bases, which is why it's used for industrial chemicals. This level of resistance is simply not needed for a neutral product like water.

So, while HDPE is an amazing packaging material, its strengths are tailored for products that are sensitive, reactive, or need protection from light. Water is none of those things. It is a simple, stable product whose primary marketing feature is its purity, which is best communicated through a clear, pristine PET bottle.

How Does PET’s Weight Advantage Impact Logistics and Costs?

Are you thinking about the hidden costs of your product? The price of the bottle is just one part of the equation. The weight of that bottle has a ripple effect on your entire supply chain, from shipping costs to your company's carbon footprint.

PET bottles are significantly lighter than their HDPE counterparts designed to hold the same volume. This lightweight nature reduces shipping costs, makes handling easier, and lowers the overall carbon footprint of transportation, a massive advantage for a high-volume product like bottled water.

When you are shipping millions of units a year, every gram matters. I've seen companies save fortunes by optimizing their packaging weight. This is another area where PET shines, and it's a purely practical, economic advantage. The beverage industry is a game of pennies, and logistics is a huge part of the playing field. The lighter your product, the more of it you can fit on a truck, and the less fuel it takes to move it.

The Economics of Lightweighting

The process of making PET bottles has been refined over decades to use the absolute minimum amount of material needed to perform its function. This is called "lightweighting."

Consider these points:

- Fuel Savings: The single biggest cost in logistics is often fuel. Lighter trucks burn less fuel. When you multiply this small saving by thousands of shipments, it becomes a major financial win.

- More Product Per Shipment: Shipping weight limits are a reality. By using a lighter bottle, you can put more units of water on each pallet and each truck without exceeding the weight limit. This means fewer trucks are needed to transport the same amount of product, leading to direct savings.

- Carbon Footprint: In today's market, environmental responsibility is a brand asset. Being able to state that your lighter packaging reduces transportation emissions is a powerful marketing tool. Consumers, especially younger ones, are increasingly making choices based on a brand's sustainability efforts.

- Ease of Handling: Lighter packages are easier and safer for workers to handle in the warehouse and for retailers to stock on shelves.

This is all made possible by the incredible strength-to-weight ratio of biaxially oriented PET. We can design bottles that weigh as little as 10-12 grams but can still be stacked on a pallet and withstand the rigors of shipping. The design of the bottle itself is crucial, and a well-engineered blow bottle mold is essential to achieving the perfect balance of light weight and structural integrity.

Why Is PET for Water and HDPE for Household Goods?

Confused about why you see different plastics used for different everyday products? There's a clear logic behind why water is in PET bottles, while your shampoo and milk are in HDPE. It's a perfect example of matching the material to the product's specific needs and market.

PET is the choice for beverages like water and soda because of its clarity, gas barrier for carbonation, and lightweight design. HDPE is used for personal care (shampoo, lotion) and household products (milk, detergent) because of its excellent chemical resistance, impact strength, and moisture barrier.

To really make this clear, let’s walk through a store in our minds. I do this with clients all the time. It’s the simplest way to see the logic in action. The packaging choices you see on the shelf are not random; they are the result of decades of research, development, and market feedback. Every material is playing to its strengths.

A Tale of Two Aisles

Imagine you are in the beverage aisle. What do you see?

- Water Bottles: Crystal clear PET. You see the pure water inside. The bottles are lightweight and often have sleek, embossed designs.

- Soda Bottles: Also clear or green/brown tinted PET. PET's excellent CO2 barrier is essential here to keep the drinks fizzy. The bottles must be strong enough to handle the internal pressure. This requires a robust preform design, made in a precision preform mold, and an efficient bottle blowing machine to form them correctly.

- Juice Bottles: Often in PET for the same reasons: clarity showcases the vibrant color of the juice, and it provides a good barrier to protect the flavor.

Now, let's walk over to the dairy case and the cleaning aisle.

- Milk Jugs: Translucent, flexible HDPE. Milk needs protection from light to prevent vitamin degradation. The package doesn't need to be perfectly clear, and the flexible, durable nature of HDPE is ideal for the classic jug design.

- Shampoo & Conditioner Bottles: Opaque HDPE. These products are often thick lotions. You don't need to see the product. What you need is a "squeezable" bottle, and HDPE's flexibility is perfect for this. It's also resistant to the complex chemicals in the formulas.

- Detergent & Bleach Bottles: Heavy-duty, opaque HDPE. Here, chemical resistance is the number one priority. HDPE will not react with or be degraded by these harsh substances. The bottle must be tough and durable for safety.

The pattern is clear. When the product's visual appeal and the perception of purity are paramount, PET is the winner. When chemical resistance, flexibility, or a light barrier are the most important factors, HDPE gets the job.

How Do Recycling and Sustainability Compare?

Are you worried about the environmental impact of your packaging? In today's world, sustainability isn't a bonus feature; it's a core requirement. Your customers expect you to make responsible choices, and your choice of plastic has a huge impact on your brand's green credentials.

PET has the most well-established and widespread recycling system of any plastic globally. It is designated by the resin code #1. The demand for recycled PET (rPET) is high, creating a circular economy. While HDPE (#2) is also widely recycled, the global infrastructure and end-market for recycled PET for food-grade applications are more mature.

This is often the final, and most important, factor for my clients. Choosing a package that is easily and widely recycled is not just good for the planet; it's good for business. Brands are making huge commitments to use recycled content in their packaging, and you can only do that if a reliable supply of high-quality recycled material exists. For PET bottles, it absolutely does.

The Clear Path of PET Recycling

The journey of a PET bottle is a circular one, which is a powerful story to tell your customers.

- Collection: Consumers place PET bottles in recycling bins. Because they are so common, collection rates are higher than for many other types of packaging.

- Sorting: At recycling facilities, PET bottles are easily separated from other plastics, often using automated optical scanners.

- Processing: They are ground into small flakes, washed to remove any residue, and then melted down.

- Creating rPET: The melted plastic is reformed into new pellets called rPET (recycled polyethylene terephthalate).

- A New Life: This rPET can then be blended with virgin PET to create new food-grade bottles. Many major beverage brands have pledged to use 50% or even 100% rPET in their bottles.

This robust system exists because there is huge demand for rPET from the beverage industry itself. It's a self-sustaining loop. While HDPE is also very recyclable (think of all those milk jugs), the end-markets are often for non-food-grade applications like plastic lumber, pipes, or non-food bottles. The ability to turn an old water bottle back into a new water bottle is a unique and powerful advantage of the PET ecosystem. This makes it the clear winner for any water brand that wants to build its identity around sustainability.

How Can We Provide a One-Stop Solution for Your Water Project?

Feeling overwhelmed by all the pieces you need to assemble for production? You have a vision for your brand, but figuring out bottle design, molds, machinery, and production lines can be a daunting technical challenge. You need a partner who can simplify the process.

We provide a complete, one-stop solution for PET bottle projects. From initial bottle design and prototyping to manufacturing the high-precision preform mold and blow bottle mold, and providing the right bottle blowing machine, we handle the entire technical process so you can focus on your brand.

Over my 16 years in this industry, I've seen too many entrepreneurs with great ideas get bogged down by technical complexities. My goal, and the goal of my company, is to be more than just an equipment supplier. We want to be your manufacturing partner. We've helped launch countless beverage brands by taking the technical burden off their shoulders. We can take your sketch on a napkin and turn it into a million bottles rolling off a production line.

From Concept to Conveyor Belt

Here's how our integrated solution works and how we ensure a smooth path to market for our clients:

- Bottle Design & Prototyping: It all starts with your vision. Our design team works with you to create a bottle that is not only beautiful but also manufacturable and efficient. We consider weight, structural integrity, and how it will perform on a filling line. We can then create 3D-printed prototypes so you can see and feel your bottle before committing to expensive tooling.

- Mold Manufacturing: The molds are the heart of the operation. The quality of your bottle is a direct reflection of the quality of your molds. We use the highest-grade steel and precision engineering to create your custom preform mold and blow bottle mold. This ensures consistency, long life, and flawless bottles every time.

- Choosing the Right Machine: Not every project needs a machine that makes 30,000 bottles per hour. We analyze your business plan, growth projections, and budget to recommend the perfect bottle blowing machine for your needs, whether it's a smaller semi-automatic model to start or a fully automated high-speed line.

- Full Line Integration: We don't just sell you a machine and leave. We can help you plan your entire production line, from the air compressors and water chillers that support the blow molder to the conveyors that carry your finished bottles to the filler and labeler. Our experience ensures all the components work together seamlessly.

This holistic approach saves you time, money, and countless headaches. You're not just buying equipment; you're buying decades of expertise and a proven process for success.

Conclusion

In short, PET is the superior choice for bottled water. Its clarity, efficiency, and recyclability make it the undisputed industry standard for very practical and powerful reasons.

Frequently Asked Questions (FAQ)

1. Is PET plastic safe for storing water long-term?

Absolutely. PET is approved as safe for food and beverage contact by all major international regulatory agencies, including the FDA in the United States. It does not contain BPA or phthalates. It is a stable material that does not leach harmful substances into the water, ensuring the purity and taste of your product remain unchanged.

2. Can I create a unique, premium-looking bottle with PET?

Yes. PET is incredibly versatile. We can create a custom blow bottle mold to produce a unique shape that sets your brand apart. We can also incorporate detailed embossing, different colors, and work with you on a design that feels heavy and luxurious in the hand, even while being lightweight.

3. What is rPET and is it as clear and safe as new PET?

rPET stands for recycled PET. Modern recycling and purification processes create rPET that is virtually indistinguishable from virgin PET. It is just as safe, clear, and strong, and it is fully approved for direct food contact. Using rPET is a great way to improve your brand's sustainability credentials.

4. How much cheaper is it to ship PET bottles compared to HDPE?

While the exact savings depend on bottle design and shipping distances, the difference is significant. A typical PET water bottle can be 30-50% lighter than an HDPE bottle designed for a similar volume. This translates directly into lower fuel costs and the ability to ship more units per truck, which can reduce overall logistics expenses by 15-25% or more.

5. What is the minimum investment needed to start producing my own PET bottles?

The initial investment can vary greatly. For a startup, we might recommend a smaller, semi-automatic bottle blowing machine and a single-cavity mold, which keeps upfront costs manageable. For a larger operation, a high-speed, fully automated line would be more appropriate. We work with you to find a solution that fits your budget and business plan.

🔗 Learn More about Blow Molding Technology

To better understand the core components of a 6-cavity automatic blow molding machine, here are some useful resources:

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr