When a new bottle defect appears on the production line, many people's first reaction is to check the mold. This is often correct, as issues with mold cooling, venting, or wear are common culprits. Before you dive into troubleshooting the blow molding machine itself, I strongly recommend you first perform a "health check" on your mold. If you are unsure how, please refer to our detailed article: The Blow Mold Health Check: A Complete Guide to Defects Caused by Mold Issues.

If you have already completely ruled out any mold issues, then it's time to turn your attention to the next primary suspect: the blow molding machine. This guide will walk you through a systematic diagnosis of the machine's core heating, pneumatic, and mechanical systems.

When a new bottle defect stops your production, I know the immediate pressure you feel. The first suspect is always the mold, and that's the right place to start. But if you've followed the guide I mentioned and are 100% certain the mold is not the problem, yet the bottles are still faulty, we must turn our attention to the blow molding machine itself. This guide is designed to walk you through a systematic diagnosis of the machine's core systems, just as a doctor would examine a patient, to find the true root cause.

Now That You've Ruled Out the Mold, Let's Begin the Machine Diagnosis?

You've confirmed the mold is fine, but bottles are still coming out wrong. Where do you start with the machine? It feels like a complex beast with countless parts.

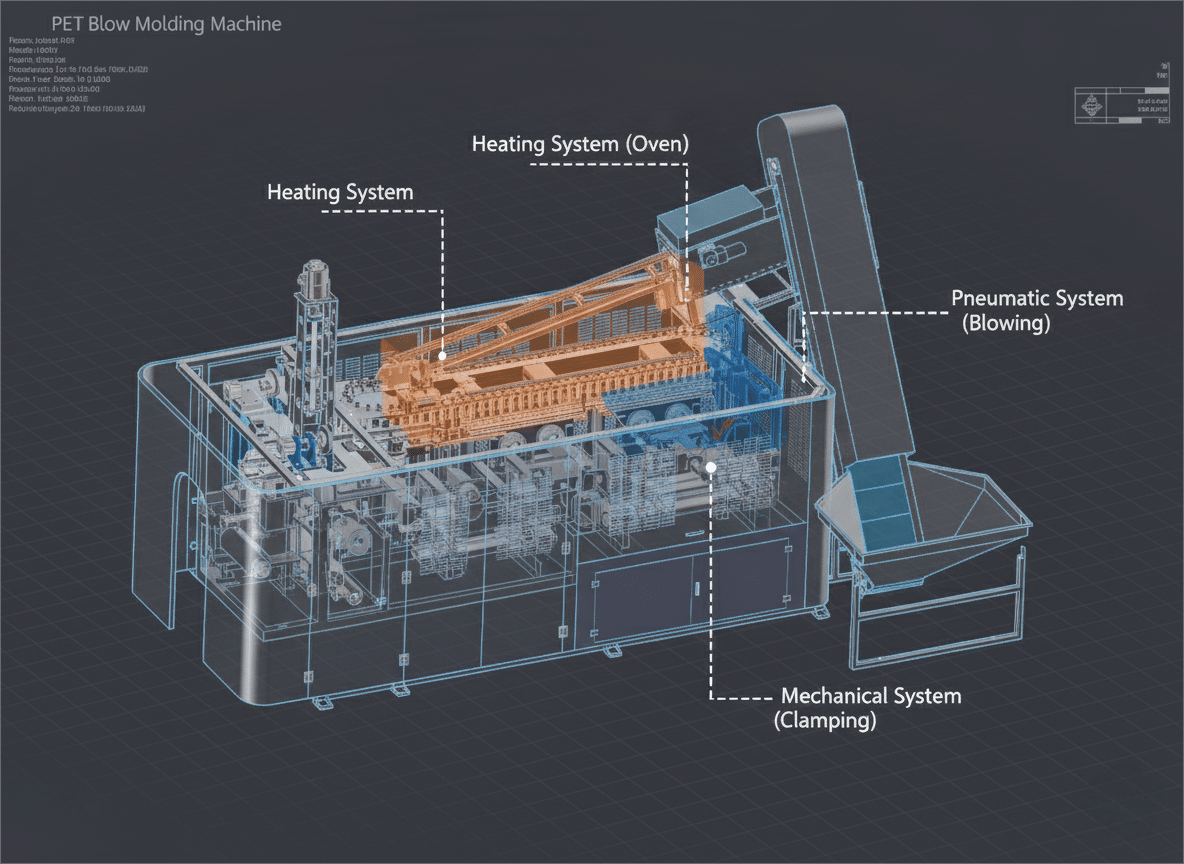

To avoid getting lost, we will treat the machine as a single system. We can break it down into three core subsystems where problems most often hide. This simplifies our troubleshooting process immensely.

This entire guide operates on one critical assumption: your mold is working perfectly. We are taking the mold out of the equation. With that settled, we can focus entirely on the machine. I find it helpful to think of the blow molding machine in three distinct parts, each with a specific job. By isolating and examining each one, we can work logically instead of guessing. I call them the three core subsystems:

- The Heating System (The Energy Input): This is the oven section. Its only job is to deliver the right amount of heat, evenly, to every preform. Any failure here creates a faulty foundation before the bottle is even blown.

- The Pneumatic & Blowing System (The Power Execution): This is the machine's lungs and muscles. It delivers the timed bursts of air pressure that shape the bottle. If the pressure is wrong or the timing is off, the bottle won't form correctly.

- The Mechanical & Clamping System (The Physical Forming): This is the machine's skeleton. It handles all physical movements: clamping the mold, stretching the preform, and ejecting the bottle. Wear and misalignment here cause physical imperfections.

By tackling them in this order, we follow the journey of the preform as it becomes a bottle, making it easier to spot where things went wrong.

Part 1: The Heating System Health Check (The Oven)?

You suspect the heating is off, but the control panel says everything is fine. The temperature settings are correct, yet the bottles are failing. What are you missing?

The control panel only shows settings, not physical reality. The actual heat delivery can be compromised by aging lamps, dirty reflectors, or blocked ventilation, causing inconsistent heating that leads to over 50% of bottle defects.

The oven is where the magic starts, and it's also where most problems begin. Inconsistent or uneven heating is the root cause of more defects than any other single factor. When I get a call about a new issue, after asking about the mold, my very next questions are about the oven. The problem usually isn't about the settings you've programmed, but about the physical ability of the oven to deliver that heat accurately.

Common Causes of Heating Failure

Here are the most common culprits I've seen over the years:

- Aging Heater Lamps: The infrared lamps used in ovens don't just burn out; they degrade over time. Their power output (infrared radiation) slowly decreases. This means that even if your control panel is set to 80% power, an old lamp might only be delivering the equivalent of 60%. This slow decay can be hard to notice until it starts producing defects.

- Dirty Surfaces: The oven is a dusty environment. A fine layer of dust can accumulate on the lamps and, more importantly, on the reflective panels behind them. This dust acts as an insulator, blocking heat from reaching the preform and reflecting it back into the oven, which can mess with temperature sensors.

- Ventilation Problems: Ovens have ventilation fans and ducts for a reason. They prevent heat from building up and creating hot spots on the preform surface. If a fan fails or a duct gets clogged with debris, the airflow is disrupted. This can lead to some parts of the preform getting much hotter than others, even if the lamps are working perfectly.

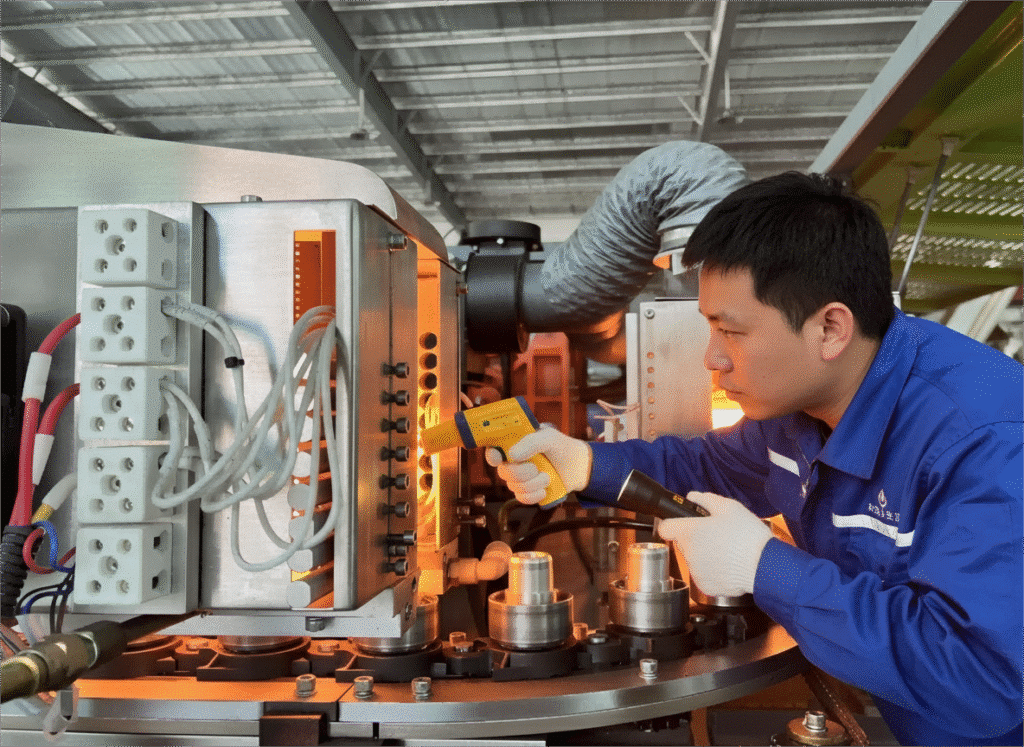

Your Heating System Checklist

To properly diagnose the heating system, you need to get hands-on. Here is a simple but effective checklist you can follow. I recommend performing these checks regularly, not just when there's a problem.

| Check | Frequency | Tools Needed | Procedure |

|---|---|---|---|

| Visual Lamp Inspection | Daily | Your Eyes | Before starting production, simply look into the oven (with proper safety glasses) and ensure all lamps are lit. A single dead lamp creates a cold stripe on every preform. |

| Surface Temperature Check | Weekly | IR Thermometer Gun | Safely stop the chain and pull out a preform right after it exits the oven. Quickly measure the surface temperature at multiple points around its circumference and from top to bottom. |

| Clean Lamps & Reflectors | Weekly | Soft Cloth, Cleaner | Power down and lock out the machine. Once cool, gently wipe down every lamp and every reflective panel. You'll be surprised how much grime comes off. |

| Ventilation Fan Check | Weekly | Your Ears & Eyes | With the machine running, listen for the sound of the ventilation fans. Visually check that they are spinning and that the air ducts are clear of any obstructions. |

By using an infrared temperature gun, you can create a "temperature map" of your preform. In a perfect world, the temperature should be consistent all the way around the preform at any given height. If you find one side is 10°C hotter than the other, you've likely found your problem—it could be a weak lamp on one side or a preform that isn't spinning correctly.

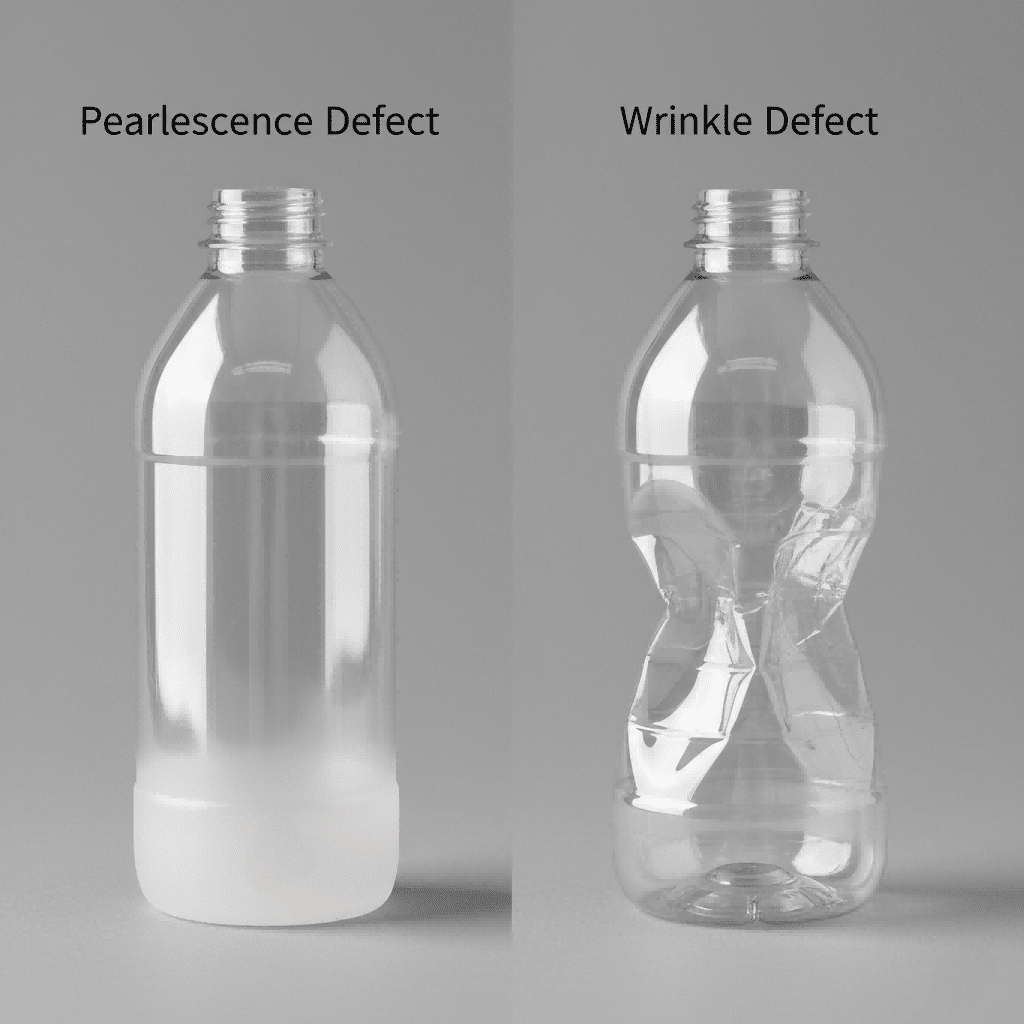

Bottle Defects Caused by Heating System Failures?

You've found an issue in the heating system. How do you connect that specific failure, like a hot spot, to the specific defect you're seeing in your bottles?

Different heating problems create distinct bottle defects. A localized hot spot causes wrinkles, while overall high heat creates a pearly haze. Knowing the cause-and-effect relationship allows for a targeted solution.

Once you've identified a problem in the oven, you can directly link it to the defects you're seeing on the production line. It’s like being a detective. The defect is the clue, and it points directly back to a specific type of heating failure. This is much better than randomly adjusting settings and hoping for the best.

Let's break down the most common defects I see that originate from the oven.

Defect 1: Uneven Wall Thickness

- The Symptom: You cut a bottle open and find that one side of the wall is significantly thicker than the other. The bottle feels unbalanced.

- The Cause: This is a classic symptom of uneven heating around the circumference of the preform. When one side of the preform is hotter than the other, the hotter, softer material stretches more easily during blowing. The cooler, stiffer side resists stretching, resulting in a thicker wall. This is often caused by a failing lamp on one side of the oven or an issue with the preform holder (mandrel) that prevents the preform from rotating smoothly as it passes the lamps.

- The Solution:

- Identify the Cold Side: Use your IR thermometer to confirm which side of the preform is cooler.

- Inspect Lamps: Check the lamps facing the cooler side. You will likely find one that is dim or completely out. Replace the faulty lamp.

- Check Preform Rotation: Watch the preforms as they travel through the oven. Ensure each one is spinning smoothly and consistently. If one is stuck or stuttering, you need to inspect its specific holder or the chain mechanism. A simple fix here can solve a major quality problem, and it's a key part of any PET bottle mold design guide.

Defect 2: Pearlescence (White or Hazy Bottom)

- The Symptom: The base of the bottle, particularly the gate area, looks milky white or hazy, almost like a pearl. The material is brittle and weak. This is also called crystallization.

- The Cause: This defect is a direct result of overheating. When PET material is heated above a certain temperature (around 120°C) for too long, its molecular structure changes and crystallizes. This crystalline material doesn't stretch properly and becomes opaque and brittle. This is usually caused by the overall heating percentage being set too high, or the preforms are moving too slowly through the oven.

- The Solution:

- Reduce Overall Heat: The simplest first step is to reduce the overall heating percentage in your machine's settings by a few points.

- Increase Speed: If possible, slightly increase the speed of the preform chain. This reduces the amount of time each preform spends in the oven, preventing it from "overcooking."

- Check Bottom Zone: Most ovens have different heating zones. You may have the zone aimed at the preform base set too high. Try reducing the power to only that specific zone.

Defect 3: Wrinkles or Folds

- The Symptom: You see horizontal wrinkles or folds in the body of the bottle, often in a specific area.

- The Cause: This is the opposite of a cold spot; it's a hot spot. When a small, localized band of the preform gets too hot, it becomes overly soft, like melted taffy. During the stretching and blowing process, this super-soft material doesn't stretch evenly and collapses in on itself, forming a wrinkle.

- The Solution:

- Locate the Hot Band: Identify the height on the bottle where the wrinkle occurs. This corresponds to the height of the lamp in the oven that is causing the problem.

- Adjust Lamp Power/Height: Go to the specific heating zone that corresponds to the wrinkled area. Lower the power output for that zone. Some machines also allow you to physically adjust the height of the lamps. You can move the offending lamp slightly further away from the preform.

- Check Ventilation: Ensure the ventilation duct for that specific zone is not blocked. A lack of cooling air can easily create a hot spot. This is a common issue that can be prevented with a good maintenance schedule.

Part 2: The Pneumatic & Blowing System Health Check?

The preforms are heated perfectly, but the bottles still come out soft or deformed. You hear a slight hiss of air, but can't pinpoint it. Where is the problem?

The issue lies in the machine's "lungs". Air leaks from worn seals in valves or cylinders, or a faulty regulator, can cause unstable pressure and incorrect timing, ruining the bottle's final form.

If the preform enters the mold perfectly heated, the next critical step is the delivery of compressed air. This is the job of the pneumatic and blowing system. Think of it as the machine's respiratory system. It needs to deliver powerful, precisely timed bursts of air to shape the bottle. Any problem here, like a leak or a slow valve, will lead to a poorly formed product. When I troubleshoot, I often find that the problems are related to pressure (is it stable and high enough?) or timing (is it being delivered at the exact right millisecond?).

Common Causes of Pneumatic Failure

- Worn Valve Seals: The most common culprits are the solenoid valves that control the airflow. Inside these valves are rubber or polymer seals. After millions of cycles, these seals wear down, crack, or become hard. This can lead to two problems: a slow response time (the valve opens or closes a few milliseconds too late) or an internal leak (air seeps through even when the valve is closed).

- Aging Cylinder O-Rings: The main cylinders that clamp the mold or move components are sealed with O-rings. Just like valve seals, these O-rings degrade over time. A worn O-ring in the main blow cylinder can prevent it from holding the required high pressure, leading to weak bottles.

- Unstable Pressure Regulators: The main pressure regulator is the gatekeeper for your air supply. If this component is faulty, it can deliver fluctuating pressure to the entire system. You might see the pressure gauge needle vibrating or dropping suddenly during a cycle.

Your Pneumatic System Checklist

Troubleshooting pneumatics is often about using your senses. Here’s how you can perform a basic health check:

| Check | Frequency | Tools Needed | Procedure |

|---|---|---|---|

| Leak Detection | Weekly | Soapy Water in a Spray Bottle | With the system pressurized but idle, spray soapy water on all air hose fittings, valve connections, and cylinder seals. If you see bubbles forming, you've found a leak. |

| Pressure Gauge Monitoring | Daily | Your Eyes | Watch the main high-pressure and low-pressure gauges during a full machine cycle. The needles should be stable. A sudden, significant drop during the blowing phase indicates a major leak or a supply problem. |

| Listen for Leaks | Daily | Your Ears | During a quiet period in the factory, walk around the machine while it's pressurized. You can often hear the distinct hiss of a small air leak that you might not notice during noisy production. |

A small leak might seem insignificant, but when you're dealing with high-pressure air, even a tiny escape path can lead to a significant pressure drop at the exact moment it's needed most. This is why connecting to a reliable air compressor is so vital for the entire line.

Bottle Defects Caused by Pneumatic System Failures?

You've found an air leak or a pressure drop. How does that translate to the specific bottle defects you're seeing, like a bottle that looks almost perfect but isn't?

A specific pneumatic failure creates a specific defect. Low high-pressure air results in weak bottles that might even burst. An unstable sealing cylinder causes deformed necks. Knowing this helps you fix the right component.

Connecting a pneumatic issue to a bottle defect is incredibly satisfying. It's direct cause and effect. You're no longer guessing; you're applying logic. Let’s look at the common defects that are tell-tale signs of a sick pneumatic system.

Defect 1: Weak or Bursting Bottles

- The Symptom: The bottles feel soft, collapse easily, or even burst during or shortly after production. They can't pass a pressure or drop test.

- The Cause: This is almost always due to insufficient or unstable high-pressure blowing air. The final "high blow" phase is what stretches the PET molecules and gives the bottle its strength and rigidity. If the pressure is too low, the material isn't stretched properly, resulting in a weak structure. This can be caused by a leak in the high-pressure air lines or, more commonly, a problem with the main high-pressure valve that isn't opening fully or quickly enough.

- The Solution:

- Check High-Pressure Supply: Verify your main high-pressure regulator is set to the correct value specified in your process sheet.

- Isolate and Inspect: Check the entire high-pressure air circuit for leaks using the soapy water method. Pay close attention to the main blowing valve itself.

- Calibrate the Valve: Ensure the main high-pressure valve's setpoint is calibrated correctly. Sometimes the gauge is correct, but the valve itself is not delivering the right pressure.

Defect 2: Deformed Necks

- The Symptom: The neck finish area of the bottle, where the cap screws on, is misshapen, oval, or has an uneven sealing surface.

- The Cause: This defect often points to a problem with the sealing cylinder. This is the small cylinder that presses the blow nozzle onto the preform neck just before blowing. If the pressure or speed of this cylinder is inconsistent, it can apply uneven force to the neck, causing it to deform while the plastic is still hot. It's a small part of the process, but critical for a perfect finish, something we focus on when discussing how to choose the right preform neck size.

- The Solution:

- Inspect Sealing Cylinder: Check the dedicated air pressure regulator for the sealing cylinder.

- Check Seals: Look for air leaks around the sealing cylinder itself. Its seals may be worn.

- Adjust Speed Control: Most sealing cylinders have a flow control valve to adjust their speed. Make sure it hasn't been knocked out of position.

Defect 3: Incompletely Formed Bottles

- The Symptom: Certain parts of the bottle, often detailed areas like handle grips or embossed logos, are not fully defined. They look soft and rounded instead of sharp.

- The Cause: This happens when the high-pressure air doesn't arrive with enough volume and velocity at the very beginning of the high-blow cycle. The plastic cools the instant it touches the cold mold wall, and if the air isn't fast enough to force it into every tiny corner, those details will be lost. This is a classic sign of a slow-to-respond or internally leaking main high-blow valve. The pressure might eventually reach the setpoint, but the initial "punch" of air is too weak.

- The Solution:

- Service the Main Blow Valve: This is the most likely culprit. The valve needs to be disassembled, cleaned, and have its core seals and O-rings replaced. This is a critical maintenance task.

- Check Air Volume: Ensure there are no restrictions in the air lines leading to the mold, such as a kinked hose or a valve that is not fully open. The problem might not be pressure, but flow.

Part 3: The Mechanical & Clamping System Health Check?

The heating and air systems are perfect, but you're still getting defects like misaligned bottoms or heavy parting lines. You can hear a clunking sound during operation. What's going on?

This is a problem with the machine's "skeleton". Years of high-speed movement cause physical wear on guide rods, stretch rods, and grippers, leading to misalignment and forming errors.

The mechanical systems are the workhorses of the blow molding machine. They perform millions of repetitive, high-force physical actions every year. It's inevitable that this constant motion leads to wear and tear. Unlike heating or pneumatic problems that can sometimes appear suddenly, mechanical issues often develop slowly over time. The machine might get slightly noisier, or a defect might gradually get worse over weeks. These are signs that the physical integrity of the machine is being compromised.

Common Causes of Mechanical Failure

- Stretch Rod Wear: The tip of the stretch rod is a small but critical component. It centers the preform and stretches it vertically. Over millions of cycles, this tip wears down, changing its shape and effective length. A worn tip can no longer properly guide the preform, leading to off-center bottoms.

- Guide Bushing Wear: The mold clamp unit slides open and closed on a set of heavy-duty guide rods and bushings. These parts wear down from the immense clamping force. As they wear, they allow for a tiny amount of "slop" or movement, which means the two halves of the mold may no longer be perfectly parallel when they close.

- Gripper Wear: The mechanical hands that move preforms into the oven and bottles out of the mold are also subject to wear. If the fingers on these grippers are worn, they might not hold the preform or bottle securely, leading to incorrect positioning at a critical stage.

Your Mechanical System Checklist

Checking mechanical systems requires measurement and careful observation.

| Check | Frequency | Tools Needed | Procedure |

|---|---|---|---|

| Stretch Rod Tip Measurement | Monthly | Digital Calipers | Remove the stretch rods and carefully measure the diameter and profile of the tip. Compare this to the dimensions of a new rod or the manufacturer's specification. |

| Mold Parting Line Check | Monthly | Feeler Gauge | With the mold closed under full clamping pressure, try to insert a thin feeler gauge into the parting line at various points. A perfectly parallel mold will have a consistent, minimal gap. |

| Visual Gripper Inspection | Weekly | Your Eyes, Flashlight | Carefully inspect the fingers and contact points on all mechanical grippers. Look for obvious signs of wear, cracks, or deformation. Replace any that look suspect. |

This is where my experience with a customer in Thailand comes in. He called me because his bottles had an off-center gate at the bottom. He was convinced it was a mold problem. I asked him to first check if the defect was in all four cavities or just one. He reported back that it was only in cavity #3. This was the key clue. A mold problem would likely affect all cavities. A single-cavity issue pointed to a component specific to that cavity. I told him, "Forget the mold for a minute. Take out the #3 stretch rod and look at it." Sure enough, he sent me a picture, and the rod was slightly bent and the tip was visibly worn. A new stretch rod fixed the problem completely. It’s a perfect example of how a small, worn mechanical part can create a defect that looks like a major mold flaw. This highlights the importance of understanding how a blow mold and machine fit together.

Bottle Defects Caused by Mechanical System Failures?

You've measured your stretch rods and found one is worn. How does this specific mechanical wear create the off-center gate you've been fighting with for days?

Mechanical wear directly causes physical defects. A bent stretch rod pushes the preform off-center. Worn guide bushings prevent the mold from closing perfectly, creating a thick parting line. These are direct physical consequences.

The link between mechanical wear and bottle defects is the most direct and easy to understand. It's pure physics. A part is in the wrong place or is the wrong shape, and it physically creates a flaw in the bottle.

Defect 1: Off-Center Gate

- The Symptom: The small injection point (gate) at the very bottom of the bottle is not in the dead center.

- The Cause: As I explained in my story about the Thai customer, this is the number one symptom of a bent or worn stretch rod, or one that is not installed and aligned correctly in its holder. When the rod pushes down on the preform, it's supposed to be perfectly centered. If it's off-center, it pushes the entire preform to one side just before blowing, resulting in the gate being off-center.

- The Solution:

- Inspect and Measure: Remove the stretch rod corresponding to the faulty cavity. Roll it on a flat surface to check for bends. Use calipers to measure the tip for wear.

- Replace if Necessary: If the rod is bent or worn beyond tolerance, replace it. Don't try to straighten a bent rod; it will never be perfect again.

- Re-align: If the rod itself is fine, you need to go through the manufacturer's procedure for re-calibrating the stretch rod's central position.

Defect 2: Heavy Parting Line / Flashing

- The Symptom: A thick, noticeable ridge of plastic runs down the side of the bottle where the two mold halves meet. In extreme cases, a thin sheet of plastic (flashing) squeezes out.

- The Cause: This defect means one thing: the mold is not closing completely and securely. There are two primary mechanical causes. First, the guide rods and bushings for the clamp unit are worn, preventing the mold platens from being perfectly parallel. Second, the clamping force itself is set too low, or the toggle mechanism is worn and can no longer deliver the required tonnage to keep the mold shut against the high-pressure blowing force.

- The Solution:

- Check Platen Parallelism: Use a feeler gauge to confirm the mold parting line is even. If it's not, you will likely need to replace the guide rods and bushings.

- Verify Clamping Force: Check the machine's settings to ensure the lock-up pressure is set correctly. If the setting is correct but the problem persists, you may need a technician to inspect the physical clamping mechanism (toggle or hydraulic) for wear.

Defect 3: Scratches on Bottle Surface

- The Symptom: You see vertical drag marks or scratches on the outside of the bottle.

- The Cause: This is almost always caused by a post-molding issue. The mechanical gripper that removes the finished bottle from the mold is either worn or misaligned. The worn gripper fingers scrape against the still-warm bottle as it's being ejected. It can also be caused by the bottle hitting a guide rail or another component on its way out of the machine. These are often small details that can be missed, but they are crucial, just like when we offer 3D printed samples to validate designs before committing to steel.

- The Solution:

- Inspect Take-out Grippers: Check the fingers on the bottle take-out arm. They often have rubber pads that wear out. Replace them if they are hardened or damaged.

- Re-Calibrate Arm Position: Watch the take-out arm in slow motion if possible. Ensure it is perfectly aligned and not causing the bottle to drag on the mold or other parts of the machine as it exits.

Your Regular Machine "Health Check": A Preventative Maintenance Schedule?

You've just spent hours fixing a problem that shut down your line. How can you prevent these "surprise" failures from happening again in the future?

The vast majority of machine failures don't happen by surprise. They are the result of gradual wear and tear that could have been caught and corrected early with a simple, consistent maintenance schedule.

Reactive maintenance—fixing things only when they break—is the most expensive and stressful way to run a production facility. The key to avoiding unplanned downtime and frustrating defect-chasing is to switch to a proactive, preventative maintenance mindset. A machine that is regularly inspected, cleaned, and serviced is a machine that is reliable. It's like taking your car for a regular oil change instead of waiting for the engine to seize. I've created a basic schedule below that you can adapt for your specific machines. This is a great starting point for building a robust maintenance culture.

A Sample Preventative Maintenance Schedule

This schedule is a general guide. You should always consult your specific machine's manual for detailed recommendations.

| Frequency | System | Task Description |

|---|---|---|

| Daily | All | Visual Inspection: Walk around the machine. Look for any loose bolts, disconnected hoses, or obvious signs of wear. |

| All | Clean Sensors: Wipe off any dust or debris from photoelectric eyes and proximity sensors. A dirty sensor is a common cause of false alarms. | |

| Pneumatics | Listen for Leaks: Take a moment to listen for any audible air leaks. | |

| Mechanical | Clear Debris: Remove any dropped preforms or bottles from the machine's interior. | |

| Weekly | Heating | Clean Oven Reflectors & Lamps: A clean oven is an efficient oven. This is one of the most important weekly tasks. |

| Pneumatics | Check for Air Leaks: Use the soapy water method on major connections and valve banks. | |

| Mechanical | Inspect Grippers: Visually inspect the preform and bottle gripper fingers for wear. | |

| Cooling | Check Chiller Water Level: Ensure your connected chiller has adequate water and is operating at the correct temperature. | |

| Monthly | Mechanical | Check Chain Tension: Inspect the tension of the oven chain and other drive chains. Adjust as needed. |

| Mechanical | Measure Stretch Rods: Perform a quick measurement on the stretch rod tips, especially if you are running abrasive materials. | |

| All | Calibrate Key Sensors: Check the calibration of critical sensors like temperature probes or pressure transducers. | |

| Pneumatics | Drain Air Filters: Drain any water accumulated in the main air filter/regulator bowls. | |

| Quarterly | All | Lubrication: Follow the manufacturer's guide to lubricate all required points (bearings, toggle joints, slides). |

| Mechanical | Check Platen Parallelism: Perform a feeler gauge check on the mold parting line. | |

| Heating | Full Oven Cleaning: Perform a deep cleaning of the entire oven section. | |

| Annually | Pneumatics | Rebuild Kits: Proactively install rebuild kits (seals, o-rings) on high-cycle solenoid valves and cylinders. |

Creating a downloadable PDF or a physical checklist from this table that operators can sign off on is a powerful way to ensure these tasks get done consistently. Over time, you will see a dramatic reduction in the number of machine-related defects. You can find more comprehensive solutions for a wide range of bottle defect problems on our website.

Conclusion

When bottles have defects, don't just blame the mold. A systematic check of the machine's heating, pneumatic, and mechanical systems will often reveal the true, and fixable, root cause.

Summary of Machine-Related Defects & Solutions

| Bottle Defect | Probable Machine System | Common Cause(s) | Solution(s) |

|---|---|---|---|

| Uneven Wall Thickness | Heating | One-sided heating; failing lamp; preform not rotating. | Replace lamp; check preform holders/chain. |

| Pearlescence (White Base) | Heating | Overall temperature is too high. | Lower overall heat percentage or increase oven speed. |

| Wrinkles/Folds | Heating | Localized hot spot on preform. | Adjust power/height of specific lamp; check ventilation. |

| Weak/Bursting Bottles | Pneumatic | Low or unstable high-pressure blow air. | Find and fix air leaks; check/calibrate high-pressure valve. |

| Deformed Necks | Pneumatic | Inconsistent sealing cylinder pressure or speed. | Check sealing cylinder's regulator and seals. |

| Incomplete Formation | Pneumatic | Slow high-pressure valve response; low air volume. | Service/rebuild the main high-blow valve. |

| Off-Center Gate | Mechanical | Bent, worn, or misaligned stretch rod. | Replace or re-align the specific stretch rod. |

| Heavy Parting Line | Mechanical | Worn clamp guide bushings; insufficient clamp force. | Replace guide components; verify clamp pressure settings. |

| Scratches on Bottle | Mechanical | Worn or misaligned bottle take-out grippers. | Replace gripper pads; re-calibrate take-out arm position. |

Frequently Asked Questions (FAQ)

1. When a new bottle defect appears, should I check the machine's parameters first, or its physical condition (like lamps and seals)?

Always check the physical condition first. Your machine's parameters and settings mean nothing if a lamp is burned out, a seal is leaking, or a rod is bent. A quick 5-minute physical inspection can save you hours of wasted time adjusting parameters that aren't the root cause of the problem. Check for the obvious physical failures first, then move on to tweaking the process settings.

2. What is the single most common machine component that fails and leads to production stops?

In my experience, it's the seals and O-rings inside the high-pressure blowing valves. These components cycle millions of times under intense pressure. They are wear-and-tear items. When they fail, you lose the ability to form bottles correctly, bringing production to a halt. Proactively replacing these seals as part of your annual maintenance is one of the best ways to prevent sudden stops.

3. How can I tell if a bottle defect is caused by gradual machine wear over time, versus a sudden component failure?

A defect from gradual wear (like a worn stretch rod or guide bushings) typically appears slowly and gets progressively worse over days or weeks. For example, a parting line might be barely visible one week and noticeably heavier the next. A sudden failure (like a blown seal or a dead heating lamp) causes an immediate and consistent defect. One minute production is fine, and the next, every bottle from a specific cavity is bad.

4. How often should I clean and calibrate my machine's sensors to prevent false alarms?

Sensors, especially photoelectric eyes that detect preform or bottle presence, should be wiped clean daily. A thin layer of dust is all it takes to cause a false reading and stop the machine. For more critical sensors like pressure transducers or temperature probes, a calibration check should be part of your monthly or quarterly maintenance schedule. Always follow the manufacturer's guidelines for calibration procedures.

5. What information from my machine's control panel (HMI) is most useful to photograph and send to a supplier for remote support?

To get the most effective remote help, send photos of three key screens. First, the main alarm screen that shows the active error code and description. Second, the specific process screen for the part of the machine that is alarming (e.g., the oven temperature page if it's a heating alarm). Third, the main production overview screen that shows cycle times, pressures, and temperatures. This combination of information gives a technician a complete picture of what the machine was trying to do and where it failed.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr