When you decide to build a new 100,000 bottle-per-day production line, it's a major milestone. But the success of this project is not decided when you buy the machine; it's decided in the planning you do before you even send your first inquiry.

Building a 100,000 bottle/day fully-automatic PET line is all about system planning. This includes defining your true BPH (bottles per hour), selecting a high-speed linear blower, creating a preform strategy, and budgeting enough for your high-pressure air system.

Building a fully-automatic PET line isn't like buying a machine. It's like designing a high-performance racing team. Every part—the mold, the air compressor, the factory layout—must work in perfect harmony. A single mistake in the planning phase can cost you thousands of dollars a day in lost production or high energy bills.

I am here to be your "project architect." I will walk you through the entire process, from a simple concept to a factory floor producing 100,000 bottles every day. We will cover the technology, budget, hidden costs, and the professional insights I've learned over 20 years.

Key Points for Your 100k/day Project

| Project Phase | Key Decision or Action |

|---|---|

| 1. Blueprint | Define your true BPH (Bottles Per Hour) based on an 8, 16, or 24-hour workday. Finalize bottle design and neck finish. |

| 2. Core Tech | Choose between a High-Speed Linear Blower (best value for this output) and a Rotary Blower (over-investment). |

| 3. Preforms & Molds | Adopt a "Buy Preforms" strategy to save startup capital. Invest in high-precision, fast-cooling multi-cavity blow bottle molds. |

| 4. Power & Auxiliaries | Do not save money on your air compressor system and chiller. This is the #1 trap. |

| 5. Factory Layout | Plan the "flow" of materials (preforms, bottles, pallets) to minimize labor and energy loss. |

| 6. Automation | Define "fully-automatic." This must include air conveyors, labelers, and end-of-line packers. |

| 7. Budget (TCO) | Focus on "Total Cost of Ownership" (TCO), not just the purchase price. Energy is key. |

| 8. Partner | Choose an "architect" who can plan the whole line, not just a "brick-seller" who sells one machine. |

Step 1: The Project Blueprint (What to Finalize Before Buying Any Machine)?

This is your project's foundation. If the foundation is shaky, everything else will be a problem. Before you contact a single supplier, you must finalize three core elements internally.

Before you ask for a price, you must define three things: your bottle design (volume, weight, shape), your neck finish (e.g., PCO 1881), and your true output goal (BPH). "100k per day" in 8, 16, or 24 hours? This answer changes everything.

I've seen too many clients come to me with a vague concept. 100,000 bottles per day, if based on 24 hours, is 4,167 BPH (bottles per hour). If based on 16 hours, it's 6,250 BPH. If based on 8 hours, it's 12,500 BPH. These three outputs correspond to completely different machine models, mold cavities, and investment levels.

You must first decide on your shift system and real output target. Only then can we create the most economical plan for you. Otherwise, we are just wasting time.

1. Define Your True Output Goal (BPH)

This number is the "lighthouse" for your entire project.

My personal advice is: Plan your production for a 16-hour or 20-hour day. Never plan for 24 hours straight. You must leave 4-8 hours per day for preventive maintenance, cleaning, and mold changes.

Therefore, for a 100k/day goal, the target you should be aiming for is ~6,250 BPH. This number is the "sweet spot" in our industry. It points directly to a 6-cavity high-speed linear machine—the most mature and cost-effective solution right now.

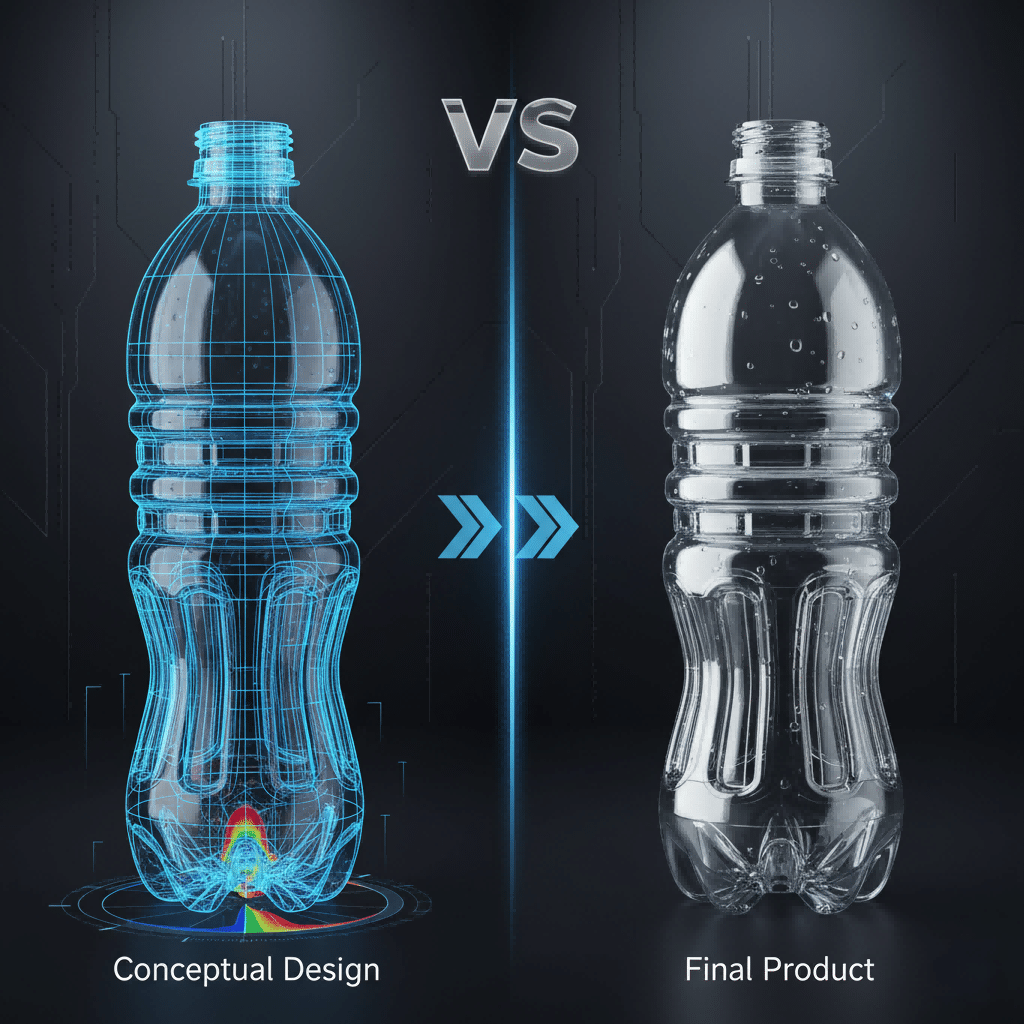

2. Finalize Your Bottle Design

This is more than just a sketch. You need to define:

- Volume: 500ml, 1L, or 1.5L?

- Shape: Is it a simple round bottle (easy to blow) or a complex square bottle with sharp edges (harder to blow)? A complex design might slow your cycle time, forcing you to buy a machine with more cavities to hit your goal.

- Weight (Grammage): How heavy is the bottle? A 15g 500ml bottle is harder to blow well than a 19g bottle. Lighter bottles save you resin costs but require a much more precise bottle blowing machine and a perfect preform.

If you're unsure about the design, our PET bottle design guide can help you optimize it for manufacturing right from the concept stage.

3. Finalize Your Neck Finish

This is the "mouth" of the bottle. Is it PCO 1881 (common for water)? 30/25 (also water)? Or PCO 1810? This choice is critical because it dictates:

- The exact preform you must buy.

- The cap you must buy.

- The precision design of the blow mold.

You cannot easily change this later without scrapping your molds and preform inventory. I strongly recommend reading a guide on choosing a preform neck size before you make a final decision.

Do not move to Step 2 until you can write these three things on a single sheet of paper.

| Shift Plan | Target BPH | Typical Machine Model | Budget Impact |

|---|---|---|---|

| 8-Hour Day | 12,500 BPH | 8 or 10-Cavity Linear / Small Rotary | Very High |

| 16-Hour Day | 6,250 BPH | 6-Cavity High-Speed Linear | High (Recommended) |

| 24-Hour Day | 4,167 BPH | 4-Cavity Linear | Medium |

Core Tech Selection: High-Speed Linear vs. Rotary PET Blower?

Choose the wrong tech, and you could double your payback period. With two main options, linear and rotary, do you know which is right for 100k/day?

For the 100k-150k/day range (6,000-8,000 BPH), a high-speed full-servo linear blower is the best value by far. Its stability is close to an entry-level rotary, but its purchase and maintenance costs are much lower.

Now that you have a clear blueprint—let's say you've confirmed a 6,250 BPH target—it's time to choose your core technology. At this output, you are at a major crossroads: High-Speed Linear Blower or Rotary Blower.

As an engineer, I love the technology in both. But as your project planner, my advice is very clear.

What is a High-Speed Linear Blower?

A linear machine is just what it sounds like: preforms move in a straight line. They pass through a heating oven and then into a mold station to be blown.

The "high-speed" part is key. We are talking about Full-Servo linear blowers. This means every major movement (preform feeding, stretching, mold clamping) is driven by a precise, fast, and efficient servo motor, not by slow and inconsistent air cylinders.

Pros for your 100k/day project:

- Perfect Speed Match: A 6-cavity full-servo bottle blowing machine will produce 6,000-7,200 BPH. This perfectly matches our 6,250 BPH target.

- Lower Investment: It costs significantly less than a rotary machine. This frees up your capital for the (very expensive) auxiliaries and downstream packaging.

- Flexibility (Fast Mold Change): A mold change is much faster. I can guide a team to swap a 6-cavity linear mold in about 30-45 minutes. This is critical if you plan to run multiple bottle shapes on one line.

- Smaller Footprint: It takes up less factory space.

Cons:

- Speed Limit: Linear machines have a physical speed limit. They usually top out around 12,000-15,000 BPH (8-10 cavities). You can't upgrade it to 20,000 BPH later.

What is a Rotary Blower?

A rotary machine is a different beast. Preforms move on a large, spinning carousel. Heating, blowing, and exiting all happen as the wheel turns. These are the machines giant brands use to produce millions of bottles a day.

Pros:

- Extreme Speed: These machines start at 10,000 BPH and can go up to 80,000 BPH or more.

- Extreme Stability: They are built for 24/7/365 operation.

Cons for your 100k/day project:

- Massive Investment: An entry-level rotary can cost 3 to 5 times more than a high-speed linear machine.

- Complex Mold Changes: A mold change on a rotary is a major event. It can take a full 8-hour shift and requires highly-trained technicians.

- Over-Investment: Using a rotary machine to run at 6,250 BPH is like using a sledgehammer to crack a nut. It is not an efficient use of capital.

My Professional Insight (Vivian's Insight)

For the 100k-150k/day range (6,000-8,000 BPH), my experience is that a high-speed full-servo linear blower is the best value by far. Its stability is now very close to entry-level rotary machines, but its purchase cost and long-term maintenance costs are dramatically lower. Rotary machines are great, but they are for a different scale—for massive water plants producing 300,000+ bottles per day from a single, unchanging bottle design.

I've had this exact conversation with clients. They are tempted by the "prestige" of a big rotary machine. But I show them the numbers. The stability and efficiency of modern full-servo linear machines are very close to entry-level rotary, but the purchase, maintenance, and mold costs are worlds apart.

| Feature | High-Speed Linear (6-Cavity) | Entry-Level Rotary (10-Cavity) |

|---|---|---|

| Output (BPH) | 6,000 - 7,200 | 15,000 - 18,000 |

| Best For | 100k-150k bottles/day | 300k+ bottles/day |

| Initial Cost | 1x (e.g., $80k USD) | 3x - 5x (e.g., $250k-$400k USD) |

| Mold Changeover | ~30-45 Minutes | ~4-8 Hours |

| Footprint | Compact | Very Large |

| Flexibility | High | Low |

| My Verdict | The clear winner for your project. | Over-investment. Not good capital allocation. |

The Heart of Output: High-Precision Molds & Preform Strategy?

Your machine is the engine, but the mold is the heart. The preform is the blood. Should you "make your own blood" (produce preforms) or "get a transfusion" (buy them)?

At the startup phase, "buying preforms" is the smarter choice to protect your cash flow. You should focus your capital on the best automatic blower and high-precision blow bottle molds. The mold's cooling design directly dictates your true output and defect rate.

Your bottle blowing machine is just the engine. The blow mold is the heart of your entire operation. Its quality will directly determine your final bottle quality, your production speed, and your scrap rate.

At the same time, you must decide where your preforms will come from. This leads to one of the biggest strategic questions for a new plant: Do you make your preforms, or do you buy them?

Preform Strategy: Make vs. Buy

You have two choices:

- Buy Preforms: Purchase ready-made preforms from a specialized supplier.

- Make Preforms: Buy a PET injection molding machine and a preform mold to produce them in-house.

My Professional Insight (Vivian's Insight)

[Case Study 1:] I had a client in the Middle East starting a new water plant. He wanted to "do it all" from day one and buy an injection machine. I advised him against it.

Why? Cash flow is king.

- Making preforms requires a massive second investment—sometimes equal to or more than the blowing line itself. A high-quality injection machine and a multi-cavity preform mold are very expensive. It also requires a separate team of skilled technicians and more factory space.

- Buying preforms keeps your startup costs low. It turns a huge Capital Expense (CAPEX) into a simple Operational Expense (OPEX). You are flexible. You can easily buy different colors or weights.

My client listened. He focused his capital on the best full-servo blowing machine and a high-speed packaging line. His plant was profitable in the first year. In his second year, he used those profits to buy his injection line. For a high-output project, "cash flow" is more important than "full vertical integration."

My rule: Don't even think about making your own preforms until your volume is so large that the cents saved per-preform justifies the massive investment. For a 100k/day line, "Buy" is the smart move.

Why You Must Invest in High-Precision Molds

Now, let's talk about the blow bottle mold. For your 6,250 BPH line, you will need one 6-cavity mold.

Clients often try to save money here. This is a disastrous mistake. A cheap mold is the most expensive thing you can buy.

Why? Cooling. Cooling. Cooling.

Your machine's "cycle time" (how fast it can make a set of bottles) is limited by one main thing: how fast you can "set" (cool) the hot PET plastic after it's blown.

- A cheap mold has simple, drilled water channels. The cooling is uneven and slow. You have to add 0.5 seconds of "cooling time" to your cycle. This slows your entire line down. You can't hit 6,250 BPH. Maybe you only get 5,000 BPH. That's a loss of 1,250 bottles every hour.

- A high-precision mold uses aircraft-grade aluminum (5x better heat transfer than steel) or beryllium-copper alloys. It has complex "conformal cooling channels" that follow the exact shape of the bottle, chilling the plastic instantly and evenly.

I once saw a client who bought a cheap 6-cavity mold from another supplier. They could never run faster than 4,800 BPH because the bottle bottoms were still soft and deforming. They were losing over 22,000 bottles of production every single day! We replaced it with one of our high-flow cooling molds, and they hit 6,300 BPH on day one. The new mold paid for itself in less than two months.

Don't let your beautiful bottle design be ruined by a cheap mold. It's the heart of your output.

The Power Source: Planning Your High-Pressure Air System & Auxiliaries?

This is the "hidden cost" that is most often ignored. An expensive blower with a cheap air compressor is like a Ferrari with a tractor engine.

Never, ever save money on your air compressor. A blower is an "air-eater." You must budget for a powerful high-pressure compressor, a low-pressure unit, a water chiller, and dryers. Your compressor output must have at least a 20% buffer.

This is the part that investors and new project managers always underestimate. And it is the #1 cause of new-line failures.

A blow molding machine is an "air-eating" monster. It consumes a massive amount of high-pressure air. Your machine is just one piece; the auxiliary system is its "life support."

If you buy an $80,000 blowing machine but try to save $10,000 on the air compressor, you have just wasted $80,000. Your machine will never reach its rated speed.

My motto is: Never, ever save money on your air compressor.

To run your 100k/day (6,250 BPH) line, you need a powerful system of four key auxiliaries:

1. High-Pressure Air Compressor (30-40 bar)

This is the "power" that blows the bottle. A 6-cavity machine needs a lot of air at 35-40 bar (500-580 PSI).

- The 20% Buffer Rule: Your compressor's output (FAD - Free Air Delivery) must be at least 20% more than the machine's stated consumption. If the machine "consumes" 5 m³/min, you need a compressor that "produces" 6 m³/min. Air consumption changes with bottle size and pressure.

2. Low-Pressure Air Compressor (8-10 bar)

This is the "control." This air powers the machine's pneumatic cylinders (valves opening, preforms moving). This must be a separate system.

3. Water Chiller

This is the "cooling." The high-precision mold we discussed needs cold water (around 10°C / 50°F) circulating through it to cool the bottles. The chiller is a refrigeration unit that keeps this water cold. No chiller = hot molds = slow production and soft bottles.

4. Air Dryers / Filters

This is the "protection." Air from a compressor is hot, wet, and can contain tiny oil particles.

- Water will rust your machine's expensive, precision-made valves.

- Oil will contaminate your valves and, worse, get inside your bottles.

You must install a refrigerated air dryer and a set of (0.01 micron) filters after your compressor. Skipping this to save $3,000 will cause a $30,000 valve manifold failure in the first year.

My Professional Insight (Vivian's Insight)

Remember this: Never save money on your air compressor. I've seen too many clients buy a beautiful, expensive blower but pair it with a cheap, undersized compressor. The result? The air pressure is unstable, the bottle defect rate is high, and the machine can't reach its rated speed. Your compressor's output must have at least a 20% buffer.

A smart investment is an "air recovery system." Modern full-servo machines offer this option. It captures "used" high-pressure air from the blowing process and recycles it to power the low-pressure "control" movements. This can save you 30% on high-pressure air, saving you electricity every single day. We have a detailed analysis of air system cost-efficiency.

| Auxiliary Component | Specification for 6,250 BPH Line | Why it's Critical |

|---|---|---|

| High-Pressure Compressor | ~6-7 m³/min @ 40 bar | The "Power". Undersize this, and you get defects and slow speed. |

| Low-Pressure Compressor | ~2-3 m³/min @ 10 bar | The "Control". Runs machine actions. (Less needed with air recovery). |

| Water Chiller | ~80,000 kcal/hr | The "Cooling". Sets the PET plastic. No chiller = slow production. |

| Dryer / Filters | Matched to compressor | The "Protection". Stops water/oil from destroying your machine and contaminating bottles. |

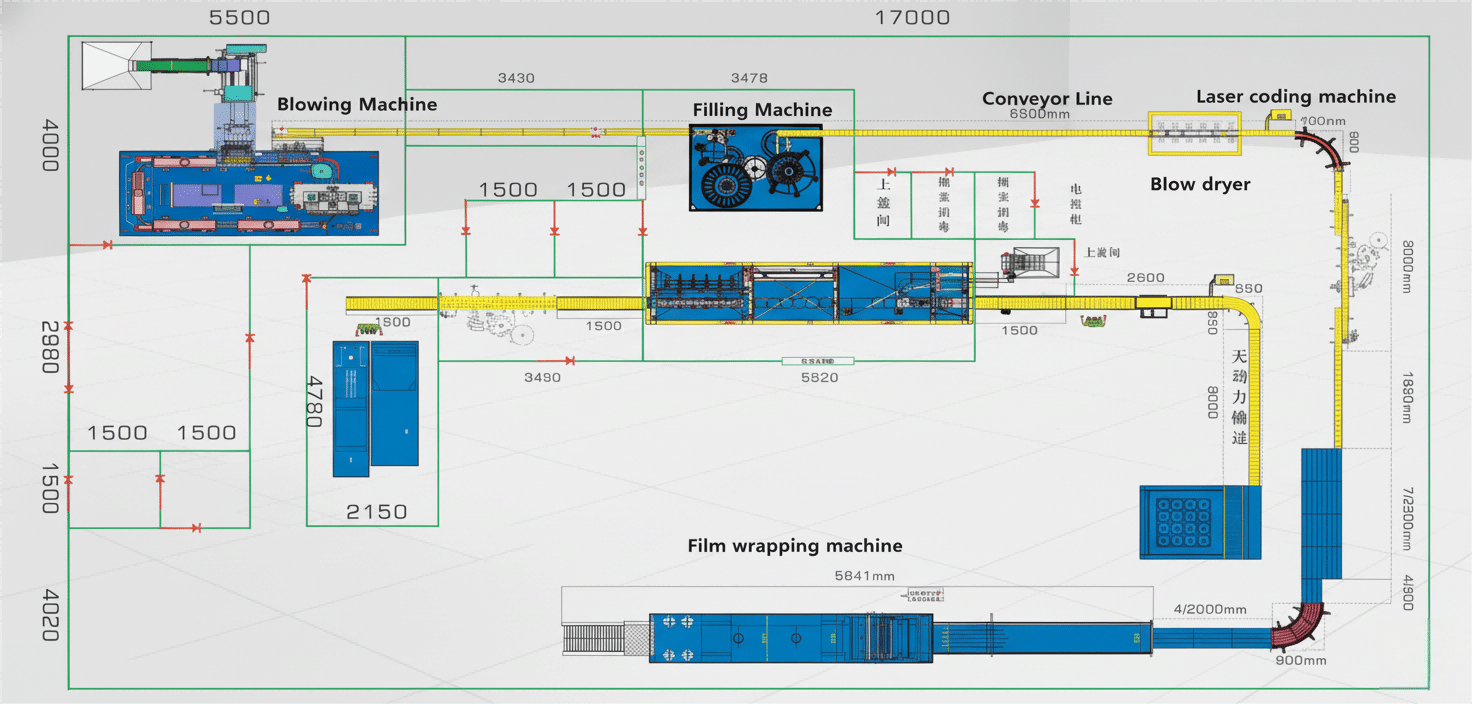

Factory Layout: The "From Scratch" Physical Space Plan?

A factory is not an empty box. A bad layout will increase your labor costs and energy waste. A good layout is a "money-making machine" in itself.

When planning a layout, logistics flow is #1. How do preforms get to the hopper? Is the air compressor close to the blower (to reduce pipe loss)? How do finished bottles smoothly enter the labeler and packer?

You have your blueprint, machine, molds, and auxiliaries. Now, where do you put them?

A factory floor is not just a big, empty box. Your factory layout is a "machine" in itself. A good layout creates a smooth, efficient flow. A bad layout creates bottlenecks, wastes energy, and forces you to hire extra people just to move things around.

When I plan a "from scratch" factory, I focus on two things: Zone Planning and Flow.

The Four Key Zones

Your factory must be divided into logical zones to control noise, contamination, and workflow.

1. The "Power" Zone (Utility Room)

- This is where your air compressors, dryers, and chillers live.

- This room is LOUD and HOT.

- It must be in a separate, well-ventilated, and sound-proofed room.

- Critical Insight: This room must be as close as possible to the blowing machine. I've seen clients put the compressor 50 meters away. They had to run 50 meters of expensive high-pressure pipe. By the time the 40-bar air reached the machine, it had dropped to 36 bar due to pipe friction loss. They had to turn the compressor up just to compensate, wasting electricity 24/7. Keep your pipes short.

2. The "Raw Material" Zone (Warehouse)

- This is your warehouse for preforms, caps, and labels.

- It must be clean and dry. Preforms must be kept in sealed bags. Cardboard dust is a major source of contamination.

3. The "Clean" Zone (Blowing & Filling)

- This is where the bottle blowing machine and (if for water/juice) the filling machine are.

- Ideally, this area should be a "clean room" with positive air pressure to keep dust out.

- This is critical for food safety.

4. The "End-of-Line" Zone (Packaging & Warehouse)

- This is where your labelers, shrink wrappers, and palletizers are.

- It's the "busiest" area, with forklifts and operators.

- It must have easy access for trucks to load finished goods.

My Professional Insight (Vivian's Insight)

When planning a layout, logistics flow is #1. How do your preforms get to the hopper fastest? Is the air compressor close to the blower (to reduce pipe loss)? How do finished bottles flow smoothly to the labeler and packer? A bad layout can cost you 2 extra salaries for 10 years. A good layout is a one-time investment that pays you back every day.

I recommend a "U-Shaped" layout. Raw materials enter on the right side. They flow through the line (hopper, blower, filler, labeler, packer) in a "U". The finished pallets exit on the right side, right next to the entrance. A single forklift operator can manage both incoming and outgoing goods from one central lane.

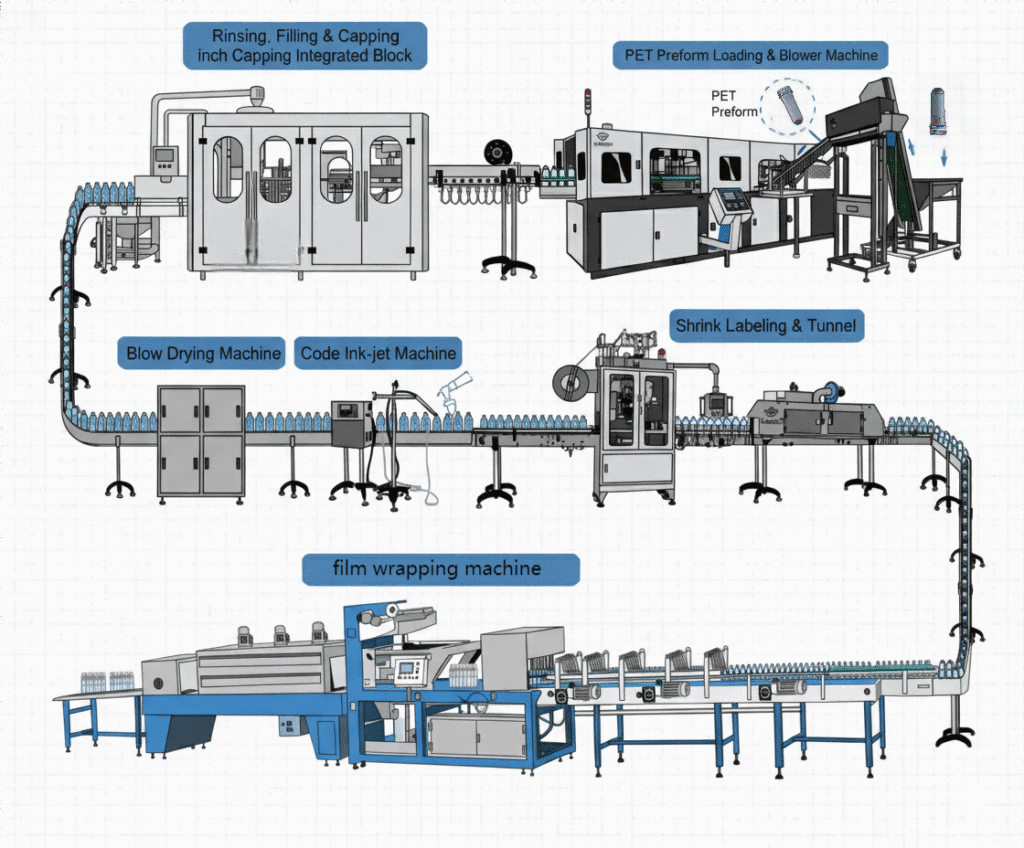

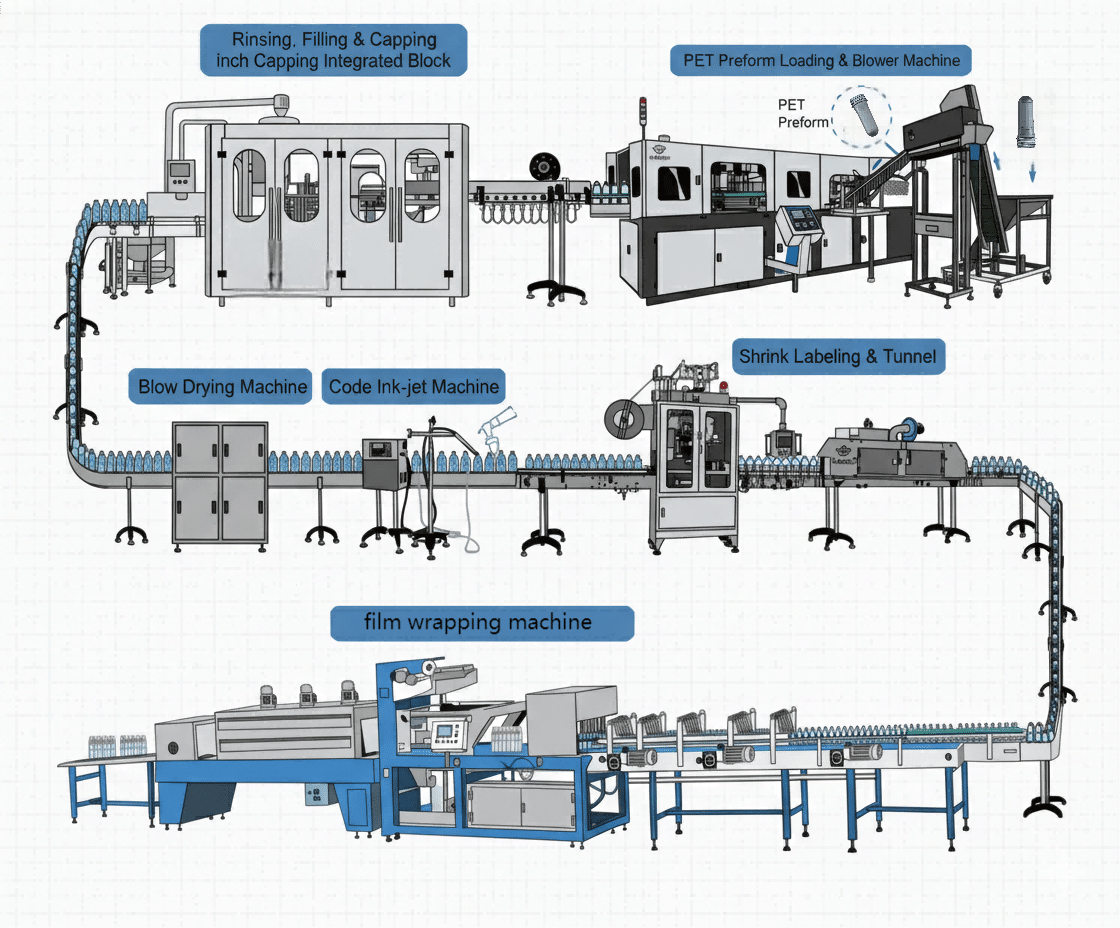

Achieving "Fully-Automatic": The Downstream Automation Line?

At 100,000 bottles per day, if you still have 3 people manually bagging bottles, that is not "fully-automatic." Automation is not just about efficiency; it's about food safety.

"Fully-automatic" means no-touch production from the blower to the pallet. This must include air conveyors, in-line leak testers, automatic labelers, and automatic shrink wrappers or case packers.

At 100,000 bottles per day (6,250 per hour), you cannot have people manually handling bottles. It's too fast, too expensive, and for food products, it's a hygiene and safety risk.

"Fully-automatic" is not a marketing term; it's a necessity. It means "no hands touch the product." Your blowing machine is just the start. The "downstream" line is what makes it automatic.

Here is the automation chain required for a modern, high-speed line:

1. Air Conveyor

- What it is: A covered, stainless-steel conveyor that holds bottles by their neck rings. It uses fans to "float" the empty bottles at high speed.

- Why it's essential: It's the "bridge." It cleanly and automatically moves 6,250 bottles per hour from the blower to the filler. It also acts as a "buffer" to absorb micro-stops.

2. In-Line Leak Tester

- What it is: A high-speed machine that grabs each bottle, seals the top, and applies a tiny bit of pressure.

- Why it's essential: It can find a "pinhole" leak that the human eye can never see. It automatically ejects the bad bottle before it gets to the filler.

- My Story: A client once skipped this to save $20,000. They produced 50,000 bottles of juice. A tiny, invisible crack in the mold (a mold defect) created a pinhole in 10% of the bottles. They didn't find out until 5,000 bottles were filled, capped, labeled, and leaking, ruining entire pallets. A leak tester would have saved them $50,000 in lost product.

3. Filling & Capping (The "Combiblock")

For a 100k/day water or juice plant, the modern standard is a "Combiblock" (Blow-Fill-Cap).

- What it is: This is one single, integrated machine. The blower is directly connected to the filler, which is connected to the capper.

- Why it's the gold standard: The blown bottle is never exposed to open factory air. It is blown, filled, and capped in a sterile environment. This is the ultimate in food safety and efficiency.

4. Labeling Machine

After filling, the bottle needs a label. Your two main choices are:

- Roll-Fed (OPP/BOPP): A fast, low-cost machine that uses hot-melt glue to apply a thin plastic label from a roll. 90% of water bottles use this.

- Sleeve Labeler: A machine that drops a full-body "sleeve" over the bottle, which is then shrunk in a heat tunnel. Looks more premium, but is slower and more expensive per-label.

5. End-of-Line Packaging

Finally, you have to pack 6,250 bottles per hour.

- Automatic Shrink Wrapper: Groups bottles (e.g., 4x6) and wraps them in PE film.

- Case Packer: Automatically forms a cardboard box and places the bottles inside.

At this scale, a shrink wrapper is the minimum requirement. You cannot pay people to pack 104 bottles every minute by hand.

My Professional Insight (Vivian's Insight)

[Case Study 2:] If you have 3 people at the end of the line manually bagging bottles, that is not "fully-automatic." I have a client in South America who installed a "Combiblock" for his new water plant. His bottles are blown, filled, and capped without any human contact. For the food and beverage industry, automation is not just "efficiency"; it is "food safety."

Budgeting & TCO: The "Total Cost of Ownership" You Actually Pay?

Investors care most about "how much." But only looking at the price quote is the biggest trap. A cheap machine can eat all your profits in three years.

When planning at the 100k/day level, you must look at TCO (Total Cost of Ownership). This includes CAPEX (investment) and OPEX (operations). The air compressor is an "energy tiger!" A high-efficiency machine can pay for itself in 1 year.

This is the most important conversation for you as the investor. When you ask a supplier, "What is the price?", you are asking the wrong question.

You are not buying a product; you are investing in a 10-to-15-year manufacturing asset. The real question is: "What is the Total Cost of Ownership (TCO)?"

The purchase price (Quote) is just the tip of the iceberg. The "cheap" machine is often the most expensive one to own.

Your total cost is made of two parts:

1. CAPEX (Capital Expenditure)

This is the one-time, upfront payment to build the line.

- The bottle blowing machine itself.

- The high-precision blow bottle molds.

- The full auxiliary system (compressor, chiller, dryer, filters).

- The downstream automation (conveyors, labeler, wrapper).

- Shipping, installation, and training fees.

- Factory modifications (electrical, piping).

2. OPEX (Operational Expenditure)

This is what you pay every single day to run the line for the next 10 years. This is where a "cheap" machine will destroy your profits.

Your main OPEX costs are:

- Energy (Electricity): This is your #1 operational cost. The high-pressure air compressor is the biggest "energy tiger" in your whole factory.

- Labor: Operators, technicians, forklift drivers.

- Raw Materials: Preforms, caps, labels, film.

- Maintenance & Spare Parts: Seals, filters, heating lamps, valves.

My Professional Insight (Vivian's Insight)

A cheap machine might, in its first three years, eat up all the money you saved through high energy bills and frequent repairs.

Let's use a more realistic TCO analysis based on your feedback:

- Machine A (Standard Linear): A standard-efficiency machine. Purchase price is $80,000. It has no air recovery system.

- Machine B (High-Efficiency Linear): A full-servo machine with a high-efficiency oven and an air recovery system (which saves 30% on compressed air). Purchase price is $105,000.

An investor sees the $25,000 price difference and wants to buy Machine A. This is a huge mistake.

Let's do the math:

- The 6,250 BPH line runs 16 hours/day.

- Let's say the part of your energy bill affected by the compressor and heating is $7,000/month.

- Machine B, with its efficient oven and air recovery, is 30% more energy-efficient.

- It saves 30% on that $7,000 cost = $2,100 per month in electricity savings.

Now, let's look at the payback on that extra $25,000 investment:

$25,000 (extra cost) / $2,100 (monthly savings) = ~12 months

In just 12 months, Machine B has completely paid back its extra cost. For the next 9+ years of its life, it is putting an extra $2,100 in pure profit into your pocket every single month.

When planning at this scale, you must look at TCO. The machine that cost $25,000 more upfront will save you over $247,000 during its lifetime.

| Cost Factor (10-Year Estimate) | Machine A (Standard) | Machine B (High-Efficiency) |

|---|---|---|

| Purchase Price (CAPEX) | $80,000 | $105,000 |

| 10-Year Energy (OPEX) | $840,000 | $588,000 |

| 10-Year Maint. (OPEX) | $100,000 | $80,000 (better parts) |

| 10-Year TCO | $1,020,000 | $773,000 |

| 10-Year TCO Savings | --- | $247,000 |

Conclusion: Choosing an "Architect," Not Just a "Brick-Seller"?

You are about to complete this complex system. The final step is your partner. Do you need a "brick-seller" who just sells a machine, or an "architect" who helps build your factory?

You need a project "architect" who can plan the entire line, not just a "brick-seller" who sells you a "brick" (the machine). An experienced supplier will help you avoid all the technical traps.

We have now planned your entire 100,000 bottle-per-day production line. We've gone from a simple idea to a complex, interconnected system of technology, fluid dynamics, and logistics.

As you can see, this project is not about "buying a machine." It is about "architecting a factory."

This brings me to my final and most important piece of advice. In your journey to find suppliers, you will meet two types of companies:

1. The "Brick-Seller"

This is a salesperson who just wants to sell you their "brick" (their blowing machine).

- They will tell you, "Yes, our machine does 6,000 BPH."

- They will not ask about your TCO.

- They will not help you size your air compressor.

- They will not analyze your factory layout or your bottle design.

- When your line doesn't work, they will blame your compressor, your chiller, or your preform.

2. The "Project Architect"

This is an engineering partner who wants your project to be successful.

- They will ask you more questions than you ask them. "What is your preform weight? What is your cost per kWh? What is your ceiling height?"

- They will analyze your bottle design and tell you if it's optimized for high-speed blowing.

- They will give you a detailed list of all the auxiliaries you need, with the exact specifications.

- They will help you compare the TCO of different solutions.

- They will help you check if your new molds will fit other machines.

- They see the whole system, not just the one machine they are selling.

My Professional Insight (Vivian's Insight)

My final advice to investors is this: You need to find a project "architect" who can help you plan the entire line, not just a "brick-seller" who sells you a "brick" (the machine). An experienced supplier (with 20+ years of factory-floor experience) will think like your own engineer, help you avoid all the technical traps you haven't thought of, and ensure your massive investment is converted into profit, on time and on quality.

Summary

Building a 100k/day automatic line is a system-engineering project. Success depends on upfront blueprinting, TCO budgeting, and choosing an "architect" partner who provides a total solution.

100k/day Project Planning Overview

| Project Phase | Key Decision or Action |

|---|---|

| 1. Blueprint | Define BPH from your workday (target ~6,250 BPH). Finalize bottle design & neck. |

| 2. Core Tech | Choose a 6-cavity full-servo Linear blower for the best value and flexibility. |

| 3. Molds & Preforms | Buy preforms to save capital. Invest heavily in a high-precision, fast-cooling mold. |

| 4. Auxiliaries | Size your air compressor with a 20% buffer. Do not save money here. |

| 5. Factory Layout | Plan for "Zones" (Power, Clean, etc.) and a "U-Shape" flow to minimize labor. |

| 6. Automation | Plan for a full line: air conveyor, leak tester, labeler, and shrink wrapper. |

| 7. Budget (TCO) | Calculate the 10-year Total Cost of Ownership. Prioritize energy efficiency over purchase price. |

| 8. Partner | Find an "Architect" partner who understands the entire system, not just a "Brick-Seller." |

Frequently Asked Questions (FAQ)

1. What is a realistic total budget for a 100k/day fully-automatic line?

This varies, but I tell clients to prepare for the "auxiliaries and downstream" budget to be more than the blowing machine itself. If a high-value 6-cavity linear blower is $80,000 - $100,000, the high-pressure air system, chiller, molds, and downstream packaging (labeler, wrapper) can easily be another $150,000 - $200,000. A total "from-scratch" project for this scale is typically $250,000 - $300,000+.

2. How much factory space do I really need for this line?

For the full line—from preform storage to the packaged pallet—you should plan for at least 600-800 square meters (6,500-8,500 sq ft). This gives you space for the utility room (power zone), the line itself, operator pathways, and storage for raw materials and finished goods. Ceiling height is also critical; you need at least 5-6 meters (16-20 ft).

3. Can I run multiple different bottle shapes on this one machine?

Yes! This is the primary advantage of choosing a linear machine over a rotary one. You will need a separate blow bottle mold for each bottle shape. A mold change on a 6-cavity linear machine can be done in about 30-45 minutes, so you could run your 500ml bottle in the morning shift and your 1.5L bottle in the afternoon shift.

4. What is the single biggest and most expensive mistake new investors make?

Hands down, it's under-budgeting the air compressor system. They buy a beautiful $80,000 machine and try to power it with a $20,000 compressor that is too small, has no dryer, and is poor quality. The result: the line never runs at full speed, bottle quality is low, and the machine's precision valves fail within a year. You must treat the air system as part of the machine's cost.

5. How long does it take from placing an order to making bottles?

A good supplier needs 90-120 days to manufacture, assemble, and test your blowing machine and molds. Shipping can take 30-45 days. Installation and commissioning (setup and training) on your factory floor will take another 2-3 weeks. A realistic timeline from placing the order to full production is about 6 to 8 months. You should use this time to prepare your factory, electrical, and piping.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr