Sourcing PET machines in China is confusing. You hear about different cities, prices, and endless suppliers. You just want a reliable partner without overpaying.

China's PET blow molding industry has three main hubs: Guangdong (high-end tech), Jiangsu (turnkey lines), and Zhejiang (parts & basic machines). Your best choice depends on your specific project needs, not just location.

I've seen buyers make costly mistakes by picking the wrong region. As a 20-year factory founder, I want to give you the map. I've watched these regions evolve. I want to show you where to find what you truly need, starting with the big picture.

Overview: China's 3 Major PET Blow Molding Hubs (And One Misconception)?

You need a machine, but where do you even start? China is huge. A supplier in one province is completely different from another, and a wrong choice is expensive.

The three core hubs are Guangdong (Guangzhou), Jiangsu (Zhangjiagang), and Zhejiang (Taizhou). Guangdong leads in high-speed tech. Jiangsu integrates huge beverage lines. Zhejiang is a "supermarket" for parts and small machines.

As a factory founder for 20 years, I've seen these three regions grow into very different specialties. There is no single "best" place to buy. The "best" supplier for a Coca-Cola plant is the wrong supplier for a local startup.

The key is to match the region's specialty to your project.

The "Big Three" Defined

Let's break this down simply. I have dealt with suppliers and competitors in all three regions. Here is my summary of what they do best.

| Hub Location | Primary Specialty | Typical Customer | Key Representative(s) |

|---|---|---|---|

| Guangdong (Guangzhou) | High-End Technology, R&D, Rotary Machines | Multinational brands, large corporations | Tech-Long |

| Jiangsu (Zhangjiagang) | Large Turnkey Beverage Lines | High-volume water/beverage plants | King-Machine |

| Zhejiang (Taizhou) | Components, Molds, Semi-Auto Machines | Startups, technical experts, parts buyers | Thousands of small factories |

My 20-Year Perspective on This Evolution

I remember in the early 2000s, the lines were blurry. Everyone was trying to do everything. Now, the market has matured.

- Guangdong invested heavily in research and development to compete with Europe.

- Jiangsu focused on its strength: integrating very large lines, where the PET blowing machine factory is just one piece of the puzzle.

- Taizhou leaned into its roots as the "Mold Capital" of China, becoming a massive ecosystem for parts and smaller-scale machines.

The "Misconception" - What About Other Regions?

I often get emails from clients asking about a supplier in Shandong, Hebei, or some other northern province. They see a cheap price online.

Here is my professional insight: This is a misconception.

While these regions make other types of plastic machines (like injection molding or extrusion), they are not specialized hubs for PET blow molding. PET blowing is a very specific technology. It requires a deep ecosystem of suppliers for high-pressure valves, specialized preform heating lamps, and precision mold processing.

A client once asked me about a supplier in the north. The price was very low. I had to explain that this supplier likely bought a machine from Taizhou, painted it, and was selling it as their own. They had no engineers, no spare parts, and no technical knowledge. Buying from them would be a huge gamble.

You must source from one of the "Big Three" hubs. Your choice just depends on your budget and your goals.

Hub Analysis 1: Zhejiang (Taizhou) - The "Component Supermarket" & Small Factory Ecosystem?

You see incredibly low prices from Taizhou. It is very tempting. But you worry if the machine will even work, or if the supplier will disappear after you pay.

Taizhou (and Huangyan) is the "Mold Capital" of China. It offers unbeatable prices on parts, blow bottle molds, and semi-auto machines. However, it lacks strong turnkey line suppliers, and quality control is a major risk.

I want to be very clear about Taizhou. I have many friends and suppliers there. It is a vital part of our industry, but you must understand its business model.

What is Taizhou Really Good For?

Taizhou, specifically the Huangyan district, is an amazing place. It is a massive, sprawling ecosystem of thousands of small factories. You can walk down a street and find:

- A shop that only makes mold bases.

- A shop that only does CNC machining.

- A shop that only polishes molds.

- A shop that only assembles semi-auto machines.

This is why I call it the "Component Supermarket." If you are a technical expert and you know exactly what you need, you can buy it here for a very low price.

It is good for:

- Spare Parts: Need a specific heating lamp or valve? You will find it here.

- Individual Molds: If you just need a single, simple blow bottle molds, you can get it made cheaply.

- Semi-Automatic Machines: This is the heart of Taizhou's machine business. They make thousands of them.

- Buyers Who Are Engineers: If you have the skill to assemble, test, and debug a machine yourself, you can save money here.

The "Taizhou Trap" for Startups

Here is the problem. I call this the "Taizhou Trap," and I've seen it happen many times.

A startup in Africa or Southeast Asia wants to start a water business. They have a limited budget. They find a "fully auto" 4-cavity machine from a Taizhou supplier for an unbelievably low price. They pay.

The machine arrives. It doesn't work.

The bottles have defects. The output is slow. The supplier's "engineer" tries to fix it over a video call, but it's no use. The supplier eventually stops answering messages.

My Professional Insight: Taizhou is a paradise for "pro-buyers" but a trap for "startups."

I had a customer from Kenya who fell into this trap. He bought a cheap line from Taizhou. It never ran properly for more than one day. He came to me a year later, having lost his entire first-year investment. He had to start over from zero. If you need a stable, reliable "turnkey" solution, Taizhou is not the place for it.

The Demark Exception

Now, you might say, "But Vivian, what about Demark? They are in Taizhou and they make high-speed rotary machines."

You are correct. Demark is an exception. They are a high-end, technology-focused company. However, they are an outlier. They do not represent the thousands of other small factories in the area. They are a "Guangdong-style" company that happens to be located in Taizhou. You cannot use them as the standard for the region.

If you must buy from Taizhou, you need to be an expert. If you are a business owner who needs a machine that just works, you must look elsewhere.

Hub Analysis 2: Jiangsu (Zhangjiagang) - The "Turnkey Line Integrators"?

Your project is huge. You need more than a machine. You need a complete, high-speed production line from blowing to palletizing, and you need it to work perfectly.

Jiangsu (Zhangjiagang) is the capital of "turnkey projects." Suppliers here, like King-Machine, excel at integrating massive, high-speed lines (20,000+ BPH) for water and beverages, including filling, capping, and packing.

The mindset in Zhangjiagang is completely different from Taizhou. They do not sell parts. They sell factories.

When a client comes to me and says, "Vivian, my goal is 30,000 bottles per hour for a national brand," I know they are a candidate for a Zhangjiagang supplier.

What Does "Turnkey Line Integrator" Mean?

A supplier in Jiangsu (Zhangjiagang) sees the blow molding machine as just one part of a much larger system.

Their expertise is in system integration. They are masters of "downstream equipment." This includes:

- Water treatment systems

- The blow molding machine (often a high-speed rotary)

- The high-speed filling and capping monoblock

- Labeling machines (shrink-sleeve or OPP)

- Shrink-wrapping machines

- Palletizing robots

They design the entire factory layout. Their strength is making all these different machines "talk" to each other on one massive, continuous line.

My Insight: When to Choose Zhangjiagang

The strength of Zhangjiagang is also its weakness. Because they focus on the entire line, the blow molding machine itself is often not their core focus. It's just one piece.

They are the right choice only if your project meets these criteria:

- High-Speed: You need 20,000 BPH, 30,000 BPH, or more.

- Beverage-Focused: Your product is water, juice, or a carbonated soft drink.

- Large Budget: You are buying a complete factory, and the price tag is in the millions of dollars.

4t You Want One Supplier: You want one company to be responsible for everything.

The Potential Downside for Medium Businesses

Here is another personal story. I had a client in Mexico. He was a successful, medium-sized business. He was impressed by the massive scale of the Zhangjiagang factories and bought a huge, 25,000 BPH line.

But his local market was not ready for that volume.

His new, expensive machine sat idle 80% of the time. It was too big, too complex, and too expensive for his actual needs. He bought a solution that was 10 times bigger than his problem.

These suppliers are great at what they do. But their solution is "all or nothing." It can be massive overkill for 95% of businesses.

Hub Analysis 3: Guangdong (Guangzhou) - The Pinnacle of High-End Tech?

You are competing against major brands. You need a machine that offers perfect bottle quality, extreme speed, and total reliability, just like European machines.

Guangdong (Guangzhou) is the center for high-end technology. Led by giants like Tech-Long, this hub competes globally with European brands, focusing on R&D, high-speed rotary machines, and full-servo technology.

This is the "top of the pyramid" in China. The companies here, with Tech-Long as the clear leader, are not competing with Taizhou or even the rest of China. They are competing with Krones, Sidel, and KHS from Europe.

The "Pyramid-Top" - Tech-Long

To understand Guangdong, you need to understand Tech-Long. They are a massive, publicly-traded company. They built their reputation by supplying to the most demanding clients in the world, like Coca-Cola, Pepsi, and Danone.

You cannot sell to those clients unless your technology is perfect.

Their focus is on R&D. They spend millions on developing new technologies.

What "High-End Tech" Actually Means for You

When I say "high-end tech," I don't just mean a faster machine. I mean a smarter machine.

- Full Servo-Electric: Most machines (including our own linear machines) use a mix of pneumatic (air) and servo motors. The high-end rotary machines from Guangdong are full servo-electric. Every movement is controlled by a precise motor. This saves energy, reduces noise, and gives you perfect, repeatable bottle quality.

- Lightweighting: This is their obsession. Their PET bottle mold design guide is not just about a nice shape. It's about how to save 0.5 grams of plastic from a bottle. When you make billions of bottles, 0.5 grams saves millions of dollars.

- Stability: These machines are designed to run 24 hours a day, 7 days a week, for 10 years. The engineering and build quality are at a completely different level.

My Insight: Is Guangdong for Everyone?

Tech-Long and the other giants in Guangdong are fantastic companies. I have great respect for them.

But here is my advice: For 90% of entrepreneurs, buying a machine from them is like buying a Formula 1 car to go grocery shopping.

It is an incredible piece of engineering, but it is also:

- Extremely expensive (millions of dollars).

- Extremely complex to maintain.

- "Locked-in" to their proprietary parts and service.

If your project is not for Coca-Cola, you likely do not need this level of machine. The solution is often too large and too expensive for most medium-sized businesses.

The good news is that this high-tech environment (the Pearl River Delta, or "Greater Bay Area") benefits all of us who are located here. My own factory, iBottler, is in Zhongshan, which is part of this ecosystem. We share the same high-quality talent pool and the same high-end parts suppliers. We just apply that technology to a different, more flexible, and more accessible type of machine.

Machine Type Analysis: Semi-Auto vs. Fully-Auto Linear vs. Rotary?

You see "semi-auto," "linear," and "rotary" machines. The prices are vastly different. How do you know which one is the right investment for your business stage?

Choose your machine based on your market stage. Semi-Auto is for low budgets and low volume. Fully-Auto Linear (2-8 cavity) is the best start for 90% of water plants. Rotary is for industrial-scale, high-speed production.

This is the most important decision you will make. Buying the wrong type of machine is a

fatal error. I always advise my clients to match the machine to their current market.

Type 1: The Semi-Automatic Machine

This is the simplest machine. An operator must manually load the preforms into the heater, and then manually transfer the hot preforms into the blowing mold.

- Pros: Very low investment cost. Simple to repair. Small footprint.

- Cons: Very high labor cost (you need 2-3 operators). Very low speed (maybe 500-800 BPH). Bottle quality is inconsistent because it depends on the operator's timing.

- Who is it for?

- Absolute beginners with a tiny budget in a market with very cheap labor.

- Specialty applications, like large 5-gallon (19-Liter) water jugs.

Type 2: The Fully-Automatic Linear Machine

This is the "sweet spot" and the workhorse of the industry. This is the category that my company, iBottler, specializes in.

Here, preforms are loaded into a hopper and automatically fed, heated, and blown. The bottles come out on a conveyor. They are often called "linear" because the preforms move in a straight line through the heater.

- Pros: The perfect balance of price, speed, and quality. Excellent flexibility (you can change molds in 1-2 hours). Very stable output (e.g., our 6-cavity machine makes 9,000 BPH).

- Cons: Not as fast as a giant rotary machine.

- Who is it for?

Honestly, 90% of all businesses. Startups who want to grow, medium-sized companies, co-packers, and anyone producing from 2,000 to 12,000 BPH. This is the "best starting point."

Type 3: The Fully-Automatic Rotary Machine

These are the "industrial monsters" I talked about from Guangdong and Jiangsu. The preforms and molds move on a high-speed carousel.

- Pros: Incredible speed (20,000 to 80,000+ BPH). Lowest cost-per-bottle at massive scale.

- Cons: A huge investment (millions). A huge footprint. Very complex maintenance. Mold changes can take an entire day.

- Who is it for? Only for multinational brands like Coca-Cola, Pepsi, and Danone.

Vivian's Case Study: The Nigerian Client

This is a true story that perfectly explains my philosophy.

I have a wonderful client in Nigeria. He started his water brand with a very small budget. He bought two of our semi-automatic machines. For two years, he ran them 24/7. His labor was cheap, and his brand grew.

He saved his profits. Two years later, he called me. "Vivian," he said, "I am ready."

He didn't buy another semi-auto. He didn't buy a giant rotary. He bought one of our 6-cavity fully-automatic linear bottle blowing machine models.

He instantly replaced his 4-5 operators, increased his output 10x, and improved his bottle quality. He made the perfect upgrade. He matched the machine to his business stage. This is the path to success.

Price Analysis: Blower Cavities & Mold Materials (7075 Al vs S136 Steel)?

You get two quotes for a "4-cavity machine." One is double the price of the other. You are confused. Is the cheaper one a scam? Is the expensive one a rip-off?

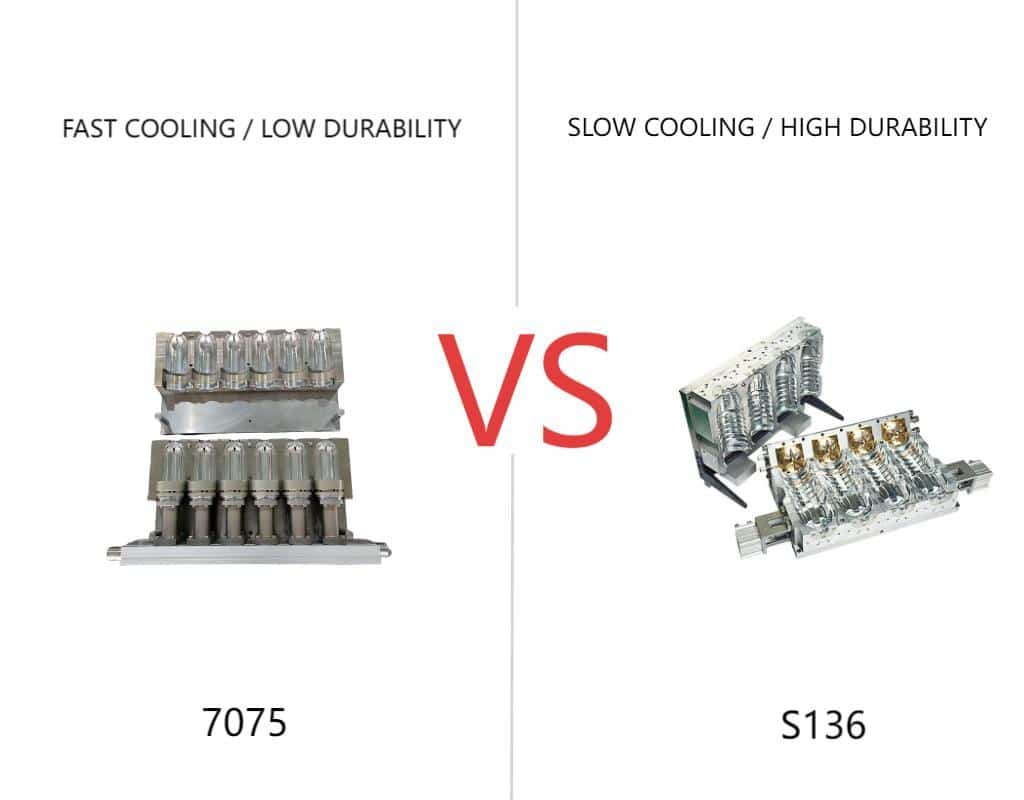

Machine price is set by cavity count and quality (PLC, valves). But the mold price is set by its material. 7075 Aluminum is for high-speed and perfect cooling. S136 Steel is for high-polish, anti-rust, and cosmetic bottles.

"Why is your 4-cavity machine more expensive than this other 4-cavity machine?" This is the most common question I get.

The answer is almost always about the quality of the components inside the machine and the material used for the mold. A "4-cavity" label means nothing.

Deconstructing Machine Price

The price of the machine itself is determined by two things:

- Cavity Count: A 6-cavity machine is more expensive than a 2-cavity. This is obvious.

- Core Components: This is the hidden cost.

- PLC (The Brain): Are they using a world-class Siemens PLC (like we do), or a cheap, no-name brand?

- Servo Motors: Are they using stable Yaskawa or Schneider servos, or a cheap alternative?

- Valves: Are they using high-speed, durable Festo valves, or low-quality copies?

A cheap machine uses cheap components. It will fail. A high-quality machine uses high-quality components. It will run for 10 years.

The Mold Material: My Core Expertise

This is the part I must explain. As a blow mold maker China for 20 years, this is my passion. The mold is not just a piece of metal. It is the heart of your bottle quality. The material is critical.

Here is a table explaining the two best materials.

| Material | 7075 Aircraft Aluminum | S136 Stainless Steel |

|---|---|---|

| Primary Benefit | Excellent thermal (heat) conductivity | High rust resistance, mirror polish |

| Best Use Case | High-speed water & beverage bottles | High-gloss cosmetic bottles |

| How it Works | Cools the hot plastic very fast and evenly. | Can be polished to a mirror finish. |

| Result | Lets you run a faster cycle (more BPH). | Creates a beautiful, shiny bottle. |

| Requirement | Needs a chiller to run cold water through it. | Good for humid climates (prevents rust). |

My Professional Advice:

For 99% of water and beverage bottles, 7075 Aluminum is the better choice.

Why? Because speed is money. 7075's superior cooling lets you shorten your cycle time. If you can save 0.5 seconds per cycle, over a year, that is millions more bottles. It is a more expensive material, but it pays for itself.

Vivian's Case Study: The "Black Dot" Disaster

This is the biggest mistake I see clients make. They try to save money on the mold.

I had a new client who, before he came to me, bought a "cheap stainless steel" mold from a Taizhou supplier. He was running a transparent bottle.

But the mold was not real S136 steel. It was a low-grade, cheap steel.

His factory is in a humid climate. Condensation (water) formed on the cold mold. Within weeks, the inside of the mold cavity began to rust, creating tiny pin-prick rust spots.

The result was a disaster. Every single transparent bottle he blew had small, ugly "black dots" and a rough surface (called "pitting").

His machine could run, but 100% of his products were waste.

He had to stop his entire production. He called me, and we had to make him a new, proper S136 mold. He saved a few thousand dollars on the first mold, but he lost tens of thousands of dollars in lost production and wasted material.

Do not be cheap on the mold. The price difference is always for a reason.

How to Verify: Are You Talking to a "Factory" or a "Trader"?

You find a supplier with a great website and a low price. But you have a sinking feeling. Are they a real factory that makes the machine, or just a middleman?

To find a real factory: Ask for a live video call to tour the workshop now. Ask to see their business license (check for "Manufacturing"). Ask deep technical questions about mold materials (7075 vs S136).

This is a very important skill for buyers. A "Trader" (or middleman) is good at sales, but they are terrible at technical support. When your machine breaks down at 2 AM, you need an engineer from the factory, not a salesperson who cannot help you.

As a real factory owner, here is my 3-step process to find out the truth in 5 minutes.

1. The "Right Now" Video Call Test

This is the easiest test.

- You: "Your factory looks great. Can we have a video call right now? I'd love for you to walk me onto the workshop floor and show me the machines you are assembling."

- A Real Factory (like me): "Sure, no problem. Let me put on my shoes and walk over." We are proud to show our work.

- A Trader: "Oh... it's not a good time. It's too loud." "It's raining." "Our workshop is in another location." "Let me send you a video."

If they cannot show you live, right now, they are 99% a trading company operating from a small office. They are just showing you pictures from our factories.

2. The Business License Deep-Dive

This is a legal check.

- You: "Please send me a copy of your Business License."

- What to look for: Every Chinese business license has a "Business Scope" (经营范围).

- A Real Factory: The scope will clearly say "Manufacturing" (生产, 制造) or "Processing" (加工).

- A Trader: The scope will only say "Sales" (销售), "Import/Export" (进出口), or "Technology" (技术).

This is a legal fact. If "Manufacturing" is not in their business scope, they are not legally a factory.

3. The Killer Technical Question

This is my favorite test. You ask them a question that only a real engineer would know.

- You: "For my 500ml water bottle, to get the highest speed, should I use a 7075 aluminum mold or an S136 steel mold?"

- A Trader: They will get confused. They will probably say "S136 steel is best" because it sounds more expensive and better. This is the wrong answer.

- A Real Factory (like me): I will answer, "That's a great question. For high speed, you 100% need 7075 aluminum. Its thermal conductivity is much better, which allows for a faster cooling cycle. S136 is for high-polish cosmetic bottles, not speed."

A trader sells products. A factory solves problems.

The 7075 aluminum question is a great test. Many small factories or traders cannot machine 7075 aluminum. It's a difficult material. If they hesitate or try to sell you "steel" instead, you know they lack the capability.

Conclusion: Why a "Machine + Mold" Dual-Expert Supplier is Your Best Choice?

The giant factories are too expensive. The Taizhou market is too risky. You feel stuck. Where can you find a high-quality, reliable machine that is scaled for your growing business?

The best partner is a "Dual-Expert" supplier who is a master of both the machine and the mold. This ensures your machine and mold are designed together to work perfectly, giving you high performance without the "giant" price tag.

After 20 years in this industry, I have seen the "market gap."

- The giants in Guangdong (Tech-Long) are too big and expensive.

- The integrators in Jiangsu (King-Machine) are focused on massive lines.

- The market in Taizhou is too risky for a serious business.

This leaves a huge gap for medium-sized enterprises and ambitious startups. This is the gap I have built my company, iBottler (Jindong), to fill.

Our iBottler "Dual-Expert" Philosophy

Our factory is in Zhongshan, part of the high-tech Guangdong ecosystem. We are not a giant, and we are not a small workshop. We are focused.

1. We are a Machine Factory First:

We are experts in the core of the machine. We master the mechanical structures, the Siemens PLC controls, the servo systems, and the air-circuit design. We build our bottle blowing machine for 24/7 reliability. It is the stable heart of your production.

2. We are a 20-Year Mold Factory Second:

This is our critical advantage. We are not just a machine assembler that buys molds from another factory. We are a true blow mold maker China. We are also experts in high-precision preform molds.

This "Dual-Expertise" changes everything.

- We know how to design the perfect 7075 aluminum mold cooling channels to match our machine's exact speed.

- We know how to polish S136 steel to a mirror finish for your cosmetic bottle.

- We can look at your bottle design and tell you exactly what preform weight you need and how to optimize the design for production.

What "100% Matched" Means for You

When you buy from iBottler, you get a machine and a mold that were designed, built, and tested by the same engineering team.

There is no "blame game." You will never have a situation where the machine supplier blames the mold supplier, or the mold supplier blames the machine. It just works.

This is a common problem for buyers. We know it so well that we even created a guide for blow mold fit for people who buy from different suppliers. But with us, that fit is guaranteed, 100%.

This is the "customized" and "high-match" solution that the giants don't have time for and the small workshops cannot provide. This is the iBottler solution.

Conclusion

Finding the right PET supplier in China is about matching. Guangdong is for tech, Jiangsu is for scale, and Taizhou is for parts. A dual machine-and-mold expert gives you the best-matched solution.

China PET Supplier Hubs: Summary Table

| Hub | Region | Primary Specialty | Best For... | Main Risk |

|---|---|---|---|---|

| Guangdong | Guangzhou | High-End R&D, Rotary Machines | Multinational brands, "cost-is-no-object" projects | Over-engineered and too expensive for 95% of businesses. |

| Jiangsu | Zhangjiagang | Massive Turnkey Beverage Lines | Huge water/beverage plants needing 20,000+ BPH | Overkill. Solution is too big for medium-sized businesses. |

| Zhejiang | Taizhou | Components, Molds, Semi-Auto | DIY experts, part-sourcing, low-budget startups | Very high risk of low quality, fakes, and no after-sales support. |

| iBottler | Zhongshan (Guangdong) | Dual-Expert: Machine + Mold | Startups and Medium-sized businesses needing a reliable, high-performance, and flexible solution. | (That's for you to decide, but we offer a balanced path!) |

Frequently Asked Questions (FAQ)

1. What is the biggest hidden cost difference between a cheap and an expensive PET machine?

The biggest differences are the core components and the mold material. A cheap machine uses a low-quality PLC, cheap pneumatic valves, and basic steel molds. A high-quality machine uses a Siemens PLC, Festo valves, Yaskawa servo motors, and a high-performance 7075 aluminum mold. The second machine will cost more upfront but will run faster and last 10 years longer.

2. How fast can I test a new bottle design before making an expensive mold?

This is a great question. You should never make a final mold without testing. We use 3D printed samples to rapidly validate blow mold designs. We can take your 2D drawing, create a 3D model, and 3D print a physical sample in 24-48 hours. You can hold it, test it, and approve the design before we cut any metal.

3. Why do I need to buy a chiller and a high-pressure air compressor?

These are not optional. The PET machine cannot run without them.

- Chiller: The chiller connects to the blow mold to pump cold water through it. This is what cools the hot plastic and "sets" the bottle shape. No chiller = melted, deformed bottles.

- Air Compressor: You need a high-pressure air compressor (around 30-40 bar) to provide the "puff" of air that stretches the preform and blows it into the mold shape.

4. What are the most common bottle problems, and how do I fix them?

The most common problems are pear-shaped bottoms, haze, white spots, or thin walls. I have seen them all. 90% of the time, it is not a "broken" machine. It is a problem with the heating or pressure settings. We have a complete guide to common PET blow molding defects and how to fix them that my clients use to solve problems in minutes.

5. What is more important: the machine, the mold, or the preform neck size?

This is a trick question! They are all critical. A great machine is useless with a bad mold. A great mold is useless with a bad preform. The first step is choosing your preform neck size, because this determines your cap, your application (water, juice, etc.), and your preform weight. This decision happens before we even design the mold.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr