When you plan to source a new PET preform mold, your engineer might insist on a "Valve Gate Hot Runner." Your finance department, however, might hesitate at its high initial price.

Is this "extra cost" a smart investment? As a 20-year mold factory (iBottler), our answer is: This isn't a "technical choice"; it's a "business model" choice. A valve gate mold is the highest-precision, highest-automation solution in the industry.

The sole purpose of this article is to help you (the boss or sourcing manager) do the math. Let's see exactly how many months it takes for this "extra cost" to "pay for itself."

Sourcing Decision: Valve Gate vs. Short Gate

| Decision Factor | Short Gate Mold | Valve Gate Mold | The Key Difference |

|---|---|---|---|

| Initial Investment | Low (e.g., $550/cavity) | High (e.g., $1,000/cavity) | $15k - $22k+ price difference |

| Production Quality | Unstable (uneven heating) | Extremely High (point-to-point) | Scrap Rate (5% vs. <0.5%) |

| Material Cost | High (has 0.2g gate tail) | Zero (no tail) | Saves ~$14,000+ USD annually |

| Labor Cost | High (needs 3 shifts of workers) | Zero (fully automated) | Saves ~$80,000+ USD annually |

| Return on Investment | None (ongoing operational cost) | Extremely High (2-3 month payback) | Valve gate is an "investment," not an "expense" |

The Price Reality: Short Gate vs. Valve Gate Cost Comparison?

Let's first clarify the cost gap. Using a 32-cavity, 30/25 neck, 18-gram preform mold as an example:

- Short Gate Mold: The price is around $550 - $600 USD/cavity.

- Valve Gate Mold: The price is as high as $1,000 - $1,100 USD/cavity.

For a 32-cavity mold, the price difference is as high as $15,000 to $17,000 USD. This price gap is real. So, why would anyone buy the expensive valve gate? The answer is simple: because behind the "low price" of the "short gate" mold, there are three "fatal flaws" hidden.

A Deeper Look at "Price Per Cavity"

In the preform mold industry, we don't quote by "one set." We calculate the price by "Price Per Cavity." This is the-fairest way to reflect the mold's scale and complexity.

The total price of a 16-cavity mold is 16 times the "price per cavity." A 48-cavity mold is 48 times the "price per cavity."

Let's look at the cost comparison at different scales:

| Cavity Count | Short Gate (Avg. $575/cav) | Valve Gate (Avg. $1050/cav) | Price Difference (Extra Investment) |

|---|---|---|---|

| 16 Cavities | $9,200 | $16,800 | $7,600 |

| 32 Cavities | $18,400 | $33,600 | $15,200 |

| 48 Cavities | $27,600 | $50,400 | $22,800 |

As you can see, this "extra investment" is real and grows linearly with the cavity count. For a 48-cavity mold, the price difference is over $22,000.

Where Does the Money Go? The Cost Breakdown of a Valve Gate System

Why is valve gate so expensive? This money isn't just "profit" for the mold maker. It is spent on much higher-grade components.

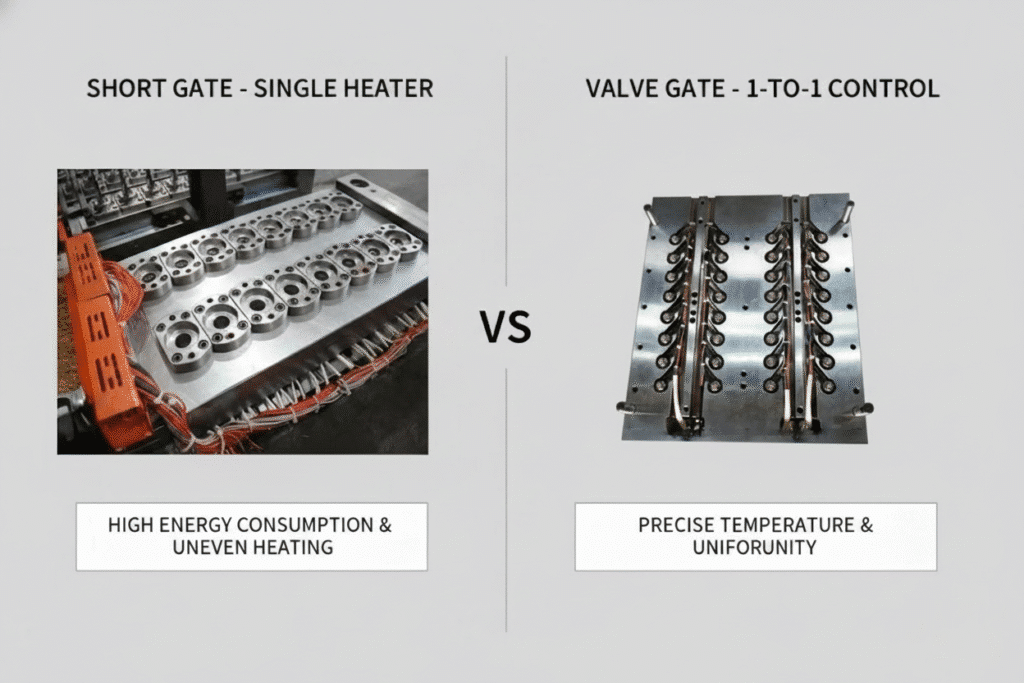

Hot Runner System: This is the biggest cost difference.

- Short Gate: Uses a very simple heating method. Often, just a few thick "heating rods" are inserted into a "manifold." The cost is extremely low, but so is the control.

- Valve Gate: Uses an extremely precise hot runner system. This includes 32 independent "Nozzles," 32 independent "Heater Bands," 32 "Thermocouples," and, most importantly, 32 "Valve Pins" driven by air or hydraulic pressure. This system is a high-precision machine in itself.

Mold Steel:

- Short Gate: Many factories will use P20 or 718H grade steel. This steel is adequate, but its lifespan and polish are limited.

- Valve Gate: Must use the absolute best steel. At iBottler, we insist on Sweden's "ASSAB" S136 steel. This is a high-mirror, corrosion-resistant stainless steel with extreme hardness. Only this steel can withstand the high-frequency opening and closing of the valve pin (4 times a minute) and guarantee a mold life of 6 million shots or more. S136 material costs 3 to 4 times more than P20.

Machining Precision:

- Short Gate: The precision requirements are relatively low.

- Valve Gate: The fit clearance between the valve pin and the gate is measured in microns (μm). This requires 5-axis CNCs, high-precision mirror EDMs, and Jig Grinding. These machines are very expensive to operate.

Control System:

- Short Gate: May only need a very simple temperature controller.

- Valve Gate: Must be equipped with an expensive "Hot Runner Temperature Control Unit" (TCU). This "box" is a computer. It has 32 independent PID processing channels to monitor and adjust 32 points in real-time, every millisecond.

In short, for that $15,000 price difference, you are buying a completely different class of production system. The "low price" of a short gate comes at the cost of everything that matters in production: quality, efficiency, and labor.

The Fatal Flaw of Short Gate: One Heating Rod Controlling 16 Cavities?

To achieve an extremely low price, "short gate" molds must save costs on the "hot runner." They often use cheap "heating rods."

This is the trap: Many small workshops and trading companies will not tell you that in their "low price" mold, one heating rod might be controlling 16 cavities at the same time!

This design makes uniform heating impossible. The cavities near the heating rod will be too hot (preforms turn yellow, high AA value), while the cavities far away will not be hot enough (preforms turn white, unmelted). This leads to an extremely high scrap rate. Many startup factories, not understanding the principle, are attracted by the "low price" and end up buying a mold with low precision that cannot run stable production.

The Physics of "1-to-16" Control: Why It's Doomed to Fail

Let's analyze the "1-to-16" heating method.

Imagine a giant steel "hot manifold." The mold maker drills a hole in the middle and inserts a 1000W "heating rod." Then, 16 nozzles are spread out across this steel plate.

Its "control point" (thermocouple) can only be in one place. Let's say it's placed next to cavity #8.

The machine starts running:

- The controller reads the temperature at cavity #8 as 270°C (target is 280°C).

- The controller orders the heating rod to "heat at full power."

- Heat begins to transfer. Cavity #8 (near the sensor) and cavity #7 (near the rod) heat up quickly.

- But, cavities #1 and #16 are at the "far ends" of the manifold. It takes a long time for heat to reach them, and much is lost.

- By the time cavity #8 finally reaches 280°C, the actual temperature of cavities #1 and #16 might only be 260°C. And cavity #7 (closest to the rod) might have "overshot" to 295°C.

The machine's controller shows "280°C, everything is normal," but in reality, your 16 cavities are running at 16 different temperatures.

H3: The Visual Proof of Disaster: Yellow, White, and Black Spots

This uneven heating shows up directly on your preforms:

Yellowing / Burning: The PET resin in cavity #7 (295°C) is "scorched." The preform looks yellow or even has black spots. Worse, the high heat degrades the PET, creating high levels of Acetaldehyde (AA). This is a chemical with a "plastic" taste. Even if the preform looks okay, the water bottled from it will have a "cheap plastic" taste, which will ruin your brand.

Cloudy / Unmelted: The PET resin in cavities #1 and #16 (260°C) is "uncooked." The plastic isn't fully melted, causing "cold slugs" or "cloudiness" inside the preform. This preform is "brittle." In the downstream bottle blowing machine, it will simply explode.

The Chain Reaction of a High Scrap Rate

Many factory owners think "scrap rate" just means "a little wasted plastic." This is completely wrong.

Cost 1: Wasted Material. This is the smallest cost.

Cost 2: Wasted Machine Time. Your injection machine (worth tens of thousands of dollars), your air compressor, your chiller, and your electricity are all running 24/7... just to produce garbage.

Cost 3: Downstream Line Stoppage (The Most Fatal Cost). If those "unmelted" cloudy preforms aren't caught, they go into the bottle blowing machine. They "explode" during the stretch-blowing process.

When a preform explodes, it causes:

- The bottle blowing machine to perform an emergency stop.

- A worker must open the machine and clean out the shrapnel.

- This can take 10-15 minutes. For those 15 minutes, your entire multi-million dollar filling line is "idle," waiting.

- If this happens 3 times an hour, your factory simply cannot be profitable.

This is the real trap of "1-to-16" control. The $15,000 you "saved" on the mold will be paid back at the price of thousands of dollars in operational losses, every single day.

Why Valve Gate is Worth It: The "Point-to-Point" Temperature Control?

In contrast to the crude "1-to-16" design, a valve gate mold has "point-to-point" temperature control. This is the core of "high precision."

In the H2-2 example, the problem was "one brain" trying to "guess" the temperature of 16 different people.

In a valve gate mold, we give 32 cavities 32 independent brains.

In a 32-cavity valve gate mold, there are 32 independent temperature control points. Each cavity has its own independent nozzle and independent heater band. This ensures that every cavity's PET resin is at the most perfect, uniform temperature. The result: preforms with extremely high clarity and very low eccentricity.

Anatomy of Valve Gate Hot Runner Operation

"Point-to-Point Control" sounds complex, but the principle is direct. Let's dissect a valve gate nozzle:

- Individual Nozzle: Each cavity has its own dedicated nozzle, connected directly to the hot manifold.

- Individual Heater Band: A high-power heater band is wrapped around the "waist" of each nozzle.

- Individual Thermocouple: The tip of a high-precision thermocouple is inserted deep into the very front of the nozzle, as close to the PET melt as possible. It measures the actual plastic temperature, not just the steel temperature.

- Individual "Brain" (PID Controller): In the Temperature Control Unit (TCU), there are 32 independent PID controllers.

- PID #1 only reads data from thermocouple #1.

- If thermocouple #1 says: "I am at 279.8°C."

- PID #1 will do a precise calculation and send only 10.5% power to heater #1 to "nudge" it.

- At the same instant, thermocouple #2 might say: "I am at 280.3°C" (because it's on a different side of the mold with different heat loss).

- PID #2 will instantly cut power to heater #2.

This "point-to-point" closed-loop feedback happens every second. The result: all 32 cavities can be controlled to within ±0.5°C of each other, 24/7.

The Overwhelming Advantages of "Point-to-Point" Control

When you achieve this level of extreme temperature uniformity, you get three unbeatable benefits:

Extreme Quality Consistency: The 32 preforms no longer have "yellow" ones and "white" ones. They are all identical. This means your blowing defect rate will drop from 5% to below 0.5%.

Very Low AA Value (Acetaldehyde): Because there are no "hot spots," you can confidently set your heating temperature just below the "safe line" for PET degradation. We don't have to "scorch" cavity #7 just to get the "coldest" cavity #1 up to temp. This achieves the lowest possible AA value, which is critical for the "taste" of premium water and beverages.

Very Low Eccentricity: Preform eccentricity (one side thick, one side thin) is the enemy of blow molding. This is often caused by poor mold concentricity or "cold slugs." The valve gate system's "point-to-point" control completely eliminates "cold slugs," ensuring the melt injects into the cavity with the most uniform pressure and speed possible.

Top-Tier Steel (S136) Requires a Top-Tier System

At iBottler, we insist on using Sweden's ASSAB S136 steel for our preform molds. This is an expensive, high-mirror-finish stainless steel.

Some clients ask, "Can I use cheaper steel with your valve gate system?"

Our answer is, "No."

That would be like putting bicycle tires on a Ferrari engine.

- The design life of S136 steel is 6 to 8 million shots.

- The design life of a valve gate hot runner is also 6 to 8 million shots.

These two are the "golden pair." Together, they ensure your mold can run stably and produce high-quality preforms for many years.

If you use a crude heating system like a "short gate," the uneven heat will "torture" the mold steel, causing "thermal fatigue" and "stress cracking." Even if you used S136 steel, its life would be drastically shortened.

Therefore, a valve gate system + S136 steel is not an "option." It is the "only combination" to achieve long-term, stable, high-return production.

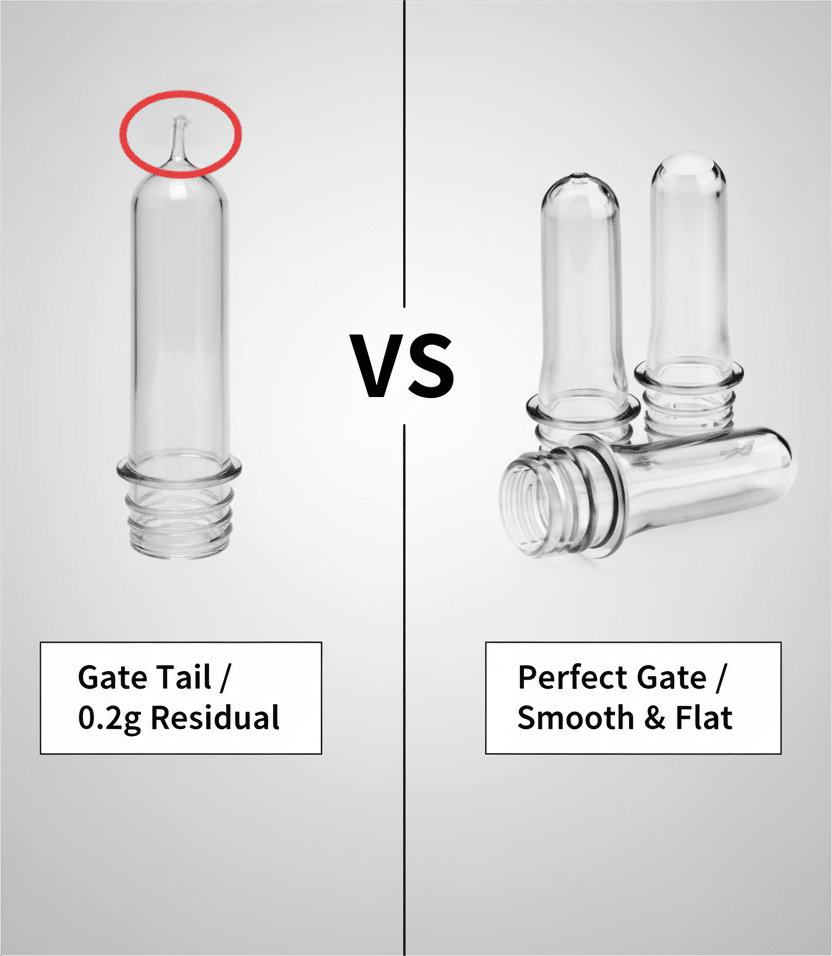

Doing the Math (Part 1): How Much PET Material Does "Zero-Tail" Save Annually?

A "short gate" mold (non-valve) automatically generates a "small tail" (gate vestige). This tail is formed when the PET plastic "freezes" at the nozzle tip and is "broken off" when the mold opens.

It looks small. But let's do the math.

- Assume this "tail" weighs 0.2 grams. (This is a very conservative, real-world figure).

- Your 32-cavity mold has a 15-second cycle time.

- It runs 24/7 (assuming 90% efficiency).

- Assume PET resin price is $1.20 USD/kg.

Let's calculate the daily wasted material:

- Shots per hour = (3600 sec / 15 sec) * 90% efficiency = 216 shots

- Daily preform production = 216 shots/hr 24 hr 32 cavities = 165,888 preforms

- Daily wasted material (grams) = 165,888 preforms * 0.2 g/preform = 33,177.6 g

- Daily Wasted Material (kg) ≈ 33.2 kg

Now, let's calculate the annual wasted money:

- Daily wasted cost = 33.2 kg * $1.20/kg = $39.84 USD

- *Annual Wasted Material Cost = $39.84/day 365 days = $14,541.60 USD**

Conclusion: From "material savings" alone, you save approximately $14,500 USD every year.

The Physics of the "Tail" (Gate Vestige)

Where does this "tail" come from?

Short Gate: Its gate is "open." After the holding pressure ends, the injection screw pulls back. The plastic in the nozzle is still molten. It relies on "cooling water" to "freeze" the plastic at the gate. When the mold opens, the preform is "pulled" out, and this "frozen" plastic "breaks off," forming the 0.2g tail.

Valve Gate: Its gate is "mechanically shut." After holding pressure, at the same instant the screw pulls back, the TCU sends a signal. 32 high-precision "Valve Pins" move forward simultaneously, mechanically and actively "plugging" the gate.

- When the mold opens, the gate is already 100% severed.

- The preform is removed, and the gate area is perfectly flat and smooth. There is no tail.

- This is the origin of "zero-tail" savings.

Why is this $14,500 a "Pure Waste"?

Some factory owners might say: "It's fine. We can collect these 0.2g tails, grind them up, and reuse them (regrind)."

At iBottler, we must tell you this is a terrible idea, especially for food and beverage packaging.

- Contamination: These tails fall under the machine and are collected by workers. This process introduces dust, hair, and oil. Do you really want to mix this "trash" with 100% food-grade virgin PET resin?

- Labor Cost: You need to pay a worker to "collect" the tails, another to "grind" them, and another to "mix" them. This is more labor cost.

- Material Degradation (I.V. Drop): PET is a sensitive plastic. Every time it is reheated, its "Intrinsic Viscosity" (I.V.) drops. PET with a lower I.V. is more "brittle." Bottles blown from this "regrind" will have poor physical strength.

- Clarity: Regrind will severely impact the preform's clarity and color. Your "crystal clear" preform will become "cloudy" or "yellow."

Therefore, for a high-standard factory, this 0.2-gram tail cannot be reused as (food-grade) raw material. It can only be sold as "scrap," and its price is extremely low.

That $14,500 in annual waste is a "pure waste" taken directly out of your pocket.

Remember H2-1? What was the "extra investment" for a 32-cavity mold? About $15,000.

This means you can pay back almost the entire extra cost of the valve gate mold within one year, just from material savings alone.

Doing the Math (Part 2): How Much Labor Cost Does "Full-Auto" Save Annually?

This is the biggest hidden cost of "short gate" molds.

With a short gate/long gate mold: You need at least 1 worker standing by the injection machine. His or her job is to "collect the parts" and then, with a pair of trimmers, "clip" that 0.2g "tail," one by one.

Your factory runs 24/7. This means you need 3 shifts, or the annual salaries of 3 workers, just to do this boring, low-efficiency job.

With a Valve Gate mold: It is fully automated.

The preform is 100% perfect inside the mold, with no tail. A Robot Arm automatically removes the preforms, places them on a Conveyor Belt, and they are automatically cooled and packed.

Conclusion: A valve gate mold saves you the salary and management costs of at least 3 operators every year. In Western markets, this can be over $100,000 USD. In Mexico or Southeast Asia, this is easily over $80,000 USD (as seen in Case Study #2).

A Detailed Comparison of the Two Workflows

Let's use a table to clearly compare how a 15-second cycle works in both models.

| Step | Short Gate Mold (Manual) | Valve Gate Mold (Automatic) |

|---|---|---|

| T=0s | Mold close, inject | Mold close, inject |

| T=10s | Hold pressure, cool | Hold pressure, cool, Valve Pins Close |

| T=13s | Mold open | Mold open |

| T=14s | Preforms drop onto a conveyor | Robot arm enters |

| T=15s | [Worker 1] begins inspecting | Robot grips 32 preforms |

| T=16s | [Worker 1] picks up trimmers | Robot places preforms on cooling conveyor |

| T=17s | [Worker 1] clips the 1st tail | Robot exits, mold ready to close |

| T=20s | [Worker 1] is clipping the 8th... | ...New injection cycle begins... |

| T=30s | [Worker 1] finishes 32 tails | Cooling conveyor moves preforms to packer |

In the "Short Gate" workflow, you are limited by the "speed" and "consistency" of a human.

In the "Valve Gate" workflow, everything is "precisely" controlled by a machine.

The Full Cost of "3 Workers"

When a financial manager calculates costs, they know "labor cost" is never just the "salary."

- Direct Salary: This is the biggest part. 3 workers, even in low-cost regions, cost $30k-40k USD per year. In Europe or the US, this is $100k-150k.

- Management Cost: You need a "shift supervisor" to manage these 3 people.

- Training Cost: "Clipping tails" is a high-turnover job. You are constantly hiring and training new people.

- Liability and Injury: This is the biggest "hidden bomb." A worker repeating a "clipping" motion for 8 hours a day has a 100% chance of getting a Repetitive Strain Injury (RSI). In the US or Europe, this leads to massive compensation claims.

- Human Error:

- Bad Clip: The worker is tired and clips part of the preform body. That preform is now scrap.

- Contamination: Humans shed hair, sneeze, and have bacteria on their hands. This is an absolute nightmare for "food-grade" production.

- Laziness: The worker goes to the bathroom, no one is at the machine, and the tails pile up, stopping the line.

The True Value of Automation: "Zero Labor" = "Zero Errors"

The "full automation" from a valve gate mold isn't just about "saving money."

Its true value is: It replaces human "unpredictability" with machine "certainty."

- 100% Consistency: The robot's action at 3:00 AM is identical to its action at 3:00 PM. It doesn't get tired, sick, or go on strike.

- 100% Cleanliness: The robot doesn't shed hair or sneeze. This is the only way to be compliant for food safety. If you want to be a supplier for Coca-Cola or Pepsi, they will audit your factory. When they see people "touching" preforms or "using scissors" on the line, you will be disqualified.

- "Lights-Out Manufacturing": An injection line with a valve gate mold, a robot, and an auto-packing system can run 24/7 with the "lights out." You only need 1 high-level engineer in a control room monitoring 10 machines. This is the final form of modern manufacturing.

Therefore, the $80,000 USD in saved labor costs is just the "beginning." What you truly get is a "predictable, manageable, and scalable" modern production system.

[Case Study #1] The "Short-Gate" Trap: How a Startup "Saved Money to Lose Money"?

A few years ago, a startup beverage factory in Southeast Asia inquired with us. They needed a 48-cavity preform mold.

We (iBottler) provided them with a "Valve Gate" quote.

At the same time, they got a "Short Gate" quote from a local small workshop.

Our quote was $22,000 more expensive. (This is consistent with our H2-1 table for a 48-cavity mold).

The owner of this startup, trying to save initial capital, chose the "cheaper" factory. He thought he had "saved" $22,000.

One year later, the owner contacted us again. He was very frustrated.

The "short gate" disaster had happened:

- Exploding Labor Costs: His original business plan had "zero" workers at the injection machine. But to "clip the tails," he had to immediately hire 3 workers (for 3 shifts). In his region, this "unplanned" labor expense cost him $30,000 USD per year.

Runaway Scrap Rate: (Just as we analyzed in H2-2) That "cheap" mold used "1-to-16" (or worse) rod heating. The heating was extremely uneven.

- Many "cloudy" preforms were scrap right out of the machine.

- Worse, the preforms that "looked okay" were "exploding like crazy" in the bottle blowing machine.

- Their quality control calculated a final blowing scrap rate of 5%!

The "Penny Wise, Pound Foolish" Annual TCO Calculation

Let's do the math for this owner. What did that "saved" $22,000 cost him in the first year?

Table: Startup's "Short Gate" Mold - 1st Year Operating Cost

| Cost Item | Amount (USD) | Notes |

|---|---|---|

| Initial "Savings" | -$22,000 | The "profit" he thought he made |

| Cost 1: Unplanned Labor | +$30,000 | 3 workers * $10k/year (local salary) |

| Cost 2: Material Waste (5%) | +$30,000 | (Assuming they buy $600k of PET per year, 5% is $30k) |

| Cost 3: Machine Downtime | +$5,000 (Est.) | Loss from blow molding line stopping |

| First-Year Net Loss | $43,000 | ($30k + $30k + $5k - $22k) |

Conclusion: This Isn't "Savings," It's a "Subscription" to High Costs

The tragedy of this case:

He "saved" $22,000 (one time).

In exchange, he got $43,000 in "extra operational costs"... every single year.

This was not a one-time loss. It was a "subscription service." As long as he used that mold, he had to pay $43,000 every year.

The second year, he lost another $43,000.

The third year, another $43,000.

His "money-saving" decision was actually a contract to "lose $43,000 per year."

In the end, he had to re-order a 48-cavity valve gate mold from us (iBottler). He wasted $22,000, plus an entire year of valuable time and market opportunity. This is the real cost of "saving money to lose money."

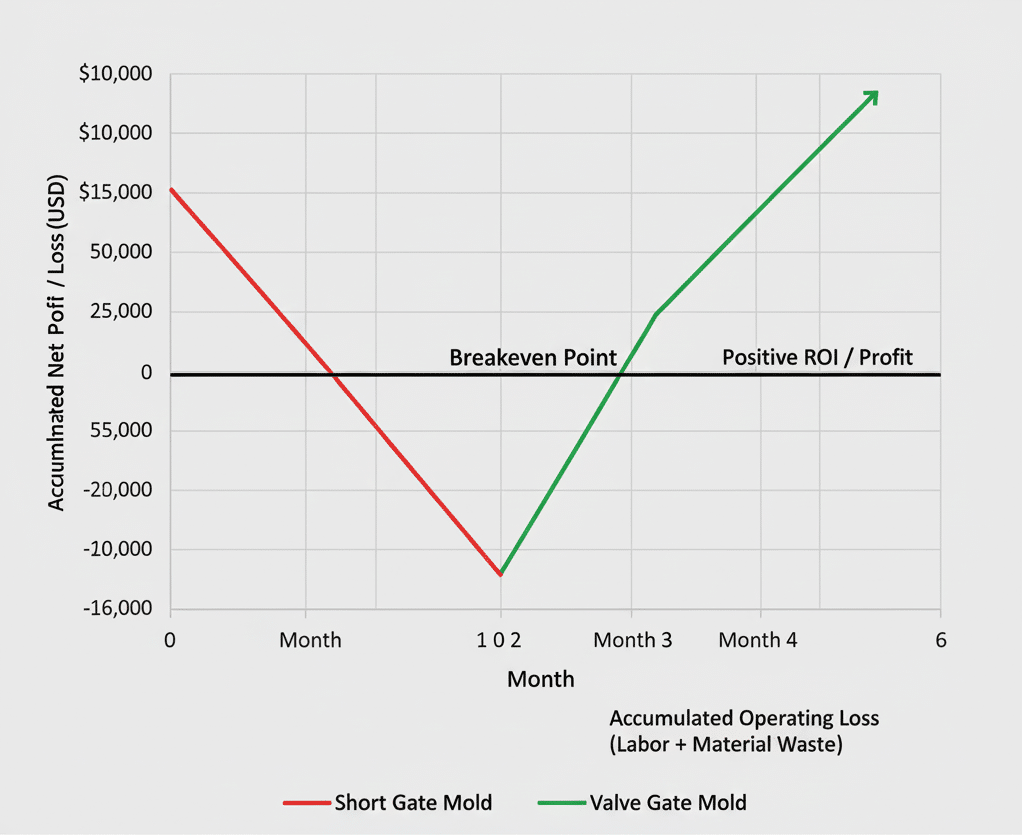

[Case Study #2] The "Valve Gate" ROI: How a Water Factory Earned Back Its Investment in 2 Months?

This is a more "mature" client. A large water factory in Mexico needed to expand with a 32-cavity production line.

They were very professional. They evaluated a "short gate" proposal and our "valve gate" proposal.

They got our quote (based on H2-1 prices), and the "extra investment" (price difference) was about $16,000 USD. (This is consistent with the $15,200 in our H2-1 table).

Their sourcing manager was hesitating. But their CFO asked us (iBottler) to provide a TCO (Total Cost of Ownership) and ROI (Return on Investment) analysis.

We did the calculation for them:

- Premise: 32-cavity mold, 24/7 operation.

- Calculation 1: Material Savings (from H2-4)

- Annual savings from "zero tail" ≈ $14,380 USD

- Calculation 2: Labor Savings (from H2-5)

- Annual salary for 3 local workers in Mexico (incl. benefits) ≈ $80,000 USD

Total: The valve gate mold would save them $14,380 + $80,000 = $94,380 USD every year.

The Decisive ROI (Payback Period) Calculation

Now, we answer the $16,000 question.

- Extra Investment: $16,000 USD

- Annual Return: $94,380 USD

- *Payback Period = (Investment / Annual Return) 12 Months**

- *ROI = ($16,000 / $94,380) 12 = 2.03 Months**

The Decision and Result: From a "Cost" to a "Profit Center"

When our sales manager put this ROI report on the table, the mood in the meeting changed completely.

That $16,000 was no longer an "extra cost."

It became an "investment project with an absurdly high rate of return."

The CFO made the decision on the spot. His exact words were: "If I can invest $16,000, get it all back in 2 months, and then make an extra $94,000 in pure profit every year for the next 10 years... why would I not do this?"

The Result:

After the mold was put into production, starting in month 3, that "more expensive" mold was generating over $94,000 in pure profit for them every single year.

Those 3 workers were not fired. They were retrained and moved to more valuable jobs in "Quality Control" and "Blow Molding Maintenance," creating even more value for the company.

This case perfectly proves: A valve gate mold is not an "expense." It is the "investment" with the highest rate of return in your factory.

Conclusion: So, Is a Valve Gate Mold "Worth It" For You?

Is a "valve gate" mold "worth" the extra money? The answer to that question depends on your business model.

My Honest Advice:

If you are a "startup company," your annual output is very low (e.g., machine uptime is less than 30%), and you are just testing the market, then a "short gate" mold might be the right choice to control your initial investment.

(But you must beware of the '1-to-16' trap in H2-2! Even with a short gate, you must insist on "point-to-point" control, or you are just buying scrap metal.)

My Professional Advice:

But, if your factory runs 24/7, or you are supplying high-standard clients (like Coca-Cola, Pepsi, Danone), then a "valve gate" mold is not an "option," it is a "necessity."

It is not an "expense."

It is not a "cost."

It is the "investment" with the highest rate of return and the fastest payback period of any equipment in your factory.

As a 20-year factory (iBottler.com), we don't just "sell molds." Our job, as in H2-7, is to sit down with your finance team and help you calculate the "most profitable solution." We don't sell steel; we sell "TCO solutions" and "predictable, long-term profit."

Summary: The Core Sourcing Decision

| Comparison Dimension | Short Gate Mold (Low-Price Trap) | Valve Gate Mold (High-Return Investment) |

|---|---|---|

| Business Model | Workshop relying on "low labor cost" & "high error tolerance" | Automated factory relying on "high efficiency" & "high quality" |

| Core Cost | Operational Cost (Labor, Scrap, Downtime) | Initial Investment (The mold itself) |

| Quality Control | Extremely Difficult (1-to-16, uneven heat) | Extremely Simple (Point-to-point, 100% consistent) |

| Automation | Impossible (Must manually clip tails) | 100% Full Automation (Robot takeaway) |

| Customer Base | Low-end market, no requirements for taste/look | High-end market (Coke, Danone, Pepsi) |

| Financial View | A "liability" that "bleeds" money every year | An "asset" that pays for itself in 2 months and prints profit |

5 FAQs About Valve Gate Preform Molds

1. Q: Do valve gate molds actually improve preform quality?

A: Yes, significantly. This is one of its biggest advantages. Because of the "point-to-point" uniform heating, preforms have extremely high clarity and very low eccentricity. Because there is no "physical stress" from breaking a tail, the gate scar is perfectly consistent. Most importantly, uniform heating eliminates "hot spots," so the AA (acetaldehyde) value is much lower, which is critical for the "taste" of mineral water and beverages.

2. Q: Is the cycle time for a valve gate mold faster?

A: Yes. The valve gate hot runner system provides better temperature control and allows for a more optimized cooling channel design (due to the more complex internal structure). Typically, it can shorten the cycle time by 1-3 seconds. This doesn't sound like much, but in 24/7 production, it can mean a 10-15% increase in annual output. That is pure, extra profit.

3. Q: Is maintenance for a valve gate mold complicated?

A: It does require more maintenance than a "short gate" mold. The hot runner system, valve pins, and seals need regular inspection. However, for a well-designed mold (like an iBottler mold using imported steel and standard parts), this maintenance is predictable and low-cost. This "maintenance cost" (e.g., $1,000/year) is tiny compared to the $94,000+ it saves you in material and labor.

4. Q: What is the lifespan of an iBottler valve gate mold?

A: Our high-precision preform molds use Sweden's "ASSAB" S136 steel for the cores and cavities to guarantee hardness and a mirror polish. The mold base uses P20 pre-hardened steel. With normal maintenance, we conservatively guarantee a mold life of no less than 6 million shots. If you run 2 million shots per year, this mold will serve you stably for 3+ years.

5. Q: Can you (iBottler) help me calculate my specific ROI?

A: Yes. This is one of our core services. We welcome you to contact us (iBottler.com) and tell us your "preform weight," "local electricity cost," and "local labor cost." Our engineers will provide you with a free, customized TCO and ROI analysis report to help your finance department make the most informed decision.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr