Vietnam's market is booming, but it is very complex. Choosing the wrong packaging wastes a lot of money. I will show you the three biggest opportunities and the technical challenges.

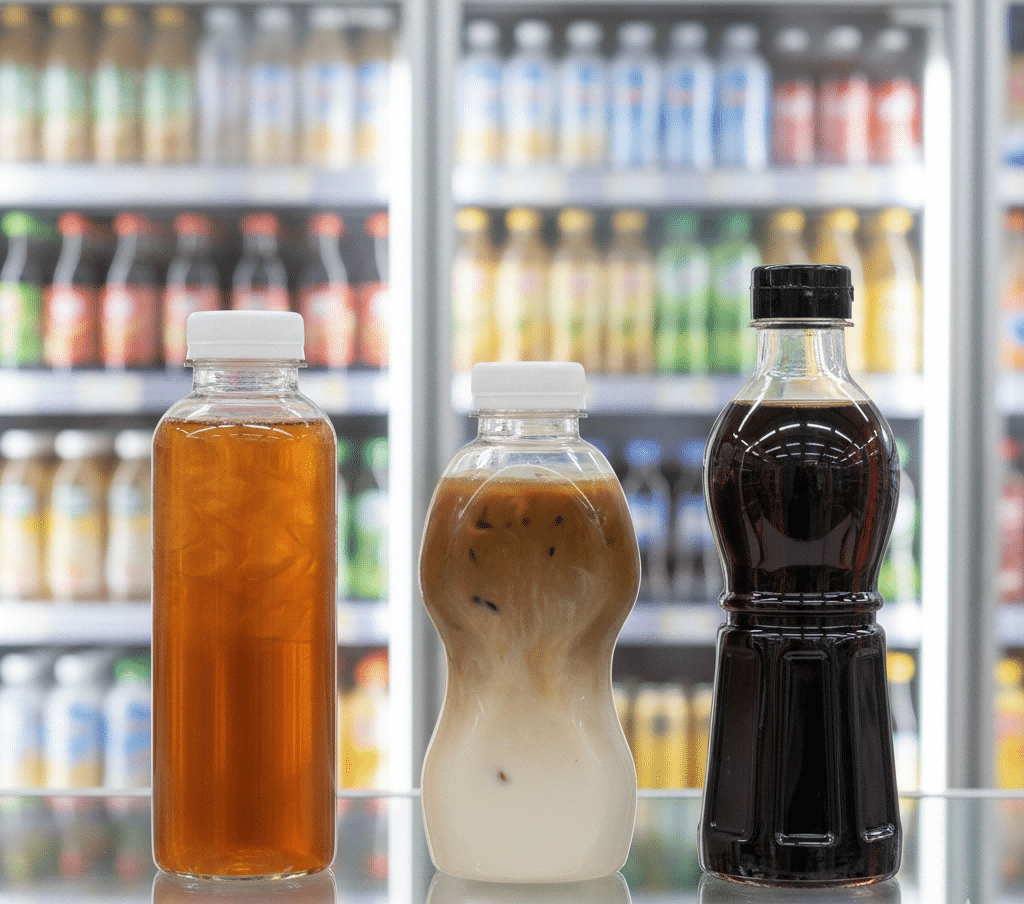

Yes, the biggest opportunities in Vietnam's PET market are in RTD tea, coffee, and sauces. This shift is driven by new manufacturing, young consumers, and a move from glass to plastic for logistics.

I've worked in this industry for 20 years. I see clients making the same mistakes. They focus on the wrong things. Let's break down where the real money is in Vietnam's PET packaging world. We need to look at the forces driving this change first.

The Twin Engines: FDI Manufacturing & A Young Consumer Class?

You see growth in Vietnam but may not know why. You might invest in the wrong area. You need to understand the two main drivers: new factories and new shoppers.

Vietnam's PET market is driven by two things. First, foreign direct investment (FDI) in manufacturing. Second, a young, large consumer class. These factors create huge B2B and B2C demand for packaged goods.

This is the foundation of the whole market. I see these two forces creating different kinds of demand.

The "B2B" Boom from Manufacturing

I have seen this personally. When a giant company like Samsung or LG builds a new factory, they build a small city. These factories are often in Binh Duong or near Ho Chi Minh City. This new "city" needs services.

These factories employ thousands, or even tens of thousands, of workers. All these workers need clean drinking water and simple beverages during their shifts. This creates a massive, stable "B2B" (business-to-business) market.

The factory canteens and all the small shops around the factory need huge volumes of bottled water and simple iced teas. This is not a "sexy" market. It is a high-volume, low-margin foundation.

This industrial boom has a positive "spillover" effect. It forces the local supply chain to become better. It brings in higher standards for logistics, quality control, and large-scale production. This industrial base makes it easier for everyone, including consumer brands, to get high-quality PET bottles.

The "B2C" Shift: Trusting the Seal

The second engine is the consumer. This is the "B2C" (business-to-consumer) market. Vietnam has almost 100 million people. The median age is only about 33. This is a very young, urban, and digitally-connected population.

Their habits are changing fast. Ten years ago, everyone drank "trà đá" (iced tea) from street stalls. These drinks were served in reusable plastic cups of unknown quality.

Now, especially after the pandemic, hygiene is a top concern. These young consumers trust a sealed package. They trust a PET bottle. They can see a brand name, a manufacturing date, and a list of ingredients.

This is a "trust transfer." Consumers are moving from unpackaged, traditional street drinks to packaged, branded, and sealed drinks. This is a permanent consumer upgrade. They will not go back. This is why the B2C demand for PET bottles is exploding. They want products that are safe, convenient, and have a modern design.

Two Engines: B2B vs. B2C Demand

| Market Driver | Primary Consumer | Key Demand | Packaging Focus |

|---|---|---|---|

| FDI Manufacturing (B2B) | Factory workers, canteens | Bottled water, simple teas | High volume, low cost, efficiency |

| Young Consumers (B2C) | Urban population (18-35) | Branded drinks (tea, coffee) | Hygiene, convenience, brand design |

Application 1: RTD Tea & Herbal Drinks (Trà) - A Cultural Powerhouse?

You want to sell drinks in Vietnam. You might ignore their strongest local tradition: tea. You need to understand how "Trà" (tea) is moving into PET bottles.

The ready-to-drink (RTD) tea market is a core opportunity. Vietnamese culture loves tea and herbal (thảo mộc) drinks. This market is not new; it is just being "packaged." Consumers are paying for convenience.

This is one of the biggest and most proven markets. But it has very specific technical needs.

Learning from the Giants: The Dr. Thanh Story

We must look at the local successes. The best example is Tan Hiep Phat. Their "Dr. Thanh" herbal tea is a massive success. It is not just a drink. It is marketed as a "health" product that "cools" the body.

This product proved a key concept. Vietnamese consumers will pay a premium for a PET-bottled drink if it connects to their traditions ("herbal") and offers a clear benefit ("health").

Tan Hiep Phat did not invent herbal tea. They just made it convenient, safe, and shelf-stable. They put a traditional recipe into a modern package. This is the key. The opportunity is in packaging tradition.

The Technical Hurdle: Keeping Tea Fresh

This brings us to the biggest challenge. Tea and herbal drinks are not like soda. They are sensitive.

I work with many clients on this. Tea is full of active compounds, like antioxidants. These compounds react badly with oxygen. Oxygen can pass through the walls of a standard PET bottle. Light also damages the product. It makes the color and flavor degrade quickly.

At the same time, consumers want "natural" products. They do not want a long list of chemical preservatives.

This means the product is not naturally shelf-stable. It needs help from the process and the package. This is why the technology here is critical. The market is dominated by two main technologies: Hot-Fill or Aseptic Cold-Fill.

Hot-Fill: The Mainstream Path

This is the most common method in Vietnam right now.

- You heat the tea (pasteurize) to a high temperature, like 85-95°C.

- You fill the bottle with the hot liquid.

- You cap it immediately.

The heat of the liquid sterilizes both the product and the inside of the bottle.

The challenge? You cannot use a normal PET bottle. It will shrink, warp, and collapse. You must use a special "Heat-Set" PET bottle.

This bottle requires a special PET blow bottle mold. The bottle itself is heavier (uses more plastic). It often has a special crystallized neck finish to keep it rigid. And it has special panels designed into the body. These panels absorb the vacuum that forms when the hot liquid cools and shrinks. This is a very specific engineering task.

Application 2: Coffee (Cà Phê) - From Phin Filter to PET Bottle?

Vietnam loves coffee, but it's all fresh-brewed. You might assume there is no market for packaged coffee. You should see the huge, new opportunity in RTD coffee.

The RTD coffee market in Vietnam is a high-growth, emerging space. While fresh coffee (Cà Phê) is king, consumers want convenience. Brands are now battling to bottle the traditional "Vietnamese" coffee taste.

This is a market I find very exciting. Vietnam is the world's second-biggest coffee exporter. Coffee is everywhere. Every street has a shop making fresh "phin" filter coffee.

The Gap Between the Street and the Shelf

For a long time, the fresh coffee in Vietnam was too good and too cheap. There was no reason to buy a bottled version.

This is changing. The same "convenience" driver from the tea market is now happening in coffee. People are busy. They work in new office towers. They want a "Cà Phê Sữa Đá" (Vietnamese iced milk coffee) they can grab from a convenience store fridge.

But the packaged RTD coffee market is still small. It is very undeveloped compared to markets like Japan, Korea, or even Thailand. This is a classic market gap.

Local brands like Trung Nguyên and Highlands Coffee are experimenting. International brands like Nescafé are pushing hard. They are all trying to win this new "grab-and-go" coffee drinker.

The "Milk Coffee" Challenge

The biggest prize is not black coffee. It is bottling the true "Cà Phê Sữa Đá." This is the national drink.

But this is a technical nightmare for packaging. Why? Two reasons: milk and acidity.

1. Milk: As soon as you add milk or condensed milk, your product is no longer high-acid. It becomes a "low-acid" food. This is a perfect environment for dangerous bacteria, like botulism. Standard hot-fill processing is often not enough to make it safe.

2. Sterilization: These milk-based products require much more intense processing. They often need UHT (Ultra-High Temperature) sterilization or even "retort" (pressure cooking) like a food can.

A normal PET bottle cannot survive a retort process. It will melt.

This is why you see many milk-coffee drinks in cans, not PET. The can handles retort easily. The solution for PET is high-tech. It requires either Aseptic (UHT) filling, or special, expensive retortable PET/PP bottles. This is a high-barrier, high-reward market.

Packaging Needs for RTD Coffee

| Coffee Type | Key Challenge | Required Technology | Recommended Packaging |

|---|---|---|---|

| Black Coffee (low sugar) | Flavor, oxidation | Hot-Fill or Aseptic | Heat-Set PET or standard PET (Aseptic) |

| Milk Coffee (Cà Phê Sữa Đá) | Milk (low-acid), bacteria | UHT + Aseptic, or Retort | Aseptic PET or Retortable PET/PP bottle |

Application 3: Sauces (Nước Mắm) - The "Glass-to-PET" Logistics Trend?

You see all sauce, like fish sauce, in heavy glass bottles. You might assume this is what consumers want. But you should understand the real driver: logistics costs.

The sauce market, especially for fish sauce (Nước Mắm), is moving from glass to PET. This change is not for consumer demand. It is driven by manufacturers who want to cut logistics costs and breakage.

This trend is purely a business decision. I have had this exact conversation with many sauce producers in Vietnam. Their biggest headache is not making the sauce. It is shipping it.

It's All About the Weight

Vietnam exports a huge amount of fish sauce (Nước Mắm) and chili sauce (Tương Ớt).

Imagine a 40-foot shipping container. If you fill it with glass bottles, a large percentage of the shipping cost is just for the weight of the glass.

Then, there is breakage. If a forklift operator drops a pallet of glass bottles, it is a total loss. It is a huge mess and a lot of lost money.

This is the entire business case for "Glass-to-PET."

A PET bottle weighs almost nothing. It is shatterproof.

When I show a factory owner the cost savings on a single shipping container, they are shocked. They can ship more product and less package. The savings on logistics and damage (shrinkage) drop directly to their profit. This is the only driver that matters.

The Barrier Problem: Keeping the Smell In

So, why isn't all fish sauce in PET bottles? Because of a giant technical problem: barriers.

A standard PET bottle (like for water) is "monolayer." It is just one layer of PET resin. This material is a good barrier for water, but it is a poor barrier for gases and aromas.

1. Oxygen Barrier: Fish sauce is a fermented product. It oxidizes. If oxygen from the air gets into the bottle, the sauce will turn dark and the flavor will spoil.

2. Aroma Barrier: This is the big one. Fish sauce has a very strong aroma. This aroma will escape out of a standard PET bottle. The sauce will lose its flavor, and the smell will contaminate other products in the shipment.

This means you cannot use a simple water bottle for Nước Mắm. You will have a disaster on the shelf in 6 months.

The Solution: High-Barrier PET

The solution is advanced packaging. This is where real engineering comes in. You cannot use a standard preform mold. You need a solution for high-barrier bottles.

- Multilayer PET: We produce these using co-injection. A special preform mold injects multiple layers at once. The structure is PET / EVOH / PET. The EVOH layer is a special polymer that is a fantastic barrier for both oxygen and aromas.

- Barrier Coatings: Another option is to take a normal PET bottle and add a special, microscopic coating (like Silicon Oxide, or SiOx) inside or outside. This coating acts like a thin, flexible layer of glass.

These technologies are the key. They allow the PET bottle to have the same 12-18 month shelf life as glass. This is a very technical sale. The client needs a partner who understands material science, not just a cheap mold.

The Retail Revolution: How C-Stores (7-Eleven, VinMart) Shape Packaging?

You have a great drink product for Vietnam. You package it in a standard, boring bottle. You need to understand how convenience stores (C-Stores) are changing bottle design.

The boom in convenience stores like 7-Eleven, GS25, and VinMart+ is forcing brands to change. Shelf space is limited. Packaging must be single-serve, look good, and stand out. Old, "family-size" designs are failing.

This is the catalyst for all the trends we discussed. The rise of modern retail, especially C-Stores, is changing product design faster than anything else.

In the past, people bought drinks at a local "tạp hóa" (a small, family-owned shop) or a wet market. Packaging was simple.

Now, walk into a 7-Eleven in Ho Chi Minh City. It looks just like one in Tokyo or Bangkok. The shelves are bright, clean, and extremely crowded.

The Battle for the Shelf

This is what I tell my clients: "The shelf is the battlefield."

Your bottle is sitting next to 20 other bottles. You have maybe 3 inches of space to catch a customer's eye.

This environment demands two things:

- Single-Serve Sizes: C-Stores are for "immediate consumption." People buy one drink for now. This means 250ml, 330ml, and 500ml formats are dominant. The old 1.5L bottles are for supermarkets, not C-Stores.

- Unique Design: Your bottle must look different. This is where PET bottle mold design becomes a primary marketing tool. Brands are using unique shapes, colors, and embossing to stand out. A boring, round bottle gets lost.

The Need for Speed

This brings us to the second point: speed.

These C-Store chains are demanding. They want "new flavors," "limited editions," and "seasonal specials" all the time.

A brand might want to launch a "Spring Blossom" tea for only 3 months. This means they need a new bottle design, a new mold, and a new production run fast.

This puts huge pressure on the supply chain.

As a mold and machine manufacturer, we have had to adapt. Our clients cannot wait 6 months for a new mold.

This is why we invested heavily in 3D printed samples and rapid prototyping.

A client can send us a design. We can analyze its "blowability" on a computer. We can fix problems. Then we can 3D print a physical model. The client can hold it in their hands in just a few days.

This speed allows brands to react to the C-Store market. If you are slow, you lose the opportunity. The retail revolution demands engineering agility.

The Investment Hurdle: Hot-Fill vs. Aseptic Processing?

You want to produce RTD tea or juice in Vietnam. You are confused by the high cost of machinery. You need to understand the biggest choice: Hot-Fill or Aseptic.

Investors must choose their filling technology first. Hot-Fill has a lower startup cost but requires expensive, heavy "heat-set" bottles. Aseptic has a huge startup cost but uses cheaper, lightweight standard bottles.

If you want to enter the tea, juice, or coffee market, this is your first and most important decision. It is a multi-million dollar choice. It will define your factory, your costs, and your product.

I have walked many investors through this. Let's break it down in simple terms.

Path 1: Hot-Fill (The Mainstream Choice)

- How it works: You pasteurize your drink (heat it to 85-95°C). You fill it hot into a special bottle. You seal it. The heat of the liquid sterilizes the package.

- The Bottle: This is the key. You must use a "heat-set" PET bottle. This bottle is made from PET with a higher crystallinity. It is heavier (uses more grams of plastic) and often has a special crystallized neck finish.

- Why: A normal bottle would deform or shrink from the heat. The neck needs to be stiff so it doesn't warp during capping. We have to design special blow bottle molds for this.

- The Cost: The filling line is cheaper. The bottles are more expensive, forever. You pay more for every single unit you sell.

Path 2: Aseptic Cold-Fill (The Future)

- How it works: This is high-tech. You have a sterile factory environment. You sterilize the drink (usually with UHT) and the bottle (with a chemical wash) separately. Then you fill the cold drink into the sterile bottle and seal it.

- The Bottle: You can use a standard, lightweight PET bottle. The same kind you use for water.

- The Cost: The filling line is extremely expensive. You are building a medical-grade cleanroom. The bottles are cheaper, forever. Your cost per unit is lower.

How to Decide?

I always ask my clients: "What is your 5-year plan?"

If you are a startup and want to test the market, maybe Hot-Fill is better. Lower risk, lower startup cost.

If you are a big company and plan to produce 50 million bottles a year, Aseptic is better. The savings on plastic (bottle weight) will pay back the high investment over a few years.

| Technology | Upfront Investment | Bottle Cost (per unit) | Product Quality | Flexibility |

|---|---|---|---|---|

| Hot-Fill | Medium | High (needs special heat-set bottle) | Good (taste can be "cooked") | Good |

| Aseptic Cold-Fill | Very High | Low (uses standard lightweight bottle) | Excellent (fresh taste) | High (can fill many products) |

This decision is critical. You cannot use a hot-fill bottle on an aseptic line (it's too heavy and expensive). You cannot use an aseptic bottle on a hot-fill line (it will melt).

The Sustainability Mandate: EPR Laws and the Rise of r-PET?

You are planning your packaging, but only thinking about cost. New laws in Vietnam will fine you for waste. You must understand EPR and the new demand for r-PET.

Vietnam's new EPR (Extended Producer Responsibility) laws are changing the industry. Brands must now pay for the plastic waste they create. This is making recycled PET (r-PET) a financial decision, not just a PR one.

For a long time, "sustainability" was just a marketing word. In Vietnam, this is changing. It is becoming a hard cost, a line item on the budget.

EPR: From "PR" to "P&L"

The reason is the new EPR (Extended Producer Responsibility) regulations.

In simple terms, the government is telling producers: "You created this plastic bottle. You are responsible for paying for its collection and recycling."

This is a big shock to the system. Starting in 2024 and 2025, companies must either recycle their packaging themselves or pay into a government fund to do it.

Suddenly, "using less plastic" is not a "green" goal; it's a financial goal.

If you can make your bottle 1 gram lighter, you save money on plastic and you save money on EPR fees.

This is why "lightweighting" is a huge trend. It requires excellent PET bottle mold design to remove material without losing bottle strength. This is a complex engineering task.

The r-PET Bottleneck

The other part of this is recycled PET, or r-PET.

The big multinational brands (Coke, Nestlé, Pepsi) have all made global promises to use 25% or 50% r-PET in their bottles. They must apply this in Vietnam, too.

This has created a huge demand for high-quality, "food-grade" r-PET.

But there is a problem. Vietnam does not have enough supply.

The local collection system is still developing. There are not many large, high-tech facilities that can take old, dirty bottles and turn them into clean, safe, food-grade r-PET pellets.

This is a classic supply bottleneck.

This creates two things:

- High Prices: Food-grade r-PET is now often more expensive than virgin (new) PET. Brands are paying a premium just to meet their goals.

- An Opportunity: This is a huge business opportunity for anyone who can build a high-quality r-PET processing plant in Vietnam.

For a bottle producer, this is also a technical challenge. r-PET behaves differently in a bottle blowing machine. It can have a different color (a slight yellow or grey tint) and different melting properties. Your machine and mold must be high-quality to handle r-PET without causing common blowing defects.

How to Choose a Partner for Vietnam's High-Growth Market?

You are ready to invest in Vietnam's PET market. You might just choose the cheapest supplier. You must understand that you need a technical partner, not just a vendor.

Choosing the right partner is key. This market is complex. You need a partner who understands the technical challenges of hot-fill, high-barrier sauces, and r-PET. You need an engineer, not just a salesperson.

We have covered a lot. We have seen the opportunities in tea, coffee, and sauces. We have seen the challenges in hot-fill, glass-to-PET barriers, and EPR laws.

Vietnam is a fantastic opportunity. But it is not an easy market.

My 20 years in this business have taught me one thing: the cheapest supplier is almost always the most expensive.

I have seen clients buy cheap molds. The molds break down. They have high defect rates. The bottle weights are inconsistent. They end up losing thousands of dollars in downtime and wasted plastic.

Match the Partner to the Problem

As we've discussed, the needs are very different. You must match your partner's skills to your specific product.

- Going into RTD Tea? You need a partner who is an expert in heat-set (Hot-Fill) bottle engineering and mold manufacturing. They must understand vacuum panels and neck crystallization.

- Going into Fish Sauce? You need a partner who is a specialist in high-barrier multilayer preform molds and co-injection.

- Going into C-Store Drinks? You need a partner with fast prototyping, 3D printing, and strong design skills to help you innovate quickly.

A "one-size-fits-all" supplier cannot do this.

Our Role as Engineers

This is where I position my company, iBottler. We are not just a factory. We are a team of engineers.

Our value is not just making the mold. Our value is the consulting that comes before it.

When a client comes to us for the Vietnam market, we ask:

- What is your product? (Tea, sauce, coffee?)

- What is your filling technology? (Hot-fill, aseptic?)

- What is your shelf life target? (12 months?)

- Are you using r-PET?

Based on these answers, our engineers design the right solution. We design the bottle structure for hot-fill. We specify the barrier materials for the sauce. We ensure the mold will run perfectly on the client's specific blowing machine.

This partnership approach is how you win in a complex, high-growth market like Vietnam. You need a partner who can help you solve these technical challenges.

Conclusion

Vietnam's PET market is full of potential in tea, coffee, and sauces. Success requires matching the right technical solution (hot-fill, barrier, r-PET) to these specific, high-growth opportunities.

Summary: Vietnam PET Market Opportunities & Challenges

| Market Opportunity | Key Driver | Main Technical Challenge | iBottler Solution |

|---|---|---|---|

| RTD Tea (Trà) | Convenience, Tradition | Hot-Fill (heat-set bottles) | Heat-Set Blow Bottle Molds |

| RTD Coffee (Cà Phê) | Market Gap, Convenience | Aseptic (for milk) | High-Tech Mold Engineering |

| Sauces (Nước Mắm) | Logistics Costs (Glass-to-PET) | High Barrier (Oxygen & Aroma) | Multilayer Preform Molds |

| C-Store Retail | Shelf Competition | Speed-to-Market, Design | 3D Printed Samples & Prototyping |

| Sustainability | EPR Laws | r-PET Supply, Processing | Molds optimized for r-PET |

Frequently Asked Questions (FAQ)

1. What is the biggest mistake investors make in Vietnam's PET market?

The biggest mistake is choosing the cheapest supplier. They buy a standard, low-cost mold or bottle blowing machine without considering their product. They fail when they try to produce hot-fill tea or high-barrier sauce bottles, because they don't have the right engineering.

2. Why is hot-fill so common for tea in Vietnam?

Hot-fill is common because the upfront investment for the filling line is much lower than for an aseptic line. This makes it a lower-risk entry point for many companies, even though the special heat-set bottles cost more per unit.

3. Can I use a standard PET water bottle for fish sauce (Nước Mắm)?

No, absolutely not. A standard PET bottle has poor barriers. Oxygen will get in and spoil the sauce. The strong aroma will get out, ruining the product and possibly contaminating other goods. You must use a high-barrier multilayer or coated PET bottle.

4. What is EPR and how does it affect my bottle costs in Vietnam?

EPR stands for Extended Producer Responsibility. It is a new law forcing producers to pay a fee for the plastic waste they create. This directly increases your cost. You can lower this fee by "lightweighting" (using less plastic) or by using r-PET (recycled PET) in your bottles.

5. Is it better to use hot-fill or aseptic for my new juice factory?

It depends on your business plan. Hot-fill has a lower startup cost, but the bottles are heavier and more expensive. Aseptic has a very high startup cost, but the bottles are lightweight and cheaper, and the product taste is often better. For high-volume production, aseptic is often cheaper in the long run.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr