Struggling with your new bottle production project? The initial quote for a blow molding machine seems low, but hidden expenses can quickly ruin your budget and timeline, causing major headaches.

The total cost of a blow molding machine goes far beyond the initial price tag. Hidden costs like unquoted auxiliary equipment, installation fees, mold rework, high defect rates, energy consumption, and poor after-sales support can significantly inflate your investment and delay your production.

I’ve spent 16 years in the PET packaging machinery industry, helping over 300 factories get their start. A common thread I've seen with startups and new buyers is the costly mistake of focusing only on the price tag. They compare quotes, pick the lowest number, and step right into a minefield of unexpected expenses. This journey almost always costs them more money and, just as importantly, more time than they ever budgeted for. To avoid these pitfalls, you need to look beyond the initial invoice and understand the full scope of your investment.

Let’s dive into the hidden costs that most suppliers won't tell you about.

Why the Lowest Price Isn’t Always the Best Deal?

Tempted by a rock-bottom price on a blow molding machine? This initial saving often leads to much larger, unexpected costs down the line, turning your great deal into a financial burden.

A low initial price is often a red flag. It can mean the supplier has cut corners on component quality, excluded essential equipment from the quote, or offers virtually no after-sales support, leaving you with massive, unforeseen expenses later.

Over my 16 years in this business, I've seen many new companies fall into this trap. They see a price that looks too good to be true, and unfortunately, it usually is. The focus on that single number on the quotation sheet is a critical error. A supplier offering a significantly lower price is likely compromising somewhere else. This could be in the quality of the steel used, the reliability of the pneumatic and electrical components, or the precision of the manufacturing process. These compromises don't show up on the spec sheet, but they will show up in your factory's performance. A cheaper bottle blowing machine might break down more often, produce inconsistent bottles, or consume more energy. These issues lead to production downtime, wasted materials, and higher operating costs that quickly erase any initial savings. I always advise my clients to ask why a price is so low. What are you not getting for that lower price? A thorough investigation into the supplier's reputation, the machine's components, and the included services is crucial. It’s about understanding the total cost of ownership, not just the purchase price.

Breaking Down the Total Cost of Ownership

When you evaluate a bottle blowing machine, you must think like an investor, not just a buyer. The total cost of ownership (TCO) is the real number you should care about. It includes the purchase price plus all the costs you'll incur over the machine's lifespan.

| Cost Category | Description | Potential Hidden Expense |

|---|---|---|

| Purchase Price | The initial amount on the quotation. | Often excludes essential items. |

| Operating Costs | Electricity, compressed air, labor. | Inefficient machines have much higher costs. |

| Maintenance Costs | Scheduled servicing, spare parts. | Poor quality machines need more frequent, costly repairs. |

| Downtime Costs | Lost production during breakdowns. | A cheap machine can cost you more in lost revenue. |

Thinking in terms of TCO protects you from the illusion of a low price. A machine that costs 20% less upfront could easily cost 40% more to run and maintain over a few years. Don't let a seductive price tag blind you to the real, long-term costs.

Hidden Cost #2: Auxiliary Equipment Not Included in the Quotation?

You've ordered your machine, but did you realize it can't work alone? Many suppliers don't include necessary auxiliary equipment in the main quote, leading to surprise purchases and budget overruns.

A blow molding machine is the heart of your operation, but it needs a support system. Essential auxiliary equipment like air compressors, chillers, and dryers are often quoted separately, or not at all, significantly increasing your total startup cost.

This is one of the most common and costly surprises for newcomers. They allocate their budget for the bottle blowing machine, only to discover they need to spend thousands more to actually make it run. I had a client in Spain last year who learned this the hard way. They were a startup, full of enthusiasm but lacking experience. They chose a supplier based on the lowest total price on the quote. After they made the payment, they were informed that a blow molding machine cannot produce bottles on its own. It needs a high-pressure air compressor to blow the bottles, a low-pressure air compressor for the machine's pneumatic movements, an air dryer and filters to ensure the air is clean and dry, and a water chiller to cool the molds. They had to scramble to order all this extra equipment, and the combined cost was already higher than what other, more transparent suppliers had quoted for a complete package. This not only strained their budget but also delayed their project timeline as they had to wait for the additional equipment to be sourced and delivered. A reputable supplier will always provide a clear and complete list of all required equipment, even if you choose to source it yourself. They will explain what each piece does and why it's necessary.

Essential Auxiliary Equipment Checklist

To avoid this situation, you must know what to ask for. A complete PET bottle production line is a system, not a single machine. Here’s a breakdown of the typical auxiliary equipment you will need. Use this as a checklist when you review quotations.

| Equipment | Function | Why It's Essential |

|---|---|---|

| High-Pressure Air Compressor | Provides the compressed air (typically 30-40 bar) to blow the PET preforms into bottles. | Without it, you cannot form the bottles. This is non-negotiable. |

| Low-Pressure Air Compressor | Provides compressed air (typically 7-10 bar) for the machine's pneumatic cylinders and valves. | Powers the mechanical movements of the machine, like clamping and stretching. |

| Air Dryer & Filters | Removes moisture and impurities from the compressed air. | Moisture in the air can cause defects in the bottles and damage pneumatic components. |

| Water Chiller | Circulates cold water through the blow bottle mold to cool it down quickly. | Ensures a fast cycle time and consistent bottle quality. Poor cooling leads to misshapen bottles. |

| Mold Temperature Controller | (Optional but recommended) Provides precise temperature control for the mold. | Critical for certain materials or complex bottle shapes to achieve optimal quality. |

When you get a quote, if you don't see these items listed, ask the supplier immediately. "Is this quotation for a complete production line? What other equipment will I need to purchase to start production?" This simple question can save you from a major financial and logistical nightmare.

Hidden Cost #3: Installation, Setup and Technical Support?

Your new machine has arrived, but it's still in crates. Now what? The costs for installation, setup, and vital technical support are often a shocking, unbudgeted expense for many buyers.

Getting your machine from the crate to full production requires skilled technicians. Many suppliers charge extra for this service, including daily fees, travel, accommodation, and food, which can add up to thousands of dollars.

Let's go back to my Spanish client's story. Their machine and auxiliary equipment finally arrived at their factory in Spain. But it sat there for two months. Why? The supplier did not have an installation team ready to send. After a lot of back and forth, they finally agreed to send a technician, but the costs were staggering. The client had to agree to pay a daily fee of $250 USD, plus cover all the technician's expenses: round-trip airfare, accommodation, local transportation, and meals. This "support" ended up costing them thousands of dollars they had never planned for. This is a classic example of how a low upfront cost hides significant backend expenses. The problem is that installing a bottle blowing machine is not a simple DIY project. It involves precise mechanical alignment, complex electrical wiring, and pneumatic connections. A small mistake during installation can lead to poor performance, bottle defects, or even damage to the machine. Professional installation and setup are not a luxury; they are an absolute necessity to ensure your investment works as intended. Before you sign any purchase order, you must have the installation terms and costs clearly defined in writing.

Comparing Installation Cost Scenarios

You generally have two options for installation, and the cost difference can be huge. It's vital to understand what's included and what's not. Let's compare a typical low-cost supplier's approach versus a full-service partner's.

| Service Aspect | Low-Cost Supplier (The Trap) | Full-Service Partner (The Smart Choice) |

|---|---|---|

| Technician Fee | Quoted separately, often as a daily rate ($200-$300/day). | Often included in the total package price. |

| Travel & Living | All flights, hotels, food, and local transport are paid by the client. | Usually included in the package. No surprise bills. |

| Training | Minimal, basic operator training. "Here is the on/off switch." | Comprehensive training for operators and maintenance staff included. |

| Timeline | Unclear, subject to technician availability. Can cause long delays. | Clearly defined in the project plan. |

| Accountability | If problems arise, it's easy for them to blame local setup issues. | They are fully accountable for the machine's performance from day one. |

As you can see, the "cheaper" option can quickly become the more expensive one, not to mention the stress and delays it causes. Always ask for a detailed, all-inclusive quotation that covers installation, commissioning, and training. Clarify who is responsible for what, and get it all in the contract. A supplier who is confident in their equipment will be transparent about these costs from the beginning.

Hidden Cost #4: Mold Compatibility and Rework?

Your machine is installed, but the bottles look wrong. A common hidden cost arises when your blow bottle mold is not perfectly compatible with the machine or your bottle design, requiring expensive rework.

Even a perfectly installed machine is useless if the mold doesn't work correctly. Compatibility issues between the machine, the preform mold, and the final bottle design can lead to defects, forcing you to pay for costly and time-consuming mold modifications.

This was the next nightmare for my Spanish client. After finally getting the machine installed, they started production trials. And they hit another wall. The bottles they produced did not match their original design specifications. The neck was slightly off, and the body wasn't formed correctly, which meant they couldn't be used on their filling line. The entire production was useless. The problem was a mismatch between the blow bottle mold they had and the machine's specific parameters. The supplier blamed the mold, and the mold maker blamed the machine. My client was stuck in the middle. In the end, they had to pay out of their own pocket to have the mold sent to a local workshop for modifications. This not only cost them more money but also added several more weeks of delay to a project that was already far behind schedule. A high-quality supplier understands that the machine and the mold are a single system. They will take responsibility for the entire process, from the preform mold design to the final, perfect bottle. They conduct rigorous testing before shipping to ensure that when the equipment arrives at your factory, it works flawlessly.

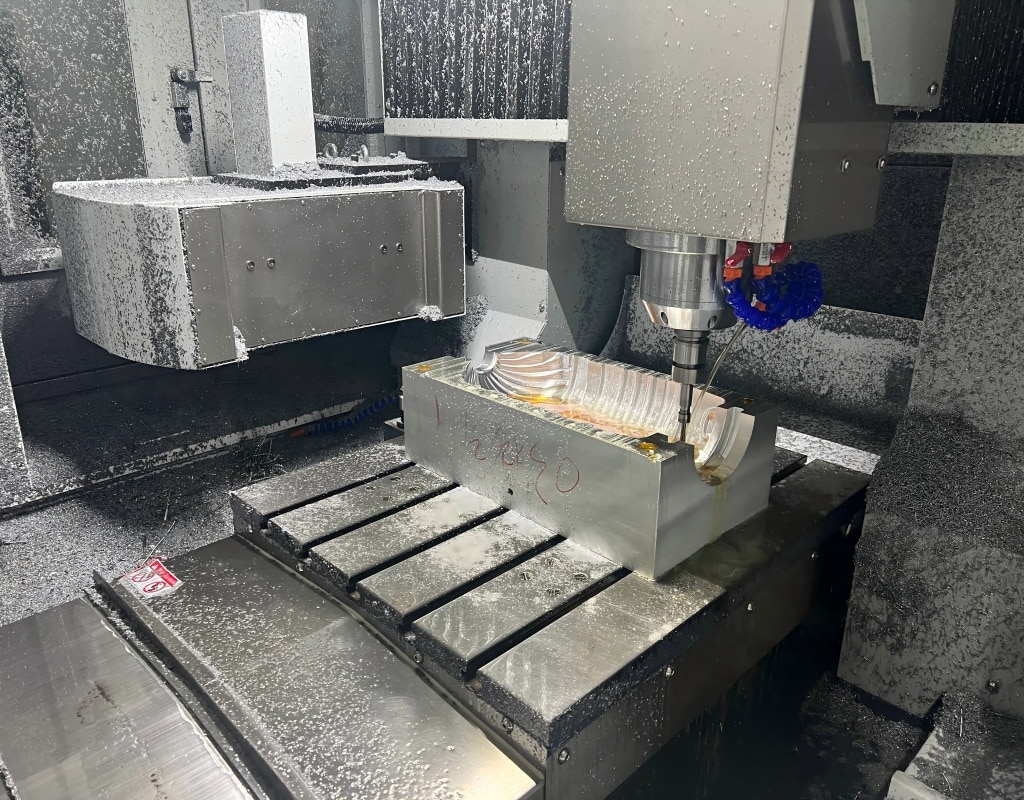

The Critical Machine-Mold-Preform Relationship

To achieve a perfect bottle, three elements must work in perfect harmony: the blow molding machine, the blow bottle mold, and the preform. A failure in any one of these areas will compromise the final product.

- The Blow Molding Machine: Provides the heating, stretching, and blowing parameters. The machine must offer precise and stable control over the heating lamps, stretching speed, and blowing pressures. A cheap machine may have inconsistent heating, leading to uneven wall thickness.

- The Blow Bottle Mold: This is the tool that gives the bottle its final shape. The quality of the steel, the precision of the CNC machining, the design of the cooling channels, and the polishing of the surfaces are all critical. A poorly designed blow bottle mold can cause defects like flash, weld lines, or an incorrect shape.

- The Preform: The quality of the PET preform is the foundation. The preform's weight, neck finish, and intrinsic viscosity (IV) must be correct for your desired bottle. Using the wrong preform with a perfect machine and mold will still result in bad bottles. A good supplier will advise you on the correct preform specifications or can even supply a high-quality preform mold as part of the package.

Before purchasing, you must clarify who is responsible for the final bottle quality. A good supplier will ask for your bottle drawings and preform samples. They will guarantee that their machine and mold will produce your bottle to your exact specifications. Don't accept anything less.

Hidden Cost #5: Bottle Defect Rate and Waste?

Your line is finally running, but you're throwing away a lot of bottles. A high defect rate from a cheap machine is a constant drain on your profits, wasting material, time, and energy.

A low-quality machine may produce a high percentage of defective bottles. This waste directly eats into your profit margin through lost material, wasted electricity, and reduced output of sellable products, a cost that continues for the machine's entire life.

After my Spanish client got their mold reworked, they could finally start producing. But their relief was short-lived. They quickly noticed that a significant number of bottles were coming out with defects – some were hazy, others had uneven wall thickness, and some had distorted necks. They were producing, but their scrap rate was nearly 15%. This is a silent but deadly hidden cost. For every 100 bottles they produced, 15 went straight into the recycling bin. This meant they were wasting 15% of their raw material (the PET preforms), 15% of their electricity, and 15% of their production time. The financial impact was enormous. The root cause was the instability of the cheap bottle blowing machine. The heating oven couldn't maintain a consistent temperature, and the blowing valves were not precise enough. These small inconsistencies in the process resulted in a high and unpredictable defect rate. A high-quality machine, with superior components and more stable process control, might have a defect rate of less than 1%. The difference in profitability is huge.

The Financial Impact of High Defect Rates

Let's look at the numbers. The cost of a high defect rate goes far beyond just the wasted plastic. It's a multiplier effect that impacts your entire operation. Consider a small-to-medium operation and see how the numbers stack up.

| Metric | High-Quality Machine (1% Defect Rate) | Low-Quality Machine (15% Defect Rate) | The Hidden Cost |

|---|---|---|---|

| Preforms Used per Day | 100,000 | 117,647 (to get 100,000 good bottles) | 17,647 wasted preforms/day |

| Material Cost (at $0.02/preform) | $2,000 | $2,353 | $353 lost per day |

| Annual Material Waste | - | - | ~$128,845 per year |

| Lost Production Time | Minimal | Significant time spent clearing jams, adjusting settings. | Reduced overall output and efficiency. |

| Reputation Damage | High, consistent quality. | Risk of defective bottles reaching the customer. | Loss of customer trust and business. |

As the table clearly shows, a high defect rate is not a minor inconvenience; it's a major financial drain. Over a year, that "cheap" machine could cost you over $100,000 in wasted material alone. This doesn't even account for the extra energy consumed and the lost sales opportunities due to lower output. When selecting a machine, always ask the supplier for a guaranteed defect rate for your specific bottle and preform. A confident manufacturer of a quality machine will be able to provide this.

Hidden Cost #6: Electricity Consumption and Air Usage?

Your production is running, but your utility bills are through the roof. The ongoing, daily costs of electricity and compressed air for an inefficient machine can become one of your biggest long-term expenses.

Blow molding is an energy-intensive process. An inefficient machine with an outdated heating system or leaky pneumatic components will consume significantly more electricity and compressed air, leading to shockingly high monthly utility bills that erode your profitability.

This is another area where the initial purchase price is incredibly deceptive. Two machines might look similar on paper and produce the same number of bottles per hour, but their energy consumption can be worlds apart. The heating oven, which gets the PET preforms to the right temperature, is the biggest consumer of electricity. Modern, high-quality machines use more efficient infrared lamps with better reflectors and oven designs that minimize heat loss. They can heat the preforms faster and with less energy. Older or cheaper designs are often like trying to heat a room with the windows open – a huge amount of energy is simply wasted. Similarly, compressed air is often called the "fourth utility" in factories because it's so expensive to produce. A machine with poorly designed or leaky pneumatic systems will constantly waste compressed air, forcing your compressors to run more often, consuming more electricity. Over the 5-10 year lifespan of a bottle blowing machine, the difference in utility costs between an efficient and an inefficient model can easily exceed the initial purchase price of the machine itself.

Analyzing Long-Term Operating Costs

Let's do a simple calculation to illustrate the point. We'll compare two machines producing the same output, but with different levels of efficiency.

- Machine A (High Efficiency): Modern heating oven, energy-saving components. Power consumption: 40 kWh.

- Machine B (Low Efficiency): Cheaper, older design. Power consumption: 60 kWh.

Assuming an electricity cost of $0.15 per kWh and the machine runs 16 hours a day, 300 days a year.

| Machine | Hourly Cost | Daily Cost | Annual Cost | 5-Year Cost |

|---|---|---|---|---|

| Machine A | $6.00 | $96 | $28,800 | $144,000 |

| Machine B | $9.00 | $144 | $43,200 | $216,000 |

| Difference | $3.00 | $48 | $14,400 | $72,000 |

In just five years, the "cheaper" Machine B would cost you an extra $72,000 in electricity alone. This doesn't even include the extra cost of running the air compressors more frequently. When you are evaluating a supplier, ask for the machine's specific power consumption data (in kWh). Ask about their energy-saving features. Do they use servo motors instead of pneumatic ones for certain movements? How is their heating oven designed to conserve energy? These questions show you are a knowledgeable buyer focused on the long-term, and the answers will tell you a lot about the quality of the machine you're considering.

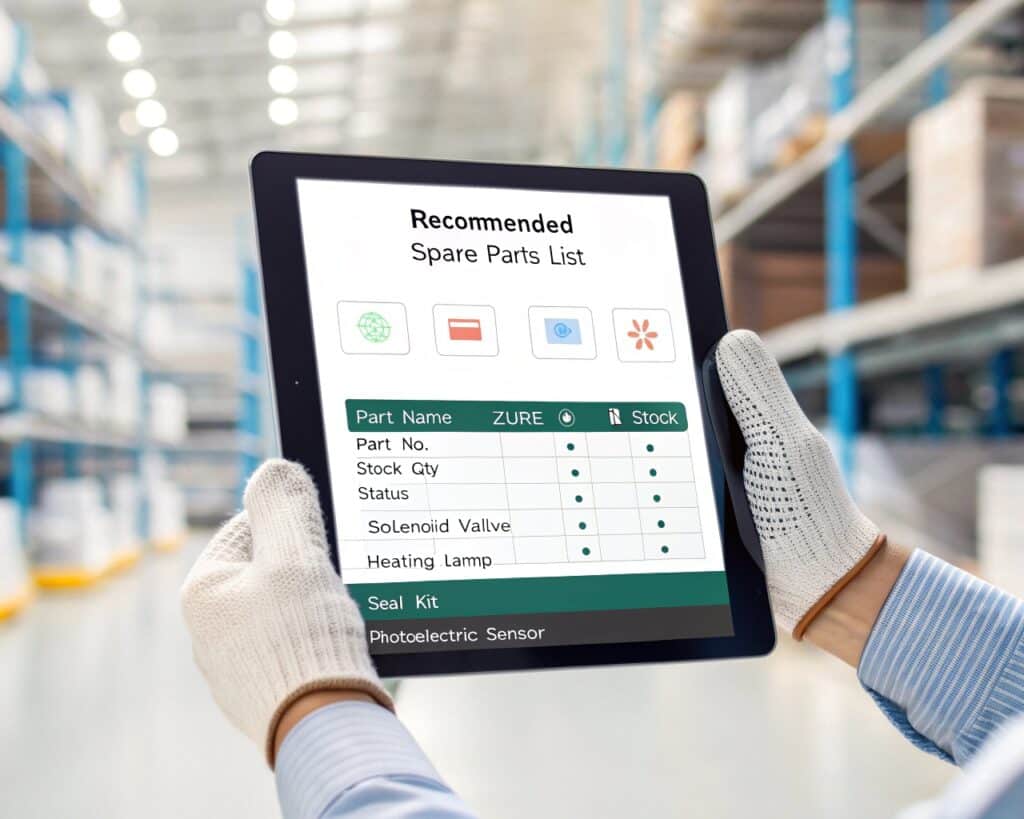

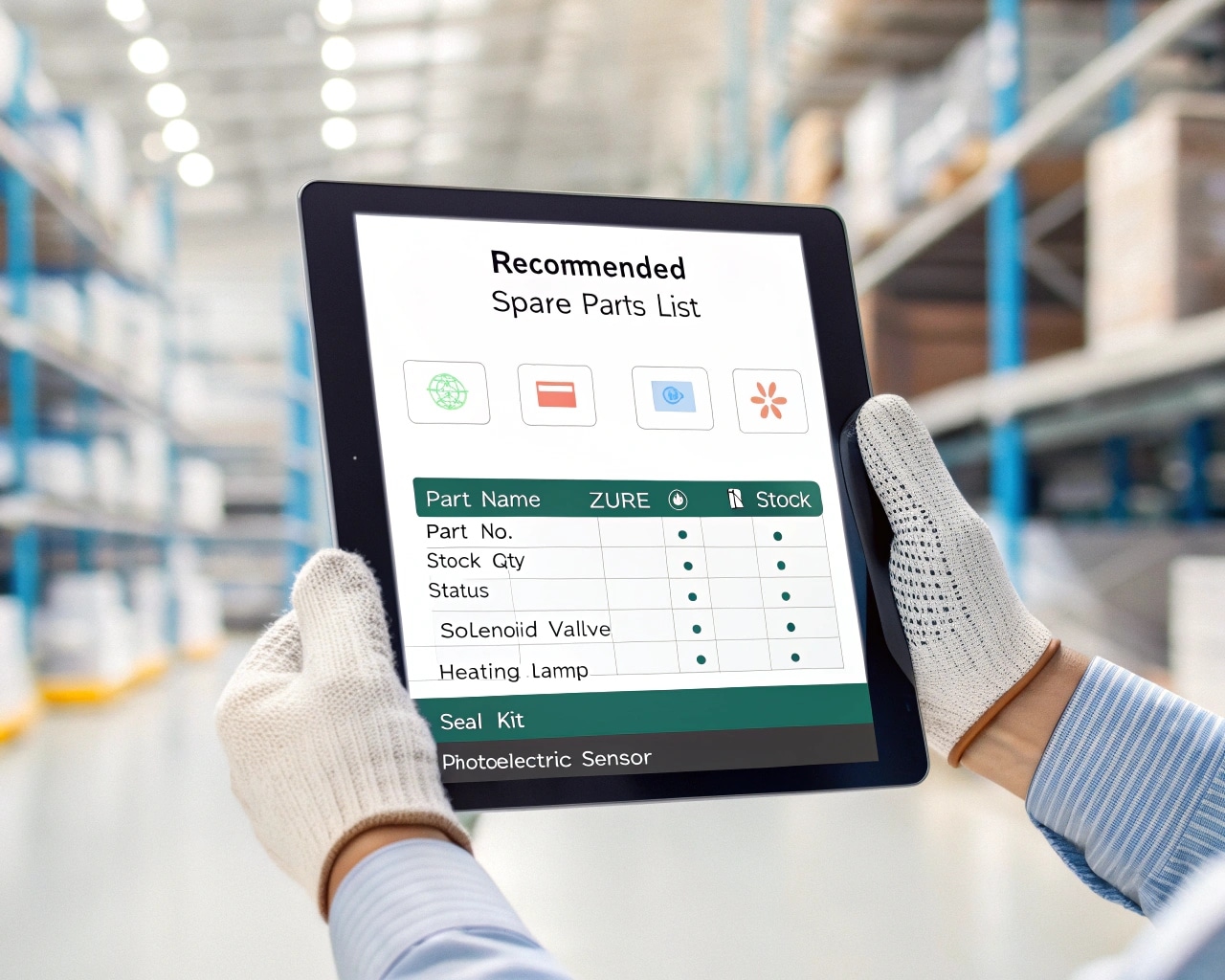

Hidden Cost #7: Spare Parts Availability and After-Sales Response?

Your machine is down, and you're losing money every hour. A hidden cost emerges when you can't get the spare parts or technical support you need quickly, leading to prolonged and costly downtime.

When a machine breaks, your ability to get it running again depends on your supplier's after-sales service. A supplier with slow response times and no local stock of spare parts can leave your production line idle for days or weeks.

This was the final, crushing blow for my Spanish client. After about six months of struggling through production, a critical valve on their machine failed. The machine stopped. They contacted the supplier for a replacement part. The supplier told them the part was not in stock and had a lead time of four weeks. Four weeks of no production. For a startup company, this is a potential death sentence. They tried to source the part locally, but it was a non-standard component specific to that machine manufacturer. They had no choice but to wait. This highlights a critical difference between a real manufacturer and a trading company or a small workshop. A reputable manufacturer understands the importance of uptime. They maintain a comprehensive stock of all critical spare parts and can ship them out within 24 hours. They have a dedicated after-sales team that can diagnose problems remotely and guide your team through repairs. Many buyers, especially first-timers, overlook this. They don't think about what will happen 6 months or a year down the road when a part inevitably fails. They are so focused on the initial purchase that they forget to investigate the supplier's ability to support them long-term. In the end, my Spanish client's project took over 8 months to get stable and cost them significantly more than if they had chosen a better, more supportive supplier from the start.

Evaluating a Supplier's After-Sales Support

Before you buy, you need to "interview" your supplier's support system. Don't just take their word for it that they have "good service." Dig deeper with specific questions.

- Spare Parts Package: Does the initial quotation include a recommended spare parts package for the first year of operation? A good supplier will always recommend this. What's included?

- Part Availability: Ask them about their stock of critical parts. For a specific critical part (e.g., a main blowing valve), what is their guaranteed shipping time?

- Technical Support: Who do you contact when you have a problem? Is there a dedicated support line or email? What are their hours of operation? Do they offer remote diagnostic support via video call?

- Distinction: Is the supplier a manufacturer or just a trading company? A trading company is just a middleman. They have no engineers, no spare parts, and no real ability to help you. Ask if you can visit their factory. A refusal is a huge red flag. A small workshop may not have the resources to provide adequate long-term support.

A supplier's after-sales support is your insurance policy against downtime. A cheap policy offers little coverage when you need it most. Investing in a supplier with a proven, robust support system is one of the smartest decisions you can make.

How We Help Clients Avoid These Hidden Costs?

Worried about navigating this minefield of hidden costs alone? Partnering with an experienced and transparent manufacturer is the key to ensuring your project's success from day one, without any costly surprises.

We act as your partner, not just a supplier. We provide fully transparent, all-inclusive quotations, guarantee mold and machine compatibility, focus on energy efficiency, and offer robust, responsive after-sales support to ensure your long-term profitability.

Having seen so many clients like the one in Spain suffer from the consequences of choosing the wrong supplier, we built our entire process around preventing these problems. Our philosophy is simple: your success is our success. We believe in transparency from the very first conversation. When we prepare a quotation, it includes everything you need to start production. We list the bottle blowing machine, all the necessary auxiliary equipment, a recommended spare parts package, and the costs for installation and training. There are no hidden fees. We take full responsibility for the entire system. You give us your bottle drawing, and we guarantee the final product. We design and test the blow bottle mold with your specific machine to ensure they work together perfectly before anything leaves our factory. We even advise on the optimal preform mold design for better results. Our machines are designed for efficiency, using modern servo technology and energy-saving heating systems to keep your operating costs low. And our commitment doesn't end when the machine is installed. We have a dedicated global support team and a comprehensive parts inventory to keep you running.

Our Commitment to Your Success: The iBottler Approach

We've structured our entire business to be the partner we wish our clients had from the beginning. It's about building a long-term relationship based on trust and shared success.

| Hidden Cost | The iBottler Solution |

|---|---|

| Unquoted Auxiliary Equipment | We provide a complete line quotation. You see the full investment upfront, including all necessary compressors, chillers, and dryers. No surprises. |

| Installation & Support Fees | On-site installation and comprehensive training are included in our project plan. Our engineers set up your line and train your team for success. |

| Mold Compatibility & Rework | We take full system responsibility. We test your blow bottle mold on your machine in our factory before shipping to guarantee perfect bottle quality from day one. |

| High Defect & Waste Rate | We use high-quality components and stable process controls to guarantee a low defect rate (typically <1%), maximizing your material usage and profit. |

| High Energy Consumption | Our machines feature energy-saving technologies, like efficient heating ovens and servo-driven systems, to minimize your long-term operating costs. |

| Poor After-Sales & Parts | We offer 24/7 remote support and maintain a large inventory of spare parts for immediate dispatch, minimizing any potential downtime. |

Choosing a machinery supplier is a major decision. It's a partnership that will impact your business for years to come. By focusing on total cost of ownership and choosing a transparent, experienced partner, you can avoid the pitfalls that have trapped so many others and set your business up for a profitable and sustainable future.

Conclusion

Choosing the right blow molding machine means looking beyond the price tag. Focus on total cost of ownership, supplier transparency, and long-term support to ensure your investment is profitable and successful.

Frequently Asked Questions (FAQ)

1. What is the single biggest hidden cost I should watch out for when buying a blow molding machine?

The most common and significant hidden cost is the exclusion of essential auxiliary equipment like air compressors and chillers from the initial quote. A machine cannot run without them, and they represent a major additional investment that many new buyers don't budget for.

2. How can I be sure the machine will actually make my specific bottle correctly?

You should demand a "bottle quality guarantee" from your supplier. Provide them with your bottle drawing and preform specifications. A reputable manufacturer will test the complete system (machine and your specific blow bottle mold) in their factory before shipping to guarantee the final product meets your quality standards.

3. The supplier's price is very low, but they charge extra for installation. Is this a good deal?

Usually not. This is a common tactic. The low initial price gets your attention, but the high, separate fees for installation, travel, and technician time can make the total cost much higher than an all-inclusive offer from another supplier. Always ask for a turnkey price that includes installation and training.

4. How much does the machine's energy consumption really matter?

It matters immensely. Over the machine's lifespan (5-10 years), the cost of electricity and compressed air can easily exceed the initial purchase price. An energy-efficient machine might cost more upfront but will save you tens of thousands of dollars in the long run, making it a much better investment.

5. What is the difference between buying from a manufacturer versus a trading company?

A manufacturer designs, builds, and supports the machine. They have engineers, spare parts, and deep technical knowledge. A trading company is just a middleman who buys from a factory and sells to you. They typically offer no meaningful after-sales support, have no spare parts, and cannot help you when a problem arises. Always verify you are dealing directly with the manufacturer.

🔗 Learn More about Blow Molding Technology

To better understand the core components of a 6-cavity automatic blow molding machine, here are some useful resources:

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr