Planning a new bottling line and worried about space? It's a massive investment, and misjudging the required factory area can lead to major production bottlenecks or wasted capital on oversized facilities.

A 2,000 bottles per hour (BPH) line needs approximately 400-600 square meters. In contrast, a 12,000 BPH line demands a much larger space, typically around 1,500-2,000 square meters, mainly due to the larger machinery, extensive conveyor systems, and significant buffer zones required for smooth, high-speed operation.

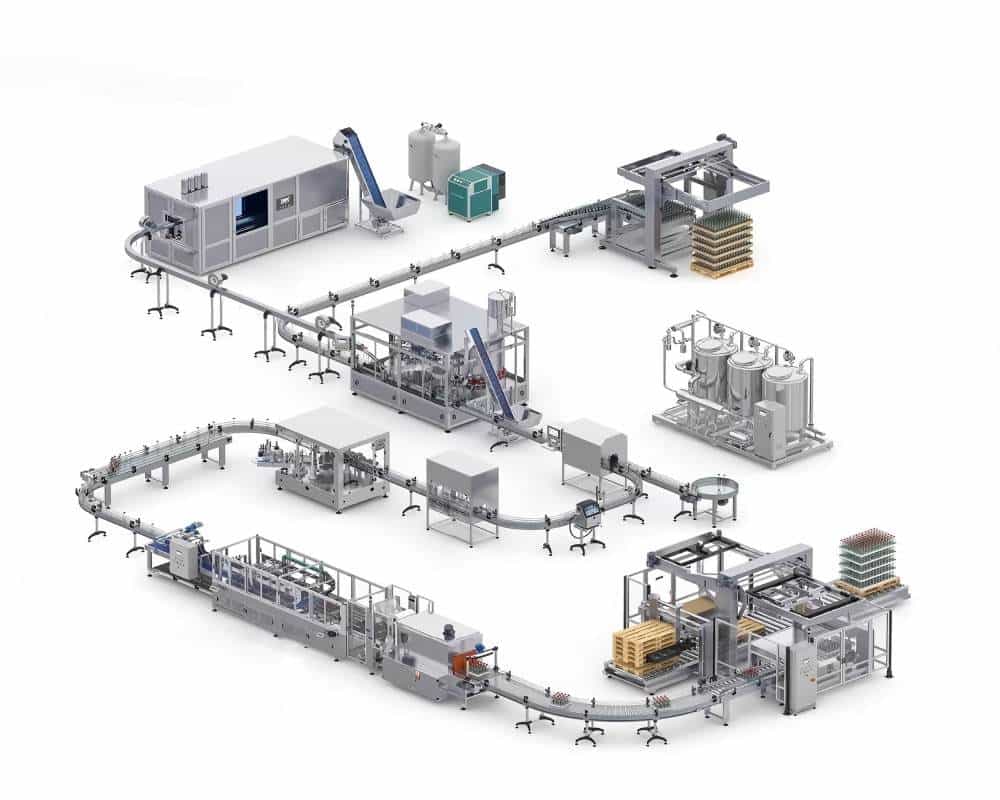

I've been in the PET packaging machinery industry for 16 years, helping clients with everything from bottle design to full production line installation. I know that procuring a complete line is a complex puzzle. You have over ten different types of machines that must fit and work together perfectly. A common question I get is, "How much factory space do I actually need?" It's a critical first step. Let's break down the space requirements by comparing a small-scale 2,000 BPH line with a high-capacity 12,000 BPH line, so you can plan your facility with confidence.

1. Why Production Capacity Drives Factory Layout and Space Planning?

Struggling to visualize your factory floor? The number of bottles you produce per hour is the single biggest factor that dictates the size and flow of your entire production line, from water treatment to final packaging.

Higher production capacity requires larger, faster machines, more complex auxiliary systems, and significantly more space for buffer zones and storage. A 12,000 BPH line isn't just six times bigger than a 2,000 BPH line; its spatial logic is fundamentally different, demanding a holistic layout approach.

When you decide on your output, you're not just picking a number. You are setting the blueprint for your entire operation. Every single component that follows is a direct consequence of this initial choice. For a 2,000 BPH line, you can often get away with a more linear, compact layout. The machines are smaller, the material flow is slower, and the margin for error is slightly more forgiving. However, when you jump to 12,000 BPH, everything changes. The machinery is physically larger and operates at incredible speeds, demanding more robust support systems like industrial-grade air compressors and chillers, which themselves need dedicated space. The key difference, and one that many clients overlook, is the need for dynamic space—areas for buffering, maintenance access, and future scalability. It’s not a simple multiplication problem; it’s an entirely different operational philosophy that must be mapped onto your physical plant.

Deeper Dive: The Core Logic of Space Planning

The fundamental principle is that flow dictates space. A smooth, uninterrupted flow of materials and products is the goal. Any bottleneck can bring a high-speed line to a halt, costing thousands in downtime.

- Linear vs. U-Shaped Layouts: A 2,000 BPH line can often be arranged in a simple straight line (I-shape). A 12,000 BPH line, due to its length and complexity, often benefits from a U-shaped layout. This can make supervision easier and centralize utilities, but it requires a wider factory floor.

- Ancillary Space: This is the hidden space consumer. For a 12,000 BPH line, you must plan for:

- Raw Material Storage: Space for a massive quantity of preforms and caps.

- Finished Goods Warehouse: An area to store at least a full day's worth of production.

- Utility Rooms: Dedicated, well-ventilated rooms for high-pressure air compressors, air dryers, and large water chillers.

- Maintenance Workshop & Spares: A place to service parts like your blow bottle mold without disrupting the production floor.

| Feature | 2,000 BPH Line (Low Capacity) | 12,000 BPH Line (High Capacity) |

|---|---|---|

| Primary Driver | Cost-effectiveness, simplicity | Speed, efficiency, uptime |

| Layout Logic | Linear (I-Shape), compact | U-Shape or complex, expansive |

| Space Focus | Minimizing footprint of core machines | Optimizing flow, buffer zones, access |

| Flexibility | Moderate | Lower (layout is highly optimized) |

2. What is the difference in water treatment system size for small vs. large scale bottling?

Worried your water treatment system will eat up your factory space? The purity of your water is non-negotiable, but the system's footprint is directly tied to the amount of water you need to process per hour.

A water treatment system for a 2,000 BPH line (approx. 1-2 tons/hr) is compact, often consisting of a few tanks and filters. A system for 12,000 BPH (approx. 7-8 tons/hr) is a large, multi-stage industrial plant with numerous large tanks, extensive piping, and a dedicated room.

The water treatment system is the starting point of your entire bottling line. Its size is a simple calculation based on your filler's consumption rate, plus a buffer for backwashing and cleaning. For a small 2,000 BPH line filling 500ml bottles, you need to produce 1,000 liters (1 ton) of purified water per hour. This can be handled by a relatively modest system. But for a 12,000 BPH line, you need at least 6,000 liters (6 tons) per hour, and we usually recommend a system with 7-8 tons/hr capacity to be safe. The physical difference is stark. You go from a system that might fit in a large garage to one that requires its own dedicated industrial room with specialized flooring and drainage.

Deeper Dive: Comparing Water Treatment Footprints

Let's look at the specific components and how they scale. The core of the system is Reverse Osmosis (RO), which uses membranes to purify water. The size and number of these membranes, along with the pumps that feed them, are the main determinants of space.

- Pre-treatment: This stage includes sand filters, carbon filters, and softeners. For a 2-ton system, these might be single, man-sized tanks. For an 8-ton system, you'll have a battery of much larger tanks, requiring more floor space and vertical clearance.

- RO Unit & Pumps: The RO membranes are housed in pressure vessels. A small system might have one or two vessels. A large system will have a long skid with multiple vessels and a powerful, noisy high-pressure pump that needs space and sound dampening.

- Tanks: You need at least two main tanks: one for raw water and one for purified product water. The size of these tanks is critical. For 12,000 BPH, the product water tank needs to be large enough to act as a buffer, ensuring the filler never runs dry. These tanks can be several meters in diameter and height.

| Component | 2,000 BPH (approx. 2 Ton/hr) | 12,000 BPH (approx. 8 Ton/hr) |

|---|---|---|

| Required Flow Rate | ~2,000 Liters/Hour | ~8,000 Liters/Hour |

| System Footprint | ~20-30 m² | ~60-100 m² (often in a dedicated room) |

| Raw Water Tank | ~2,000-3,000 Liters | ~10,000-15,000 Liters |

| Product Water Tank | ~2,000-3,000 Liters | ~10,000-15,000 Liters |

| Layout | Can be integrated along a wall | Requires a separate, planned area |

3. How do semi-automatic vs. fully automatic blow molding machines impact space requirements?

Choosing a blow molder and unsure how it fits? The machine that creates your bottles is a major space consumer, and the choice between semi-automatic and fully automatic has huge implications for your factory layout.

A semi-automatic blow molder has a small footprint but requires significant manual labor space around it. A fully automatic bottle blowing machine is much larger and is connected to a network of auxiliary machines, demanding a larger, integrated, and well-planned operational area.

For a 2,000 BPH line, a semi-automatic machine is a viable option. The main unit itself is compact. However, you need to account for the manual processes. An operator must physically load preforms into the heater and then transfer the heated preforms to the blowing unit. You also need space for operators to move around, tables for preforms, and carts to transport the finished bottles to the filler. When you step up to 12,000 BPH, you are exclusively in the realm of fully automatic linear machines. These are long, integrated systems that handle everything from preform unscrambling to bottle outfeed via air conveyor, requiring a much larger, dedicated, and unobstructed footprint.

Deeper Dive: The Full Picture of Blow Molding Space

The blowing machine itself is only part of the story. The auxiliary equipment is what truly defines the space requirements, especially for a high-output machine.

- The Machine Itself: A 2-cavity semi-automatic machine might be 2 meters long. A 12,000 BPH fully automatic machine (typically 8 cavities) can be 6-7 meters long, not including the preform feeding system.

- Preform Handling: A 12,000 BPH machine needs a large preform hopper, an elevator, and an unscrambler to feed preforms automatically. This system alone can take up 10-15 square meters.

- High-Pressure Air System: This is a non-negotiable and space-intensive part of a high-speed line. You need a high-pressure air compressor (40 bar), an air receiver tank, and air dryers. This is loud, hot equipment that must be placed in a separate, well-ventilated utility room. A smaller line might get by with a smaller, integrated compressor, but it's less efficient.

- Molds & Maintenance: You need a designated area for storing and maintaining your molds. A precision blow bottle mold is a heavy, critical asset that needs to be handled carefully.

| Feature | Semi-Automatic (for ~2,000 BPH) | Fully Automatic (for 12,000 BPH) |

|---|---|---|

| Main Machine Footprint | ~4-6 m² | ~25-40 m² |

| Auxiliary Equipment Area | ~10-15 m² (small compressor, chiller) | ~40-60 m² (large utility room needed) |

| Labor/Operational Space | High (space for 2-3 operators) | Low (space for access and maintenance) |

| Total Estimated Area | ~25-40 m² | ~80-120 m² |

4. What are the space differences between compact and high-speed rotary filling machines?

Picking a filling machine seems simple, right? But the technology used to fill your bottles has a massive impact on its size. The choice between a compact filler and a high-speed rotary system will dramatically alter your factory layout.

A compact, linear filling machine for 2,000 BPH is self-contained and relatively small. A high-speed 12,000 BPH rotary triblock (rinsing, filling, capping) system is a large, circular machine that demands significant central space in your production hall and dictates the flow around it.

At the heart of any bottling line is the filler, and its design philosophy changes completely with speed. For a 2,000 BPH line, you can use a simple linear gravity filler. Bottles enter in a line, get filled by a set of nozzles, and exit. It’s straightforward and space-efficient. But to achieve 12,000 BPH, you need a rotary machine. Bottles are fed onto a spinning carousel, where they are rinsed, filled, and capped in a continuous, high-speed motion. These machines are much larger in diameter and often serve as the central hub of the entire production line, with conveyors feeding into and out of them.

Deeper Dive: Linear vs. Rotary Footprints

The difference isn't just the machine's core size, but also how it integrates with other functions and the space it requires for operation and cleaning.

- Function Integration: For 12,000 BPH, you almost always use a "triblock" system, which combines the rinser, filler, and capper into one synchronized rotary machine. This is efficient but creates a large, single piece of equipment. For 2,000 BPH, you might have separate, smaller machines for each task, offering more layout flexibility but potentially less efficiency.

- Clean-In-Place (CIP) System: High-speed lines require an automated CIP system to clean the filler thoroughly. A CIP system consists of its own set of tanks (for acid, caustic, hot water) and pumps, and it needs to be located near the filler. This can add another 10-15 square meters of required space that isn't necessary for a small line that can be cleaned manually.

- Operator Access: A rotary filler needs 360-degree access for maintenance, changeovers, and quality checks. You can't just push it against a wall. You must plan for a wide walkway all the way around it.

| Attribute | Linear Filler (~2,000 BPH) | Rotary Triblock Filler (12,000 BPH) |

|---|---|---|

| Machine Footprint | ~6-10 m² | ~20-30 m² |

| Operational Principle | Intermittent, in-line | Continuous, rotary motion |

| Required CIP System | Manual cleaning or small, mobile CIP | Dedicated, fixed CIP system (~10-15 m²) |

| Layout Impact | Fits easily into a linear layout | Acts as a central hub for a U-shaped layout |

| Total Estimated Area | ~10-15 m² | ~40-55 m² |

5. How does bottle flow impact conveyor lines and buffer zone layout?

Think you just need space for the big machines? The hidden space-eater in any bottling plant is the conveyor system. The way your bottles flow and accumulate between stations is one of the most critical and underestimated parts of factory planning.

For a low-speed line, conveyors are simple links. For a high-speed 12,000 BPH line, conveyors become a dynamic buffer system. You need long stretches of accumulation conveyors—often over 100 meters—to absorb micro-stoppages and keep the high-speed filler running continuously.

This is where planning often goes wrong. I had a client in Thailand who wanted to install a 12,000 BPH line in their existing factory. They had measured the main machines and thought everything would fit. However, when we mapped out the full line, we discovered there was no room for the necessary buffer conveyors. At 12,000 BPH (that's over 3 bottles per second!), the filler, labeler, and packer must be perfectly synchronized. But in reality, the labeler might need a new roll of labels, or the packer might jam for 30 seconds. Without a buffer, this would force the entire line, including the multi-million dollar filler, to stop. The buffer conveyor acts as a shock absorber, accumulating bottles so the filler can keep running during these brief downstream stops.

Deeper Dive: The Science of Accumulation

The length of your buffer conveyor is not arbitrary; it's calculated based on the line speed and the potential downtime of downstream equipment.

- Air Conveyors vs. Slat Conveyors: From the bottle blowing machine, empty PET bottles are transported by air conveyors, which hold them by the neck ring. These can be routed overhead, saving valuable floor space. After filling, heavier bottles are moved by stainless steel slat conveyors on the floor.

- Calculating Buffer Time: Let's say your shrink wrapper takes about 2 minutes to change a roll of film. On a 12,000 BPH line, you produce 400 bottles in those 2 minutes (12,000/60 * 2). You need enough conveyor space to hold at least 400 bottles without them backing up and stopping the filler.

- The Thai Client's Solution: After we showed him the simulation, my Thai client realized his existing space was insufficient. He couldn't afford to have his new high-speed line constantly stopping. Rather than lease a new facility, he wisely decided to scale down his plans. We optimized the layout for his existing building, and he successfully installed a 6,000 BPH line, which was the maximum his space could truly support. It was the right decision, prioritizing smooth operation over just a higher number on paper.

| Feature | 2,000 BPH Line | 12,000 BPH Line |

|---|---|---|

| Conveyor Type | Mostly slat conveyors | Air conveyors (pre-fill) & Slat conveyors (post-fill) |

| Conveyor Function | Simple transport | Transport & Dynamic Buffer |

| Required Buffer Time | Minimal (10-20 seconds) | Critical (90-120 seconds) |

| Approx. Conveyor Length | ~20-30 meters | ~100-150 meters |

6. What are the space considerations for inline laser coding and labeling stations?

Planning for your product's final look? The labeling and coding stations might seem small, but their integration into a high-speed line requires careful spatial planning to ensure quality and prevent bottlenecks.

For a 2,000 BPH line, a simple self-adhesive labeler and inkjet coder can be placed inline with minimal space. For a 12,000 BPH line, a high-speed rotary labeler (sleeve or hot-melt OPP) is a larger machine that needs precise integration with infeed and outfeed conveyors and requires dedicated access space.

After filling and capping, your bottles need to be coded with production dates and dressed with a label. The technology and speed here again dictate the footprint. At low speeds, a bottle can be stopped momentarily for an adhesive label. At 12,000 BPH, this is impossible. The bottles are moving continuously through a rotary labeler that applies either a shrink sleeve or a wrap-around OPP (Oriented Polypropylene) label with hot-melt glue. These machines are more complex and physically larger than their low-speed counterparts. The laser coder is usually a small head mounted over the conveyor, but it requires a controller cabinet and a safe, accessible position.

Deeper Dive: Integrating Labeling and Coding

The key to this stage is seamless integration. These machines are inserted directly into the slat conveyor line connecting the filler to the final packaging.

- Labeler Technology & Space:

- Self-Adhesive: Common for lower speeds. The machine is linear and compact.

- Hot-Melt OPP: A rotary machine that is very cost-effective for high-volume runs. The machine itself is larger and needs space for glue pellets and the heating system.

- Shrink Sleeve: This requires two stages: a sleeve applicator (mandrel) and a steam or heat tunnel to shrink the label onto the bottle. The tunnel adds significant length to the line.

- Access for Consumables: This is a crucial planning point. The operator needs easy and safe access to the labeler to load giant rolls of labels (which can be heavy) and to the coder to replace ink or solvent cartridges. For a 12,000 BPH line, label rolls are consumed quickly, so you need space to stage the next roll nearby.

- Rejection System: After labeling and coding, a vision inspection system is often used to check for correctness. A rejection station (usually a pneumatic pusher) needs a small amount of space to divert faulty bottles into a collection bin.

For a high-speed line, the entire labeling and inspection section can easily occupy a 10-15 meter stretch of the conveyor line. While the machines themselves might only have a footprint of 10-15 m², the linear space they consume is significant.

7. What are the layout needs for the shrink wrapping and final packaging area?

Your bottles are filled and labeled, but how do you prepare them for shipping? The final packaging stage can range from a simple manual table to a fully automated system, with vastly different space requirements.

A 2,000 BPH line can be managed with a semi-automatic L-bar sealer and a manual packing table, requiring minimal space. A 12,000 BPH line needs a fully automatic shrink wrapper and potentially a palletizer, creating a large, automated zone that includes extensive outfeed conveyors and space for pallet maneuvering.

The end of the line is where individual bottles are grouped into saleable packs (e.g., 12-packs or 24-packs). For a small operation, an operator can manually group bottles and feed them into a simple shrink wrapper. It’s slow, but the capital cost and space are minimal. For a 12,000 BPH line, this must be fully automated. An automatic lane divider arranges the bottles into the correct pattern (e.g., 4x6), pushes them through a curtain of film, and sends them into a heat tunnel to shrink the wrap. This machine is long—often 5-7 meters—and requires clear space on all sides.

Deeper Dive: From Shrink Wrap to Warehouse

The space planning doesn't end at the shrink wrapper's outfeed. You have to consider how these finished packs are handled and stored.

- Outfeed Conveyors & Turntables: After the shrink tunnel, you need conveyor space for the packs to cool and solidify. Often, a rotating turntable is used to accumulate packs, giving an operator time to stack them onto a pallet.

- Palletizing:

- Manual: For 2,000 BPH, an operator will manually stack the ~3-4 packs produced per minute onto a pallet. You need space for the operator, the pallet itself, and a pallet jack to move it.

- Automatic/Robotic: For 12,000 BPH, you're producing ~15-20 packs per minute. Manual stacking is exhausting and inefficient. An automatic or robotic palletizer is often used. These machines need a significant safety-fenced area, space for empty pallet dispensers, and slip sheet applicators.

- Finished Goods Storage: This is a critical calculation. A 12,000 BPH line produces 96,000 bottles in an 8-hour shift. If they are in 24-packs, that's 4,000 packs, or roughly 80-100 pallets of finished goods per day. You need a warehouse area large enough to store several days' worth of production, plus room for forklift operations.

The final packaging and staging area for a high-speed line can easily require 200-300 square meters or more, a space far larger than the core production machines themselves.

8. What is the complete factory space comparison for a 2000 BPH vs. 12000 BPH full line?

Ready to see the big picture? Let's put all the pieces together. Understanding the total required space, including all the auxiliary and storage areas, is the key to a successful project launch.

A 2,000 BPH line can fit into a 400-600 m² workshop. A 12,000 BPH line requires a dedicated factory of 1,500-2,000 m² or more, factoring in larger machines, extensive buffer conveyors, utility rooms, and massive storage areas for raw materials and finished goods.

The final decision on your factory size comes from a holistic view. You can't just add up the footprints of the individual machines. You must plan for flow, access, and storage. This is where experience really counts. I had a client in Australia who was planning a new 12,000 BPH greenfield project. Because they came to us before securing a building, we had the flexibility to do it right. We provided them with a detailed layout plan, showing not just the production line, but also the optimal locations for the warehouse, the room for the high-pressure compressors, and even the workflow for loading and unloading trucks. They used our plan to lease a factory that was perfectly suited to their needs, and their high-speed line has been running smoothly ever since. It highlights the value of planning the space around the line, not trying to force the line into a pre-existing space. This also includes planning for things like your preform mold storage and maintenance areas.

Deeper Dive: Comprehensive Space Allocation Summary

Let's break down the approximate space requirements for each section in a side-by-side comparison. These are estimates and can vary based on specific machine choices and layout efficiency, but they provide a strong baseline for your initial planning.

| Area / Component | 2,000 BPH Line (Approx. m²) | 12,000 BPH Line (Approx. m²) | Key Considerations |

|---|---|---|---|

| Water Treatment System | 20 - 30 m² | 60 - 100 m² | High capacity needs a dedicated room. |

| Blow Molding & Auxiliaries | 25 - 40 m² | 80 - 120 m² | Includes space for compressors, chillers, and molds. |

| Filling & Capping Zone | 10 - 15 m² | 40 - 55 m² | High speed requires rotary machine and CIP system. |

| Conveyors & Buffer Zone | 15 - 20 m² | 100 - 150 m² | Critical for high-speed uptime. Includes floor space under air conveyors. |

| Labeling & Coding Line | 10 - 15 m² | 25 - 40 m² | Considers machine length and operator access. |

| Shrink Wrapping & Packing | 15 - 20 m² | 40 - 60 m² | High speed often requires an automatic palletizer. |

| SUBTOTAL (PRODUCTION LINE) | ~95 - 140 m² | ~345 - 525 m² | This is just the equipment area! |

| Raw Material Storage | 50 - 80 m² | 300 - 400 m² | Space for preforms, caps, labels. |

| Finished Goods Warehouse | 150 - 250 m² | 600 - 800 m² | To hold at least 2-3 days of production. |

| Offices, Labs, Amenities | 50 - 80 m² | 100 - 150 m² | Quality control lab, offices, staff areas. |

| Pathways & Access | 50 - 80 m² | 150 - 200 m² | Forklift paths, maintenance access, safety zones. |

| TOTAL ESTIMATED AREA | ~400 - 600 m² | ~1,500 - 2,000 m² | A complete and realistic factory footprint. |

Conclusion

Ultimately, the factory space required is dictated not just by machine size, but by your production ambition. A 12,000 BPH line isn't just bigger; it's a more complex, interconnected system that demands significantly more strategic planning for flow and storage.

Frequently Asked Questions (FAQ)

1. Can I fit a 12,000 BPH line into a 1,000 square meter factory?

It would be extremely difficult and is not recommended. As the detailed breakdown shows, once you account for necessary storage for raw materials and finished goods, plus essential access pathways for forklifts and maintenance, a 1,500-2,000 m² facility is a much more realistic minimum for safe and efficient operation.

2. What is the most commonly forgotten space requirement when planning a bottling line?

The buffer conveyor zones and the finished goods warehouse are the two most frequently underestimated areas. Clients focus on the main machines but forget that smooth flow (buffers) and output storage (warehouse) are what make the line profitable. A lack of buffer space leads to constant stops, while a lack of warehouse space can halt production entirely.

3. How much vertical height do I need for a bottling plant?

A minimum ceiling height of 5-6 meters is recommended for a standard line to accommodate machinery like preform hoppers and allow for overhead air conveyors. For larger systems with tall water storage tanks or potential integration of a robotic palletizer, a clear height of 7-8 meters is safer.

4. Is it better to find a factory first or plan the line first?

It is always better to plan the ideal line layout first. As my Australian client's story shows, this allows you to find a facility that fits your optimal process. If you buy or lease a factory first, you are often forced to make compromises on your line layout that can hurt efficiency for years to come, just as my Thai client had to scale down his ambition.

5. How much space should I reserve for future expansion?

A wise strategy is to secure a facility that is 25-30% larger than your immediate needs. This allows you to add a second production line, expand your warehouse, or incorporate more automation like robotic palletizing in the future without needing to relocate. Plan your initial layout on one side of the facility to leave a large, open area for this future growth.

🔗 Learn More about Beverage Packaging and Production Equipment

Water Purification – Wikipedia

Explains the process of removing impurities from water, essential before beverage filling.Filling Machine – Wikipedia

Overview of liquid filling machines, including those used in beverage and bottle filling lines.Blow Molding – Wikipedia

The core manufacturing process for forming PET and plastic bottles from preforms.Laser Engraving – Wikipedia

Used for laser coding and date marking on bottle surfaces.Shrink Wrap – Wikipedia

Describes the packaging material and wrapping machines used for bundle packaging, such as shrink wrap bundlers.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of automatic blow molding solutions for PET bottles.Semi-Automatic Blow Molding Machines – iBottler

Ideal solutions for startups and small-scale PET bottle production.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr