Struggling with the high cost of automated production? Starting small and worried about big investments for making your own PET bottles? A mini blow molding machine could be your answer.

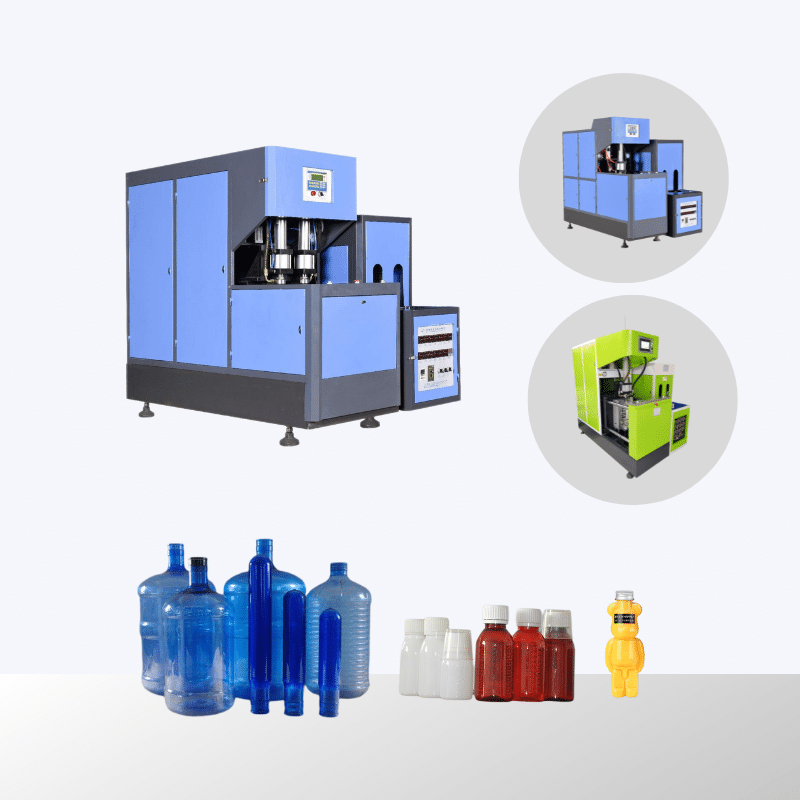

Yes, absolutely. Specifically for producing PET bottles on a smaller scale, the mini blow molding machine remains a very practical and cost-effective choice for startups, small brands, or those with limited budgets and space. It offers a low entry barrier despite the industry trend towards full automation.

I often talk to entrepreneurs excited about launching their own bottled product – maybe craft soda, local honey, or a unique cosmetic line. They need PET bottles, see the huge automated lines, and think it's out of reach. That's when I bring up the mini blow molding machine. It’s not about comparing every type of blow molding out there; it’s about understanding this specific tool and if it fits your specific need. Let’s dive into why this smaller, often semi-automatic, PET bottle-making solution is still a smart move for many.

What does this specific 'mini blow molding machine' do?

Confused about how those clear plastic drink or cosmetic bottles are made on a smaller scale? Let's clarify how these mini machines, typically for PET, work.

This type of mini blow molding machine is usually a Semi-Automatic Stretch Blow Molding (SBM) machine. It takes pre-made PET 'test tubes' called preforms, heats them, and then blows them into the final bottle shape inside a mold, requiring some manual help.

Forget the complexities of Extrusion Blow Molding (EBM) for milk jugs or Injection Blow Molding (IBM) for tiny pharma vials for a moment. The mini machine we're focused on targets PET bottles – the kind used for water, juice, oils, soaps, etc. The process is usually 'two-step':

- Preforms: You start with ready-made PET preforms, which look like thick-walled test tubes with the bottle neck already finished. You buy these based on the neck size and weight needed for your final bottle.

- Heating: The mini machine often has an infrared oven section. An operator (maybe you or me!) loads the preforms onto holders that rotate through the oven, heating them precisely until they are soft and pliable.

- Blowing: The operator quickly takes the heated preform and manually places it into the blow mold clamped shut within the machine. The machine then inserts a stretch rod (stretching the preform vertically) and injects high-pressure air (blowing it outwards) to shape it against the mold cavity.

- Ejection: Once cooled for a few seconds, the mold opens, and the operator removes the finished PET bottle.

It’s called 'semi-automatic' because the heating rotation and blowing/stretching are automated, but loading preforms and unloading bottles is manual. This is the key difference from fully automatic lines but is exactly what makes it affordable and compact.

What are the specific drawbacks of using a mini blow molding machine?

Thinking this low-cost option sounds perfect? While great value, the mini PET machine has trade-offs compared to full automation or just buying ready-made bottles. Let's be realistic about its limitations.

The main disadvantages are lower production speed due to manual steps, reliance on operator consistency which can affect output quality, higher labor cost per bottle compared to automation, and limitations on bottle complexity or size.

Let's break these down from the perspective of someone choosing this machine. First, production speed. A typical semi-auto machine might produce 800-1800 bottles per hour, depending on the bottle size and number of mold cavities (often just one or two). A fully automatic rotary machine can churn out many thousands per hour. So, if you need massive volume, the mini machine isn't the right fit. Second, manual labor and consistency. Because an operator handles loading and unloading, their speed and consistency directly impact output. If someone is slow or loads a preform slightly wrong, it affects production. This also means higher labor costs factored into each bottle produced compared to a 'lights-out' automated factory. I always advise clients to factor in dedicated operator time. Third, bottle complexity and size. While great for standard bottle shapes, very complex designs or very large bottles might be challenging or impossible on simpler mini machines. Fourth, tooling costs still exist. While the machine is cheaper, you still need to buy the specific blow mold for your bottle design, which can cost several thousand dollars depending on complexity. It’s less than molds for high-speed machines, but still an investment. These are the trade-offs for the lower initial investment and smaller footprint.

Are there other ways to get PET bottles besides using a mini blow molder?

Need PET bottles but unsure if running even a mini machine is right for you? What are the alternatives for a small brand?

Yes, the main alternatives are buying stock bottles directly from a supplier, or potentially using other materials/packaging types if PET isn't essential (though less common for the typical applications). Full automation is the other end of the scale.

For many startups I've worked with, the first step isn't making bottles, it's buying stock bottles. Numerous suppliers offer standard PET bottles in various shapes and sizes off-the-shelf.

- Pros: No machine investment, no manufacturing hassle, readily available, good for testing the market with low volume.

- Cons: Limited design choices (everyone uses the same bottles), potentially higher cost per bottle long-term, reliant on supplier stock levels.

The other alternative within manufacturing is the fully automatic blow molding machine. - Pros: Very high speed, low labor cost per bottle, high consistency.

- Cons: Very high initial investment (machine, installation, space, ancillary equipment), requires skilled technicians, less flexible for small runs or frequent changeovers.

Comparing these, the mini blow molding machine sits in a sweet spot: - Pros: Lower initial investment than auto, allows custom bottle shapes (with custom mold), control over production schedule and quality, potentially lower cost per bottle than buying stock (especially for custom shapes or higher volumes than initial tests).

- Cons: Requires machine investment and space (though less than auto), requires manual labor, lower speed than auto.

So, the choice between buying stock, using a mini machine, or going fully automatic depends heavily on your required volume, budget, need for custom design, and operational capacity.

What kind of PET bottles are typically made with these mini machines?

What specific products are these mini PET blow molders ideal for creating, especially for smaller businesses?

These machines are perfect for producing many common PET bottle types used by startups and niche brands: water bottles, juice & beverage bottles, cooking oils, sauces, cosmetics (lotions, shampoos), cleaning supplies, and specialty food containers.

Think about the products where a unique bottle shape can help a brand stand out, or where producing in-house gives cost or logistical advantages over buying stock bottles. I've seen mini machines successfully used by:

- Local spring water companies: Creating their own branded bottles in 250ml, 500ml, or 1L sizes.

- Craft beverage makers: For juices, iced teas, or specialty sodas needing PET.

- Cosmetic startups: Producing bottles for lotions, serums, or shampoos where a custom look is important.

- Food producers: Making bottles for oils, dressings, honey, or sauces. They gain flexibility and can ensure cleanliness standards by making bottles right before filling.

- Household chemical suppliers: For smaller batches of cleaners or detergents for local markets.

The common thread is usually production volumes that are too high or specialized for buying stock bottles to be economical or practical, but not yet high enough to justify a massive investment in fully automatic equipment. The mini SBM machine allows these businesses to take control of their packaging with a manageable investment, producing the clear, strong PET bottles consumers expect for these kinds of products.

What does the future hold for mini blow molding technology?

Is this small-scale technology just fading away, or is it adapting? With automation and sustainability being key trends, where do mini PET machines fit in the future?

The future for mini blow molders involves incorporating smarter, user-friendly controls, improving energy efficiency, and potentially adding simple automation assists, while retaining their core value of low cost and simplicity for smaller scale PET bottle production.

While the high-end of blow molding races towards full robotic automation, integrated systems, and advanced AI for process optimization, the mini machine segment has its own evolution path. We likely won't see mini machines become fully automated 'dark factory' solutions – that defeats their purpose. Instead, future developments will probably focus on:

- Smarter Controls: Touch screen interfaces become standard, offering easier setup, recipe storage for different bottles, better diagnostics, and maybe even remote monitoring capabilities via basic IoT connectivity. I expect interfaces to get much more intuitive.

- Energy Efficiency: Using servo motors for clamping instead of hydraulics (quieter, cleaner, less energy), more efficient oven designs using better reflectors or lamps to reduce electricity consumption during preform heating.

- Simplified Automation Assists: Perhaps simple robotic arms for loading/unloading could become optional add-ons, bridging the gap between semi-auto and full-auto without the huge cost jump. Or improved conveyor systems for preform feeding.

- Sustainability Focus: Machines will be better designed to handle rPET (recycled PET) preforms, which can sometimes require different heating profiles.

- Continued Emphasis on Value: The core appeal – low investment, small footprint, ease of use for producing quality PET bottles – will remain the primary driver. The 'future' here isn't about replacing operators entirely, but making the machine easier and more efficient for the operator and the small business owner. It secures its niche by not trying to be a fully automatic machine.

Conclusion

So, back to the main question: is the mini PET blow molding machine worth buying today? Absolutely. It fills a vital gap for startups and smaller operations needing affordable, in-house PET bottle production capability.

🔗 Learn More about Blow Molding Technology

To better understand the core components of a 6-cavity automatic blow molding machine, here are some useful resources:

-

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding. -

Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding. -

Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes. -

PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles. -

Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

-

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines. -

Semi-Automatic Blow Molding Machines – iBottler

Ideal solutions for startups and small-scale PET bottle production. -

Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles. -

Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.