Choosing your preform mold cavities is a huge decision. A bad choice locks in high costs or low output for years. This guide will help you decide.

To choose the right preform mold cavitation, you must balance four factors: your annual production target, your injection molding machine's tonnage and specs, your upfront budget, and your long-term cost per preform. This guide helps you calculate the best choice.

| Key Decision Factor | Why It Matters (The Quick Version) |

|---|---|

| Production Target | This is your destination. It tells you how fast your "car" (mold) needs to be. |

| Injection Machine (IMM) | This is your engine. The mold must perfectly match your machine's power and size. |

| Budget (CapEx) | This is your upfront cash. A bigger mold costs more and needs a bigger, more expensive machine. |

| Cost Per Preform (OpEx) | This is your long-term profit. Higher cavities can mean lower cost per part, but only if you have the volume. |

| Energy Efficiency | A big machine on a small mold wastes massive amounts of electricity and kills your profit. |

This single number, "how many cavities," is a complex choice. It affects everything from your factory layout to your profit margin. I've seen this decision make or break a new production line. Let's walk through my 16 years of experience, step-by-step.

Introduction: The Million-Dollar Question - How Many Holes to Punch?

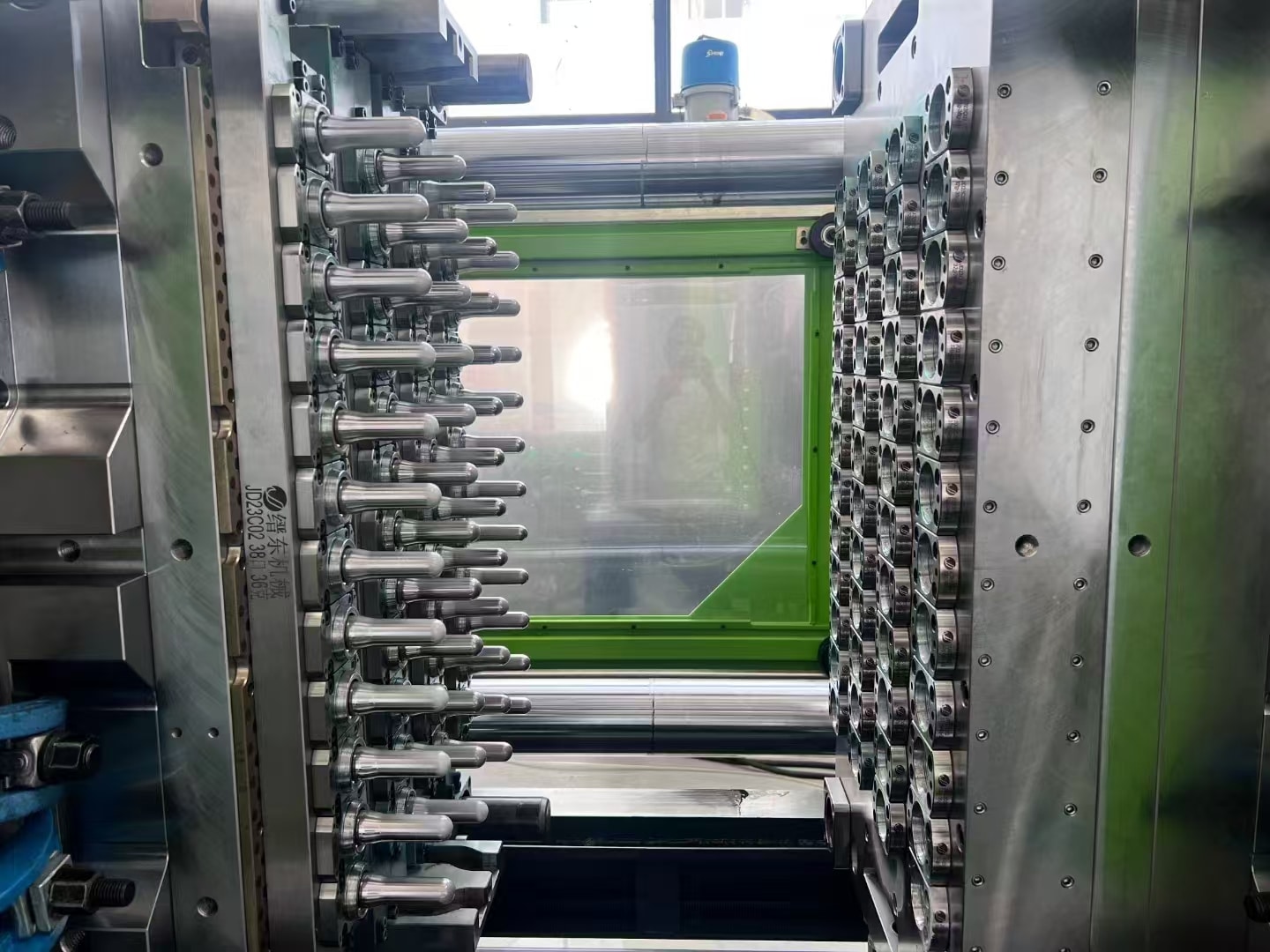

Buying a preform mold? The core decision is "how many cavities?". This choice impacts your price, efficiency, and even your required injection machine.

This isn't a guess. Choosing your preform mold cavitation is a scientific and financial decision. It determines your unit cost and production capacity for years. Get it wrong, and you've built in failure from day one.

This is the "million-dollar question" I ask every client. Why a million dollars? Because the answer—whether it's 16, 32, 72, or 96—sets off a chain reaction. This single number dictates the entire production system you must build.

This decision is not just about the price of the mold. It is about your entire production line.

- A 96-cavity mold requires a massive, high-tonnage Injection Molding Machine (IMM).

- That massive IMM requires a more powerful dryer, a larger chiller, and sometimes even a transformer upgrade for your factory.

- This entire system costs far more upfront than a 32-cavity line.

But, if you have the orders, that 96-cavity line will produce preforms at a much lower cost per piece.

I have been helping clients plan production lines for over 16 years. I have seen clients make costly mistakes in both directions.

I had a client in the Middle East. He wanted to save money, so he bought a 16-cavity mold. He was starting a water bottling business. His water was very popular. In his second year, his demand exploded. His 16-cavity mold ran 24/7, but he could not produce preforms fast enough. He was losing sales every day. He had to place an emergency order for a new 48-cavity mold. But the mold takes months to build. He lost more money in missed sales than he "saved" on that first mold.

I also had a client in Eastern Europe. He was very ambitious. He bought a 96-cavity line before his business even launched. He overestimated his sales. His order volume was too low. That giant, expensive 96-cavity "money-printing machine" sat idle for 20 days a month. It became a huge financial burden. His depreciation and bank loan payments were eating him alive.

| The Mistake | Why It's a Mistake | The Result |

|---|---|---|

| Buying Too Small (e.g., 16-cav) | You cap your own growth. | Lost sales, angry customers, and the emergency cost of buying a second line. |

| Buying Too Big (e.g., 96-cav) | Your costs are too high for your sales volume. | Negative cash flow. The machine sits idle, but depreciation and loan payments continue. |

This article is my summary of those 16 years of experience. It is a guide to help you calculate your perfect number, not your competitor's.

Why Cavitation Matters: The Simple Math of Output & Cost Per Preform?

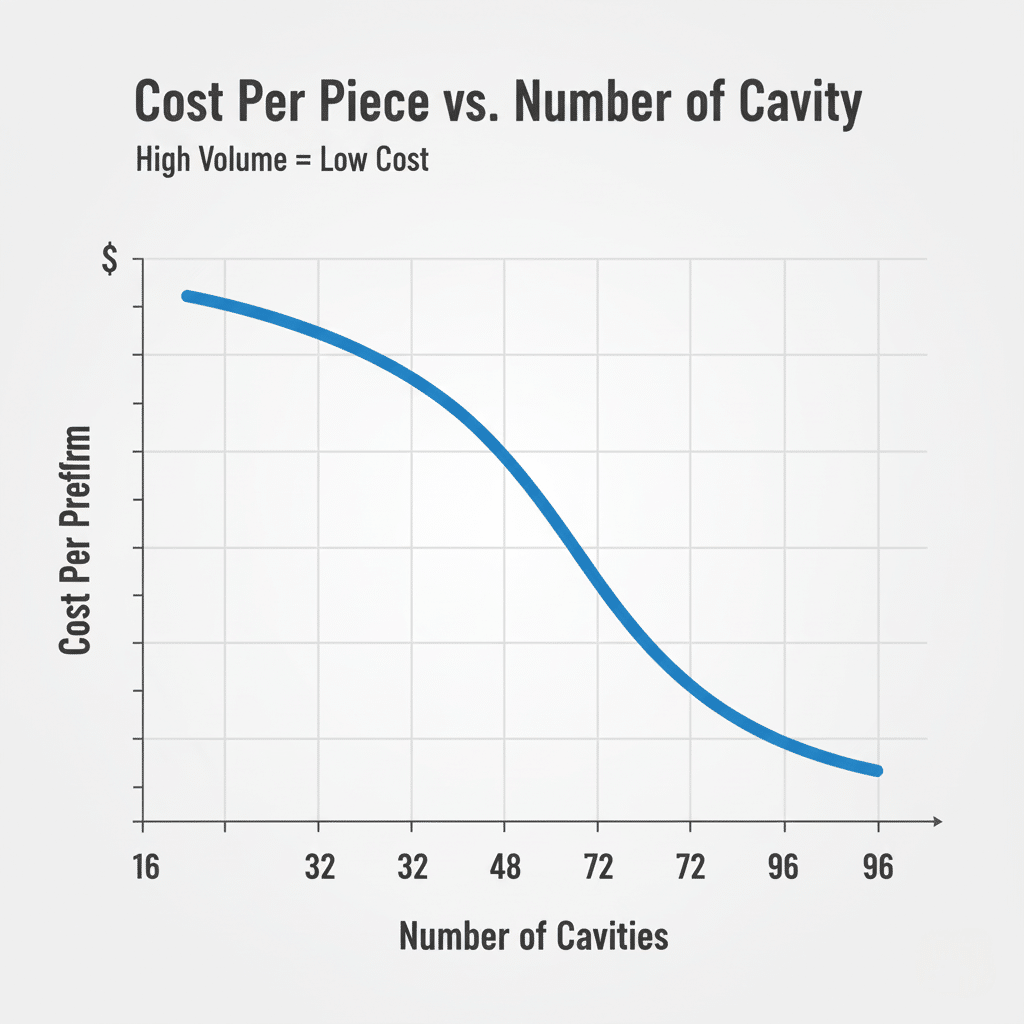

Think more cavities just means more output? It's really about your unit cost. Higher cavitation, if used fully, drastically cuts your cost per preform.

Higher cavitation (e.g., 32 vs. 16) doubles your output per cycle. This spreads fixed costs like labor, electricity, and mold depreciation across more products. Your long-term unit cost drops significantly.

Let's look at the simple math.

First, there is the output. The formula is basic:

Hourly Output = (3600 seconds / Cycle Time in seconds) * Number of Cavities

Let's assume an average cycle time of 15 seconds. Look at how the output explodes.

| Mold Cavitation | Cycles per Minute | Output per Hour | Output per Day (24h) |

|---|---|---|---|

| 16 Cavities | 4 | 3,840 | 92,160 |

| 32 Cavities | 4 | 7,680 | 184,320 |

| 48 Cavities | 4 | 11,520 | 276,480 |

| 72 Cavities | 4 | 17,280 | 414,720 |

| 96 Cavities | 4 | 23,040 | 552,960 |

As you can see, a 96-cavity mold produces six times more product than a 16-cavity mold in the same amount of time. This is obvious.

But the real magic is in the Cost Per Preform.

Your total cost is made of Fixed Costs and Variable Costs.

Cost Per Preform = (Total Fixed Costs + Total Variable Costs) / Total Preforms Produced

- Fixed Costs: These do not change. Examples: Operator's salary, factory rent, mold/machine depreciation.

- Variable Costs: These change with production. Example: PET resin, electricity.

Cavitation has a massive impact on your fixed costs per preform.

Think about Labor Cost. You pay one operator (let's say $20/hour) to watch one injection machine.

- With a 16-cavity mold: That operator costs you

$20 / 3,840 preforms= $0.0052 per preform. - With a 96-cavity mold: That same operator costs you

$20 / 23,040 preforms= $0.0008 per preform.

Your labor cost per preform just dropped by 85%! The same logic applies to your mold depreciation. A 96-cavity mold is not 6x the price of a 16-cavity mold (it's maybe 3-4x). But it produces 6x the product.

This is called Economies of Scale. In simple terms, higher cavitation, when used fully, gives you powerful economies of scale. Your long-term unit production cost becomes much lower.

But this brings us to the single most important condition: Your order volume must be large enough to keep this 'money-printing machine' running. A 96-cavity mold sitting idle is just an expensive piece of steel. This is why our first factor is your production target.

Factor #1: Your Production Target - How Many Million Preforms Per Year?

Don't know your annual production target? You are driving without a destination. You cannot choose the right mold if you don't know your target.

Your annual production target is the starting point. We use this "end goal" to work backward. It tells us how many cavities you need to hit your goal.

I always ask clients this first: What is your finish line? We must first define the destination. Then we can build the car to get you there.

How do you calculate this target? It depends on your business.

Case 1: You are a bottler (Captive Use). You make preforms for your own water, juice, or oil bottles. This is easy to calculate.

Formula: (Daily Bottles Sold * 365 days) * 1.03 (for 3% scrap/waste)- Example: You sell 200,000 bottles of water per day.

Target = (200,000 * 365) * 1.03 = 75,190,000- Your annual target is 75.2 million preforms.

Case 2: You sell preforms (Market Use). This is much harder. You cannot just guess. You must have real forecasts or contracts from your customers.

My Pro-Tip: Plan for Year 3

This is my core advice. Do not buy a mold based on today's sales. Buy a mold based on your projected sales for Year 3.

- Why not Year 1? It is too short-sighted. You will outgrow your mold in 12 months, like my client in the Middle East.

- Why not Year 10? It is too speculative. The market changes. Technology changes. You risk buying a giant mold that you will never fully use.

- Year 3 is the "sweet spot". It gives you room to grow but is still a realistic business plan.

So, let's say your "Year 3 Target" is 100 million preforms. Now we can work backward.

Daily Target = 100,000,000 / 365 days = 273,972 preforms per day

BUT! Your factory is not a robot. It does not run 24/7/365. You have holidays. You have machine maintenance. You have mold changes.

A well-run factory has an OEE (Overall Equipment Effectiveness) of about 85%.

So, your real daily target must account for this.

Real Daily Target = 273,972 / 0.85 (OEE) = 322,320 preforms per day

Now, look back at Table 1.

- A 48-cavity mold makes 276,480/day. (Too small)

- A 72-cavity mold makes 414,720/day. (Looks right. It hits your target and gives you some extra capacity).

| Your 3-Year Annual Target | Avg. Daily Preforms Needed (at 85% OEE) | Recommended Cavitation (at ~15s cycle) |

|---|---|---|

| 30 million | ~97,000 | 16 Cavities |

| 50 million | ~161,000 | 24 Cavities |

| 75 million | ~242,000 | 32-48 Cavities |

| 100 million | ~322,000 | 48-72 Cavities |

| 200 million | ~645,000 | 96 Cavities (or 2x 48-cav lines) |

| 300 million+ | ~967,000 | 128 Cavities (or 2x 72-cav lines) |

This table gives you a starting point. Your target is the first piece of the puzzle. Now we have to see if you have the engine to run it.

Factor #2: Your Existing Powerhouse - Matching the Mold to Your Injection Molding Machine (IMM)?

Have an existing Injection Molding Machine? You can't just buy any mold. A mismatch will fail, costing you time, money, and possibly damaging your equipment.

Your IMM's specifications are the most important technical limit. We must match the mold to your machine's tonnage (clamping force), shot weight, and platen size.

This is the most critical technical check. I call this the "horse and cart" problem. The mold is the cart, and the IMM is the horse.

- You cannot put a giant cart (96-cavity mold) on a small horse (150-ton IMM). The horse cannot pull it.

- You should not put a tiny cart (8-cavity mold) on a giant racehorse (500-ton IMM). It is a huge waste of power. (We will cover this in Factor 6).

If you already have an IMM, your decision is 80% made for you. We just need to find the biggest, most efficient how many cavities preform mold your machine can safely run.

When a client gives me their IMM specs, I check four critical things:

- Clamping Force (Tonnage): This is the "squeeze" power. The IMM must hold the mold shut against the extreme pressure of the plastic injection. If the tonnage is too low, the mold will be pushed open by a tiny amount, creating "flash" (thin plastic around the preform). This is a fatal defect.

- Shot Weight (Shot Size): This is the "meal size." The machine must be ableto melt and inject enough total plastic in one "shot."

Total Shot = (Preform Weight * Cavities) + (Runner Weight)- If your machine's max shot is 800g, you cannot run a mold that needs 900g. Your preforms will be incomplete ("short shots").

- Platen Size & Tie Bar Spacing: This is the "door frame." Your mold is a big block of steel. It must physically fit between the four giant posts (tie bars) of the machine.

- Plasticizing Rate (kg/hr): This is the "cooking speed." It measures how fast the machine can melt PET resin. If your 72-cavity mold consumes 400kg of PET per hour, but your machine can only melt 350kg/hr, you have a problem. You will be forced to add seconds to your cycle time, waiting for the plastic to melt. You will lose all your efficiency.

Just as the prompt says, I often see a client with a 280-ton machine. For a common 15g water preform, they might be able to run 48 cavities. But it would be pushing the machine to 100% of its limits. This is not healthy. A 32-cavity mold is a much more stable, reliable, and efficient choice for that machine.

| IMM Tonnage (Est.) | For 30/25 Water Preform (~15g) | For PCO1881 CSD Preform (~21g) |

|---|---|---|

| 160 - 200 Tons | 16 - 24 Cavities | 12 - 16 Cavities |

| 250 - 280 Tons | 24 - 32 Cavities | 16 - 24 Cavities |

| 320 - 380 Tons | 32 - 48 Cavities | 32 Cavities |

| 450 - 500 Tons | 72 Cavities | 48 Cavities |

| 550 - 700 Tons | 96 Cavities | 72 Cavities |

This is why we have a huge database of mold and machine matching dimensions. We can ensure a perfect fit.

Factor #3: Your Budget Realities - Upfront Investment vs. Long-Term ROI?

Just looking at the mold's price tag? This is a huge mistake. A bigger mold requires a bigger, more expensive machine and support system.

You must compare the Total Upfront Investment (CapEx) against the Long-Term Return (ROI). A more expensive 48-cavity line might pay for itself in one year if your volume is high enough.

Let's talk about the real cost. This is your Upfront Investment, or Capital Expenditure (CapEx).

When you decide to buy a 48-cavity mold instead of a 24-cavity, you are not just paying the price difference for the mold. You are buying a whole new system.

Look at this cost comparison.

| Item | Scenario A: 24-Cavity Line | Scenario B: 48-Cavity Line | Notes |

|---|---|---|---|

| Preform Mold | ~$50,000 | ~$90,000 | Price does not scale 1:1 |

| IMM | ~250 Ton (e.g., $90,000) | ~380 Ton (e.g., $150,000) | The machine is a huge cost jump |

| Dryer | 300 kg/hr (e.g., $15,000) | 600 kg/hr (e.g., $25,000) | Must feed twice the plastic |

| Chiller | 25 HP (e.g., $15,000) | 50 HP (e.g., $25,000) | Must cool a much bigger mold |

| Robot | Standard (e.g., $10,000) | Standard (e.g., $10,000) | Cost is similar |

| TOTAL CapEx | ~$180,000 | ~$300,000 |

In this example, the number of cavities doubled. But your total upfront investment increased by $120,000.

Now, you must ask the ROI (Return on Investment) question: Is spending that extra $120,000 a good decision?

This is when we look at your Operating Expenditure (OpEx), or your long-term cost.

Let's go back to our labor example.

- Annual Labor Savings: The 48-cavity line needs the same one operator as the 24-cavity line, but it produces twice the product. You just saved one full operator's salary on the night shift. Let's say that's $40,000/year.

- Annual Energy Savings: The 48-cavity line is more efficient per preform. Let's say this saves you $20,000/year.

- Total Annual Savings: $60,000

Payback Period = (Extra Investment) / (Annual Savings)

Payback = $120,000 / $60,000 = 2 years

This means that after 2 years, the 48-cavity line has paid for its extra cost. From Year 3 onward, it is $60,000 more profitable every year. If you have the orders, this is a brilliant investment.

But this calculation is what I used to help my startup client in Africa.

He wanted the 48-cavity line.

I showed him this math. I asked him: "Do you have the orders to run this 48-cavity line 24/7?" He said, "No, not in Year 1. Maybe in Year 3."

I said, "Then you cannot afford it. Your cash flow in Year 1 will be negative. You will be paying for a machine that is sitting idle."

We chose a 32-cavity mold. It cut his upfront CapEx by 30%. It let him be profitable in his first year. Two years later, he was successful and came back to buy a second 32-cavity line. That was the right choice for his budget and his business.

The Energy Efficiency Trap: Why Bigger Isn't Always Better?

Have a big, 500-ton machine lying around? Thinking of putting a small 16-cavity mold on it? This is like driving a semi-truck to buy milk.

The "big machine, small mold" mismatch is an energy disaster. A large IMM consumes huge power just to be "on." This will destroy your cost per preform.

This is the "big horse, small cart" analogy, and it's a trap I see clients fall into when they buy used equipment.

A client will call me and say, "Vivian, I got a great deal on a used 500-ton machine! Now I want to buy a 16-cavity preform mold for it."

My answer is always a strong "No."

Technically, can it work? Yes.

Economically? It is a financial disaster.

An IMM's energy use has a "base load." This is the power it uses just to stay on, heat the oil, and run the computers.

- The base load of a 500-ton machine is massive.

- The base load of a 220-ton machine (which is the correct size for a 16-cavity mold) is small.

Think of it this way: A V8 truck idling at a red light burns more fuel than a 4-cylinder car driving 60 mph.

Let's look at the numbers.

| Scenario | A: Bad Match (Big Horse, Small Cart) | B: Good Match (Correct Size) |

|---|---|---|

| IMM Size | 500-Ton Machine | 220-Ton Machine |

| Mold Size | 16-Cavity Mold | 16-Cavity Mold |

| Machine Load | ~30% (Very Inefficient) | ~85% (Very Efficient) |

| Est. Power Use | ~50 kW/hr | ~28 kW/hr |

| Output per Hour | 3,840 Preforms | 3,840 Preforms |

| Cost per Hour (@ $0.15/kWh) | $7.50 | $4.20 |

| Energy Cost per Preform | $0.00195 | $0.00109 |

Look at that last row. This is the killer.

You are making the exact same product. But in Scenario A, your electricity cost for every single preform is 79% higher.

Your competitor, who is using the correct (Scenario B) setup, is making more profit than you on every single bottle. You will never win a price war. You are losing money on every cycle.

The lesson is simple: You must match the mold and the machine. Do not try to "save money" by using a mismatched machine.

Finding Your Sweet Spot: A Case Study in Optimization?

Stuck between a low-cost, low-output 24-cavity and a high-cost, high-output 48-cavity? This decision feels impossible. But it's just a math problem.

Your "sweet spot" is the perfect balance of all these factors. It is the option that meets your 3-year production target at the lowest total cost.

So, how do we find your perfect number?

There is no "best" cavitation. There is only the "best" cavitation for you.

I call this finding the "sweet spot." It's where all the factors we discussed—Target, Machine, Budget, and ROI—all come together.

Let me show you with a real case study.

- The Client: A large beverage co-packer in Southeast Asia.

- The Asset: They had an idle 350-ton European-brand IMM. It was in great condition from a previous project.

- The Goal: They won a new contract and needed to add a preform line for a 23g PCO1881 preform.

- The Question: "Vivian, what is the best mold to put on this 350-ton machine?"

We did not guess. We ran the calculations.

- Option 1: 32-Cavity Mold.

- Calculation: Total shot weight = ~800g.

- Result: This would only use ~65% of the machine's injection capacity. It would under-utilize the clamping force. This is the "big horse, small cart" problem. It's inefficient.

- Option 2: 72-Cavity Mold.

- Calculation: Total shot weight = ~1750g.

- Result: The machine's max shot was only 1300g. The clamping force was also too low. Impossible.

- Option 3: 48-Cavity Mold.

- Calculation: Total shot weight = ~1200g.

- Result: This uses ~90% of the machine's injection capacity. The required clamping force was a perfect match for the 350-ton press. The required plasticizing rate (~265 kg/hr) was a perfect match for the machine's spec (~280 kg/hr).

This was the "sweet spot."

This 48-cavity solution was perfect.

- It put their idle asset (the 350-ton machine) to work at its peak efficiency.

- It maximized their output and minimized their cost per preform.

- It saved them from buying a new, smaller machine.

- It perfectly matched their new production target.

That is optimization. We did not just "sell a mold." We provided the most profitable solution for that client's specific situation.

Let Us Help You Calculate Your Optimal Cavitation?

Still staring at spec sheets and quotes? Guessing is gambling. A wrong choice now will cost you thousands every month for the next decade.

This is a complex math problem with one "best" answer for you. Stop guessing. Let our experts calculate it. We can provide a free report.

Choosing how many cavities your preform mold should have is a complex calculation. It is not a standard answer.

Your competitor's number is not your number. Their machine, their order volume, their preform neck size, and their electricity costs are all different from yours.

So, let us help you.

As part of our service, we provide a free "Cavitation Optimization & ROI Report" for all serious clients.

Here is how it works:

You Provide Us With:

- Your preform drawing or sample (weight and neck finish are key).

- Your 3-Year Annual Production Target (in millions).

- Your existing IMM specs (if you have one) or your planned IMM brand.

- Your factory's approximate cost of electricity (e.g., $0.10 / kWh).

We Will Provide You With (For Free):

- A clear comparison of 2-3 different cavitation options (e.g., 32 vs 48).

- The exact IMM Tonnage and specs required for each option.

- An estimated CapEx (Total Upfront Cost) for each line.

- An estimated OpEx (Cost Per Preform) for each line.

- A clear ROI Payback calculation.

- Our final, expert recommendation for your "sweet spot."

Why do we do this?

Our business is built on long-term partnerships. If your production line is efficient and profitable from Day 1, you will be successful. When you succeed, you will grow. And when you grow, you will come back to us for your next preform mold and blow bottle mold. We succeed when you succeed.

Stop guessing. Contact us today. Let's get this foundational decision 100% right.

Conclusion

Choosing the right cavitation is not a guess. It is a calculation. It balances your target, your machine, your budget, and your long-term ROI.

| Decision Factor | Key Question | My Pro-Tip |

|---|---|---|

| Production Target | How many preforms do I need to make? | Use your 3-year forecast. Then divide by 0.85 (for OEE) to find the true capacity you need. |

| Machine Matching | What machine do I need? | The mold and machine are a system. Match tonnage, shot weight, and platen size perfectly. |

| Budget (CapEx) | How much will it cost? | Calculate the Total System Cost (Mold + IMM + Dryer + Chiller), not just the mold price. |

| ROI (OpEx) | Is a bigger mold worth it? | Calculate the payback period. (Extra Cost) / (Annual Savings). If it's < 2-3 years, it's a good investment. |

| Energy Trap | Can I use my big machine for a small mold? | NO. This is the "big horse, small cart" trap. You will lose your profit on high electricity bills. |

| The "Sweet Spot" | What is the final answer? | It's unique to you. Let us calculate it for you. |

Frequently Asked Questions (FAQ)

Q: Does higher cavitation always mean a shorter cycle time?

A: Not necessarily. While the mold itself might be designed for speed, the actual cycle time is often limited by the injection molding machine's plasticizing capacity (how fast it can melt plastic) and clamping speed, as well as the cooling efficiency.

Q: What is the minimum cavitation you recommend for starting a preform business?

A: It depends heavily on your target market and volume. For a small-scale startup, sometimes a 4 or 8-cavity mold paired with a smaller, efficient IMM can be a good starting point to minimize initial investment.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr