Introduction to the World of Bottle Blowing Machines

The manufacturing industry is constantly evolving, with machines at its core. Among these machines, bottle blowing machines play a crucial role in sectors like food and beverage, pharmaceutical, and cosmetic. They transform preforms into the desired bottle shapes using air pressure.

Understanding the Importance of Bottle Blowing Machines

Bottle blowing machines cater to a wide range of industries, contributing significantly to the economy. With the right machine, businesses can effectively meet customer demands, uphold quality, and scale their production.

Different Types of Bottle Blowing Machines

Bottle blowing machines come in different types, including injection, extrusion, and stretch blow molding machines. Each type is suited to different production needs and budgets.

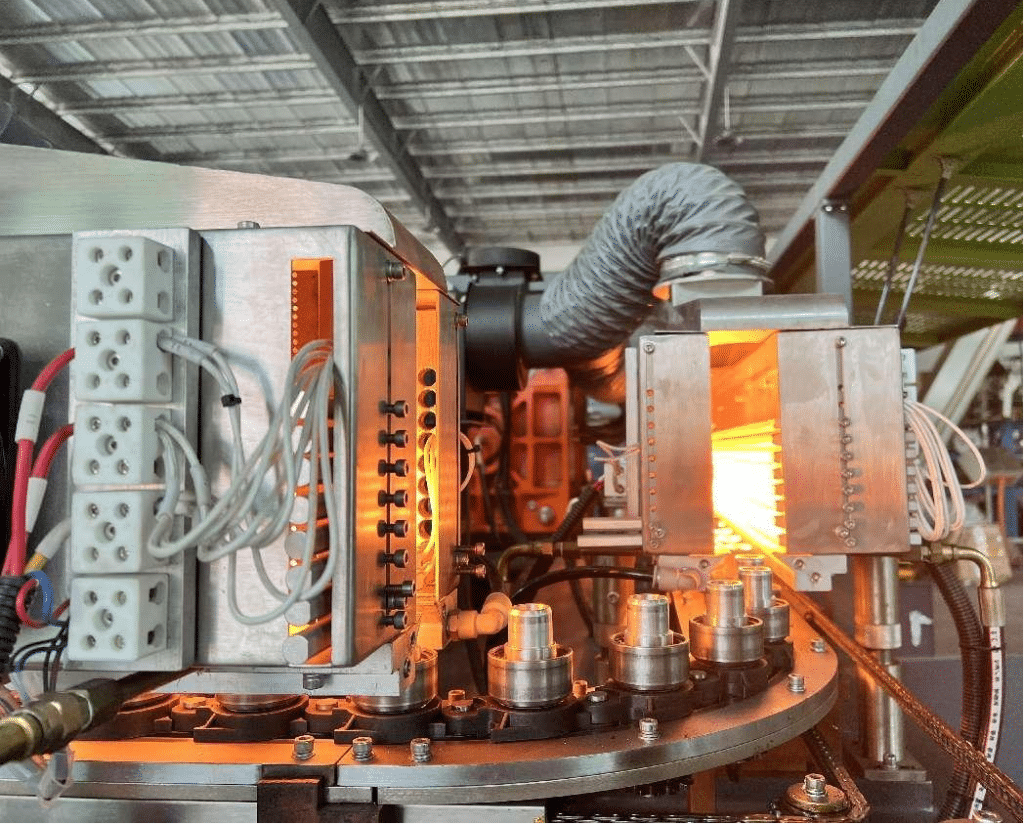

The Mechanism Behind Bottle Blowing Machines

These machines operate by heating preforms, then using air pressure to inflate them against a mold, creating the desired bottle shape.

The Ten Key Factors to Consider When Purchasing a Bottle Blowing Machine

Investing in a bottle blowing machine is a significant decision. It requires careful consideration of several factors.

Factor 1: Machine Capacity

Consider your production requirements. The machine capacity should align with your desired output.

Factor 2: Efficiency

Efficiency impacts productivity. A high-efficiency machine can reduce waste and increase production speed.

Factor 3: Machine Size and Space Considerations

Ensure the machine fits within your facility, and that there’s adequate space for operation and maintenance.

Factor 4: Automation Level

Full-automatic machines can save labor costs but may have a higher initial cost compared to semi-automatic machines.

Factor 5: Durability and Maintenance

The machine should be durable and easy to maintain, to avoid frequent downtimes.

Factor 6: Price and Value

Look for a machine that offers value for money. It may not always be the cheapest option.

Factor 7: After-Sale Support and Service

Choose a manufacturer that provides excellent after-sale service and technical support.

Factor 8: Bottle Volume and Shape Flexibility

The machine should be flexible enough to cater to different bottle shapes and volumes as per market demands.

Factor 9: Machine’s Energy Consumption

Energy-efficient machines can save operational costs in the long run.

Factor 10: Manufacturer’s Reputation

The manufacturer’s reputation can give you an insight into the machine’s quality and the service you can expect.

Introducing Zhongshan Jindong Machinery Co., Ltd.

As a key player in the manufacturing industry for over 20 years, Zhongshan Jindong Machinery Co., Ltd. specializes in bottle blowing machines, molds, and complete production lines.

Our History

Founded 20 years ago, our company has grown into a reputable industry leader. We operate from an 8000 sqm factory and have a dedicated team of around 50 skilled employees.

Our Products and Services

We offer top-quality bottle blowing machines, molds, and complete production lines, from injection molding to bottle filling.

Why Choose Zhongshan Jindong Machinery Co., Ltd.?

Our products are recognized for their quality, efficiency, and durability. We serve a diverse client base across Southeast Asia, Europe, and America. We pride ourselves on our excellent after-sales service, ensuring every client receives the support they need.

Connect with Us

To learn more about how we can meet your production needs, visit us at www.ibottler.com. We’re ready to help you select the best bottle blowing machine that fits your requirements and budget.

Visit us now: www.ibottler.com

Common FAQs

- What industries do we cater to? We cater to a diverse range of industries, including food and beverage, pharmaceutical, and cosmetic.

- Do we provide after-sales services? Yes, we provide excellent after-sales services and technical support.

- Can our machines produce different types and sizes of bottles? Yes, our machines are flexible and can cater to different bottle shapes and volumes.

- Where are our clients located? We serve clients across Southeast Asia, Europe, and America.

- How can you contact us? You can reach us through our website: www.ibottler.com.