Struggling with high shipping costs and breakage for your olive oil? You're not alone. The traditional glass bottle, while beautiful, is becoming a logistical and financial burden for many brands.

The primary reasons for this shift are significant cost savings in logistics, greater design freedom for branding, superior product protection with modern technology, and a surprisingly stronger case for sustainability from a full-lifecycle perspective.

For years, glass has been the undisputed king of premium packaging. It feels substantial. It communicates quality. But in today's fast-moving global market, tradition is being challenged by practicality. I've been in this industry for 16 years, and I've seen the conversation shift dramatically. Brands are no longer just asking "What looks best?" They're asking "What works best for our bottom line, our brand, and our planet?" This article will walk you through the exact reasons why so many are finding the answer is PET.

The End of an Era? Why is the Timeless Glass Bottle Facing New Challenges?

Your glass bottles look amazing on the shelf, but behind the scenes, are they causing headaches? The high costs of shipping and losses from breakage are eating into your profits.

Glass bottles are facing challenges due to massive logistical costs from weight and fragility, inflexibility in retail handling, and rising production costs tied to energy-intensive manufacturing processes, making them less viable in the modern market.

I've been in the PET blow molding industry for 16 years. During that time, I've had countless conversations with brand managers, especially those focused on exports. A recurring theme is how their profits are being squeezed by things outside their control. I've personally witnessed how brands, particularly those exporting their products, see their margins get eaten away by soaring sea freight charges and insurance claims for broken shipments. The elegance of a glass bottle feels very heavy when you're staring at a spreadsheet filled with these kinds of costs. The ground is shifting, and what was once a symbol of pure quality is now becoming a source of significant business pain.

The Supply Chain Pain Point

Glass is heavy. That's a simple fact with huge financial consequences. Think about a standard 40-foot shipping container. You are paying to ship the weight of the container, your product, and the packaging. When the packaging itself is a major contributor to that weight, your cost per unit skyrockets. A typical 750ml glass olive oil bottle can weigh around 500-600 grams when empty. The equivalent PET bottle? Maybe 50 grams. That's a 90% reduction in packaging weight.

This weight difference has a cascading effect on your entire supply chain.

- Freight Costs: Whether by sea, rail, or truck, you pay by weight. Lighter packaging means you can either ship more units for the same cost or simply pay less for the same number of units.

- Breakage and Spoilage: Glass breaks. It's an unavoidable part of the business. Even with careful packing, a 1-3% breakage rate is often considered standard. Every broken bottle is a total loss of both the product and the packaging. Furthermore, a single broken bottle can leak and ruin the labels of surrounding bottles, creating even more unsellable stock. This isn't just a loss; it's a messy, labor-intensive problem to clean up.

- Labor and Handling: Heavier boxes require more effort to load, unload, and move around a warehouse. This can lead to slower operations and an increased risk of workplace injuries.

I’ve seen financial models where the switch to PET reduced total logistics costs by over 30%. For a company shipping dozens of containers a year, that saving goes directly to the bottom line.

The Retail and Safety Pain Point

The challenges don't end when the product leaves your warehouse. For retailers, glass presents its own set of problems. Stocking shelves with heavy glass bottles is physically demanding for employees. A dropped bottle isn't just a simple cleanup; it's a safety hazard. The store has to block off the aisle, clean up sharp glass shards, and dispose of the waste carefully. This is a liability that retailers are increasingly wary of.

From the consumer's perspective, an unbreakable bottle is a huge plus. Think about a busy family kitchen. A PET bottle can be knocked off the counter without shattering into a dangerous mess. This peace of mind is a powerful, though often unspoken, selling point. In e-commerce, where packages are handled by multiple carriers and often dropped on doorsteps, an unbreakable olive oil bottle significantly reduces customer complaints and returns due to shipping damage.

The Rising Cost Pain Point

The manufacturing of glass is an incredibly energy-intensive process. It requires melting sand, soda ash, and limestone at temperatures exceeding 1500°C (2700°F). As global energy prices continue to rise and carbon taxes become more common, the production cost of glass is on a steady upward trend. This cost is, of course, passed on to you, the brand owner.

PET production, while also energy-dependent, is generally less intensive. The raw material is derived from petroleum, but the conversion into bottles happens at much lower temperatures. This gives PET a more stable cost structure compared to the volatility of glass manufacturing. When you're planning your budget for the next five years, having a more predictable packaging cost is a significant strategic advantage.

| Challenge Area | Glass Bottles | PET Bottles |

|---|---|---|

| Weight (750ml) | ~500-600g | ~40-50g |

| Typical Breakage Rate | 1-3% | < 0.1% |

| Energy Requirement | Very High (Melting at >1500°C) | Moderate (Processing at ~250°C) |

| Retail Handling | Heavy, risk of shattering | Lightweight, safe |

| Consumer Safety | High risk if dropped | Very low risk, shatterproof |

Advantage #1: Could You Really Slash Your Logistics Costs by over 30%?

Are you tired of seeing freight and damage claims destroy your profit margins? What if a simple packaging change could put that money back into your business for growth?

Yes, by switching from heavy, fragile glass to lightweight, durable PET, brands can slash total logistics costs. The savings come from dramatically lower shipping weights, near-zero breakage, and more efficient warehousing and handling.

Cost saving is the number one driver for every brand I've worked with on a glass-to-PET transition. It's the most immediate and measurable benefit. We once did a cost analysis for a medium-sized olive oil brand in Greece that exports about 100 containers a year to the United States. When we calculated the total savings from switching to PET, the numbers were staggering. The money they would save in just one year on ocean freight and damage replacement was enough to invest in a brand-new, fully automated filling line. That’s not just a cost saving; it’s a growth accelerator.

Deep Dive into Freight Savings

Let's break down the math. Logistics companies calculate shipping costs based on either volumetric weight or actual weight, whichever is greater. Because PET bottles can have thinner walls than glass, they can sometimes be designed to be slightly smaller externally for the same internal volume, but the biggest factor is always the actual weight.

Consider a standard pallet of olive oil.

- Glass Scenario: If a pallet holds 1,000 bottles, and each empty glass bottle weighs 550g, you have 550 kg of just packaging weight on that pallet before you even add the oil.

- PET Scenario: With a 50g PET bottle, that same pallet has only 50 kg of packaging weight. That's a 500 kg difference per pallet.

Now, multiply that by the 20 pallets you might fit in a 20-foot container. You've just removed 10,000 kg (10 metric tons) of dead weight from your shipment. When you're paying per kilogram for ocean or air freight, the savings are immediate and massive. This isn't a small optimization; it's a fundamental change to your cost structure.

The "Hidden Tax" of Breakage

We often accept in-transit damage as a cost of doing business with glass. But we shouldn't. It's a hidden tax on your revenue. Let's say your breakage rate is 2%. That sounds small. But it means that for every 100 bottles you ship, 2 are lost. If you ship 1 million bottles a year, that's 20,000 bottles of lost product and packaging. If your cost per bottle is $5, that’s a $100,000 loss right off the top.

With PET, the breakage rate is virtually zero. The material is incredibly resilient and can withstand being dropped or crushed without failing. This doesn't just save you the cost of the lost product. It also saves you:

- Insurance Premiums: Lower risk of damage claims can lead to lower insurance costs over time.

- Administrative Costs: You save the time and manpower needed to file claims, document losses, and arrange for replacement shipments.

- Reputational Damage: You avoid the negative experience for your distributors and retailers who receive damaged goods. A seamless, damage-free delivery enhances your reputation as a reliable supplier.

If you are experiencing issues with bottle performance, it might be due to a range of factors. We've compiled a guide on common PET blow molding defects and how to fix them, which can be a valuable resource.

Warehousing and Handling Efficiency

The benefits continue in the warehouse. Lighter packaging is easier and faster for your team to handle. This can improve loading/unloading times and reduce the physical strain on your employees. Because PET is shatterproof, you can also stack pallets higher and more densely, optimizing your warehouse space. Some of our clients have reported a 15-20% improvement in warehouse space utilization after switching from glass. This means you can either store more product in the same footprint or reduce your warehousing costs. The durability also means less risk of accidents and cleanups within your own facility, contributing to a safer and more efficient work environment.

Advantage #2: Can You Unleash Your Brand's Creativity with Design Freedom?

Does your standard glass bottle look just like every other brand on the shelf? You're fighting for attention with packaging that limits your creativity and blends in with the competition.

Absolutely. PET (polyethylene terephthalate) is far more versatile than glass in the molding process. It allows for intricate shapes, embossed logos, and unique textures that are difficult or prohibitively expensive to achieve with glass, enabling true brand differentiation.

Design is the silent salesman on the retail shelf. I remember working with a French brand of organic walnut oil. Their original glass bottle was generic and did nothing to convey the premium, artisanal nature of their product. They wanted their packaging to reflect their values of "nature and art." This was a perfect challenge for PET. We developed a custom PET bottle mold design that featured a subtle, elegant walnut-grain texture embossed on the shoulder of the bottle. The body itself mimicked the organic shape of a water droplet. When the new bottle launched in high-end supermarkets, it was an instant success. It stood out so much that they were able to increase the price by 15%, and their sales doubled. That is the power of design.

Breaking Free from the Cylindrical Mold

For centuries, glass bottle production has favored simple, symmetrical shapes like cylinders and rectangles. This is due to the nature of the glass blowing process. Creating complex, asymmetrical shapes or detailed surface features in glass is technically challenging and often results in higher rejection rates and costs.

PET blow molding is a far more precise and flexible technology. Because the process starts with a preform that is then inflated into a metal mold, we can achieve an incredible level of detail. This opens up a world of possibilities:

- Ergonomic Shapes: You can design bottles with integrated grips, curved bodies, or unique profiles that are more comfortable for the consumer to hold and pour.

- Embossed and Debossed Details: Your brand logo, quality seals, or decorative patterns can be directly molded into the bottle's surface. This adds a tactile, premium feel that a simple paper label cannot replicate. It also acts as a permanent branding element that cannot be peeled off or damaged.

- Unique Silhouettes: Want a bottle shaped like an olive? Or one with a twisting, sculptural form? With PET, these ambitious designs are not just possible; they are affordable. This allows your packaging to become a true icon for your brand.

We can even help you visualize these concepts quickly. Our process of using 3D printed samples for rapid validation allows you to hold a physical prototype of your custom bottle in your hands within days, not weeks.

The Power of Texture and Finish

Beyond just the shape, PET offers a range of options for the bottle's finish. While a crystal-clear, glass-like appearance is most common for showcasing the beautiful color of olive oil, you aren't limited to that.

- Frosted or Matte Finishes: A frosted effect can communicate a cool, modern aesthetic and make the bottle feel soft to the touch.

- Colored PET: We can introduce tints to the PET material itself, creating bottles in shades of green, amber, or even custom brand colors. This provides color consistency and eliminates the need for secondary processes like spray coating.

- High-Gloss Surfaces: Advanced polishing techniques for the blow bottle mold can create a PET bottle with a luster and clarity that is virtually indistinguishable from high-quality glass.

This ability to control shape, detail, and finish gives your brand a powerful toolkit to tell its story. You can create a package that looks and feels unique, justifying a premium price point and building a stronger connection with your customers.

Advantage #3: Can Modern Technology Offer Superior Product Protection?

You believe glass is the gold standard for preserving your olive oil's delicate flavor. You worry that plastic will compromise the quality you've worked so hard to achieve.

Yes. Modern PET bottle technology now offers protection that is equal to, and in some cases better than, glass. By using specialized UV-blocking additives and multi-layer barrier technologies, PET can effectively protect olive oil from degradation by both light and oxygen.

Technology is always moving forward. The idea that "PET bottles don't protect from light" is based on the technology of ten years ago. It's simply not true anymore. I've had so many conversations where clients are amazed to learn what's now possible. We can now engineer PET materials that provide top-tier UV and oxygen protection while remaining crystal clear. This allows brands to showcase the beautiful, translucent color of their oil without compromising its shelf life. It’s the best of both worlds, something that was once thought impossible.

Defeating the Enemy: UV Radiation

One of the biggest enemies of high-quality extra virgin olive oil is ultraviolet (UV) light. UV radiation triggers photo-oxidation, a chemical reaction that rapidly degrades the oil, destroying its healthy polyphenols and creating off-flavors. This is why olive oil has traditionally been packaged in dark green or amber glass bottles—the colored glass helps to block some of the damaging UV rays.

However, "some" is the key word. Standard green glass doesn't block all UV light. Modern PET technology offers a more complete solution.

- UV-Blocking Additives: During the manufacturing of the PET resin, we can blend in special, food-safe additives that act as powerful UV absorbers. These additives are completely invisible to the naked eye, so the bottle can remain perfectly clear.

- Targeted Protection: A PET bottle with these additives can be engineered to block over 99.9% of harmful UV radiation up to 380-400 nanometers, which is the most damaging part of the spectrum for olive oil. This is a level of protection that even dark glass often fails to achieve.

This means you are no longer forced to choose between showing off your product and protecting it. You can have a crystal-clear bottle that provides better UV protection than a traditional dark green glass bottle.

Winning the War on Oxygen

The second major enemy of olive oil is oxygen. Oxidation causes the oil to go rancid, developing stale, unpleasant flavors and smells. Glass is an excellent oxygen barrier because it is non-porous. For a long time, standard single-layer PET couldn't match this performance, which limited its use for products with a long shelf life.

This has been solved by multi-layer technology. Instead of making the bottle from a single layer of PET, we can create a preform that has a sandwich-like structure.

- The Barrier Layer: We embed an ultra-thin core layer of a high-barrier material like EVOH (Ethylene Vinyl Alcohol). EVOH is incredibly effective at blocking the transmission of oxygen gas.

- The Protective Layers: This EVOH layer is sandwiched between inner and outer layers of PET, which protect it and provide the bottle's structural integrity.

A multi-layer PET bottle can reduce oxygen ingress by a factor of 100 or more compared to a standard PET bottle. This gives it a shelf-life performance that is directly comparable to glass, ensuring your olive oil stays fresh and flavorful for its entire intended life. This technology is a game-changer and makes PET a truly viable option for even the most delicate, premium oils. It's a critical part of the PET bottle mold design process to ensure the final product meets these high standards.

| Protection Factor | Dark Glass Bottle | Standard PET Bottle | Enhanced PET Bottle |

|---|---|---|---|

| UV-B/UV-A Blocking | Good (absorbs most, but not all) | Poor (transparent) | Excellent (>99.9% with additives) |

| Oxygen Barrier | Excellent (impermeable) | Fair (suitable for short shelf-life) | Excellent (with multi-layer EVOH) |

| Physical Protection | Poor (fragile, shatters) | Excellent (shatterproof, durable) | Excellent (shatterproof, durable) |

| Product Visibility | Poor (hides the oil's color) | Excellent (crystal clear) | Excellent (crystal clear) |

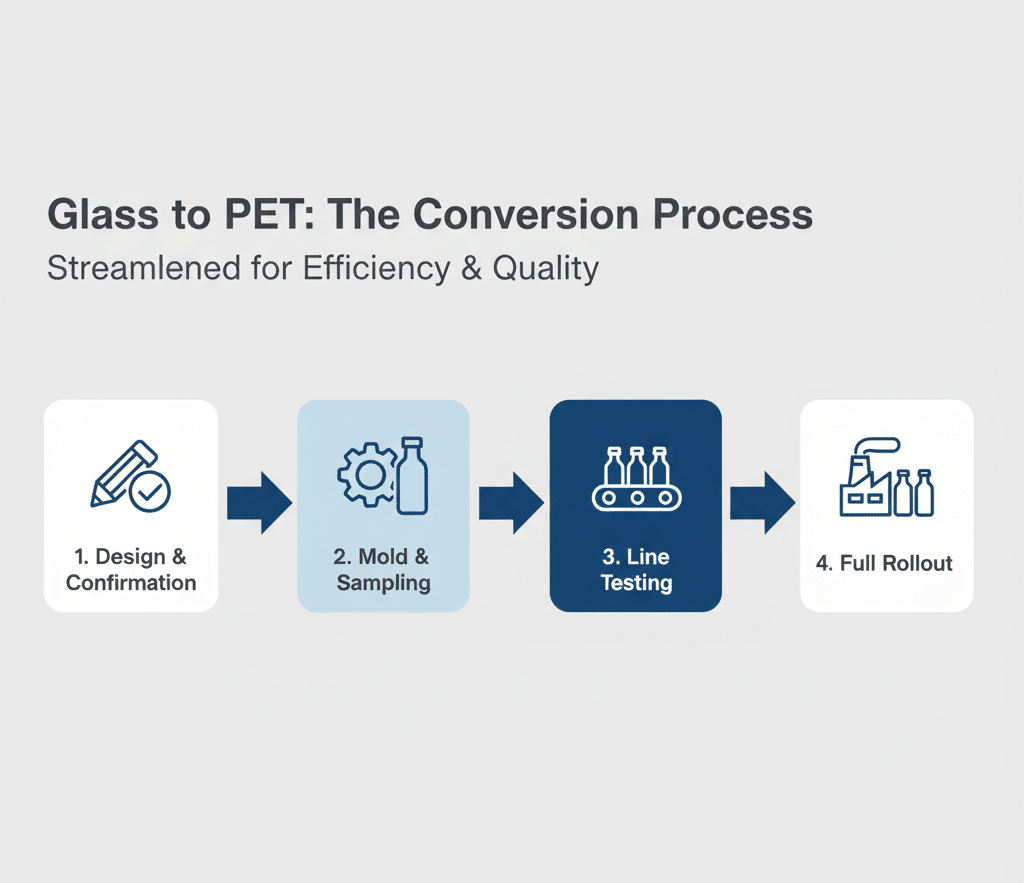

The Transition Plan: Is a 4-Step Guide Enough for a Seamless Switch?

You're intrigued by the benefits of PET, but the thought of changing your entire packaging process is overwhelming. You worry about compatibility with your existing machinery and the potential for costly downtime.

Yes, a structured 4-step process makes the transition smooth and predictable. It involves collaborative design, precision mold manufacturing, thorough testing, and a planned rollout, minimizing disruption and ensuring the new packaging works perfectly with your existing infrastructure.

The fear of the unknown is the biggest barrier for many brands. We recently helped a major Turkish olive oil exporter make the switch. Their biggest concern was, "Will these new PET bottles work with our existing Italian-made filling line?" It was a valid and critical question. Before we even started designing the bottle, our engineering team contacted the filling line manufacturer directly. We got all the technical specifications—the gripper dimensions, the conveyor spacing, the capping head torque. We then designed the PET bottle and the blow bottle mold to perfectly match those parameters. The result was a true "drop-in" solution. They didn't need to change a single major component on their line. This is what we mean by a seamless, "painless" switch.

Step 1: Bottle Design and Confirmation

This is the foundational stage where we work closely with your team. The goal is to define a PET bottle that meets your branding, performance, and operational needs.

- Replication or Redesign: We can start by creating a PET version that perfectly mimics your current glass bottle's shape and volume. This is the fastest route if you want to maintain brand continuity. Alternatively, this is the perfect opportunity to explore a new, unique design to refresh your brand's look, as we discussed earlier.

- Technical Specification: We analyze your production line. We need to know the exact dimensions of your existing bottle, especially the neck finish (the threads for the cap) and the base diameter. Making sure the new PET bottle fits your capper, labeler, and case packer is critical. Our guide on how to choose the right preform neck size is a great starting point for this conversation.

- Virtual and Physical Prototypes: We create 3D CAD models and renderings for your approval. Once the design is close, we can produce 3D printed samples. This allows you to hold the bottle, test its feel, and even run it on your line to check the fit before committing to expensive tooling.

Step 2: Mold Manufacturing and Sampling

Once the bottle design is finalized and approved, we move to manufacturing the production tool: the blow mold. This is a high-precision engineering process.

- Material Selection: Molds are typically made from aircraft-grade aluminum or steel, depending on the expected production volume and bottle complexity.

- Precision Machining: Using advanced CNC machines, we craft the mold cavities to the exact specifications of the bottle design. The surface finish of the mold is critical for ensuring the final bottle is crystal clear and flawless.

- Initial Sampling (T1): After the mold is complete, we run the first samples in one of our test machines. We check every dimension, the bottle's weight, and the overall quality. We send these first-off-the-tool samples to you for final approval.

Step 3: Small-Batch Production and Testing

With the T1 samples approved, we can run a small batch of a few thousand bottles. This is the crucial real-world testing phase.

- Line Trials: You run these bottles on your actual production line. This is the ultimate test of compatibility. We confirm that they feed, fill, cap, and label smoothly without any jams or errors.

- Shipping Tests: We recommend packing a few cases and sending them through your normal distribution channels. This verifies that your existing cartons and pallet configurations work well and protect the product during transit.

- Consumer and Market Feedback: This is a great opportunity to share the new packaging with key distributors, retailers, or a consumer focus group to gather feedback on the new look and feel before a full-scale launch.

Step 4: Full-Scale Production and Rollout

Once all the tests are passed and you give the green light, we move to full production.

- Production Scheduling: We coordinate with your team to manufacture the quantity of bottles you need, timed to align with your depletion of old glass bottle stock.

- Ongoing Support: We remain your partner. We have extensive knowledge on how to ensure your molds and blow molding machines are perfectly matched for optimal performance. We are always available to help troubleshoot any issues or plan for future packaging needs. This structured, collaborative approach removes the guesswork and risk, turning a potentially daunting project into a manageable and successful upgrade.

Overcoming the Final Hurdle: What About Consumer Perception?

You're sold on the cost and design benefits, but you're worried your customers will see a PET bottle and think "cheap." How can you maintain your premium brand image?

You overcome this by focusing on high-quality execution and strategic communication. A well-designed, heavy-feeling PET bottle with premium labeling, combined with marketing that highlights its practical and eco-friendly benefits, can successfully shift consumer perception from "plastic" to "modern."

Consumer perception is real, and it’s the most important hurdle to clear. But it is absolutely possible to guide that perception. I always say that the feeling of "premium" comes from the sum of the details, not just the raw material. When a customer picks up a PET bottle that has a substantial weight, a beautiful shape, a high-quality cap, and an elegant label, their brain doesn't register "cheap plastic." It registers "thoughtful, modern design." The conversation then shifts from the material to the experience. They appreciate that it won't break, that it's easier to handle, and when you tell them it has a lower carbon footprint, it becomes a point of pride.

Designing for a Premium "Hand-Feel"

The "cheap" feeling often associated with plastic comes from flimsy, thin-walled water bottles. We can combat this directly through design.

- Increased Preform Weight: By using a slightly heavier preform, we can create a bottle with thicker walls. This adds rigidity and weight, making the bottle feel more substantial and valuable in the hand. The difference between a 30g bottle and a 50g bottle is immediately noticeable to a consumer.

- Strategic Wall Thickness: We can design the blow bottle mold to distribute the plastic in specific ways, creating a thick, heavy base that gives the bottle stability and a premium feel, while keeping other areas thinner to save material.

- Quality Closures: The cap is a critical touchpoint. Pairing your PET bottle with a high-quality metal or well-finished plastic screw cap, or even a functional pouring spout, elevates the entire package. The sound and feel of opening and closing the cap contributes significantly to the perception of quality.

Communicating the "Why"

You cannot just change your packaging and expect customers to understand. You have to tell them the story and frame the change as an improvement.

- Focus on Practical Benefits: Your marketing messaging, both on the label and online, should highlight the consumer-focused advantages. Use phrases like "Shatterproof bottle for a safer kitchen," "Lightweight and easy to pour," or "Perfect for picnics, boating, and outdoor use." This turns the material into a feature, not a compromise.

- Highlight the Hidden Benefits: Educate your customers about the advanced technology inside the bottle. A small icon or a line of text saying "UV-blocking technology protects freshness" or "Advanced barrier preserves flavor" reassures them that quality and preservation are still your top priorities.

- Tell the Sustainability Story: As we'll see in the next section, PET has a strong environmental story to tell, especially regarding its lower carbon footprint in transport. This is a powerful message for environmentally conscious consumers and can become a key part of your brand identity.

By proactively managing the design details and the marketing message, you don't just overcome the perception hurdle; you can actually turn the switch to PET into a powerful branding advantage that positions you as a modern, innovative, and customer-focused company.

Sustainability: What is The Surprising Environmental Case for PET?

You've always believed that "glass is green" and "plastic is bad." The idea that PET could be a more sustainable choice for your olive oil seems completely backward.

From a full-lifecycle perspective, PET is often more sustainable than glass. Its lower weight drastically reduces carbon emissions during transport, and its manufacturing is less energy-intensive. When recycling is factored in, PET's overall environmental impact can be significantly lower.

This is a topic that surprises many of our clients. We're all conditioned to think glass is the ultimate recyclable material. While it's true that glass can be recycled endlessly without loss of quality, that's only one part of a much larger picture. When you look at the entire "cradle-to-grave" lifecycle of the packaging, from raw material extraction to final disposal, the data often favors PET. I've found that for the European and North American markets, where consumers and regulators are increasingly focused on ESG (Environmental, Social, and Governance) metrics, being able to tell a compelling carbon reduction story is becoming a major competitive advantage.

The Carbon Footprint of Weight

The single biggest environmental advantage of PET is its light weight. Transportation is a major source of greenhouse gas emissions. As we've already discussed, a truck or ship filled with PET-bottled oil is carrying tons less dead weight than the same vessel filled with glass-bottled oil.

Think about it this way:

- Less Fuel per Unit: Moving less weight requires less fuel. Less fuel burned means fewer carbon dioxide (CO2) emissions released into the atmosphere for every single bottle you ship.

- Global Impact: For a brand that exports globally, this adds up incredibly fast. The journey from a grove in Spain to a supermarket in Japan is thousands of miles long. Reducing the shipment weight by 10-20% results in a massive reduction in the product's overall carbon footprint.

This transportation efficiency is PET's environmental superpower. In a world rightly concerned about climate change, it's an advantage that is impossible to ignore.

Energy Consumption in Manufacturing

The second key factor is the energy required for production.

- Glass Manufacturing: As mentioned before, creating glass bottles requires melting raw materials at extremely high temperatures (around 1500°C). This process is fueled primarily by natural gas and is a major source of industrial CO2 emissions.

- PET Manufacturing: The process of creating PET bottles from resin (blow molding) happens at much lower temperatures (around 120°C to heat the preform). While the initial creation of the PET resin is energy-intensive, the overall energy profile per bottle is generally lower than for a glass bottle of the same size.

The Reality of Recycling

While glass is infinitely recyclable, the process still requires the collected glass (cullet) to be crushed, cleaned, and re-melted, which is another energy-intensive cycle.

PET, designated by the #1 recycling symbol, is the most widely recycled plastic in the world. The infrastructure for collecting and reprocessing PET is well-established.

- rPET (Recycled PET): Recycled PET flakes can be cleaned and reprocessed to create new food-grade containers. Using rPET to make new bottles requires significantly less energy and fossil fuel resources than creating virgin PET. Many brands are now proudly marketing their bottles as being made from 25%, 50%, or even 100% recycled content.

- Lower Recycling Energy: The process of recycling PET (chopping, washing, melting) is also less energy-intensive than re-melting glass.

When you combine the lower manufacturing energy, the dramatically lower transportation emissions, and a robust and energy-efficient recycling stream, the environmental case for PET becomes clear and compelling.

| Sustainability Metric | Glass Bottle | PET Bottle |

|---|---|---|

| Manufacturing Energy | Very High | Moderate |

| Transportation Carbon Footprint | High | Very Low (due to light weight) |

| Recyclability | Infinite (but energy-intensive) | High (less energy to reprocess) |

| Recycled Content Use | Common | Increasingly common (rPET) |

| Overall Lifecycle Impact | High, primarily from energy and transport | Lower, primarily from raw material |

Is It Time for Your Brand to Make the Switch?

You've seen the data on cost, design, protection, and sustainability. The case for PET is strong. But is it the right strategic move for your specific brand right now?

If you are facing pressure from rising shipping costs, want to differentiate your brand on crowded shelves, and wish to improve your environmental credentials, then it is absolutely the right time to seriously evaluate a switch from glass to PET.

Making the move from glass to PET is more than just swapping out one type of container for another. It's a strategic business decision that impacts your finances, your marketing, and your supply chain. It’s an upgrade. This decision requires careful thought and data. That's where we can help. I encourage you not to make this decision on your own. Contact us, and we can provide a free Packaging Conversion Preliminary Assessment Report. All you need to do is provide a sample of your current glass bottle and your annual production volume. Our team will analyze it and give you a concrete report on your potential cost savings, design possibilities, and a clear roadmap for transition.

A Quick Recap of the PET Advantage

Let's summarize the key arguments we've covered. Switching from glass to PET for your premium olive oil offers:

- Massive Cost Savings: Primarily through a 90% reduction in packaging weight, which slashes shipping costs and virtually eliminates losses from breakage.

- Creative Branding Freedom: The flexibility of PET molding allows for unique shapes, embossed logos, and textures that make your product stand out.

- Modern Product Protection: Advanced UV-blocking and oxygen-barrier technologies ensure your oil's freshness and flavor are preserved as effectively as in glass.

- A Better Environmental Story: A lower carbon footprint from manufacturing and transportation provides a powerful, data-backed sustainability message for your customers.

- Enhanced Consumer Experience: A shatterproof, lightweight bottle is safer and more convenient for your customers to use in their daily lives.

Your Next Step

The market is not waiting. Consumer preferences are evolving, and logistical costs are only going to increase. The brands that thrive in the next decade will be the ones that are agile, forward-thinking, and willing to embrace modern solutions that benefit their business and their customers.

The question is no longer "Can PET protect premium olive oil?" The technology has already answered that with a resounding yes. The real question is, "Can your brand afford to ignore the immense logistical, financial, and marketing advantages of making the switch?"

Take the first step. Let's analyze your specific situation and provide you with the data you need to make an informed decision for the future of your brand.

Conclusion

Switching from glass to PET offers olive oil brands major cost savings, design freedom, and a stronger sustainability story, making it a smart, strategic upgrade for a modern market.

| Feature | Glass Bottle | PET Bottle | Key Advantage of Switching |

|---|---|---|---|

| Logistics | Heavy, fragile, high shipping cost | Lightweight, shatterproof, low shipping cost | >30% Cost Reduction |

| Branding | Limited to simple shapes | High design freedom (shapes, embossing) | Enhanced Shelf Appeal |

| Protection | Good (but often requires dark glass) | Excellent (with UV/Oxygen barriers) | Better protection with full visibility |

| Sustainability | High energy use, high transport CO2 | Lower energy use, low transport CO2 | Lower Overall Carbon Footprint |

| Consumer Use | Heavy, risk of breaking | Lightweight, safe, convenient | Improved Safety and Usability |

Frequently Asked Questions (FAQ)

Q: Will the taste of my premium olive oil be affected by a PET bottle?

A: No. Modern food-grade PET is completely inert and will not interact with or alter the taste of your oil. With added oxygen barriers, like a multi-layer structure containing EVOH, it preserves the oil's freshness and delicate flavor profile just as effectively as glass, protecting it from oxidation.

Q: What is the initial cost to switch from glass to PET?

A: The main initial cost is the investment in a new set of blow bottle molds. This is a one-time capital expense. However, the ongoing savings in material costs (PET bottles are often cheaper per unit than glass) and the significant reduction in shipping and damage costs typically lead to a full return on this investment (ROI) in as little as 12-18 months for most brands.

Q: Can PET bottles be hot-filled?

A: Standard PET has limitations with high temperatures, typically softening around 70°C (158°F). However, for edible oils or other products that require hot filling, we can use special heat-set PET materials and production processes. By designing specific heat-resistant molds and using a specialized bottle blowing machine, we can create bottles that handle fill temperatures up to 85-90°C (185-194°F) without distortion.

Q: Are PET oil bottles recyclable?

A: Yes, absolutely. PET is one of the most widely recycled plastics in the world, designated by the #1 recycling symbol. The global infrastructure for PET recycling is well-established. To ensure proper recycling, empty oil bottles should be rinsed to remove residue before being placed in recycling bins. This prevents contamination and allows the material to be efficiently reprocessed into rPET for use in new bottles and other products.

Q: Do I need a new filling line to switch to PET bottles?

A: Not always. This is a major concern for many brands, and we address it early in the process. In many cases, our engineers can design the PET bottle's exterior dimensions, base, and neck finish to be perfectly compatible with your existing glass bottle filling line. We conduct a thorough technical audit of your equipment to ensure a seamless, "drop-in" transition that minimizes downtime and avoids major new capital investment.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr