Key Takeaways: China's PET Mold Sourcing

| Feature | Zhejiang (Mainly Taizhou/Huangyan) | Guangdong (Shenzhen, Dongguan, Zhongshan) |

|---|---|---|

| Primary Identity | "The Mold Supermarket" | "The High-End Department Store" / "Engineering Hub" |

| Core Strength | Extreme cost-performance, speed, high volume | High quality, high precision, technology, reliability |

| Best For | Standard bottles, cost-sensitive projects | Complex designs, hot-fill, high-speed machines, low TCO |

| Main Risk | Inconsistent quality (requires high QC) | Higher initial investment |

| My Advice | A "paradise" if you have strong project management. | Your first choice for "high quality + low risk". |

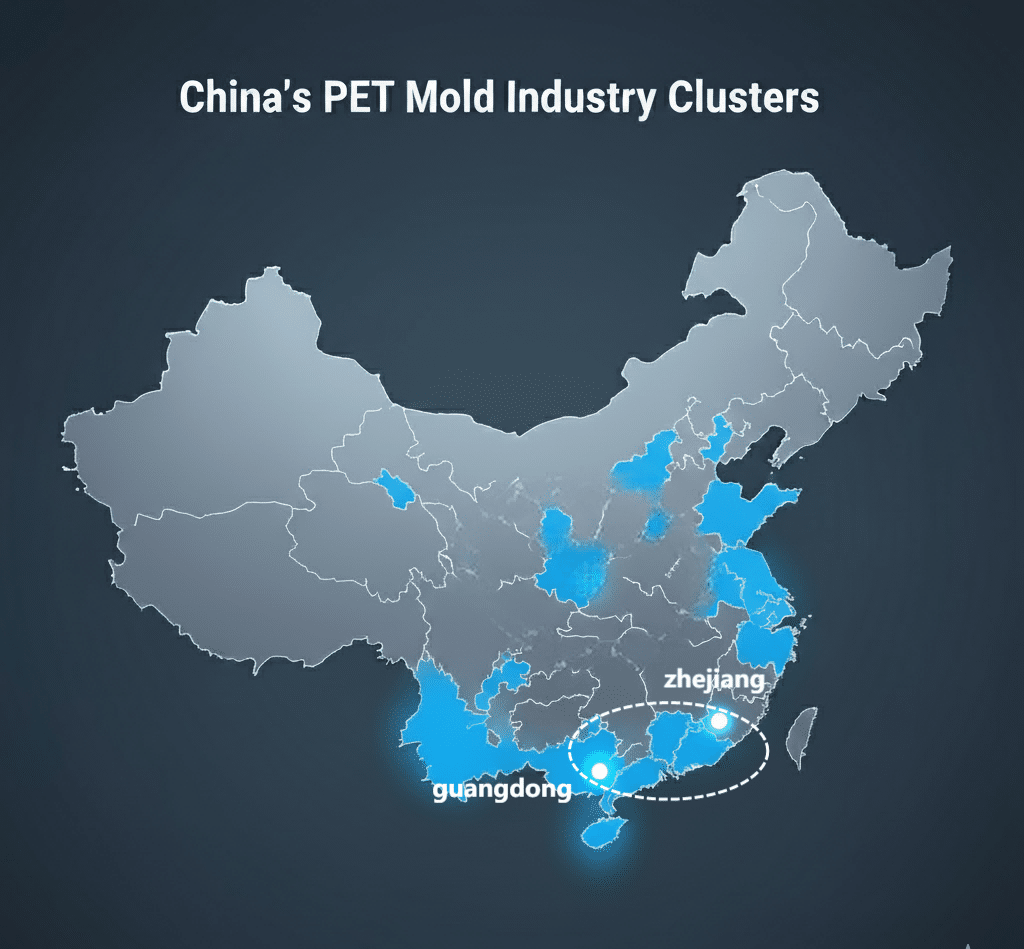

Intro: China is huge, where are the good factories hidden?

China is the world's factory. Everyone knows this. Many people come to China to find molds. But China is a huge country. Good PET blow mold factories are not spread out evenly. You will not find them in every city. Instead, they are grouped together in special areas. We call these "industry clusters."

As a factory owner, I understand this deeply. I have been running iBottler, my PET blow mold factory, in Zhongshan, Guangdong for 16 years. I have watched these regions grow. I know the "local flavor" of each place. The factories in the north are very different from my factory here in the south. The "soil" is different. This "soil" creates factories with different skills and different styles.

Finding the "best" factory is not simple. What does "best" mean to you?

- Does "best" mean the lowest possible price?

- Does "best" mean the highest quality and longest life?

- Does "best" mean the best service and communication?

- Does "best" mean the newest technology?

A factory in one region might be the "best" for price. A factory in another region might be the "best" for technology. This guide is my personal map for you. I want to help you understand these clusters. This article will take you deep into the two main mold areas. I will show you their unique strengths. I will also be honest about their potential challenges. My goal is to help you "choose the right place" (因地制宜). I want you to make the smartest choice for your project.

This is not just a list of factories. This is a strategic guide. I will compare the two great "engines" of China's mold industry. One is the Yangtze River Delta (we call it YRD). The other is the Pearl River Delta (we call it PRD). I live and work in the PRD. I compete with the YRD every day. I know their strengths and I know mine.

Many buyers make the same mistakes. They send an email to 50 factories on a big website. They get 50 prices. They choose the lowest price. This is a very risky way to buy. The price is only one part of the story. A cheap mold that breaks down after one year is the most expensive mold you can buy. A mold that costs 20% more but runs 2 seconds faster on your bottle blowing machine can make you rich.

I remember a client from South America. He bought a mold from a factory in a northern region. The price was very, very low. He was very happy. But the mold arrived, and it did not fit his machine. The drawings were wrong. He spent two months and thousands of dollars trying to fix it. It was a disaster. He came to us, iBottler, for his next project. Our price was higher. But we spent two weeks only confirming the technical drawings. We checked every single dimension. We have a huge library of mounting dimensions for 80% of blow molding machines worldwide. We guaranteed the fit. The mold arrived, he installed it, and it ran perfectly on the first day. This is the difference. The region, the factory, and the process all matter.

In this guide, I will break it all down for you. We will look at the two big players first.

The "Gemini" of the Mold World: Yangtze River Delta vs. Pearl River Delta?

When we talk about molds in China, we are really talking about two giant areas. We call them the "Gemini," or the twin stars. One is the Yangtze River Delta (YRD). The other is the Pearl River Delta (PRD). Almost all high-quality export molds come from one of these two places.

Let's define them simply.

First, there is the Yangtze River Delta (YRD), or 长三角.

- This region is around Shanghai.

- For molds, the most important part is Zhejiang Province.

- Inside Zhejiang, the key cities are Taizhou (especially the Huangyan district) and Ningbo.

- This area is famous for volume, speed, and incredible prices.

Second, there is the Pearl River Delta (PRD), or 珠三角.

- This region is in the south, in Guangdong Province.

- It is near Hong Kong.

- The key cities are Shenzhen, Dongguan, Foshan, Guangzhou, and my city, Zhongshan.

- This area is famous for high technology, high quality, and international standards.

I see these two regions like two different masters of martial arts. The YRD (Zhejiang) is a master of scale and speed. It can produce thousands of molds quickly and cheaply. The PRD (Guangdong), where I am, is a master of precision and integration. We are focused on making very complex, very reliable, high-performance molds. Both regions make excellent products. But their "philosophy" and their way of working are completely different.

Let's look at the ecosystem of each. The "ecosystem" is the network of suppliers, workers, and logistics.

The YRD (Zhejiang) Ecosystem:

The YRD ecosystem, especially in Taizhou's Huangyan district, is built on hyper-specialization.

- Supply Chain: The supply chain is incredibly dense. In Huangyan, you can find a company that only makes mold bases. Next door is a company that only does polishing. Three streets away is a company that only does heat treatment.

- Factory Type: This means there are thousands of small, specialized factories. A "mold factory" in Huangyan might only do design and assembly. They outsource all the machining and parts.

- Dominant Industries: This system is perfect for industries like home appliances (like washing machines) and automotive parts. It is also perfect for high-volume commodity items, like standard PET water bottles.

- Logistics: They have massive, world-class ports in Ningbo and Shanghai. Getting products out is very easy.

The PRD (Guangdong) Ecosystem:

The PRD ecosystem is different. It was built around the high-tech electronics industry.

- Supply Chain: Our supply chain is built for precision. Shenzhen is the "Silicon Valley" of China. Companies like Huawei, DJI (drones), and Foxconn (who builds Apple products) are here.

- Factory Type: These high-tech companies demand extreme precision and total quality control. Because of this, PRD factories tend to be more vertically integrated. This means we control more of the process inside our own factory. We have our own high-speed CNC machines, our own inspection machines (CMMs), and our own R&D teams. We cannot risk outsourcing a critical part for a medical device or a high-tech part. This quality culture applies to all molds we make, including PET preform molds and blow molds.

- Dominant Industries: Our region is dominated by 3C (Computer, Communication, Consumer Electronics), medical devices, and high-end precision manufacturing.

- Logistics: We also have world-class ports in Shenzhen, Guangzhou, and of course, Hong Kong.

This difference in "DNA" is the most important thing to understand. It changes the final product. A mold from the YRD might be optimized for the lowest possible price for a 5 million cycle life. A mold from the PRD might be optimized for the fastest possible cycle time and a 15 million cycle life, even if the starting price is higher.

Here is a simple table to show my view on this.

| Feature | Yangtze River Delta (YRD) - Mainly Zhejiang | Pearl River Delta (PRD) - Mainly Guangdong |

|---|---|---|

| Main Cluster | Taizhou (Huangyan), Ningbo | Shenzhen, Dongguan, Foshan, Zhongshan |

| Core Strength | Extreme specialization, cost efficiency, speed | High precision, technology integration, international standards |

| Price Level | Very competitive (often the lowest) | Moderate to High (value-oriented) |

| Factory Type | Many small-to-medium specialized shops | More medium-to-large full-service factories |

| Supporting Industry | Automotive, Home Appliances | Electronics, Medical, High-Tech |

| International Focus | Very high volume, strong export | High, strong focus on complex projects, high quality |

| My View | "The 'Mold Supermarket'" | "The 'Precision Engineering Hub'" |

Understanding this difference is the key. Now, let's look at each region, one by one.

Heart of YRD: Zhejiang Taizhou (Huangyan) - "China's Mold Hometown" and Ultimate Cost-Performance?

When you ask people in China "Where do I buy molds?" they will all say one name: Huangyan. This is a district within the city of Taizhou in Zhejiang province. It is known as the "Hometown of Molds in China." This is not just a marketing name. It is the truth. The concentration of mold factories here is unbelievable.

This is the heart of the Yangtze River Delta's mold industry. Its entire economy is built on one thing: making molds efficiently.

As I said in my insight, "Huangyan is like a giant 'mold supermarket'." When you go to a giant supermarket, you can find everything. The prices are very low. But you have to do the work yourself. You have to find the right aisle. You have to check the quality. You have to pack your own bags. This is exactly what sourcing in Huangyan is like. If you are a professional buyer, and you have strong project management and quality control skills, this place is a "paradise" for you.

Let's break down the Huangyan model and its pros and cons.

The Huangyan Model: Hyper-Specialization in Action

The key to Huangyan's success is its network. A single PET blow mold project is not made by one company. It is made by a network.

- Factory A is the "main" factory. You talk to them. They take your order and do the mold design.

- They send the design to Factory B, which makes the steel mold base.

- They send the parts to Factory C for rough CNC machining.

- Then they go to Factory D for high-speed precision CNC.

- Then to Factory E for heat treatment.

- Then to Factory F for final polishing.

- Finally, all the parts come back to Factory A for assembly and testing.

This network is incredibly efficient. Each small factory is an expert at one thing. Factory C's machines run 24/7 doing only rough cutting. Factory F's workers only do polishing. This specialization drives the cost down to the absolute minimum.

The Advantages of Huangyan:

- Extreme Concentration: There are thousands of suppliers. On some streets, every single building is a mold shop or a supplier. This competition is intense.

- Price Advantage: This is the number one reason to go to Huangyan. Because of the specialization and competition, their prices are often the lowest in the world.

- Flexibility and Speed: Because of this large network, they can often make simple molds very quickly. If one CNC shop is busy, they just go to the one next door.

The Potential Challenges of Huangyan:

This model also has big risks. These are the "potential challenges" you must know.

- Inconsistent Quality: This is the biggest risk. The final quality of your mold depends on the weakest link in that chain. The main factory (Factory A) must have excellent quality control over all its suppliers (B, C, D, E, F). If Factory E does the heat treatment wrong, the steel will be too soft. The mold will fail. Will Factory A catch it? Maybe. Maybe not.

- My Story on Quality: I have visited Huangyan many times. I once audited a factory for a client. The main assembly shop was new and clean. It looked great. I asked, "Where do you do your high-speed CNC?" The boss said, "Oh, Mr. Chen's shop, two streets away." I asked to see it. We walked over. Mr. Chen's shop was small, oily, and the machines were old. The quality control was just one man with a caliper. This is the risk. At my factory, iBottler, my expensive Makino high-speed CNC machine is in my building. My QC team checks the part right when it comes off the machine. I control the full process. This is the Guangdong model. It costs more, but the risk is much lower.

- Technology Level: Huangyan factories are masters of mature technology. They can make a standard 500ml water bottle mold with their eyes closed. But if you need a very complex, lightweight hot-fill bottle with a brand new PET bottle mold design, they might not be the best choice. The average factory there may not invest as much in R&D and simulation software as a top Guangdong factory.

- Communication: Many factories have good sales teams. But will their engineer understand your complex technical needs? The engineering culture in Guangdong is generally more international.

Who is Huangyan For?

So, should you buy from Huangyan? You should, if:

- Your project is a standard bottle (like a water bottle, CSD bottle).

- Your number one, most important factor is the lowest price.

- You are an experienced buyer.

- You have your own strong engineering team that can write a perfect technical specification.

- You have a plan for quality control (like hiring a third-party inspector or visiting yourself).

Here is a simple table to summarize the risk.

| Aspect | High Reward (Potential) | High Risk (Potential) |

|---|---|---|

| Price | Lowest possible unit price for the mold. | Hidden costs from delays, rework, or mold failure. |

| Speed | Very fast turnaround for standard molds. | Delays if one part of the subcontractor chain fails. |

| Quality | Can be very good if you find a top-tier supplier. | Can be very poor if you choose the wrong supplier. |

| Management | Low, if you find a great, self-managing partner. | Requires high, constant project management and QC. |

Huangyan is a "supermarket." It's a land of opportunity. But you must be a smart shopper.

PRD Engine: Guangdong (Shenzhen/Dongguan/Foshan/Zhongshan) - Integration of Internationalization and High Standards?

Now, let's travel south to my home. This is the Pearl River Delta (PRD) in Guangdong Province. If Huangyan is the "supermarket," then Guangdong is the "high-end department store" or the "precision engineering firm."

In a department store, the items are curated. The quality is high. The price is also higher. You get service. You get a guarantee. This is the philosophy of the PRD. My insight is this: "If you are looking for 'high quality + low risk + smooth communication,' and you are willing to pay a fair price for that value, the PRD is your first choice."

My factory, iBottler, is in Zhongshan. We are right in the middle of this cluster, surrounded by Shenzhen, Dongguan, and Guangzhou. We live and breathe this high-tech atmosphere every day. We benefit from the talent, the suppliers, and the high standards of this region.

The Guangdong (PRD) Model: Vertical Integration

Our model is very different from Huangyan's. The PRD industrial base was built to serve the high-tech electronics industry. Think about the smartphone in your pocket. The mold for that plastic case must be perfect. The tolerance is 0.01mm. You cannot outsource that to a cheap shop.

This high-tech DNA created a different kind of factory:

- More In-House Control: PRD factories, like iBottler, invest heavily in their own expensive machinery. We have our own high-speed CNC centers. We have our own precision EDM machines. We have our own CMM inspection machines.

- Focus on Systems: We are built on systems, not just connections. Many factories here are ISO 9001 certified. Some even have ISO 13485 (for medical devices) or IATF 16949 (for automotive). We "speak the language" of international quality.

- Investment in R&D: We invest in engineers and software. We don't just "make" the mold. We design it. We run computer simulations for mold flow and for cooling. We can analyze a complex PET bottle mold design and find problems before we cut any steel.

The Advantages of Guangdong:

- International Standards & Communication: This is our biggest strength. Our project managers and engineers often speak good English. More importantly, they understand international technical requirements.

- High Technology & Precision: We are excellent at complex projects. Do you have a difficult hot-fill bottle? Do you need an ultra-lightweight water bottle? Do you need a mold with complex cooling channels to run at a very fast cycle time? This is our specialty.

- Reliable Quality Systems: Quality is not just a final check. It is In-Process Quality Control (IPQC). We check the parts at every step. This means fewer bad surprises at the end.

- Strong Talent Pool: We have a huge pool of skilled, experienced engineers who have worked with German, Japanese, and American companies for decades.

The Potential Challenges of Guangdong:

- Higher Cost: This is the main "challenge." Our molds are not the cheapest. You are paying for the expensive machines, the skilled engineers, the in-house quality control, and the professional project management. But I do not call this a "cost." I call it an "investment."

- My Story on Total Cost of Ownership (TCO): I had a client from Mexico. His factory runs 24/7. He was looking for a new PET blow mold. He got a quote from Huangyan that was $5,000 cheaper than my quote. He almost took it. But I asked him, "What is your current cycle time?" He said, "12 seconds." I showed him our cooling simulation. We designed special cooling channels. I told him, "My mold costs $5,500 more. But I guarantee it will run at 10 seconds." He didn't believe me at first. He visited us. We showed him the simulation. We showed him our CNC machines. He gave us the order. Six months later, he called me. The mold was running perfectly at 10 seconds. He saved 2 seconds on every single bottle. He told me he made back the extra $5,500 in six weeks of production. That is Total Cost of Ownership (TCO). Guangdong factories sell TCO, not just a low price. We also help him analyze why PET blow molds need to be connected to a chiller to get this stable, fast cycle time.

- Less PET Concentration: In Huangyan, every factory makes molds. In Guangdong, we are more diverse. You have to find the PET mold specialists (like iBottler) among all the electronics, medical, and auto mold factories.

Who is Guangdong For?

You should start your search in Guangdong (PRD) if:

- Quality and Reliability are more important to you than the lowest possible price.

- You have a complex project (hot-fill, lightweight, special shape).

- You need a mold for a high-speed rotary machine (like Krones, Sidel, KHS).

- You value smooth communication and professional project management.

- You understand Total Cost of Ownership (TCO) and want the best long-term value.

As the founder of iBottler, this is the standard we try to set. We use the high-tech advantages of our Guangdong location to build molds that deliver real, measurable value to our clients.

Other Regions to Note: Jiangsu, Shandong, and Inland?

China is massive. While Zhejiang (YRD) and Guangdong (PRD) are the "Gemini," they are not the only places making molds. There are other important regions. But, as an expert, I must give you focused advice.

My insight is this: "While these areas have good mold factories, they have different specialties. If you are specifically looking for PET blow molds for the international market, focusing your main energy on Zhejiang and Guangdong is the most efficient use of your time."

Let's briefly look at these other regions so you have a complete picture.

1. Jiangsu Province (Part of the YRD)

- Key Cities: Suzhou, Kunshan, Nanjing.

- Specialty: Jiangsu is geographically next to Zhejiang and Shanghai. But its "personality" is closer to Guangdong. The cities of Suzhou and Kunshan are full of high-tech foreign investment. They are extremely strong in high-precision injection molds. This includes molds for electronics, medical devices, and automotive.

- My Take on Jiangsu: I have great respect for Jiangsu factories. They are high-quality and very professional. If I were sourcing a high-precision cap mold or a complex PET preform mold, I would absolutely include Jiangsu in my search. They are excellent at that. For PET blow molds, the specialization is just not as deep as it is in Zhejiang or Guangdong. The "cluster" for blow molds is simply smaller.

2. Shandong Province (Northern China)

- Key Cities: Qingdao, Yantai.

- Specialty: Shandong is a powerhouse for heavy industry. They are famous for making very large molds. Think about the molds for car bumpers, dashboards, or the main body of a washing machine or refrigerator. They have huge CNC machines and massive overhead cranes.

- My Take on Shandong: The engineers in Shandong are very skilled at large, heavy-duty molds. If I needed a blow mold for a 5-gallon (20-liter) PC water jug, Shandong would be a good place to look. But for the high-speed, multi-cavity, thin-wall PET bottle molds used in the beverage industry, this is not their main focus. The technology and skills are different.

3. Inland Regions (Chongqing, Chengdu, Wuhan)

- Key Cities: These are major cities in central and western China.

- Specialty: These are rising industrial clusters. The Chinese government has invested heavily to develop these areas. Usually, a huge "anchor" factory (like a giant car factory or a Foxconn electronics plant) moves there. Then, a local supply chain grows around it to support it.

- My Take on Inland Regions: I am watching these regions. They are growing very fast. But their focus is almost 100% on the domestic Chinese market. For an international buyer, there are many challenges.

- Logistics: The factories are far from the sea. Getting a heavy mold to a port in Shanghai or Shenzhen adds time and cost.

- Export Experience: The factories are less experienced with international trade, communication, and export standards.

- Supply Chain: The local supply chain (for steel, hot runners, polishing) is not as deep or as competitive as it is on the coast.

Summary Table: Other Regions

To make it simple, here is a table.

| Region | Key Cities | Primary Mold Specialty | Best For PET Blow Molds? |

|---|---|---|---|

| Jiangsu | Suzhou, Kunshan | High-precision injection molds (Electronics, Medical) | Good, especially for preform molds. Similar to Guangdong. |

| Shandong | Qingdao, Yantai | Large molds (Automotive, Home Appliances) | Generally No. Specialized in large-size items. |

| Inland (e.g., Chongqing) | Chongqing, Wuhan | Automotive, local industrial support | Not Yet. Primarily focused on the domestic market. |

My advice for you is to be efficient. Your time is valuable. Start your search where the experts are. For PET blow molds, that means 95% of your best options are in two provinces: Zhejiang (for cost) and Guangdong (for quality and technology).

How to Choose and Cooperate Based on the Region?

You now know where the factories are. You know the "personality" of Zhejiang and Guangdong. The next question is: How do you use this information? How do you choose, and how do you work with them?

This is the most important part. And it starts before you send a single email.

My most important insight is this: "No region is perfect. The key is to first understand your own core needs. Then, find a partner who matches those needs. Location is a clue, not a conclusion."

I will share my story again because it is the perfect example.

- The Client: A client from the USA.

- The Project: Molds for a high-speed rotary blowing machine. This is a very demanding, high-performance machine.

- The Quotes: He got two quotes. One from a Huangyan factory (very low price). One from us, iBottler, in Guangdong (price was 20% higher).

- The Problem: The client thought he was buying "a mold." He was tempted by the low price.

- My Action: I asked him about his core need. His core need was not "a mold." His core need was "a mold with excellent cooling and high stability for a high-speed rotary machine."

- The Solution: The Huangyan factory just sent a price. We sent a full technical proposal. We included our cooling channel design and a computer simulation showing the heat transfer. We proved how our design would achieve a faster cycle time and a longer life.

- The Result: The client understood that we were solving his core need. The other factory was just selling him a piece of steel. He chose iBottler. The molds are still running today, and they outperformed his expectations.

This story teaches us the process.

Step 1: Define Your Core Need (Before You Search!)

Ask yourself: "What is really the most important thing for this project?"

- Is it the lowest possible upfront price?

- Is it the lowest total cost (TCO) over 3 years?

- Is it a very complex bottle shape that other factories cannot make?

- Is it a guarantee that the mold will run perfectly on my specific machine?

- Is it a hot-fill bottle that must perform under high heat?

This "core need" is your guide. It tells you where to look.

| If Your Core Need is... | The Best Starting Region is... | Your Sourcing Strategy Should Be... |

|---|---|---|

| Lowest Possible Price (for a standard bottle) | Zhejiang (Huangyan) | Send RFQs to 10+ factories. Prepare for strict QC. |

| High Performance & Reliability (e.g., hot-fill, CSD) | Guangdong (PRD) | Send RFQs to 3-5 high-quality factories. Focus on technical discussion. |

| Complex Bottle Design | Guangdong (PRD) | Look for factories with strong R&D and 3D-printed sample services. |

| Fastest Delivery for a Standard Mold | Zhejiang (Huangyan) | Confirm their real (not promised) lead time. Check their subcontractor network. |

| Smooth Communication & PM | Guangdong (PRD) | Interview the project manager. Check their English and technical level. |

Step 2: Adapt Your Sourcing Strategy for the Region

You must work differently with each region.

If you choose to source from Zhejiang (Huangyan):

- Be the Expert: You must provide a perfect technical specification. List every detail: the steel type, the hardness, the cooling connector type, the preform neck size. Assume nothing.

- Audit Deeply: Do not just visit the main factory's assembly shop. Ask to see their key suppliers. "Show me your CNC shop." "Show me your heat treatment supplier." If they refuse, this is a red flag.

- Get References: Ask for a list of 5 clients in your country who bought a similar mold. Call them.

- QC, QC, QC: You must plan for a final inspection. Either visit yourself or hire a professional inspection company. Check the steel certificate. Check all dimensions.

If you choose to source from Guangdong (PRD):

- Discuss Technology: Go beyond the price. Ask why their design is better. Ask for a design guide. Ask them to explain their cooling design.

- Talk TCO: Ask about guaranteed cycle time. Ask about mold life. Ask about spare parts. A good Guangdong factory loves to talk about this. This is where we provide value.

- Check Systems: Ask for their ISO 9001 certificate. Ask to see their quality manual. Ask to meet the project manager who will handle your project.

- Visit and Verify: A visit is still essential. When you visit, check their in-house equipment. Do they really have the high-speed German or Japanese CNC machines they claim? Do they have a CMM (inspection machine) in a clean, temperature-controlled room?

Step 3: Verification is Non-Negotiable

I must say this again. Never buy a mold from a new supplier without verification.

- A video audit is the minimum. Ask them to walk through the shop with a camera live.

- An in-person visit is best.

- My Advice: When a client visits my factory, iBottler, I am happy. I want them to be critical. I want to show them our clean workshop. I want to show them our Makino CNC machines running. I want them to see our CMM machine measuring a part. A good factory is proud to show its process. A factory that hides things is a red flag, no matter where it is located.

Beyond Geography: Common Traits of Top-Tier Manufacturers?

We have talked a lot about regions. Zhejiang is the "supermarket." Guangdong is the "department store." This is a good guide. But it is not the final answer.

Why? Because there are excellent factories in Zhejiang. And there are bad factories in Guangdong.

The region gives a factory its "personality." But the core of "excellence" is universal. A top-tier manufacturer in Huangyan and a top-tier manufacturer in my city of Zhongshan share the same basic DNA. Your job as a buyer is to find these "top-tier" companies, inside your target region.

My company, iBottler, tries to be the best of both worlds. As my insight says: "We absorb the technical advantages and international vision of the Pearl River Delta. But we also learn from the high efficiency and flexibility of our Zhejiang peers. We do this to give our clients the best total value, a value that is beyond just one region."

So, what are these "common traits"? What should you look for?

Trait 1: Deep Understanding of the PET Process

A top factory does not just cut steel. They are process experts. They understand your business.

- They must understand PET material science.

- They must understand stretch ratios, material flow, and how to fix common PET blowing defects.

- They will ask you many questions.

- My Example: When a new client sends me a bottle drawing, I never just send a price. My team sends a list of questions:

- What bottle blowing machine are you using? (Make, model, number of cavities)

- What is your preform weight and neck finish?

- Is this for cold-fill, warm-fill, or hot-fill?

- What is your target cycle time?

- What is your target mold life (e.g., 10 million cycles)?

A supplier who just gives a price without asking these questions is a "machinist." A supplier who asks these questions is a "partner."

Trait 2: Investment in Advanced Equipment

You cannot make a precision mold with old, slow machines. The quality of the machine determines the quality of the part.

- Look for High-Speed CNC Machines from top brands (like Makino, DMG Mori, Fanuc, Okuma). These machines cut steel faster and much more accurately.

- Look for Precision EDM Machines.

- Look for a CMM (Coordinate Measuring Machine). This is a special machine used only for inspection. It proves that the parts are perfect.

- This equipment is very expensive. A single machine can cost over $300,000. A factory that buys this machine is serious about quality. At iBottler, our investment in Japanese Makino machines is the core of our quality.

Trait 3: A Robust Quality System (Not just a QC Guy)

A "QC guy" at the end of the line is not a quality system. A true system is built into every step.

- Incoming QC: The factory must check the raw materials. They should show you a steel certificate for the S136 or 718H steel they are using.

- In-Process QC (IPQC): They must check the parts during manufacturing. They check the dimensions after CNC. They check the hardness after heat treatment.

- Final QC (FQC): They must do a full inspection of all parts before assembly.

- Mold Trial (FOT): They must test the mold. They should check for water leaks. They should test the cooling channels. And they should run the mold (if possible) to produce sample bottles.

Trait 4: Reliability, Service, and Support

This is a huge factor. What happens after you pay and the mold is on a ship?

- Does the factory provide a full set of spare parts? (Seals, O-rings, heaters, etc.)

- Does the factory provide clear documentation?

- If you have a problem, will they answer the phone?

- My Story on Service: We shipped a mold to a client in Poland. When it arrived, the client saw the wooden crate was damaged. The shipping company had dropped it. A small, critical alignment pin was bent. The client was panicking. He had a big production order to fill. He called our project manager at 9 PM China time. Our engineer got on a video call immediately. He saw the problem. He identified the part number from our drawing. We have a policy for this. We machined a new pin that night. By 8 AM the next morning, the new pin was on a DHL express flight to Poland. The client got the part in 48 hours, installed it, and was in production. That is service. That is what you are paying for.

Trait 5: A Customer-Centric, Solution-Oriented Mindset

This final trait ties everything together. A top manufacturer sees you as a long-term partner, not a one-time purchase order.

- They are proactive. They suggest improvements. ("I see your design. If we change this small curve, we can make the bottle stronger and save 0.5 grams of PET.")

- They are honest. If there is a delay, they tell you before the shipping date.

- They focus on your success. They know that if you are successful, you will come back.

This is the iBottler philosophy. We use our Guangdong location for technology. We learn efficiency from all of China. But our mindset is to be a global partner for our clients.

Conclusion: Finding the Right "Place" is Good, Finding the Right "Partner" is Better?

We have gone on a long journey across China.

We started by asking where to find the best PET blow mold factories.

We learned that China is not one single place. For our industry, it is dominated by two "Gemini":

- Zhejiang (YRD): The "Supermarket." This is the king of cost and speed. It is a great choice for standard projects, if you have strong management and QC.

- Guangdong (PRD): The "High-End Department Store." This is my home. We are the leaders in quality, technology, and service. We are the best choice when performance and reliability are your core needs.

- We also learned that other regions (like Jiangsu and Shandong) have their own strengths, but they are less specialized in PET blow molds for the international market.

But what is the real conclusion? The region is your first filter. It helps you clear away 90% of the noise. It helps you aim your search.

But the final decision, the one that determines the success or failure of your project, is not about the place. It is about the partner.

A bad factory in Guangdong is still a bad factory. A great, top-tier factory in Huangyan can be a wonderful asset. Your goal is to find that top-tier partner within the region that best matches your needs.

I have been in this business for 16 years. My single biggest piece of advice for all buyers is this:

"Do not let $1,000 in price blind you to $10,000 in risk. And do not let it blind you to $20,000 in opportunity."

A cheap mold that runs slow, breaks down, or makes bad bottles is the most expensive mold you will ever buy. A high-quality mold that runs 1 second faster, lasts 5 million more cycles, and gives you perfect bottles every time... that mold pays for itself many, many times. A good air compressor system and chiller setup are also part of this total solution.

This is the partner we try to be.

My insight is my invitation. "Understanding China's mold map gives your sourcing direction. But the specific factory determines your success. My company, iBottler, was built to be this partner. We are located in Guangdong, and we live the high-tech, high-quality standards of this region. But we also stay lean and focused only on PET. This gives us efficiency."

"If you are looking for a factory that has Guangdong's technology and quality, a deep understanding of global customer needs, and a focus on TCO, then I sincerely invite you to put iBottler on your shortlist."

Visit our website. Look at our list of blow bottle molds. Read our technical design guides. Send us your project. Let my team and I show you the difference a true partner can make.

Final Summary: Regional Sourcing Guide

| Region | Core Identity | Best For... | Watch Out For... | My Key Advice |

|---|---|---|---|---|

| Zhejiang (Taizhou/Huangyan) | The "Mold Supermarket" | Lowest Price, High Volume, Standard Molds | Quality Inconsistency, Subcontractor Risk | Use only if price is #1 priority and you have a strong QC team. |

| Guangdong (PRD) | The "Engineering Hub" | High Performance, Complex Designs, Reliability, TCO | Higher Initial Price | The best choice for low-risk, high-return projects. |

| Other (Jiangsu, Shandong) | Specialized Hubs | Precision Injection (Jiangsu), Large Molds (Shandong) | Less specialization in PET blow molds for export | Focus your search on Zhejiang and Guangdong first. |

Frequently Asked Questions (FAQs)

Q: When I come to China to source molds, which region should I prioritize for a factory visit?

A: If your core goal is PET bottle molds, Zhejiang Taizhou (Huangyan) and Guangdong (Dongguan, Shenzhen, Zhongshan, Foshan, etc.) are the two most efficient choices. If your primary standard is ultimate cost-performance and your project is relatively standard, you can fly to Shanghai and then go to Taizhou (Huangyan). If you are pursuing high quality, complex technology, and smoother international service, you can fly to Guangzhou or Shenzhen (or Hong Kong) and then visit the factories in the Pearl River Delta.

Q: What is the general price difference between Zhejiang and Guangdong molds?

A: This is a common question, but there is no fixed answer. Generally speaking, under the same quality and configuration requirements (e.g., using the same brand of steel and hot runner), the price in Zhejiang (especially Huangyan) may be 10%-20% lower than in Guangdong. However, this often requires you to invest more energy and risk in screening and management. For high-demand molds, a quote from a Guangdong factory may include a superior design and more reliable components, and its "Total Cost of Ownership (TCO)" may be lower.

Q: In terms of language and communication, which region has an advantage?

A: It is generally believed that Guangdong has an advantage in internationalization due to its longer history of foreign trade and its proximity to Hong Kong. You will find that the average English proficiency and international communication skills of the sales staff and project engineers here are slightly stronger. However, this is just a general trend, and top-tier factories in Zhejiang also have very professional foreign trade teams.

Q: If I need very high-end mold technology (like extreme light-weighting, special materials), where should I go?

A: For top-tier and cutting-edge mold technology, Guangdong (especially around Shenzhen and Dongguan) is usually the first choice. Because this is the center of the high-tech electronics and medical industries, local investment in R&D and the adoption of the latest technologies (such as advanced simulation software, micron-level machining) are more active. These technologies "spill over" into other mold fields, including PET.

Q: iBottler is in Zhongshan, Guangdong. How do you show an advantage that goes beyond just one region?

A: We are rooted in Guangdong, which allows us to fully benefit from the Pearl River Delta's mature technical ecosystem, high-standard quality systems, and international talent pool. This ensures a high-quality starting point and reliability for our molds. At the same time, we have a deep understanding of the entire Chinese mold market, including the practices of regions like Zhejiang in cost control and rapid response. We enhance efficiency through lean internal management, an optimized supply chain, and an absolute focus on the PET field. Our goal is to provide customers with an optimal comprehensive solution that combines Guangdong quality with national cost-competitiveness.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr