Problem: Are you worried about inconsistent quality and poor fit when ordering high-precision PET blow moulds from China? Agitation: The risk of production failure from an incompatible mould can cost you millions. Solution: The manufacturing standards in Guangdong offer the highest reliability in the industry.

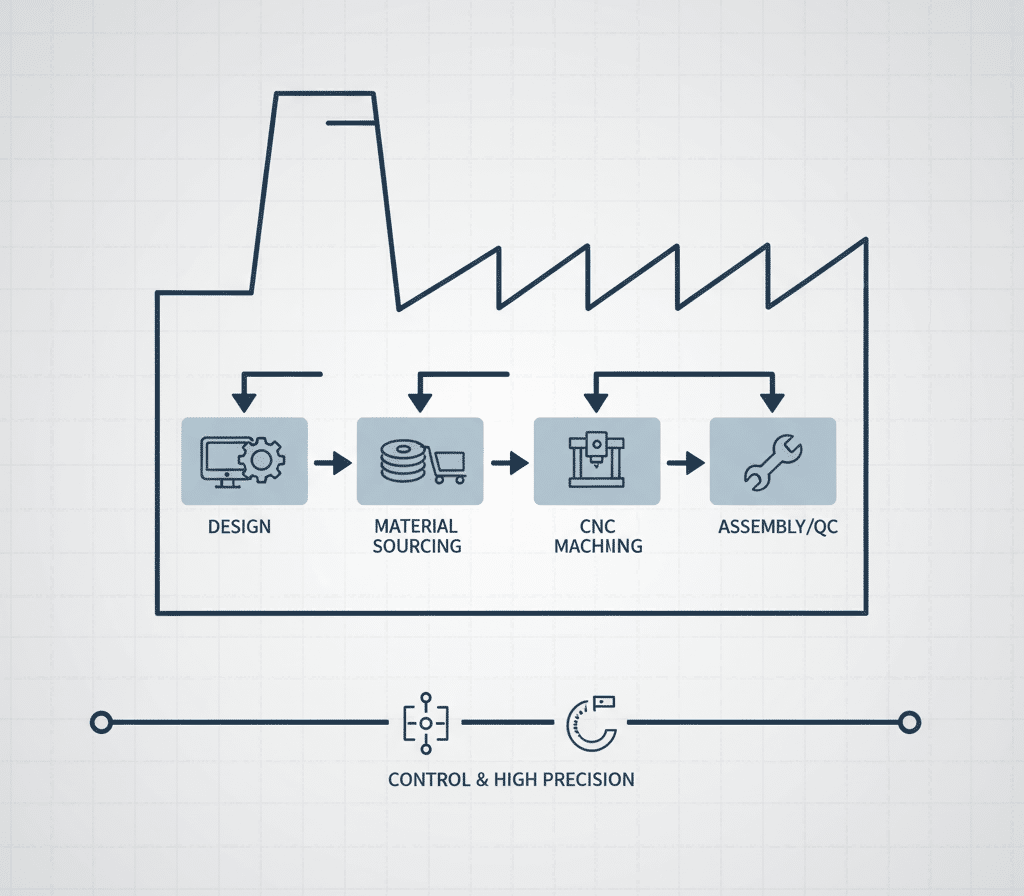

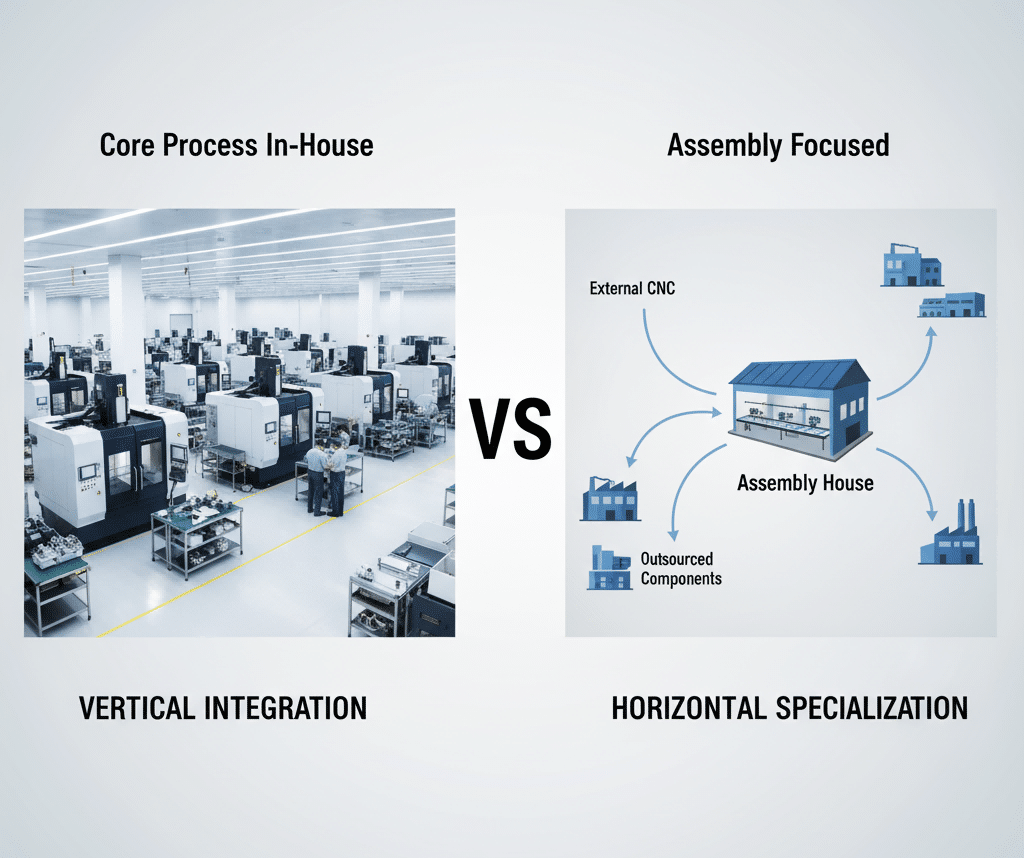

The Guangdong region holds a distinct advantage in blow moulding because its dominant business model—vertical integration—ensures absolute control over design, material sourcing, and core machining processes; this directly minimizes the critical risk of data incompatibility and tolerance accumulation that affects horizontally specialized manufacturers, guaranteeing superior precision and long-term stability.

You need to understand the fundamental difference between manufacturing philosophies, because what seems like a small price saving today can turn into a complete production line shutdown tomorrow. When you are investing in critical equipment, knowing who controls the core technology separates successful operations from costly delays.

The Core Model: Vertical Integration vs. Horizontal Specialization?

Problem: Do you assume all PET blow mould factories operate the same way, simply making a tool from your design? Agitation: This assumption is dangerous because regional differences in factory structure directly impact the final mould precision and longevity. Solution: Recognizing whether a factory is vertically integrated or specialized will tell you the real level of quality control you can expect.

The fundamental difference defining the quality gap between major Chinese mould-making regions is their core business model: Guangdong factories predominantly use vertical integration, meaning they control core design, CNC machining, and final assembly in-house; by contrast, many Taizhou factories rely on horizontal specialization, serving as rapid assembly points that depend heavily on external, often less controlled, component suppliers.

When I look at the competitive landscape, I see a clear distinction in how factories approach manufacturing. In the Guangdong model, which we follow, we control the entire process. This is the definition of vertical integration. The factory manages the core design team, the specialized CNC workshop, and the final assembly. This structure guarantees that the design data flows directly and seamlessly into the machining process. The other model, common in regions like Taizhou, is horizontal specialization. These are often "assembly houses." The main factory focuses on fast assembly and debugging, while relying on a sprawling network of external partners for key components and processing. The main difference lies in control.

Why Factory Structure Determines Quality Control?

The type of factory structure is the most important factor in determining the final quality of a blow mould China. It is simple: the more processes a single entity controls, the higher the control over precision and consistency. I have seen that most factories in Taizhou operate as "integrated" or assembly-based setups. The master factory brings in mould components, like mould bases, core cavities, and cooling plates, from various outside shops and then handles the final assembly and testing. This approach can offer a lower initial price. However, my professional analysis shows that mould factories in Guangdong, for example in Guangzhou and Foshan, insist on owning and managing their own core CNC workshops and design teams. This commitment to owning the core manufacturing process means we control the material choice, the heat treatment process, and the precision of the physical machining, which are the fundamental building blocks of a high-quality mould.

Understanding Control and Consistency in Mould Manufacturing

The advantage of vertical integration (the Guangdong way) is the absolute control over the quality source. When we control the entire process, we ensure that the material composition, the heat treatment required for specific components, and the machining precision remain completely consistent. When you look at the required interface between the blow mould and the bottle blowing machine, precision cannot vary. The physical dimensions, the positioning pin holes, and the interfaces must match perfectly. My professional experience shows that when a factory outsources core components, they lose the ability to ensure that the external supplier adhered to the required precision at every step. This loss of control is the number one source of later installation problems. The factory that controls the core manufacturing is the only one that can truly guarantee the final product's quality.

The Trade-off: Speed of Assembly vs. Precision of Machining

Horizontal specialization is great for speed and low cost. You can assemble a mould quickly if you have components readily available from multiple external shops. But this speed comes at a price: the accumulation of tolerances. Every time a component moves from one subcontractor to another—from the material supplier to the heat treatment shop to the external CNC shop—a small variation (a tolerance) is introduced. When the master factory in Taizhou receives and assembles these components, the tiny variations add up. A few microns here and a few microns there can quickly turn into a critical millimetre difference in the finished mould cavity, which affects the bottle's shape and weight. In our vertically integrated system, the design data is locked in, and the same high-precision machines process the components. This control eliminates the tolerance stack-up problem, which is vital for any client who demands consistent bottle quality and trouble-free installation. This difference is why the Guangdong PET mould advantage is really about process control.

The Integration Risk: Why Outsourced Data Leads to Installation Failure?

Problem: Is your biggest fear that a new mould will arrive but not fit your existing blowing machine? Agitation: This is a very common and costly issue when dealing with assembly-focused mould makers who lack control over critical interfacing data. Solution: The absence of integrated data control in horizontally specialized models is the fatal flaw that often causes mould installation failures on fully automatic machinery.

The integration risk, a fatal flaw in the horizontally specialized model, arises because the main assembly factory loses control over the high-precision data required to match the mould to the blowing machine interface; this outsourcing of core component manufacturing leads to the accumulation of geometric tolerances and data incompatibility, meaning the final mould cavity spacing, positioning, or frame size often fails to align with the client’s machine specifications.

This is a point I have to emphasize. The high-precision requirement of a PET blow mould does not just mean the bottle shape is perfect; it means the mould must be a seamless extension of your blowing machine. The mould's interface data—like the pitch between cavities, the diameter of the positioning pins, and the overall frame dimensions—must be exact. If the factory is only doing "assembly," they are not generating or strictly controlling this core data; they are merely accepting components from outside partners.

The Real-World Impact of Data Incompatibility

I recall a case involving a client in Saudi Arabia who purchased a 10-cavity blow mould from a Taizhou-based assembly factory. The price was low, and they were happy until the mould arrived. The assembly factory had not rigorously controlled the data between their mold components and the specifications of the client's full-automatic blowing machine. The result was a total failure: the pitch (cavity distance), the main locating holes, and even the mould frame dimensions were incompatible with the machine's interface. The mould could not even be physically installed. This is the reality of the integration risk. The core problem was a lack of strict data control by the assembly factory over the outsourced components. They were not manufacturing the core parts; they were simply putting them together.

How Guangdong's Model Guarantees Fit and Function

In the Guangdong model, because we own the design and the manufacturing, the mould's drawing (the initial design) and the final machining (the manufacturing) are part of a single, high-precision system. We control all the interface data points. We know exactly what our CNC machine is cutting because our own engineers designed it. This process absolutely prevents the problem of "data incompatibility" caused by external suppliers using different standards or having inconsistent component tolerances. This is also why we have a process for sharing mounting dimensions to prevent such issues; it is a critical step in providing a high-quality product. (You can see our commitment to fit here: Worried about blow mold fit? We have mounting dimensions for 80% of blow molding machines worldwide). When the drawing and the final product are controlled by the same hands, the risk of installation failure drops to almost zero.

Analyzing the Tolerance Accumulation Effect

The issue is not that the external parts are necessarily bad; the issue is that they are not precisely controlled within the same, integrated system. Consider a set of 12 separate parts, each with a tolerance of $\pm 0.02 \text{mm}$. In an outsourced scenario, the total tolerance accumulation can potentially lead to a $\pm 0.24 \text{mm}$ deviation in the final assembly, which is significant in high-speed, high-precision blow mould operations. The factory using horizontal specialization trusts its external suppliers to maintain their standards. The vertically integrated factory removes this trust factor by owning the process. We eliminate the reliance on external component standards, which means the required precision for the mould to seamlessly fit the blow molding machine is guaranteed from the outset. Choosing a vertically integrated partner is choosing a zero-tolerance approach to installation and operation.

Material Philosophy: The Cost of Choosing Inferior Aluminum?

Problem: Do you think saving a small percentage on mould materials is a smart cost-saving strategy? Agitation: That seemingly minor saving on material quality will inevitably lead to bottle surface defects, massive product rejection rates, and increased Total Cost of Ownership (TCO). Solution: The philosophy of using high-grade materials like 7075 aviation aluminum or S136 stainless steel is a long-term investment that guarantees consistent bottle quality and extends the mould's operational life.

The material philosophy of choosing low-cost, inferior aluminum alloys is a short-sighted approach prevalent in cost-driven manufacturing, which leads to structural issues like pitting and porosity under the repetitive thermal cycling of the PET blow moulding process; in contrast, the Guangdong standard insists on high-grade materials like 7075 aviation aluminum or S136 stainless steel, ensuring the internal uniformity and structural integrity needed to produce high-clarity bottles without surface defects over millions of cycles.

Material choice is not a place to save money; it is the foundation of the entire PET mould quality. Factories focused only on the lowest price often use low-grade aluminum alloys that have not undergone stringent quality checks. The Guangdong standard, which is the high-precision standard, dictates the use of high-specification materials, typically 7075 aviation aluminum or premium S136 stainless steel. We see the material as the first line of defense against production failure.

The Real Cost of Compromising on Aluminum Quality

My professional analysis shows that inferior aluminum alloys suffer from poor internal structure and uneven metal density. A blow mould goes through an extreme thermal cycle constantly: the hot preform is blown into the mould, and then the mould is rapidly cooled. This continuous thermal shock causes micro-stresses in the metal. When the aluminum quality is poor, this thermal cycling causes tiny surface defects like pitting or micro-porosity to develop on the mould cavity surface.

I had an experience with a client in Ghana where the mould, purchased cheaply elsewhere, started showing surface pitting after only a few months of operation. The pits on the mould surface were directly transferred to the finished bottle. The bottles came out with a noticeable 'foggy' appearance, lacking the clarity and smoothness required for their product on the supermarket shelf. The entire batch of bottles produced after this point was commercially unacceptable. This is a very clear example: the money saved on the cheap aluminum was quickly lost through rejected product and stopped production. The attempt to reduce the initial cost on materials ultimately resulted in an unbearable operational loss.

A Comparison of Core Mould Materials

To illustrate the difference in the material philosophy, you must look at the mechanical properties. The material choice defines the PET mould TCO (Total Cost of Ownership).

| Material Type | Typical Use/Source | Key Advantage | Common Defect Risk (Low-Quality) |

|---|---|---|---|

| 7075 Aluminum | High-Grade/Aviation Aluminum | Exceptional strength-to-weight ratio, excellent thermal conductivity for fast cooling. | Poor structural uniformity leads to pitting/surface defects under thermal stress. |

| S136 Stainless Steel | Premium Cavity Material | Superior corrosion resistance, high polish retention, long life for highly demanding, high-cavity moulds. | High initial material cost, difficult to machine if not sourced correctly. |

| Low-Grade Alloy | Cost-Driven Sourcing | Lowest initial cost. | Low yield strength, rapid thermal degradation, poor surface finish, leading to bottle blemishes. |

When we choose 7075 aluminum, we are investing in rapid, uniform heat transfer, which is crucial for fast cycle times and a clear bottle finish. When we use S136 stainless steel for the cavities—especially for water or beverage bottles that require perfect clarity and long life—we eliminate the risk of corrosion and maintain a mirror-like surface for years of production. This choice is based on engineering integrity, not simple cost reduction. It is the only way to ensure the consistent, high-quality output your business demands. (We also offer a deep dive on how cooling affects the final product: Why do PET blow molds need to be connected to a chiller?).

R&D Leadership: Where Core Technology is Developed?

Problem: Do you wonder if all Chinese mould manufacturers have the same underlying technical ability? Agitation: Relying on a factory that simply "copies" a technology means you will have no support when the inevitable complex production issues arise. Solution: The real high precision blow mould China capabilities originate in Guangdong because it possesses the necessary foundational R&D leadership and engineering knowledge, which assembly factories cannot replicate through simple imitation.

The heart of China’s blow mould innovation lies in Guangdong, which benefits from being a national hub for advanced manufacturing and research; this R&D leadership means that high-level technologies, such as all-electric servo systems and advanced fluid dynamics for high-speed rotary blowing, are first developed and mastered here, providing a foundational engineering knowledge that assembly-based operations in other regions can only attempt to quickly borrow or imitate.

Innovation is not something you can outsource. The latest and most advanced technologies in packaging and automation start in Guangdong. This province has a long history as a technological pioneer in China. Other regions, when faced with a new technology, often focus on fast imitation and then low-cost production. But they miss the underlying engineering knowledge. This is a crucial distinction.

The Foundation of High-Level Technology

In the high-tech fields of all-electric servo technology and high-speed rotary blow moulding, which are essential for large-scale production, true mastery requires core knowledge of fluid dynamics and mechanical design. These are complex engineering sciences. In a vertically integrated factory, our R&D team works directly with the manufacturing floor. This collaboration allows us to understand exactly how air flow behaves inside a bottle or how stress distributes through the mould frame under high pressure. This deep, bottom-up R&D capability is not something a factory can get by simply "outsourcing the appearance." Imitation only gives you the shape; it does not give you the performance or the long-term reliability.

The Advantage in Customization and Non-Standard Work

The R&D leadership becomes most apparent when you need something outside the standard specifications. Think about a custom blow mould for a highly specialized, non-standard bottle shape or a complex bottle base. Because a Guangdong factory controls the source CAD files and the engineering knowledge, we can quickly perform the necessary engineering analysis, structural simulations, and design modifications. An assembly-type factory cannot do this. They are limited by the design files provided by their external component suppliers. If you ask for a complex modification, they often have to go back to the original source, creating delays and introducing the risk of data mismatch. Our ability to handle non-standard requirements quickly and accurately is a direct result of owning the engineering and R&D process from the start.

The Role of Engineering Analysis in Mould Performance

Our ability to adapt and customize relies heavily on advanced engineering tools. We use Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) to predict how the mould and the bottle will perform before a single piece of metal is cut.

| Engineering Tool | Application in Mould Design | Benefit to the Client |

|---|---|---|

| CAE/FEA (Computer-Aided Engineering/Finite Element Analysis) | Simulates stress on the mould frame and the bottle wall under high-pressure blowing. | Prevents structural failure, ensures uniform bottle wall thickness, and guarantees high-pressure resistance. |

| CFD (Computational Fluid Dynamics) | Models the flow of air and the cooling water/liquid within the mould. | Optimizes cooling channel design for faster cycle times, which directly increases production output. |

| Kinematic Simulation | Predicts the mechanical movement of complex mould components (e.g., base-push-up, side core slide). | Ensures smooth, reliable mould opening and closing, reducing wear and minimizing downtime. |

This type of engineering analysis is not optional; it is mandatory for any factory claiming to offer a high precision blow mould China. It is the only way to scientifically optimize every part of the mould's performance, ensuring maximum efficiency and reliability for the customer. This commitment to deep engineering is a hallmark of the Guangdong standard.

The Benchmark: Xinglian (XL) and the Coca-Cola Quality Mandate?

Problem: How can you be sure a mould-making region meets true international quality standards? Agitation: Without independent, world-class validation, any quality claim is just marketing. Solution: The selection of Guangdong-based suppliers like Xinglian (XL) by major international brands like Coca-Cola serves as a non-negotiable, verifiable industry benchmark for the region's overall engineering compliance and quality mandate.

The selection of Xinglian (XL) as a designated mould supplier by The Coca-Cola Company is a powerful validation of the entire Guangdong region’s adherence to world-class standards; this partnership underscores the region’s systemic advantages in engineering compliance, rigorous confidentiality, and the capability of the entire Pearl River Delta supply chain to reliably provide internationally certified, high-quality components and rapid technical response.

When an organization like The Coca-Cola Company chooses a mould supplier, they are not just looking at one factory; they are looking at the factory's entire system and supply chain. Xinglian's presence and its partnership with Coca-Cola are a profound statement about the standards in Guangdong. This relationship confirms that the region can consistently meet the most demanding global requirements for intellectual property protection, rigorous engineering compliance, and flawless delivery.

Systemic Trust and Supply Chain Integrity

Coca-Cola's choice is a result of systemic trust. They require a partner that can offer intellectual property protection because bottle designs are highly confidential. They demand quick technical response for global operations. Most importantly, they need a partner whose surrounding ecosystem—the supply chain—can deliver international-standard components (like specialized steel, seals, and electronics) with unwavering stability. The entire Pearl River Delta, where Guangdong is located, provides this stability. The presence of major players like Xinglian and Dalong (Dajiye) forces the entire local supply chain—from the specialized material shops to the heat treatment facilities—to maintain a very high minimum standard of quality. This creates a high quality floor for the Guangdong PET mould advantage.

The Ripple Effect on the Entire Industry

The standard set by these industry giants has a powerful ripple effect. When Coca-Cola requires a specific level of finish on the mould surface or a certified heat treatment process, all local suppliers must upgrade their processes to compete for this high-end business. This continuous pressure to upgrade means that even smaller, specialized mould makers in the Guangdong area benefit from a better local supply chain and higher overall technical knowledge. This is a primary reason why the overall quality bar is significantly higher here compared to regions where the focus is mainly on assembly and cost reduction. You benefit from this elevated industry standard, even if you are not Coca-Cola.

Technical Requirements for International Mandate

Meeting the standards of a major beverage brand means adhering to very specific technical protocols that go beyond simple functionality. These requirements are where the high precision blow mould China truly shines.

| Quality Requirement | Technical Implication | Why Guangdong Excels |

|---|---|---|

| Material Certification | Full traceability of S136 steel or 7075 aluminum, with mill-test reports required. | Vertically integrated factories control sourcing and demand high certification, unlike assembly houses. |

| Surface Finish Compliance | Specific Ra (Roughness Average) value for the cavity, typically less than $0.05 \mu \text{m}$, to ensure bottle clarity. | Advanced in-house polishing and inspection capabilities are necessary, not outsourced. |

| Cycle Consistency | The mould must maintain dimensional stability and cooling performance across millions of cycles. | Guaranteed by precise thermal design (CFD analysis) and high-uniformity, vertically processed materials. |

When you choose a mould from a region validated by such mandates, you are not just buying a piece of metal; you are buying into a system of proven compliance and quality assurance. This is the ultimate form of risk mitigation for your production investment.

Bottle Engineering: The Science of Cost, Pressure, and Drop Resistance?

Problem: Do you think mould making is just about carving a bottle shape into a block of metal? Agitation: A simple mould copy can result in a bottle that is too weak for filling, too heavy for profitability, or collapses during stacking. Solution: Professional bottle engineering design is a critical science that uses advanced structural analysis to strategically reduce material cost while simultaneously guaranteeing the bottle's necessary strength, pressure resistance, and anti-drop performance.

For a professional mould factory, the work extends far beyond simple machining; it involves complex bottle engineering design utilizing CAE/FEA software to perform structural mechanics simulations, which aims to strategically reduce the PET bottle's gram weight, ensuring material cost savings while maintaining critical performance parameters like stacking strength, internal pressure resistance (for CSD), and anti-drop reliability.

The real value of a top-tier mould factory is not in its CNC machines; it is in the engineering brains that control them. Our work starts with engineering the bottle itself. A poorly designed bottle is a waste of money—it is too heavy, which raises your raw material costs, or it is too weak, which causes product failure and leakage. We approach bottle design as an optimization problem. The goal is to maximize strength while minimizing weight.

Scientific Light-Weighting and Cost Optimization

The process of light-weighting must be scientific. If you simply remove material from the bottle wall, the bottle will fail. We use CAE/FEA (Computer-Aided Engineering/Finite Element Analysis) software to create a virtual simulation of the bottle's structural mechanics. This allows us to map out the stress points when the bottle is filled, capped, stacked on a pallet, or dropped. The engineering is about strategically removing material from low-stress areas and reinforcing high-stress areas like the base and shoulder. We can achieve significant light-weighting, saving the client substantial PET raw material costs over the life of the production run, while still ensuring the bottle can withstand all real-world pressures. This is a key part of our service for every PET bottle mold design.

Ensuring Product Performance Under Load

The required performance of the bottle depends entirely on the product it contains. For a product like Carbonated Soft Drinks (CSD), the bottle must be designed to contain high internal pressure. The mould engineer must ensure the bottle base and the heel area—the transition between the body and the base—can handle this pressure without failure. For high-risk products like oil or chemicals, the bottle's anti-drop performance is paramount. This requires advanced analysis to ensure the stress is dissipated correctly upon impact. This level of analysis demands a deep understanding of material science and mechanical stress distribution, which is only found in engineering-led mould factories.

| Bottle Performance Requirement | Engineering Focus Area | Consequence of Poor Design |

|---|---|---|

| Stacking Strength | Base geometry, shoulder radius, and mid-section wall thickness. | Pallet collapse, product damage during warehousing and transport. |

| Pressure Resistance (CSD) | Base design (petaloid or champagne), base crystallinity, and heel radius. | Bottle bursting during filling, storage, or transport. |

| Drop Resistance | Heel geometry and consistent wall thickness distribution at impact points. | Catastrophic failure (shattering) upon minor impact. |

| Material Cost | Strategic light-weighting via CAE analysis. | Unnecessary high TCO due to excessive PET consumption. |

This is why, when we are asked to create a mould, the first phase is always about validating or optimizing the bottle design. We do not just process a drawing; we apply engineering science to make sure your product performs perfectly and profitably. (We even use 3D printed samples to production for quick validation).

Geographical and Supply Chain Advantage?

Problem: Does the location of your mould supplier matter beyond shipping distance? Agitation: A remote supplier can mean slow access to high-quality raw materials and delayed delivery of critical spare parts. Solution: Guangdong's geographical advantage as a massive industrial cluster and international trade hub ensures a uniquely stable, high-quality supply chain and superior logistics efficiency compared to inner China regions.

The strategic location of Guangdong, particularly the Guangzhou and Foshan industrial cluster, offers an insurmountable geographical and supply chain advantage; this regional concentration guarantees rapid access to premium S136 steel and high-precision machining services, and its status as a major global port (Shenzhen, Guangzhou) provides unparalleled logistics efficiency for mould delivery and the crucial, fast shipment of urgent spare parts.

You must consider the entire ecosystem in which your mould is produced. The physical location of a factory is not just about the shipping port; it is about the network of support industries surrounding it. Guangdong's Pearl River Delta region is one of the world's most dense and sophisticated manufacturing hubs. This concentration creates a significant advantage for high-precision mould manufacturing.

Stability and Quality of the Supply Chain

The stability of the supply chain is critical. In Guangdong, we can reliably and quickly source high-quality components: certified S136 stainless steel, advanced precision machining services, international-standard electronic components (like PLCs and sensors) for automated systems, and specialized surface treatments. This is not the case for factories located in more remote or less industrialized regions, which may face delays or have limited access to the highest-grade materials. Our ability to secure these premium inputs rapidly is a direct result of being at the center of a world-class manufacturing cluster. This advantage is crucial for maintaining the Guangdong PET mould advantage.

Logistics and After-Sales Efficiency

Logistics efficiency is often overlooked until you need a critical spare part urgently. The Pearl River Delta hosts some of the world's largest container ports (Shenzhen and Guangzhou). This proximity to major international shipping lanes means we can move large moulds and small spare parts with maximum speed and minimum cost. If a small component fails in your production line on the other side of the world, getting a replacement from us is significantly faster and more reliable than sourcing it from a factory located deep inside China's interior. This is a major factor in reducing your overall production downtime and is a key component of our service.

Competitive Advantages in Mould Manufacturing

The geographical advantage translates directly into competitive benefits for our clients:

| Advantage Factor | Guangdong Benefit | Impact on the Client |

|---|---|---|

| Raw Material Access | Immediate availability of high-grade 7075 Aluminum and S136 Steel. | Shorter lead times and certified material quality for the mould. |

| Skilled Labor Pool | Large concentration of highly trained precision engineers and CNC operators. | Higher machining accuracy and reduced human error in production. |

| International Trade Hub | Proximity to Shenzhen, Guangzhou, and Hong Kong ports. | Faster, more reliable, and lower-cost mould and spare part delivery. |

| Ancillary Services | Access to world-class heat treatment, surface coating, and plating services. | Superior mould durability and longer operational life. |

This holistic environment is what allows us to consistently deliver a high precision blow mould China. It is a synergy of geography, infrastructure, and an established culture of high-quality manufacturing that simply cannot be replicated quickly in other areas.

Conclusion: Choosing the Guangdong Standard (The iBottler Position)?

Problem: How do you ensure your mould investment provides reliable, long-term production and international-level quality? Agitation: A low-cost, unproven supplier risks your entire production schedule and reputation. Solution: Choosing the Guangdong standard means securing a high-quality system backed by industry validation, engineering leadership, and a commitment to precision.

The decision to choose a Guangdong-based mould means selecting a manufacturing standard that has been validated by global industry leaders, guaranteeing technical compliance, material integrity, and long-term production stability; at iBottler, with our 20 years of experience, we embody this standard, providing end-to-end blow moulding solutions backed by our dedication to precision and international recognition.

Choosing a mould supplier is not a transactional decision; it is a partnership. When you choose a mould from Guangdong, you are choosing a system and a standard. You are choosing the integrity of vertical integration over the risk of outsourced assembly. You are choosing certified materials over cost-saving compromises. The Guangdong standard represents reliability and international recognition.

Our Commitment to the Guangdong Standard

We, at iBottler, have been a dedicated manufacturing factory for 20 years, and we are proudly rooted in Zhongshan, Guangdong. We only commit to the highest manufacturing standards, which is why we have been the specified blow mould supplier for international, well-known brands across multiple countries for over five years. Our factory structure, our processes, and our commitment to using only certified 7075 and S136 materials directly reflect the superior Guangdong PET mould advantage.

The iBottler Value Proposition

Our value to you is simple: we provide a complete suite of blow, fill, and cap moulding solutions. Our core advantage is our technical compliance, the perfect match of our full product line—from preform molds to blow moulds—and a lasting commitment to quality. Choosing us means you are choosing the reliability, technical expertise, and international standing that the Guangdong standard represents. We ensure you avoid the risks of assembly houses and instead gain a partner committed to your long-term success.

Frequently Asked Questions (FAQs)

1. How does the "Guangdong vs Taizhou PET mould" difference affect my Total Cost of Ownership (TCO)?

The initial price difference between a Guangdong PET mould (vertically integrated) and a Taizhou mould (horizontally specialized) can be up to 20-30% lower for the Taizhou option. However, TCO analysis shows this initial saving is misleading.

| TCO Factor | Guangdong Mould (Higher Initial Cost) | Taizhou Mould (Lower Initial Cost) |

|---|---|---|

| Operational Lifetime | 5–7 years minimum (Due to high-grade materials and precision). | 2–4 years (Due to lower-grade materials, material fatigue, and wear). |

| Scrap Rate | Less than 1% (Due to high precision and cooling uniformity). | Up to 5% or more (Due to poor cooling and surface defects like pitting). |

| Downtime Risk | Low (High fit compliance, fewer material failures). | High (High risk of installation failure and part incompatibility). |

| Annualized Cost | Significantly lower TCO due to reduced scrap, maintenance, and longer life. | Higher TCO due to frequent repairs, high scrap rate, and early replacement. |

Choosing the Guangdong standard significantly lowers the TCO by maximizing uptime and product quality over the mould's life.

2. If I have an existing blowing machine, how can I guarantee a new mould will fit without major modifications?

The fit is guaranteed through a rigorous process of Mould and Blowing Machine Matching. Our core advantage is 20 years of accumulated global blowing machine installation data. We possess the precise mounting dimensions for over 80% of mainstream blowing machines worldwide.

| Key Step | iBottler's Action | Guarantee Objective |

|---|---|---|

| Mounting Data Preparation | Mastered data for over 80% of global blowing machines. | Fast response, ensuring interface data accuracy from the source. |

| Pre-Production Confirmation | Send detailed mould-to-machine interface drawings for client verification. | 100% avoidance of installation misalignment and assembly risk. |

| Handling Missing Data | Provide mould data for client self-measurement, or arrange on-site engineer measurement. | Eliminates the risk of data mismatch, guaranteeing 100% compatibility. |

3. What role does "bottle engineering" play in saving me money on PET resin?

Professional bottle engineering design directly impacts your PET material consumption, which is the single largest operating cost in blow moulding. It is a cost-saving measure that happens before production even starts.

| Engineering Principle | Resulting Cost Saving | Example |

|---|---|---|

| CAE/FEA Simulation | Strategic light-weighting (reducing gram weight). | Reducing a 500ml bottle from 23g to 21.5g saves $15,000 per million bottles produced. |

| Stress Analysis | Optimizing the base and heel strength with minimal material. | Allows the use of a lower overall weight without compromising pressure or drop resistance. |

| Wall Thickness Uniformity | Eliminates overly thick areas (hot spots) that waste material. | Ensures the entire bottle contributes equally to the required strength. |

A factory with true R&D leadership can use these engineering tools to reduce your material usage by 5-10% without affecting bottle performance.

4. What are the advantages and disadvantages of S136 stainless steel compared to aluminum?

The maximum value of S136 stainless steel lies in its superior corrosion resistance and durability. This makes it the preferred material for daily chemical products, hot-fill bottles, and transparent bottles requiring extremely high surface finish.

| Feature (Material Philosophy) | Advantage (Applicable Scenarios) | Disadvantage (Impact on Operations) |

|---|---|---|

| Corrosion Resistance | Highly suitable for daily chemicals, water-based cooling lines, and hot-fill bottles. | No obvious disadvantage. |

| Durability/Hardness | Ensures an extremely long service life and cavity dimensional stability. | No obvious disadvantage. |

| Density/Weight | Guarantees high precision and long-term stability. | The steel's heavy weight increases mould transportation costs and changeover difficulty, and is more prone to impact damage on the mould frame. |

This material choice represents the high-standard philosophy, but clients must weigh its operational costs against durability needs.

5. What is the complete process for manufacturing our custom blow moulds?

Our custom process is designed to ensure every phase from concept to production meets the highest precision, integrating our commitment to engineering design, machine compatibility, and high-quality manufacturing.

| Process Stage | Key Task Content | Key Output/Advantage |

|---|---|---|

| 1. Concept & Engineering Design | Bottle design optimization, CAE/FEA structural analysis, material selection recommendations. | Final bottle design determined (light-weighting, strength compliance), ensuring adherence to the PET bottle mold design guide. |

| 2. Mould Drawing Confirmation | Mould design (including cooling system) and machine compatibility drawings confirmed with the client. | Eliminates data mismatch risk, ensuring 100% installation compatibility. |

| 3. Core Component Manufacturing | 7075 Aluminum/S136 Steel procurement, in-house CNC precision machining, and heat treatment. | Vertical integration advantage, guaranteeing the precision and material integrity of core cavities. |

| 4. Assembly and Commissioning | Mould assembly, cooling circuit testing, blow moulding debugging, and bottle defect inspection. | Ensures perfect mould function and production of defect-free bottles common PET blow molding defects and how to fix them. |

Summary Table: Guangdong Advantage

| Feature | Guangdong Standard (Vertical Integration) | Alternative (Horizontal Specialization) | Key Client Benefit |

|---|---|---|---|

| Quality Control | Absolute control over design, CNC, and assembly. | Relies on external, less-controlled component suppliers. | Guaranteed high precision and fit compliance. |

| Material Sourcing | High-grade, certified 7075 Aluminum and S136 Steel. | Cost-driven, often using lower-grade, non-certified alloys. | Minimized risk of surface defects and extended mould life. |

| R&D/Engineering | In-house CAE/FEA analysis and core technology development. | Focus on appearance copying and quick assembly. | Scientific light-weighting and reliable performance under load. |

| Industry Validation | Supported by international mandates (e.g., Coca-Cola supplier validation). | Lacks external validation for systemic compliance. | Proven system security, confidentiality, and high-level quality. |

| Logistics/Supply | Access to world-class logistics and stable supply of premium parts. | Limited access to high-end suppliers and slower logistics. | Faster mould delivery and reliable, rapid spare parts service. |

The entire text focuses on the central argument that the Guangdong PET mould advantage is a systemic, engineering-driven standard that protects your investment and guarantees long-term operational success.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr