Are you running a top-tier Krones blow molding machine but getting frustrated by the slow and expensive process for new molds? You need to launch new products faster, but OEM limitations are holding you back. There is a better way.

The simple answer is that we provide a faster, more flexible, and cost-effective solution without sacrificing quality. Our deep understanding of Krones' technical requirements ensures our custom molds are 100% compatible, offering a "plug-and-play" experience that gets your new bottle to market in record time. As a trusted partner to even major international brands, we deliver proven performance.

I've spent 16 years in the PET packaging industry, and I've seen this situation countless times. You invest in a powerful, high-performance bottle blowing machine from a brand like Krones because you want the best. But when it's time to innovate—to launch a new bottle shape or enter a new market—you hit a wall of corporate process, high costs, and long delays from the very same company. This is a huge source of frustration for production managers and brand owners who need to be agile. In this article, I'll break down exactly why so many Krones users, including a world-famous cola brand, trust us as their go-to partner for molds. We will explore the technical details, the cost benefits, and the service experience that makes this choice a strategic advantage.

Krones Machines Are Excellent—But Why Are Their Molds Not Always Flexible?

You have a powerful Krones machine ready for production, but your new product launch is stalled. The original equipment manufacturer's (OEM) mold will take too long and cost too much, putting your market advantage at risk.

Krones builds incredible machines, but their original molds come with high price tags and long lead times. Their internal processes are not designed for the rapid, custom responses that modern brands need to stay competitive. This lack of flexibility can become a significant bottleneck for your production goals.

When you invest in a Krones machine, you are buying German engineering at its finest. The precision, speed, and reliability are often unmatched. However, this strength in machine manufacturing doesn't always translate to flexibility in mold supply. The reality is that for a large, multinational corporation, a custom blow bottle mold is a relatively small part of a massive operation. This means your urgent request has to go through a long internal chain. From my experience, what holds customers back isn't the quality of the OEM mold, but the practicality of getting it. The market moves fast. You might need a new bottle for a promotional campaign next quarter, not next year. You need a partner whose primary focus is the mold itself, not just an accessory to a machine sale. That's the gap we fill. We offer a Krones bottle mold alternative that prioritizes your timeline and budget.

OEM vs. Our Custom Solution: A Quick Comparison

| Feature | Krones Original Mold | Our Custom Mold Solution |

|---|---|---|

| Typical Lead Time | 8–16 weeks | 3–4 weeks |

| Estimated Cost | 100% (Baseline) | ~50-60% of OEM |

| Customization Speed | Slow, formal process | Fast, direct communication |

| Point of Contact | Multiple departments | Direct to an expert (me) |

This table clearly shows the advantage. It's not just about saving money; it's about gaining speed and agility, which is often more valuable in today's market.

How Does Corporate Process Complexity Delay OEM Mold Delivery and Response?

You've sent an inquiry for a new mold to the OEM, but it feels like it went into a black hole. You're dealing with different departments, long email chains, and a frustrating lack of clear answers on delivery.

The complex structure of a large multinational corporation like Krones is the main reason for delays. Your request has to pass through sales, regional management, central engineering, and production planning. Each step adds time and potential for miscommunication, slowing your project down.

Let me walk you through a typical scenario I've heard from my clients before they started working with me. First, they contact their local Krones sales representative. That representative then has to coordinate with a technical sales team, who then communicates with the central design and engineering department, likely in Germany. Once a design is approved, it goes to a production planning department that has to schedule it among multi-million dollar machine orders. Any small change or question requires this entire chain to work in reverse. It's a system built for large-scale, planned-out projects, not for a brand that needs to react to a market trend in weeks.

Our Streamlined Communication Process

My approach is completely different. As the founder of iBottler and a 16-year industry veteran, I am your direct point of contact. Here is how we work:

- Direct Consultation: You speak directly with me. We discuss your goals, your bottle design, and the specific Krones machine you're using.

- Rapid Technical Review: I work with my engineering team. We review your drawings and provide feedback or a final design, often within 24-48 hours.

- Transparent Quoting & Timeline: You get a clear quote and a firm 3-4 week delivery timeline.

- Direct Production Oversight: I personally oversee the production of your

custom blow molds for Kronesto ensure quality and timing.

There are no layers of bureaucracy. There is no "I'll have to ask another department." You get direct answers and fast action. This is why clients who value their time and need to be responsive to the market choose to work with us.

What Is the Real Cost Comparison Between Krones Original Molds and Our Custom Solutions?

Your budget for a new product line is tight, and the quote for an OEM mold is shocking. This high cost eats directly into your project's profitability and makes it harder to justify the launch.

Our custom-compatible molds provide the same high performance at roughly half the cost of an original from Krones. We also cut the delivery time down to 3–4 weeks, saving you not just money but also valuable time to market.

The cost difference is one of the most compelling reasons customers come to us, but it's important to understand where these savings come from. It's not from cutting corners on quality. The savings come from efficiency and lower overhead. As a specialized mold manufacturer, our entire business is optimized for producing high-quality molds quickly. We don't have the massive corporate overhead of a company that builds entire bottling lines. We focus on being the best at one thing: making molds. This specialization allows us to source materials efficiently and run a lean manufacturing process.

Beyond the Price Tag: Total Cost of Ownership

When you evaluate a Krones blow mold replacement, you must look beyond the initial purchase price. The total cost of ownership includes factors like downtime, speed to market, and service responsiveness.

| Cost Factor | Krones Original Mold | Our Custom Mold Solution | Impact on Your Business |

|---|---|---|---|

| Initial Investment | High | Moderate (~50% less) | Frees up capital for marketing or other investments. |

| Lead Time | 8-16 Weeks | 3-4 Weeks | Faster product launch, quicker revenue generation. |

| Opportunity Cost | High (due to delays) | Low | You can capture market trends as they happen. |

| Service/Support | Formal, slower process | Direct, 24-hour response | Problems are solved faster, minimizing downtime. |

A faster time to market can be worth hundreds of thousands of dollars for a popular product. A lower initial investment reduces the financial risk of launching a new design. When you look at the complete picture, our solution offers a significantly better return on investment, which is critical whether you're running a single bottle blowing machine or a whole fleet of them.

How Can We Guarantee Our Molds Fit Your Krones Machine Perfectly?

You're considering a third-party mold, but you're worried. What if it doesn't fit? The thought of shipping a mold back, or worse, having machine downtime while you make modifications on-site, is a major concern.

We guarantee a "plug-and-play" fit because we are experts in Krones' technical specifications. Our team has years of experience with their mold holders, cooling interfaces, and positioning systems, ensuring a perfect match every time.

This is a non-negotiable point for us. A mold that doesn't fit is useless. That's why we've invested so much time into reverse-engineering and mastering the interface points of Krones rotary machines. We understand that it's a system of components that must work in perfect harmony at very high speeds. Simply making a cavity with the right shape is not enough. The Krones mold compatible supplier must be an expert in the machine itself. My team and I have documented every critical dimension and specification needed for a seamless integration.

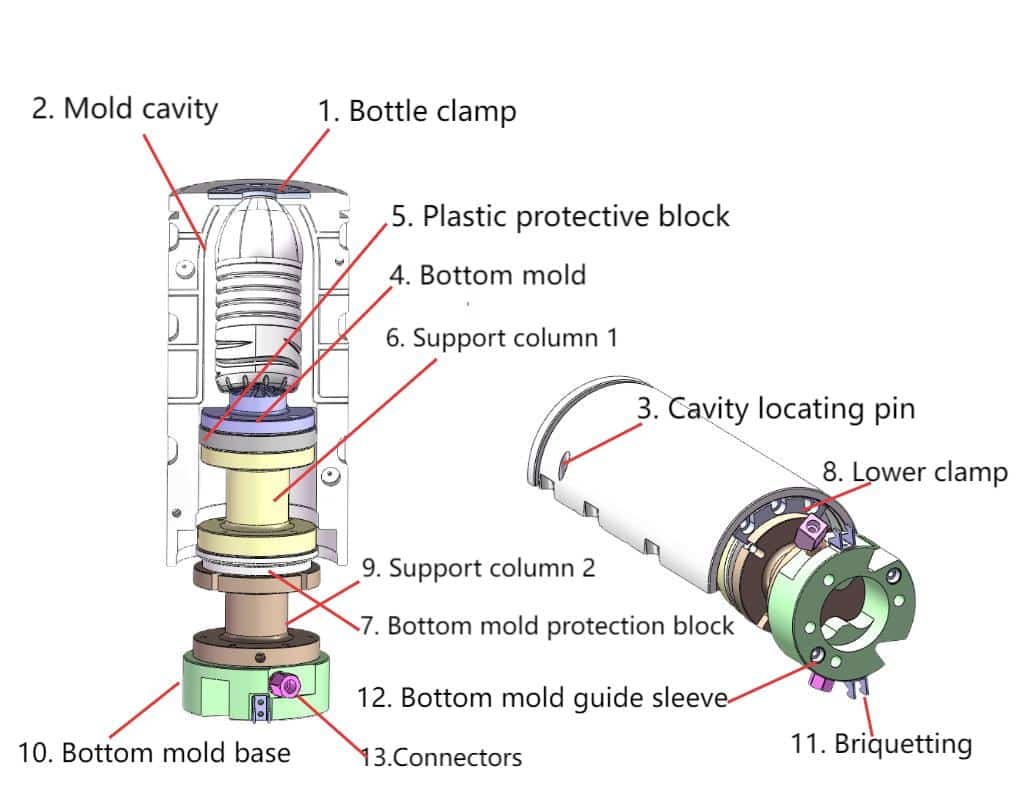

Key Technical Specifications We Master

To ensure 100% compatibility, we focus on several key areas:

- Mold Holder & Base Structure: We replicate the exact mounting footprint, ensuring the mold slides into the Krones mold station without any modification.

- Positioning & Locking Systems: We understand the specific dovetails, pins, or clamps Krones uses to lock the mold in place, guaranteeing precise alignment.

- Cooling Channel Interfaces: The location, size, and type of connectors for the cooling water circuits are matched perfectly to the machine's ports for optimal thermal performance.

- Gripper & Transfer Arm Specs: We ensure that the areas where the machine's grippers handle the mold are dimensionally accurate to prevent any interference.

- Air and Water Circuitry: All internal and external connections for process air and water are placed exactly where the Krones system expects them to be.

Because we have this deep technical knowledge, we can confidently say our molds are "plug-and-play." You can take the mold out of the crate, install it on your machine, and start production. This removes the risk and uncertainty that might make you hesitant to work with a third-party supplier.

Why Did a Leading Cola Brand Choose Our Molds for Their Krones Blow Molding Lines?

You want proof. It's one thing to say we can do the job, but it's another to know that we are trusted by the biggest names in the industry. You need confidence that we can handle a high-stakes, high-volume project.

A world-renowned cola brand with plants in the Middle East uses our custom molds for their Krones production lines. They chose us—and continue to work with us—because we consistently deliver on speed, precision, and collaborative problem-solving for their new product launches.

This is one of my proudest partnerships, and it perfectly illustrates our value. A few years ago, this company's innovation team in the Middle East was tasked with launching a whole new range of bottle shapes for a new product line. They were running state-of-the-art Krones machines, but their global procurement process for original molds was too slow to meet the aggressive launch schedule. They needed a partner who could move as fast as they did.

They found me through my website, www.ibottler.com, where I regularly share technical articles. They were initially cautious, so we started with a single blow bottle mold](https://ibottler.com/blow-bottle-mold/) as a trial. The challenge was a uniquely shaped bottle that required very precise material distribution to meet their strict performance and lightweighting standards. My team and I worked closely with their designers, providing feedback on the preform mold](https://ibottler.com/preform-mold/) design to ensure it would blow correctly. We delivered the finished mold in under four weeks. It was a perfect fit, and it ran flawlessly in their Krones machine from day one.

Since then, we have become their exclusive mold supplier for all new product development in that region. We have built a relationship based on trust and results. They know that when they have a new idea, they can call me directly, and we will find a way to make it happen on time and on budget. This long-term partnership with a brand that has the highest quality standards is the best proof I can offer. It shows that our aftermarket molds for Krones rotary blow machines are not a compromise; they are a competitive advantage.

Does “Compatible” Mean “Low Quality”—Our Material Meets Application Needs?

You're thinking about the lower price and faster delivery, but a doubt creeps in. Does "compatible" or "aftermarket" just mean you're using cheaper, lower-quality materials that will wear out or fail quickly?

Absolutely not. "Compatible" refers to the fit and function, not the quality. We use high-grade, application-specific materials like 6061-T6 aluminum and S136 stainless steel to ensure our molds meet or exceed the demands of your production environment.

This is a critical point of concern for any experienced production manager, and I want to address it directly. The integrity of your final bottle depends entirely on the quality and precision of the mold. Using inferior materials would be a foolish way to save money, as it would lead to poor performance, shorter mold life, and damage to our reputation. We build our business on long-term relationships, which is why we never compromise on material quality. Our goal is to provide a Krones bottle mold alternative that is equal in performance and durability.

Material Selection for Optimal Performance

Our material choices are deliberate and based on the specific application of the bottle. We don't believe in a one-size-fits-all approach.

| Material | Primary Use Case | Key Properties | Resulting Benefit |

|---|---|---|---|

| Aircraft-Grade 6061-T6 Aluminum | Standard PET Bottles (CSD, Water) | - Excellent Thermal Conductivity - Good Hardness - Easy to Machine | Faster cooling cycles, which means higher production speeds. High precision (we achieve ±0.01mm) for consistent bottle quality. |

| S136 Stainless Steel | Hot-Fill or High-Caustic Environments | - Superior Corrosion Resistance - High Hardness & Polishability - Excellent High-Temp Stability | Prevents rust and degradation from high temperatures or harsh cleaning chemicals. Ensures a long mold life for demanding applications. |

We source our materials from reputable suppliers and provide material certificates upon request. The choice between aluminum and steel is a technical decision we make with you, based on your product. For most standard water and soda bottles, 6061-T6 aluminum is the industry standard—used by OEMs as well—because its thermal conductivity allows for the fastest possible cycle times on a modern bottle blowing machine. For hot-fill juices or products requiring harsh cleaning protocols, the durability and corrosion resistance of S136 steel is the superior choice. Quality is not just a promise; it's engineered into every mold we make.

What Makes Your Faster Turnaround, Local Support, and Real Customization Possible?

You're located in another country and operate multiple plants. You're wondering how we can possibly provide faster support and turnaround than an OEM with a local office. The logistics seem complicated.

Our speed comes from our streamlined process and modern communication tools. We offer fast drawing analysis, rapid prototyping, and remote video support to solve problems in hours, not weeks. Our global experience means we can support your plants anywhere in the world.

-2.jpg)

In today's connected world, physical distance is no longer the barrier it once was. The real barrier is organizational complexity, which we have eliminated. An OEM's "local" office is often just a sales or basic service branch that still has to route all serious technical questions back to headquarters in Europe. This creates a time lag that can be crippling when you have a production issue. My team and I leverage technology to provide direct, expert-level support much faster. I've helped commission a new blow bottle mold](https://ibottler.com/blow-bottle-mold/) for a client in Mexico via a WhatsApp video call at 10 PM my time. That's the kind of support you get from a dedicated partner.

Our Agile Service and Support Workflow

Our entire process is built around speed and direct communication, allowing us to deliver custom blow molds for Krones and support them effectively, no matter your location.

- 24-Hour Response Guarantee: When you contact us with a technical question, you get a response from an expert within 24 hours.

- Rapid Design & Prototyping:

- Bottle Design Analysis: We review your proposed bottle design and provide feedback on its blow molding feasibility for free.

- 3D Printed Samples: We can ship a physical 3D printed model of your bottle for you to hold and approve before we even cut the metal.

- Remote Commissioning & Troubleshooting:

- We provide detailed video guides for mold installation.

- We can join a live video call with your on-site technicians to walk them through setup or troubleshoot any issues.

- Global Logistics: We have extensive experience shipping to dozens of countries and handle all the logistics to ensure your mold arrives safely and on time.

This combination of a flat, responsive organization and the smart use of technology means you get better, faster, and more personalized support from us than you often get from a global giant.

What Extra Value Do You Get When You Work with Us?

You need a mold, and you're looking for a supplier. But what if you could get more than just a piece of metal? What if you could get a partner who actively helps you improve your product and your process?

When you work with us, you get a long-term technical partner. We offer free bottle design advice, drawing reviews, and integration support. Our goal is not just to sell you a mold, but to help you succeed with your product launch and beyond.

After 16 years in this business and running my educational website, I've learned that our most successful clients see us as an extension of their own technical team. They don't just send us a purchase order; they engage with us. They ask for our opinion on lightweighting a bottle, on choosing the right preform mold](https://ibottler.com/preform-mold/) for a new shape, or on how a new design might impact their capping process. This is the part of the job I love the most. Providing a high-quality Krones blow mold replacement is the foundation, but being a trusted advisor is what builds an 80%+ repurchase rate.

Our Partnership-Based Services

We believe that our success is tied to yours. That's why we include a range of value-added services at no extra cost.

| Value-Added Service | How It Helps You |

|---|---|

| Free Bottle Design Feasibility Analysis | We review your concept and identify potential blowing issues before you invest in a mold, saving you from costly redesigns. |

| Preform Compatibility Suggestions | We can advise if your existing preform is suitable for your new bottle or suggest a more optimal design, improving bottle quality and performance. |

| Lightweighting Recommendations | We can analyze your bottle design and suggest ways to reduce resin weight without sacrificing strength, saving you significant material costs over time. |

| Full Production Line Integration Advice | Because of my broad experience, I can offer insights on how your new bottle will interact with fillers, cappers, and labelers. |

| Ongoing Technical Support | Our relationship doesn't end on delivery. We are here to help you solve any production challenges you face with the mold in the future. |

Choosing us is not a simple transaction. It's an investment in a partnership that gives you access to deep industry expertise. We are here to help you innovate faster, reduce your risks, and make your entire production process more efficient.

Conclusion

Choosing our custom molds for your Krones machine is a strategic decision. You get a high-quality, perfectly compatible product for about half the cost and in a fraction of the time, all backed by a dedicated technical partner invested in your success.

Frequently Asked Questions (FAQ)

1. Is the lifespan of your aluminum molds comparable to an original Krones mold?

Yes, absolutely. We use high-grade 6061-T6 aircraft-grade aluminum, the same material class often used by OEMs for standard applications. When properly maintained, our molds are designed to last for millions of cycles, ensuring a long and productive life in your Krones machine. The key to longevity for any mold, OEM or ours, is proper handling and maintenance.

2. What is the process if a mold needs a small adjustment after delivery?

Our goal is a perfect mold on the first delivery. However, we are your partners. If a minor adjustment is needed, our process is fast and simple. We first diagnose the issue with your team via photos and video calls. For very small adjustments, we can guide your local technicians. If a physical modification is needed, we will arrange and cover the cost of expedited shipping back to our facility, make the adjustment with the highest priority, and return it to you immediately.

3. Do you have experience with unique or complex bottle shapes?

Yes, this is one of our specialties. We have extensive experience with asymmetrical designs, bottles with intricate embossing, and challenging handleware. Our work with the international cola brand involved several complex, non-symmetrical shapes. Our process includes a thorough design-for-manufacturing analysis where we identify potential challenges with complex shapes and work with you to find solutions before any metal is cut.

4. Can you work with our existing preform design?

Certainly. A large part of our job is to design a blow bottle mold](https://ibottler.com/blow-bottle-mold/) that works with a client's existing preform inventory. When you send us your bottle design, please also provide the drawing for your existing preform. We will run a simulation and analysis to ensure the material distribution will be optimal. If we foresee any issues, we will advise you on potential adjustments to the bottle or preform.

5. How do you handle shipping and logistics to our country?

We have years of experience shipping our molds to clients across the globe, including North America, Europe, the Middle East, and Southeast Asia. We work with reliable international carriers like DHL, FedEx, and Kuehne + Nagel. We handle all export documentation and packaging to ensure the mold is protected during transit and clears customs smoothly. We provide you with tracking information and support you until the mold is safely in your facility.

🔗 Learn More about Krones Blow Molding Systems and Mold Compatibility

Krones Lifecycle Services – Official Website

Details about Krones' official maintenance and mold replacement cycle, relevant when comparing aftermarket alternatives.Blow Molding – Wikipedia

General explanation of the blow molding process, used in both Krones and compatible third-party mold systems.Mold (Manufacturing) – Wikipedia

Overview of mold design and production, including compatibility considerations.Polyethylene Terephthalate – Wikipedia

PET is the primary material used in Krones-compatible bottle production, influencing mold precision and cooling.Bottle Design – Wikipedia

Explains how bottle shape, neck finish, and branding considerations influence mold development.

Many of our clients previously used Krones stretch blow molding systems, especially the Contiform series. After the warranty period, they found that official mold replacement services often came with high costs and long delivery times.

As a result, they turned to us for custom-designed molds that are 100% compatible with Krones machines — with faster turnaround and competitive pricing.

“Krones is a registered trademark of Krones AG. We are not affiliated with or endorsed by Krones. Our molds are third-party compatible solutions designed for Krones blow molding machines.”

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr