Struggling with the idea of switching your blow mold supplier? You're worried a new mold won't fit your machine, causing costly downtime and frustration, especially when sending samples overseas is not an option.

Relax. We have the mounting dimensions for over 80% of blow molding machines globally. By matching your machine's brand and model to our extensive database, we guarantee a perfect fit for your blow bottle mold without needing you to ship a single template.

You might be wondering how we can be so confident. It comes down to years of experience, meticulous data collection, and a commitment to making our clients' lives easier. Let me break down exactly how we eliminate the guesswork and deliver a mold that fits perfectly, every single time.

Why Do International Buyers Hesitate to Switch Blow Mold Suppliers?

Many of our international clients initially feel stuck with their original equipment manufacturer for molds. The fear of a new blow bottle mold not fitting their machine is a major barrier, especially when you're thousands of miles away and can't just send a physical sample for matching.

The primary hesitation comes from the risk of dimensional incompatibility. Buyers worry about mismatched mounting plates, incorrect hole positions, and incompatible air and water connections, which can lead to significant production delays and extra costs. This fear keeps them from exploring more cost-effective options.

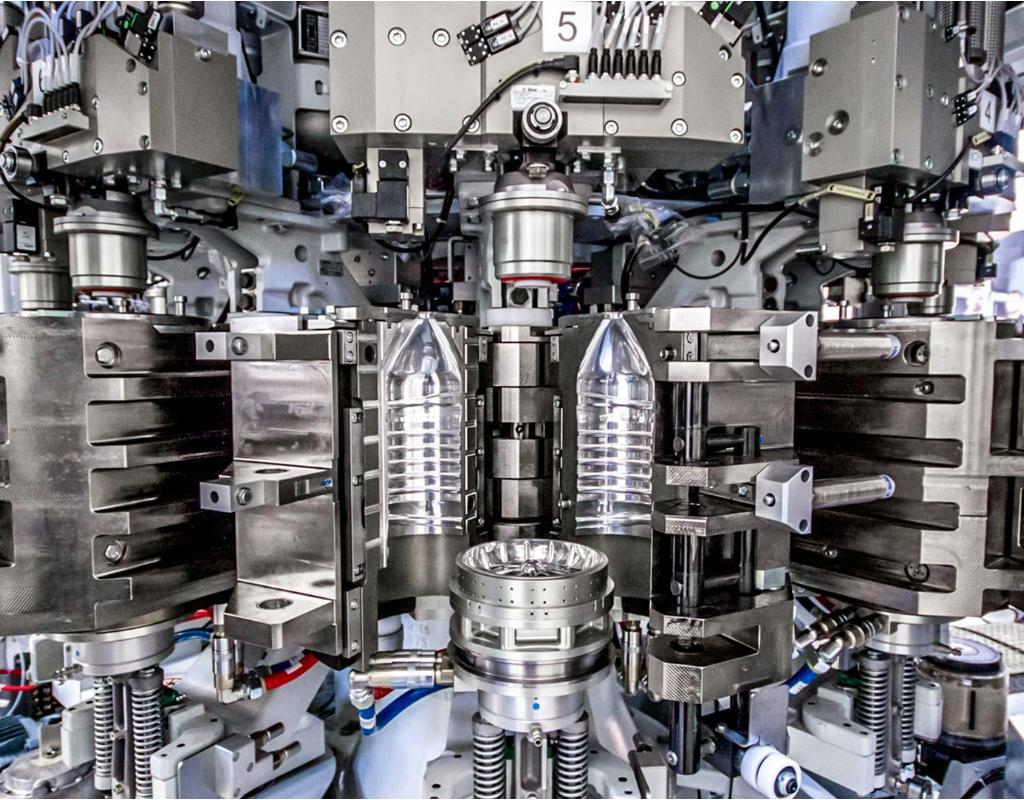

This concern is completely valid. A blow mold is not a one-size-fits-all component; it's a precise piece of engineering that must integrate seamlessly with a specific bottle blowing machine. I remember a client from Ghana who was paying a 20% premium for molds from his machine's manufacturer. He was interested in our services because of the significant cost savings but was extremely worried about the fit. He told me, "I can't afford a mistake. If the mold doesn't fit, my production line stops." This is the core anxiety for many global buyers. They are weighing potential savings against the risk of operational paralysis. The critical interface points are not just about the mold's outer dimensions; it's about the fine details that ensure a perfect lock-up.

Key Mold Interface Points

| Feature | Importance | Risk of Mismatch |

|---|---|---|

| Mounting Plate Holes | Secures the mold to the machine's clamping unit. | Machine cannot hold the mold. |

| Cooling Channel Ports | Connects to the machine's water lines for temperature control. | Ineffective cooling, poor bottle quality. |

| Air & Vacuum Lines | Interfaces for the blow and pre-blow process. | Bottle formation failure. |

| Stripper/Gripper Interface | Ensures the finished bottle is removed correctly. | Jamming and production stoppage. |

Understanding these potential failure points is why we've moved beyond needing physical templates. We rely on data.

Do You Already Have Interface Data for 80% of Chinese Blow Molding Machines?

You're sourcing from China and need a new mold supplier, but the thought of coordinating technical details is daunting. How can you be sure a new supplier understands the specific requirements of your Chinese-made bottle blowing machine?

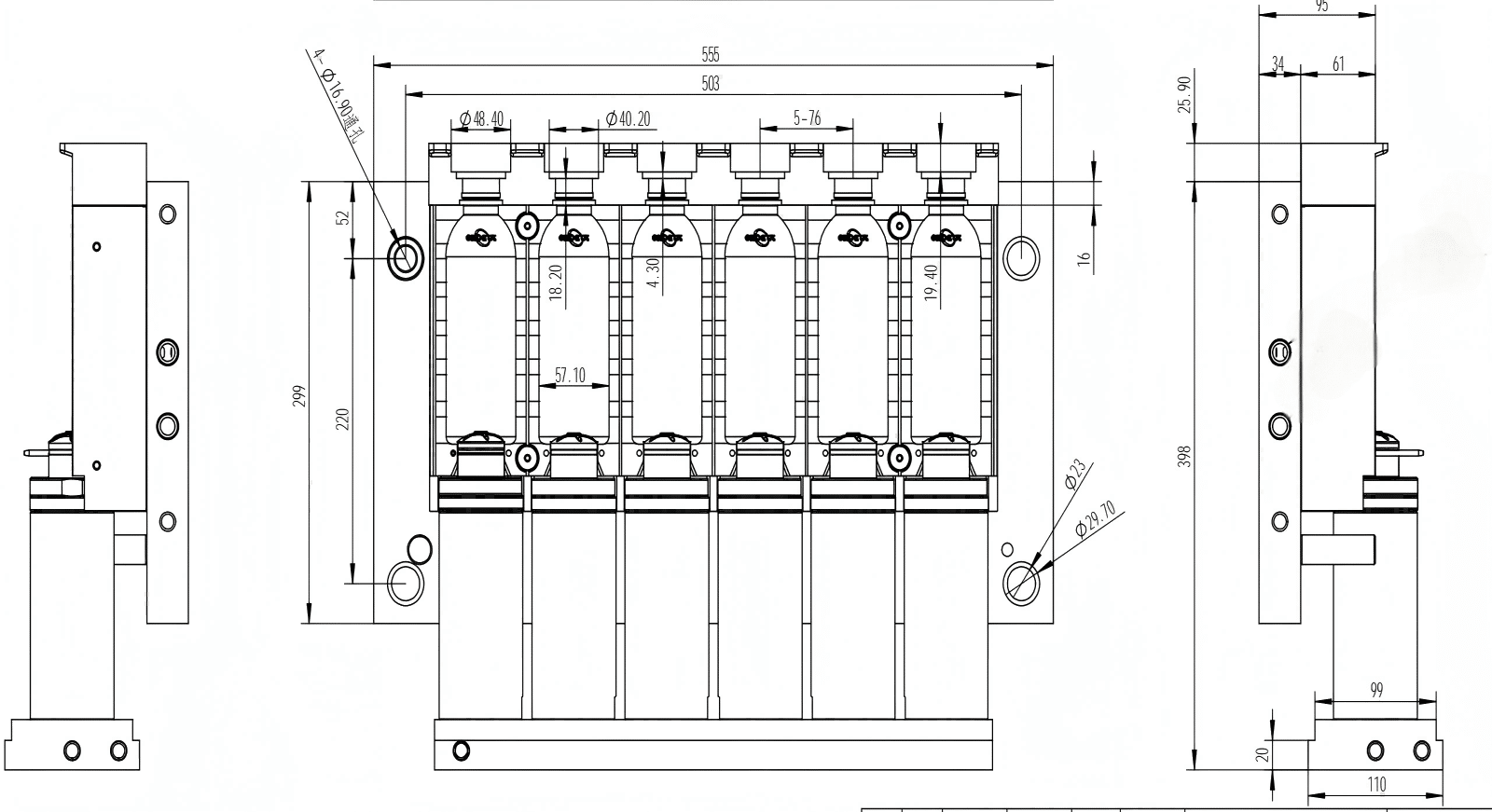

Yes, we do. Having served the domestic Chinese market for years, we have accumulated a massive database covering the mold holder dimensions, template hole positions, and air/cooling connection structures for over 80% of blow molding machines manufactured in China.

Our advantage comes from our deep roots in the local industry. We haven't just sold molds; we've partnered with countless factories running a wide variety of Chinese machine brands. Every time we create a blow bottle mold for a new client, we meticulously document the host machine's specifications. This isn't just a simple measurement; it's a complete digital blueprint of the mold interface. This includes the exact pitch and diameter of bolt holes, the type of quick-connect fittings for cooling lines, and the precise location of the blowing needle assembly. For instance, brands from Zhangjiagang, Taizhou, and Guangzhou all have their own subtle variations. A machine model from one year might have a different platen layout than the next. Our database accounts for these nuances, allowing us to select the correct template from the get-go. This proactive data collection means when a client tells us they have a specific model, we can often pull up the exact drawings immediately.

Sample of Chinese Machine Brands in Our Database

| Brand Origin | Common Brands Covered | Key Data Points |

|---|---|---|

| Zhangjiagang | Bestar, Newamstar, Huihe | Mold holder, clamp interface, cooling circuit |

| Taizhou | Demark, Sino | Platen hole pattern, blow nozzle height, stripper plate specs |

| Guangzhou | Tech-Long,Ribo | Rotary machine interfaces, custom air/water manifolds |

This library of information is our secret weapon for providing fast, accurate, and reliable mold solutions for users of Chinese machinery.

Do You Also Support Leading Global Brands Like SIDEL, Krones, SACMI, SIPA?

You run a high-end production line with machines from global leaders like SIDEL or Krones. You want the cost benefits of sourcing molds from China, but you're concerned a Chinese supplier won't meet the stringent standards of your premium bottle blowing machine.

Absolutely. Our molds are exported worldwide, and we have extensive experience working directly with users of SIDEL, Krones, SACMI, and SIPA machines. We have mastered the standard mold frame, interface, and blow pin position parameters for these leading international brands.

Working with premium brands requires a different level of precision. These machines, especially the rotary blow-fill-cap systems, operate at incredible speeds, and the tolerance for error in a blow bottle mold is virtually zero. We recognized early on that to serve this market segment, we had to become experts in their specific systems. We have invested heavily in reverse-engineering and documenting the interfaces for their most popular series, like the SIDEL SBO Universal or the Krones Contiform. This means we know the exact specifications for their quick-change mold systems, the precise alignment features, and the standardized utility connections they use. It’s not just about fitting; it’s about performing. Our molds are designed to be a direct replacement, offering the same reliability and ease of installation as an OEM mold, but at a more competitive price point. This allows our customers to reduce their operational costs without compromising on the quality and performance they expect from their top-tier equipment.

Key Parameters for Global Brands

- Quick-Change System Compatibility: Ensuring our molds work with the machine's rapid changeover mechanisms.

- Blow Nozzle Alignment: Perfect alignment is critical for high-speed rotary machines.

- Cooling Efficiency: Matching or exceeding the OEM cooling channel design for optimal cycle times.

- Material Durability: Using high-grade aircraft aluminum and stainless steel to withstand high production demands.

This expertise gives our clients the confidence to trust us with their most critical production lines.

Do I Really Not Need to Ship Templates for a Verified Machine Match?

The logistics of shipping heavy, bulky mold templates across continents are a nightmare. You're faced with high costs, customs delays, and the risk of damage, all before production can even start. Is there a better way?

That's correct. There is absolutely no need to ship templates. Simply provide us with the brand and model of your bottle blowing machine. We can then pull the matching interface data directly from our verified database, completely avoiding the complicated and expensive process of shipping physical samples.

Let me walk you through the experience of my Ghanaian client. He had a 6-cavity fully automatic machine from a Zhangjiagang supplier. He was paying too much for molds. He came to us for a better price, but his biggest fear was the fit. He said, "I trust your quality, but I am very worried you can't match the mounting data correctly." I understood his concern completely. Instead of asking for a template, I simply asked for the machine's brand and model number. As it turned out, we had already made molds for that exact machine. To give him 100% peace of mind, I pulled the technical drawings for that specific blow bottle mold interface from our database and sent them to him for confirmation. He checked the platen layout, the cooling port locations, and the clamp dimensions against his machine. Everything matched perfectly. Only after he gave his confident "okay" did we begin manufacturing. This "data-first" approach transforms the process from a logistical problem into a simple information exchange.

Traditional Process vs. Our Data-First Process

| Step | Traditional Mold Making | Our Data-First Method |

|---|---|---|

| 1. Initial Inquiry | Client expresses interest, worries about fit. | Client expresses interest, worries about fit. |

| 2. Data Gathering | Client must prepare, pack, and ship a physical mold template. | Client provides machine brand and model. |

| 3. Verification | We receive and measure the template. | We pull verified data and send a 2D/3D drawing for client confirmation. |

| 4. Lead Time | Delayed by international shipping (weeks or months). | Instantaneous. Production can start after drawing confirmation. |

| 5. Cost | High shipping and insurance costs for the client. | Zero shipping costs. |

This streamlined workflow not only saves time and money but, more importantly, it eliminates the primary source of anxiety for our overseas customers.

Will I Get a Standardized Blow Mold Interface Drawing for Confirmation Before Production?

You're about to invest in a new mold, and the last thing you want is a surprise on installation day. How can you be absolutely certain that every connection and mounting point will match your machine perfectly?

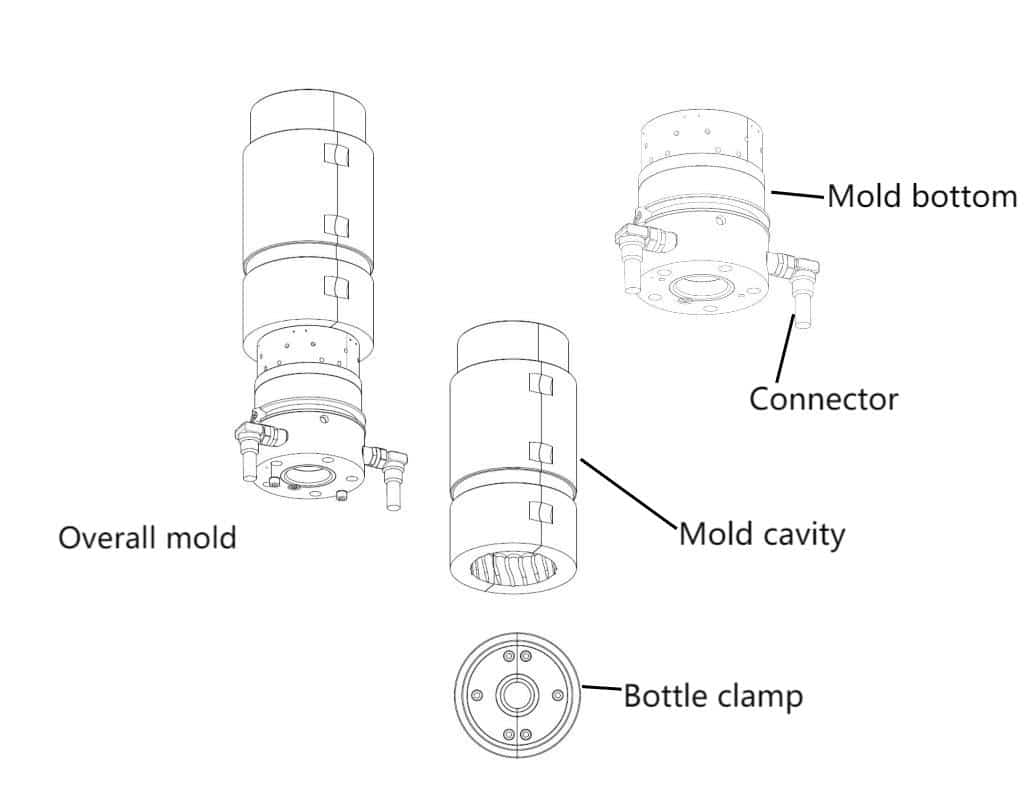

Yes, always. Before we begin any machining, we provide you with a standardized interface drawing for final confirmation. This drawing details every critical point—bolt holes, gripper interfaces, cooling water ports—to ensure a 100% match. We only proceed after you approve it.

This confirmation step is a non-negotiable part of our process. It serves as a final, critical check to guarantee a flawless fit. The drawing we send is a clear, easy-to-read technical blueprint. It's not a complex CAD file that requires special software to open; it's a universal format like a PDF. On this drawing, we highlight all the interface dimensions. The client, or their on-site engineer, can then take this drawing to the bottle blowing machine and visually verify every single point. They can check the distance between mounting holes, the thread size of the water connections, and the position of the neck finish clamps. This simple act of verification builds immense confidence and removes all doubt. For the overall bottling process to be smooth, everything from the preform mold that creates the initial shape to the final blow mold must be precise. By getting your explicit sign-off on the interface drawing, we create a shared commitment to accuracy. This ensures that when your mold arrives, it's not a moment of hope, but a moment of certainty.

Do You Support Mixed Machine Lines and Custom Adaptation?

Your production line isn't standard. It's a mix of different machine brands, or maybe you've modified machines over the years. You're worried that finding a mold that works across your unique setup is impossible.

Yes, we specialize in these complex scenarios. Even if you have modified machines or a mixed production line, we can design a compatible solution. By analyzing your bottle design drawing and on-site installation photos, we can create a custom-adapted blow mold that fits your unique requirements.

Customization is where our engineering expertise truly shines. We understand that many factories evolve over time. They might buy a machine from one brand and later add a second from another. Or, they might modify a machine to handle a new type of preform or bottle shape. In these cases, a standard "off-the-database" solution might not work. This is where our collaborative approach comes in. We ask the client to provide two key things: the final bottle drawing and some clear photos of the machine's mold mounting area. Our engineers use the bottle drawing to design the mold cavity itself. Then, they use the photos—which might show the platen, the cooling manifolds, and the stripper assembly—to custom-design the mold base and interface. We can create hybrid designs, for example, a mold base that has mounting holes for two different types of machines, allowing you to use the same mold on different lines. This flexibility is invaluable for factories looking to optimize their mold inventory and production scheduling. It's about providing a solution, not just a product.

Are You Trusted by Global Buyers in Over 30 Countries?

You've heard the promises, but you need proof. You want to know if other international companies, facing the same challenges as you, have successfully used this service and are happy with the results.

Yes, our data-driven approach has earned the trust of buyers in over 30 countries. Clients from the USA, Saudi Arabia, Indonesia, Nigeria, and many more regularly purchase our molds as direct replacements for original equipment, achieving a perfect, first-time installation.

Our global track record speaks for itself. The reason we have built long-term relationships with clients from such diverse markets is simple: our system works. A buyer in Saudi Arabia, running a high-speed line with a European bottle blowing machine, has the same fundamental need as a buyer in Nigeria with a Chinese machine: a mold that fits perfectly and performs reliably. Our process removes the geographical barriers and technical uncertainties that often complicate international sourcing. I recently worked with a client in the United States who was replacing molds for an older, less common machine model. They were skeptical at first. By providing them with detailed confirmation drawings and showing them case studies from other clients, we earned their trust. They received the molds, installed them without a single issue, and were so pleased with the seamless process and the quality of the final bottles that they've already placed a repeat order. This is a common story for us. Trust isn't built on words; it's built on consistently delivering a perfect-fit blow mold that gets our clients into production faster.

How Can I Work with You to Save Time, Avoid Errors, and Start Production Faster?

You're tired of the endless back-and-forth, the risk of rework, and the long delays associated with sourcing molds internationally. You need a process that is fast, accurate, and gets you to market quicker.

Work with us and experience "data-level matching." You don't need to send templates or worry about rework. Our ability to match your machine using verified data saves you from overseas shipping hassles and repetitive confirmations, helping you launch production fast.

Starting is easy. The first step is to simply reach out to us with your requirements. All you need to provide is the brand and model of your blow molding machine and your desired bottle design. From there, our process is designed for speed and accuracy. We handle the technical heavy lifting, cross-referencing our database to find the perfect match or to engineer a custom solution. Forget about the costs and delays of shipping templates. Forget about the anxiety of wondering if the new mold will fit. We replace that uncertainty with a clear, simple confirmation process. Our goal is to make acquiring a new, perfectly-fitting blow mold as easy as possible. This efficiency has a direct impact on your bottom line. Less downtime, no modification costs, and a faster start to production mean a quicker return on your investment. Let us show you how our data-driven approach can de-risk your mold procurement and accelerate your business. The entire bottling line, from the preform mold to the filler, depends on precision. We deliver that precision right from the start.

Conclusion

Stop worrying about blow mold fit. With our extensive database and data-driven confirmation process, we guarantee a perfect match, helping you save time, avoid errors, and start production faster.

Frequently Asked Questions (FAQ)

1. What if my machine is very old or the brand is not well-known?

This is a common concern. Even if your machine is from a lesser-known manufacturer or is an older model not in our primary database, our custom adaptation process is designed to handle it. You would need to provide us with clear photos of the mold mounting area (the platens) and some basic measurements that we will guide you through. Our engineering team can then create a custom interface drawing for your confirmation, ensuring a perfect fit.

2. How can I be 100% sure the drawing you send is correct for my machine?

The confirmation drawing is your ultimate safety check. We provide clear, dimensioned views of all critical contact points. We highly recommend that you or your on-site technician take this drawing to the machine and physically compare the dimensions. You can measure the bolt hole pattern, check the location of water and air ports, and verify the overall size against the space in the machine. We do not start production until you are 100% confident and have given your official approval.

3. What is the typical lead time difference between your data-matching process and the traditional method of sending a template?

The time savings are significant. Shipping a physical template internationally can take anywhere from one to four weeks, depending on the destination and customs clearance. This is dead time before we can even start our work. With our data-matching process, we can often send you a confirmation drawing within 24-48 hours of your initial inquiry. This means we can potentially start manufacturing your mold weeks earlier, directly shortening your overall project timeline.

4. Do your molds perform as well as the original ones from manufacturers like Krones or Sidel?

Yes. We use high-quality materials, such as aircraft-grade aluminum and stainless steel, and we pay close attention to critical performance factors like cooling channel design. Our goal is to match or even exceed the performance of OEM molds in terms of cycle time, durability, and bottle quality. Many of our clients who run high-end European machines choose us as their long-term partner because they achieve the same performance at a better price.

5. What information do I need to provide to get a quote and a confirmation drawing?

To start the process, you only need to provide two pieces of information:

- Your bottle blowing machine brand and model number. (e.g., SIDEL SBO 14, a Zhangjiagang 6-cavity machine, etc.)

- Your bottle drawing or sample. (A 2D or 3D drawing is best, but a clear photo with dimensions can also work for an initial quote.)

With this information, we can provide you with a quote and, in most cases, a preliminary interface drawing for your review.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr