China is home to a vast number of mold factories, primarily concentrated in the Zhejiang and Guangdong provinces. The scale and quality of these factories vary immensely, which makes it incredibly difficult for a first-time buyer to determine if they're dealing with a high-quality supplier.

This challenge brings to mind a client of mine from Ghana. He told me he had once ordered a 4-cavity blow mold from a Chinese company. The primary reason he chose them was the incredibly low price. However, when he received the mold, it was a complete disaster. The mold's structure didn't match his blowing machine at all; it was impossible to install. To make matters worse, the material was cheap P20 steel, which began to rust almost immediately. This single experience destroyed his confidence in Chinese mold factories. When he contacted me, he was adamant that he didn't want to source from China again and was looking at suppliers in Turkey instead.

I completely understood his frustration. But I asked him, "When you chose that factory, did you ask them 10 critical questions?" He was confused. "What 10 questions?"

Today, I'm sharing those 10 questions with you. By mastering this checklist, you'll have a clear framework to audit any potential supplier when you need to source a PET blow bottle mold, ensuring you find a trustworthy, high-quality partner.

Question 1: Are You a Factory or a Trading Company?

This foundational question remains the most critical starting point. Direct communication with a true PET blow mold manufacturer is the only way to guarantee technical accuracy, faster problem-solving, and better value for your investment.

Think about the workflow. When you have a technical query or need an urgent design modification, a trading company acts as a middleman. They relay your message to the factory and then relay the factory's response back to you. This process is not only slow but also incredibly prone to errors and misunderstandings. I’ve seen cases where a simple change request gets distorted through this "telephone game," leading to a final product that deviates from the client's requirements. Direct access to the factory’s engineers means you can solve problems in real-time, share technical drawings, and have a nuanced discussion.

What to Look For in Their Answer:

Don't just accept a "Yes, we are a factory." The proof is essential. A legitimate factory will be proud to show you their operations. Insist on a live video tour. Ask them to walk you through their workshop, showing you their CNC machining centers, their EDM machines, and their mold assembly area. Seeing the machines running and the technicians working is the most powerful evidence of their status. If they hesitate or offer excuses, it’s a major red flag.

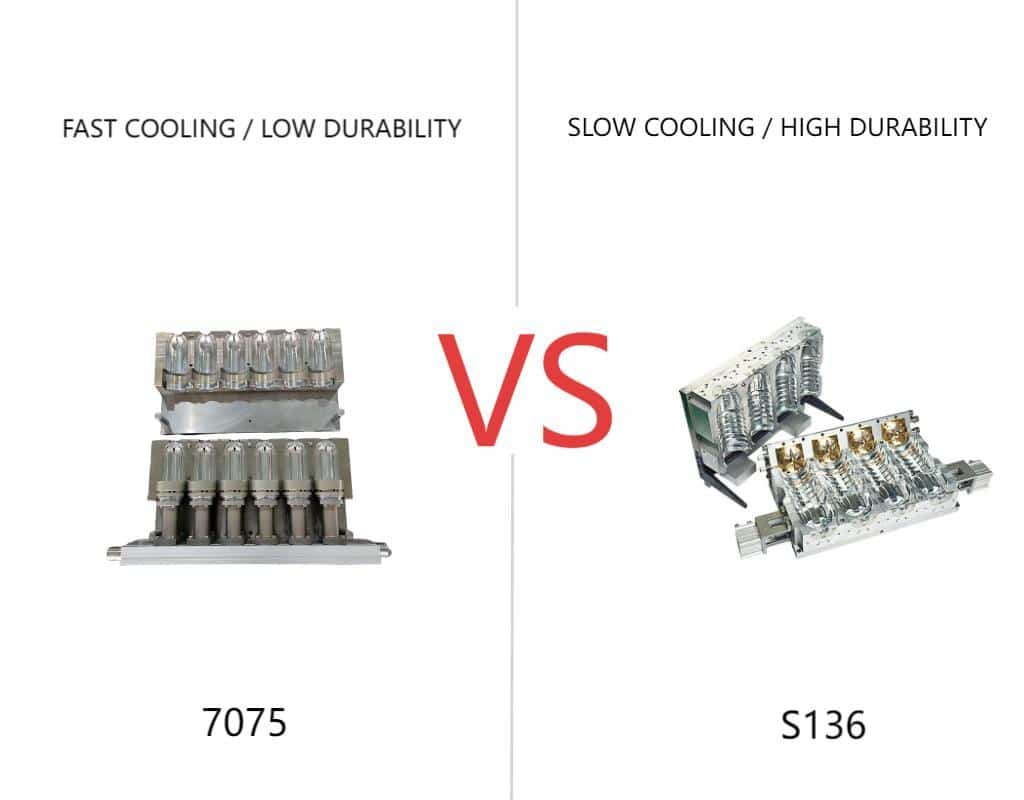

Question 2: What Is the Right Mold Material for My Bottle? (7075 Aluminum vs. S136 Steel)

Choosing the correct material for your bottle directly impacts production efficiency, mold lifespan, and the final quality of your product. A professional bottle mould maker in China will recommend the most suitable material based on your specific application, rather than just pushing the most expensive option or, even worse, using cheap materials to lower their quote. My client in Ghana learned this the hard way with his rusty P20 mold.

Here’s a clear breakdown of the two primary materials we use and recommend for automatic machine molds:

| Feature | 7075 Aircraft-Grade Aluminum | S136 Stainless Steel |

|---|---|---|

| Primary Advantage | Excellent Thermal Conductivity | Superior Corrosion Resistance & Hardness |

| Production Speed | Faster (shorter cooling/cycle times) | Slower (longer cooling times) |

| Best For | High-volume water, CSD, juice bottles | Corrosive materials, medical, mirror-polish |

| Weight | Lightweight (easier handling) | Heavy |

| Cost | More cost-effective | Higher initial investment |

| Guaranteed Lifespan | ~5 Million Shots | >8 Million Shots |

7075 Aircraft-Grade Aluminum: This is the go-to material for most high-volume applications like bottled water and carbonated soft drinks (CSD). Its key advantage is its phenomenal heat transfer capability. It pulls heat out of the blown bottle much faster than steel, allowing for shorter cycle times and significantly higher output. This makes a 7075 aluminum mold a very cost-effective choice for maximizing production efficiency.

S136 Stainless Steel: This is the premium, top-tier choice. If your product contains corrosive elements, or if you require a flawless, crystal-clear finish that demands a true mirror polish on the mold cavity, S136 is the only answer. Its hardness and corrosion resistance ensure the mold cavity surface remains perfect over millions of cycles, which is critical for medical or high-end cosmetic applications.

The P20 Steel Trap: We explicitly refuse to use low-grade steel like P20 for molds intended for automatic machines. The reason my client’s mold rusted is that P20 has poor corrosion resistance. Furthermore, it's a softer steel that cannot be hardened to the same degree as S136, making it prone to wear and damage under the high clamping forces of an automatic bottle blowing machine. It's a shortcut that leads to production nightmares and a short mold life.

Question 3: How Do You Guarantee the Mold Will Perfectly Match My Blowing Machine?

This is a crucial technical checkpoint that can make or break your entire project. A beautifully crafted mold that doesn't fit your machine is nothing more than a very expensive paperweight. This question directly tests a supplier's technical diligence and professional processes.

The nightmare scenario my Ghanaian client faced—receiving a mold that simply wouldn't install—is entirely avoidable. A professional manufacturer has a robust process to prevent this. We guarantee a 100% drop-in fit, but this guarantee is based on a meticulous data exchange process. We require our clients to provide either the machine’s technical drawings or a set of key interface dimensions. If you're worried about blow mold fit, providing this data is the most important step.

To make this process easier, here is a checklist of the typical dimensions we would need to confirm:

| Critical Dimension Checklist | Purpose |

|---|---|

| Mold Plate Thickness & Mounting Holes | Ensures the mold base fits on the machine platen. |

| Locating Ring Diameter & Height | Centers the mold correctly within the machine. |

| Slider/Carriage Stroke & Path | Confirms that side actions (like for handles) can move freely. |

| Stretch Rod Interface & Stroke | Guarantees the stretch rods can enter and move correctly. |

| Cooling Water Connector Specs & Location | Allows you to connect your chiller without issues. |

| Air Pipe Connector Specs & Location | Ensures the high-pressure air from your cost-efficient air system connects properly. |

With this data, our design team creates a mold structure that is a perfect match for your specific machine brand and model. This ensures you can simply load the mold, connect the utilities, and start production with minimal downtime. It’s a core part of any good custom blowing mold project.

Question 4: How Do You Ensure Uniformity Across All Cavities in a Multi-Cavity Mold?

For a multi-cavity bottle mold, consistency is everything. If a 6-cavity mold produces six bottles with slight variations in weight, wall thickness, or volume, it creates a cascade of downstream problems: inconsistent fill levels, issues with capping, and skewed labels. It is a quality control nightmare.

The secret to perfect uniformity is machining precision. Vague promises of "good quality" are meaningless. You need to ask about their technical capabilities. We explain to our clients that all core cavity components are machined in our high-precision CNC centers, which operate with a tolerance of under +/- 0.01mm.

This incredibly tight tolerance ensures that every cavity is a virtual clone of the others. From the first cavity to the last, the dimensions, contours, and volume are identical. This results in every single bottle produced having the same weight, thickness, and volume, with zero deviation. This is fundamental to protecting your product quality and brand image. Inconsistent bottles are often the first sign of a poorly made mold, and can lead to many of the issues detailed in guides about common PET blow molding defects.

Question 5: Can I Review and Approve the 3D Bottle & Mold Design Before You Cut Steel?

Absolutely. This is not just a right; it's a mandatory step in our workflow. This modern, collaborative approach is far more intuitive than relying on complex mold flow analysis reports and ensures the final product perfectly matches your vision.

Our transparent design approval process is broken into two key stages:

3D Bottle Model Approval: Before we even think about the mold structure, we create a complete 3D model of the final bottle based on your requirements. We send this to you for a full review. You can rotate it 360 degrees, zoom in on details, and check every curve. This is the time to make adjustments. Once you are 100% satisfied and give written confirmation, we lock the bottle design. This is the most crucial step detailed in any good PET bottle mold design guide.

3D Mold Assembly Approval: After the bottle design is confirmed, our engineers create the complete 3D mold assembly drawing. This technical drawing shows all the components, the cooling channels, the venting system, and how it will interface with your machine. This is sent to your technical team for a final review before a single piece of steel is machined. For even faster validation, we can also discuss services like 3D printed samples to rapidly validate designs before committing to the final tool.

This two-stage process completely eliminates the risk of misunderstandings and ensures your vision is perfectly translated into the final product.

Question 6: How Do You Test the Mold, and What Will I Receive for Approval?

Seeing is believing. A mold that looks perfect on a computer screen must be validated through real-world testing. A responsible manufacturer will never ship a mold without putting it through a rigorous trial.

Our standard procedure includes in-house mold testing on our own bottle blowing machines. Once the trial is successful, we compile a comprehensive "approval package" for you, which includes:

- A Full Set of Initial Samples: We will send you physical samples from every single cavity. If it’s a 6-cavity mold, you will receive at least six samples. This is non-negotiable as it allows you to verify the consistency we promised in Question 4.

- A Detailed Parameter Report: This document records all the key settings used during the trial, including heating temperatures, blowing pressures, and cycle times. This report is an invaluable starting point for your team to quickly set up successful production in your own factory.

- A High-Definition Testing Video: We will film the mold running smoothly in the machine, showing the clear and consistent production of bottles. This provides visual confirmation that the mold is functioning correctly. It also shows that all auxiliary systems, like the connection to a chiller for proper cooling, are working as designed.

We only consider the manufacturing phase complete after you have received and approved this package.

Question 7: Can You Share Case Studies for My Specific Industry (e.g., Water, CSD, Oil)?

This is an excellent question to gauge a supplier’s relevant experience. Different types of bottles have vastly different performance requirements, and a top-tier mold manufacturer must understand these nuances.

- Water Bottles: The focus is on high clarity, lightweighting (especially the neck finish), and fast cycle times.

- CSD Bottles: These must withstand significant internal pressure, requiring a very strong petaloid base design and precise wall thickness distribution.

- Edible Oil Bottles: These often have integrated handles, which makes the mold structure more complex. The design must also account for top-load strength for stacking.

When a client asks us this, we are happy to share case studies from their specific industry. Whether it’s showcasing a high-strength CSD mold for a major beverage brand or a complex handle-ware mold for an edible oil company, these real-world examples prove that we don't just know how to machine metal—we understand the unique demands of your market. This expertise includes understanding how the initial preform, often made from a high-quality PET preform mold, will behave, and even advising on details like how to choose the right preform neck size for a specific application.

Question 8: What Is Your Quoted Mold Lifespan in Number of Shots?

A mold is a long-term capital investment, and its durability directly affects your cost per unit. A vague promise of "high quality" is not enough. You need a specific, quantifiable guarantee of its lifespan.

Based on the material you choose, we provide a clear guarantee in our quotes and contracts:

- 7075 Aircraft-Grade Aluminum Molds: A guaranteed lifespan of at least 5 Million Shots.

- S136 Stainless Steel Molds: A guaranteed lifespan of over 8 Million Shots.

We can confidently offer these guarantees because they are supported by our manufacturing process. It starts with sourcing certified raw materials from top brands, followed by precise heat treatment protocols to achieve the desired hardness, and finished with high-precision CNC machining. Each step is designed to maximize the mold's longevity and performance.

Question 9: What Is Your After-Sales Support and Warranty Policy for International Clients?

For overseas buyers, after-sales support is one of the biggest concerns. If a problem arises, will you get timely and effective help from a supplier who is thousands of miles away? This question probes their commitment to long-term partnership.

We provide a clear and reliable after-sales policy for all international clients:

- 1-Year Warranty: From the date of delivery, we offer a one-year warranty on all non-wear-and-tear components of the mold.

- Spare Parts Support: Each mold is shipped with a kit of essential wearing parts (e.g., seals, cutting blades). If you need additional spare parts during the warranty period, we will ship them to you quickly via international courier.

- Remote Technical Support: If you encounter any operational or troubleshooting issues, our engineering team is available via video call to provide remote guidance and help you get back into production as quickly as possible.

Question 10: What Are Your Payment Terms and How Do You Protect My Investment?

Finally, establishing financial trust is the bedrock of a successful partnership. A transparent and fair payment structure protects both parties.

Our standard payment terms are designed to tie our success directly to yours, protecting your investment:

- 50% Down Payment: Paid after you confirm the order and approve the final 3D mold designs. This allows us to start the project and procure the certified materials.

- 50% Balance Payment: Paid only after we have completed the mold trial and you have received and approved the physical samples, testing report, and video. We do not ask for the final payment until you are 100% satisfied with the results.

This "approval before balance" model means we take on the full responsibility for making the mold successful. It demonstrates our confidence in our work and our commitment to a fair, long-term partnership.

Conclusion: Your Supplier Audit Checklist

To help you in your practical communications with potential suppliers, we've summarized these 10 core questions into a clear checklist.

| No. | Core Question |

|---|---|

| 1 | Are you a factory or a trading company? |

| 2 | What is the right mold material for my bottle? (7075 Aluminum vs. S136 Steel) |

| 3 | How do you guarantee the mold will perfectly match my blowing machine? |

| 4 | How do you ensure uniformity across all cavities in a multi-cavity mold? |

| 5 | Can I review and approve the 3D bottle & mold design before you cut steel? |

| 6 | How do you test the mold, and what will I receive for approval? |

| 7 | Can you share case studies for my specific industry? |

| 8 | What is your quoted mold lifespan in number of shots? |

| 9 | What is your after-sales support and warranty policy for international clients? |

| 10 | What are your payment terms and how do you protect my investment? |

Keep this list handy. By asking these questions and evaluating the answers, you are doing much more than just asking for a price. You are conducting a professional technical and commercial audit. This process will help you filter out the unqualified suppliers and find a true PET blow bottle mold partner who will create long-term value for your business.

Frequently Asked Questions (FAQ)

Q1: What's the real difference in production speed between a 7075 Aluminum and S136 Steel mold?

A: The difference is significant and comes down to thermal conductivity. 7075 Aluminum can dissipate heat much faster, potentially reducing the in-mold cooling portion of your cycle time by 15-25% compared to S136 steel. For a high-volume product where every second counts, this can translate to thousands of extra bottles produced per day, making aluminum the more efficient choice for pure speed.

Q2: If I only provide my machine's brand and model, is that enough to guarantee a fit without technical drawings?

A: While experienced manufacturers have databases for major brands like Krones, Sidel, and SIPA, relying on the model name alone is risky due to variations in machine series and custom configurations. A professional manufacturer will insist on verifying critical dimensions. At a minimum, they will provide a template drawing for you to measure and confirm key points on your actual machine, ensuring a 100% guaranteed fit.

Q3: What specific information should a good mold test video contain?

A: A truly transparent test video should show more than just bottles coming out. It should clearly display: 1) A close-up of the mold installed in the machine. 2) The machine's control screen showing stable cycle times and parameters. 3) The mold opening and closing smoothly for several cycles. 4) A clear shot of the freshly blown bottles being ejected, ideally from all cavities, to show consistency.

Q4: How is the mold lifespan (number of shots) actually verified or guaranteed?

A: The lifespan guarantee should be explicitly written into your purchase contract. While it's difficult to verify a number like "5 million shots" in advance, the guarantee is based on the manufacturer's engineering standards for material choice, heat treatment, and processing. The warranty (Question 9) is your recourse. If the mold fails prematurely due to a manufacturing defect (not wear and tear), the supplier is contractually obligated to provide a solution.

Q5: What happens if the bottle samples from the new mold are not approved?

A: A reputable manufacturer will not ask for final payment until the samples are approved. If there are issues, they will analyze the problem (e.g., uneven wall thickness, cosmetic defects) and make necessary modifications to the mold at their own cost. They will then conduct a new mold trial and send new samples, repeating the process until you are fully satisfied. This is a key part of the "approval before balance" payment term. If a supplier pressures you for final payment before sample approval, it's a major red flag.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr