Starting a new water bottling business is exciting, but the first big equipment decision can be paralyzing. You see the market demand, but you fear making a costly mistake on the wrong production line, potentially draining your capital before you even begin.

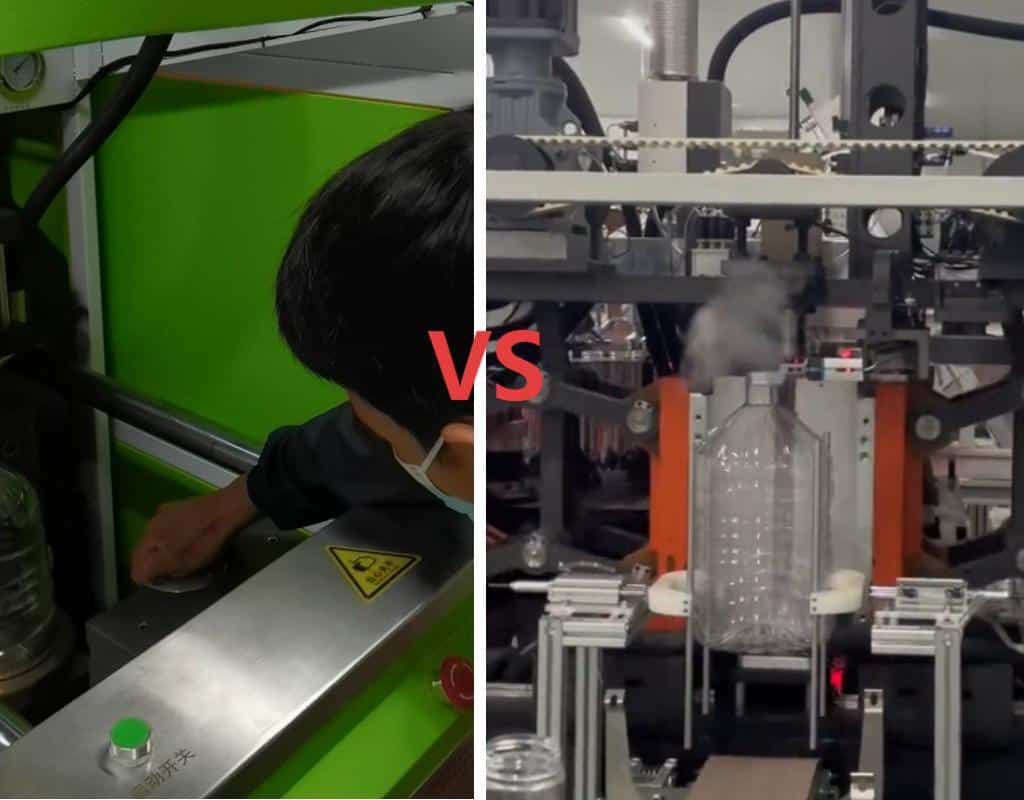

The core decision for a 15L single-use bottle startup boils down to two paths: a semi-automatic line for around $22,000 or a fully-automatic line for about $85,000. The right choice depends entirely on your budget, market certainty, and long-term business strategy, not just the technology.

I'm going to walk you through a complete, data-driven analysis of these two options. We'll look beyond the machine prices and examine the total project cost, operational realities, and even a clever hybrid strategy. My goal is to give you the clarity you need to invest confidently and build a successful business from day one. Let's dive in.

The Market Opportunity: Why Are Single-Use 15L PET Bottles a Startup Goldmine?

Are you noticing fewer of those old, scratched-up water cooler jugs and more crystal-clear, single-use bottles? This isn't just a trend; it's a fundamental market shift. You're trying to enter this market, but you're worried about the established players with their complex logistics.

The single-use 15L PET bottle is a goldmine for startups because it eliminates the single biggest barrier to entry: the massive cost and complexity of reverse logistics. This allows you to compete on product quality and service from day one, without needing a huge fleet of trucks for Recycle.

Over the past few years, especially since 2024, I've seen a massive surge in demand for machines that produce these bottles. We've sent over 15 complete lines for 15L bottles to countries like Malaysia, Thailand, Vietnam, and Australia. The reason is simple and has three main parts.

The Hidden Costs of the Old Reusable Model

For decades, the standard was the 5-gallon (approximately 18.9L) reusable PC (polycarbonate) bottle. For established companies, this model worked because they already had the infrastructure. But for a startup, it's a nightmare. Think about the costs you don't have with single-use PET bottles:

- No Washing Stations: You don't need expensive, large-footprint industrial washing and sterilizing equipment.

- No Reverse Logistics: You don't need a fleet of trucks and drivers dedicated to collecting empty bottles from thousands of locations. This is a huge operational expense in terms of fuel, vehicle maintenance, and salaries.

- No Bottle Tracking & Management: You don't have to worry about losing bottles, bottles being damaged, or managing deposits. Each bottle is a one-way trip to the customer.

- No Secondary Pollution Risk: The biggest consumer complaint about reusable bottles is hygiene. Were they cleaned properly? Did the previous user store something else in them? I've heard horror stories. Single-use bottles completely eliminate this concern, which is a powerful marketing tool.

By choosing a single-use model, you remove these massive operational headaches and financial drains. Your business becomes simpler, leaner, and more focused on production and sales.

The Consumer Pull: Hygiene, Convenience, and Aesthetics

The modern consumer is more health-conscious than ever. They want to know that the water they are drinking is pure and untouched. The crystal-clear appearance of a brand-new PET bottle conveys a sense of purity and quality that a scratched, dull, reusable PC bottle simply cannot match. It’s a psychological advantage that translates directly into sales.

Here's what the consumer sees:

| Feature | Reusable PC Bottle | Single-Use PET Bottle |

|---|---|---|

| Appearance | Often scratched, cloudy, looks "used" | Perfectly clear, shiny, looks "new and clean" |

| Hygiene Perception | Uncertain history, potential for contamination | Sealed, brand new, no prior use |

| Convenience | Requires deposit, storage for pickup | No deposit, can be recycled with household plastics |

This shift is not a fad. It's a permanent change in consumer expectations. People are tired of the hassle of returning old jugs and questioning their cleanliness. They are willing to pay for the peace of mind that comes with a fresh, single-use bottle.

The Startup Advantage: Lean and Focused

As a startup, your biggest advantages are speed and a low cost-base. The single-use 15L PET bottle model is tailor-made for this. You can focus your initial investment on a high-quality production setup, like a reliable bottle blowing machine, and a great water source. You don't have to split your capital between production and a complicated logistics network.

This allows you to:

- Enter the Market Faster: With a simpler business model, you can get from concept to first sale in a fraction of the time.

- Maintain a Lower Overhead: Fewer employees, no fleet of collection trucks, and smaller factory space requirements all contribute to a healthier bottom line.

- Compete on Quality: You can market your product as the most hygienic option available, directly addressing the main weakness of your established competitors.

The move away from reusable PC to one-way PET is creating a gap in the market perfectly sized for agile startups. You're not just selling water; you're selling safety, convenience, and quality assurance.

Your First Major Investment: Is it the $22k "Low-Risk Entry" or the $85k "High-Scale Leap"?

You've validated the market opportunity. Now comes the hard part: writing the check. You're staring at two quotes, one for about $22,000 and another for $85,000, and you feel the pressure. This decision feels permanent and will define your company's trajectory for years.

This is not a choice between two machines; it's a choice between two distinct business strategies. The $22k semi-automatic line is a cautious, capital-efficient start to test the market, while the $85k fully-automatic line is an aggressive, high-growth strategy built for immediate scale.

The goal of this article is to provide the data and framework you need to choose the right path for your specific situation. There is no single "best" answer. The right choice for a well-funded company with existing sales contracts is the wrong choice for a boot-strapped entrepreneur entering a new city.

Path 1: The Low-Risk Entry ($22,000)

This path is defined by capital preservation and flexibility. You invest the minimum amount required to produce a high-quality product. This strategy is perfect if:

- You have limited initial funding.

- You are entering a new, untested market.

- You want to start by serving a small group of initial clients to prove the concept.

- You prefer a hands-on approach and want to minimize technical complexity.

I often recommend this path to first-time entrepreneurs. A few months ago, a client from South Africa came to me. He had a great plan to supply 15L single-use bottles to local offices, but his budget was tight. He was tempted by the high output numbers of a fully-automatic line but worried about the high initial cost. I advised him to start with a semi-automatic line. It allowed him to get into the market, build a customer base, and generate cash flow without taking on massive debt or risk. Today, his business is growing steadily, and he's now considering adding a second line.

Path 2: The High-Scale Leap ($85,000)

This path is about speed and automation. You are making a significant upfront investment to capture a large market share quickly and minimize long-term labor costs. This strategy is the right fit if:

- You have secured significant funding.

- You already have large sales contracts or guaranteed distribution channels (e.g., a partnership with a supermarket chain).

- Your business plan is based on high volume and low margins.

- You want to build a highly automated factory from day one.

This is a powerful strategy, but it carries higher risk. If your large contracts fall through or market demand is slower than projected, the high monthly payments on your equipment loan can become a serious burden. It requires a high degree of confidence in your sales forecast.

Making Your Choice

The rest of this article will break down the numbers, the operational realities, and the hidden costs associated with each path. We will compare them head-to-head, explore a creative "third way," and build a final decision framework. By the end, you won't just be choosing a machine; you'll be confidently executing a well-reasoned business strategy.

The Semi-Automatic Path: How to Maximize ROI with a ~$22,000 Investment?

You have a solid business plan but a tight budget. The idea of an $85,000 machine is daunting. You need a way to enter the 15L water bottle market, produce a quality product, and prove your concept without risking all your capital on day one.

The semi-automatic production line, at an approximate investment of $22,000, is the ideal low-risk entry point. It's designed for startups to test a local market, serve initial clients, and keep financial risk to an absolute minimum while still producing up to 300 bottles per hour.

This path is about being smart, lean, and efficient. It’s the embodiment of the "crawl, walk, run" approach to building a business. Let's break down exactly what you get for your investment and why it's such a powerful starting point.

What Does ~$22,000 Actually Buy You?

When we talk about a "line," it's more than just one machine. For this investment, you get a complete, ready-to-produce blowing solution. It’s a package deal that includes the essential components to turn a small plastic preform into a finished 15L bottle.

Here is a typical breakdown of the package:

| Component | Description | Function |

|---|---|---|

| Semi-Auto Blower | The core machine. An operator manually loads preforms into the heater and then transfers them to the blowing station. | Heats the PET preforms and blows them into the shape of the blow bottle mold. |

| Custom 15L Mold | A high-quality mold engineered specifically for your bottle design. | Shapes the heated preform into your final 15L bottle. Good design is key. |

| High-Pressure Air Compressor | A 30HP compressor system. | Provides the high-pressure air (around 35 bar) needed to stretch and form the bottle. |

| Air Dryer & Filters | A refrigerated air dryer and a set of three air filters. | Removes moisture and oil from the compressed air to ensure bottle clarity and hygiene. |

| Industrial Water Chiller | A 5HP chiller unit. | Circulates cold water through the blow bottle mold to cool it, allowing the bottle to solidify quickly and maintain its shape. |

This isn't just a collection of parts; it's a complete system. With this setup, you have everything you need on the blowing side to start production. The output of around 300 bottles per hour (BPH) is a very manageable starting point. It's enough to supply dozens of offices, small stores, or a local delivery service without creating a massive inventory you can't sell.

The Business Case: Perfect for a Lean Startup

The true strength of the semi-automatic path lies in its business application. It aligns perfectly with the goals of a new venture.

- Market Testing: You can start producing bottles and getting them to customers with a fraction of the capital. This allows you to test your pricing, delivery model, and marketing message in the real world. You get valuable feedback without having taken a huge financial gamble.

- Serving Seed Clients: This output level is ideal for securing and serving your first 5-10 significant clients. You can provide them with a consistent supply, build relationships, and use their testimonials to win more business.

- Operational Simplicity: These machines are straightforward. The operation involves simple, repetitive tasks: load preforms, move them to the blower, press a button, and remove the finished bottle. You don't need a highly paid engineer with years of experience to run it. A properly trained operator can manage the entire process. This drastically reduces your initial payroll burden.

- Low Maintenance: The mechanical systems are simpler than their fully-automatic counterparts. This means less can go wrong. Maintenance is typically straightforward and can often be handled in-house with basic mechanical skills, minimizing downtime. If you do encounter tricky common PET blow molding defects, the simpler system makes troubleshooting much faster.

Validating Your Idea Affordably

Furthermore, this path allows for affordable design validation. Before you even commit to the final steel mold, you can take advantage of services like creating 3D printed samples to rapidly validate blow mold designs. This lets you hold a physical version of your bottle, test its ergonomics, and get feedback from potential customers for a very low cost.

The semi-automatic path isn't about limitations; it's about control. It gives you, the startup founder, complete control over your cash flow, your operational complexity, and your business risk. It's the smartest way to step into the 15L water bottle market, build a solid foundation, and prepare for future growth.

The Fully-Automatic Path: Is it Built for Scale, Requiring ~$85,000 in Capital?

Your business plan isn't about testing the waters; it's about making a splash. You have funding, you have confirmed interest from large buyers, and your primary goal is to achieve high-volume production with maximum efficiency from day one. Labor costs are a major concern, and you want a "lights-out" operation wherever possible.

The fully-automatic production line, with an initial capital requirement of around $85,000 for a 600 BPH machine, is engineered for this exact scenario. It's built for startups that need to scale quickly, prioritize automation, and have secured the sales channels to justify the investment.

This path is an aggressive move. It signals to the market that you are a serious player. It replaces manual labor with machine precision, promising consistent quality and high output. But this power comes with greater cost and complexity, not just for the machine itself, but for the entire factory ecosystem.

Deconstructing the ~$85,000 Investment

Similar to the semi-automatic option, this price tag covers a complete blowing system, but every component is bigger, faster, and more automated. This is for a single-cavity line producing 600 BPH; higher outputs require even larger investments.

Here’s what the fully-automatic package includes:

| Component | Description | Key Advantage over Semi-Auto |

|---|---|---|

| Fully-Auto Blower | A fully enclosed, integrated machine. Preforms are automatically loaded from a hopper, fed into the heating oven, and transferred to the blowing station. | Labor-Free Operation: Eliminates the need for an operator to handle preforms, drastically reducing labor costs and human error. |

| Custom 15L Mold | A precision-engineered mold designed for high-speed cycling and optimal cooling. | Higher Performance: Built to withstand the stresses of faster, continuous operation. |

| High-Performance Auxiliaries | Includes an automatic preform hopper and elevator, a larger air compressor system (e.g., 50HP), and a higher capacity chiller (e.g., 10HP). | Uninterrupted Production: The system feeds itself, ensuring the blower is never waiting for preforms or utilities, maximizing output. |

| Integrated Controls | A central PLC (Programmable Logic Controller) touchscreen that manages the entire blowing process. | Precision & Diagnostics: Allows for fine-tuning of heating and blowing parameters. Provides advanced error messages for quicker troubleshooting. |

This integrated system is a production powerhouse. It can run for hours with minimal human intervention, churning out a perfectly consistent product. The output of 600 BPH is double that of the semi-automatic line, making it suitable for supplying regional distributors or supermarket chains.

The Business Case: For the Well-Funded and Well-Connected

This path is not for everyone. It's a strategic choice for businesses with specific prerequisites.

- Guaranteed Sales Channels: You should have contracts or firm commitments from buyers before investing in this line. An output of 600 BPH means you are producing almost 5,000 bottles in an 8-hour shift. You need a guaranteed place for that inventory to go.

- Sufficient Capital: The ~$85,000 is just the beginning. As we'll discuss later, a faster blower requires a faster, and more expensive, filling line to keep up. You need to budget for a much higher total project cost.

- Focus on Automation & Labor Reduction: If you are operating in a region with high labor costs, the savings from automation can be significant. The machine effectively pays for itself over time by reducing payroll expenses.

- Skilled Technical Staff: While it runs automatically, this machine is more complex. When something goes wrong, you need a skilled technician or engineer who can diagnose and fix issues within the complex pneumatic, electronic, and mechanical systems. Downtime is expensive when you have large orders to fill.

The Hidden Costs and Higher Stakes

The primary "hidden cost" of the fully-automatic path is the required investment in downstream equipment. A 600 BPH bottle blowing machine is pointless if your filling machine can only handle 300 BPH. This creates a bottleneck and wastes the potential of your expensive investment. You must be prepared to invest in a filling, capping, and labeling line that can match its speed.

This path represents a "high-scale leap." It offers the potential for higher profits through volume and efficiency, but it also comes with higher fixed costs, greater complexity, and less room for error. It's a powerful tool for the right business, but you must be certain you have the financial resources and market demand to support it.

Head-to-Head: Which Path Makes More Sense for an Investor?

Making a capital investment decision requires stripping away the sales pitches and looking at the cold, hard numbers. As an investor in your own company, you need a clear, side-by-side comparison to understand the trade-offs you are making. Which path offers the better return for your specific situation?

A direct data-driven comparison reveals that the semi-automatic line excels in low initial cost and flexibility, making it ideal for market entry. The fully-automatic line excels in lower long-term labor cost per bottle and scalability, making it suitable for established demand.

Let's put them head-to-head across the key metrics that matter most to a business owner.

Detailed Comparison Table

This table goes beyond the basics to give you a fuller picture of the operational and financial implications of each choice.

| Metric | Semi-Automatic Line | Fully-Automatic Line | Analysis for the Investor |

|---|---|---|---|

| Initial Investment | ~$22,000 | ~$85,000 | The ~$63,000 difference is significant startup capital. It could be used for marketing, distribution, or working capital. |

| Output per Hour | ~300 BPH | ~600 BPH | Full-auto has double the output, but only if you have the sales to support it. Unsold inventory costs money. |

| Labor Requirement | 1-2 Operators | <1 Operator (Supervision) | This is the key long-term advantage of full-auto. The break-even point depends on your local labor wage. |

| Cost per Bottle (Labor) | Higher | Lower | At $15/hr for an operator, the semi-auto line adds ~$0.05 of labor to each bottle. The full-auto cost is negligible. |

| Factory Footprint | Compact | Larger | The full line, including the auto-loader and larger auxiliaries, requires more expensive factory floor space. |

| Skill Level Required | Low (Trained Operator) | High (Skilled Technician) | Technician salaries are much higher than operator wages, and they can be harder to find. |

| Maintenance Complexity | Simple, Mechanical | Complex, PLC/Electronics | Downtime on the full-auto line can be longer and more costly if you don't have an expert on staff. |

| Flexibility | High (Easy mold changes) | Moderate (More complex changeovers) | It's faster to switch bottle types on a semi-auto machine, which is great for serving multiple small clients. |

| Scalability | Scale by adding more units | Scale by running more shifts or buying a faster machine. | The semi-auto model allows for gradual, modular scaling. The full-auto model is a bigger leap. |

Analyzing the Trade-Offs

As you can see, the decision is a classic trade-off between upfront capital (CapEx) and ongoing operational costs (OpEx).

The Semi-Automatic Bet: You are betting that the flexibility and low initial capital outlay will allow you to find a profitable market niche quickly. You accept a higher labor cost per bottle in the short term to avoid crippling upfront debt. Your risk is lower, and your business is more agile. You can easily adapt to customer requests for different bottle shapes by simply investing in a new blow bottle mold, which is a relatively small expense.

The Fully-Automatic Bet: You are betting that your sales forecasts are accurate and that high volume will allow you to achieve a lower cost-per-unit that your competitors can't match. You are taking on higher initial risk and debt in exchange for long-term efficiency and scale. Your success is tied directly to your ability to keep the machine running and sell its massive output.

My advice is always to be honest about your position. Don't let ego drive the decision. If you don't have guaranteed sales, the "safer" semi-automatic path is often the smarter business decision. It preserves your capital, which is the lifeblood of any startup. If you have secured a major contract with a supermarket, then the higher investment in the fully-automatic line is not just justifiable; it's necessary.

But what if there was a third option? A way to get the output of a fully-automatic line without the high price tag and risk?

The "Twin Semi-Auto" Strategy: Can You Get 600 BPH for Under $45,000?

You've seen the data. The ~$22,000 semi-auto line feels safe but maybe too slow, while the ~$85,000 full-auto line seems powerful but too risky. You're stuck in the middle, wishing there was a solution that offered more output without the huge financial leap.

There is a powerful and creative alternative: the "Twin Semi-Auto" strategy. By purchasing two complete semi-automatic lines for a total investment of under $45,000, you can achieve the same 600 BPH output as a fully-automatic line for nearly half the price, while gaining unmatched operational flexibility and redundancy.

This is an insider's approach that I often recommend to ambitious startups who are financially savvy. It's a way to de-risk the scaling process and build a more resilient production floor. It combines the low cost of the semi-automatic model with the high output of the automatic one.

The Financial Case: Half the Price, Same Output

Let's look at the numbers directly. The value proposition is incredibly compelling.

| Metric | 1 x Fully-Automatic Line | 2 x Semi-Automatic Lines ("Twin") | Advantage of the "Twin" Strategy |

|---|---|---|---|

| Total Investment | ~$85,000 | ~ $44,000 ($22k x 2) | ~$41,000 in Capital Saved |

| Total Output | 600 BPH | 600 BPH (300 BPH x 2) | Identical Production Volume |

| Labor Requirement | <1 Operator (Supervision) | 2 Operators | Higher labor cost is the main trade-off. |

| Initial Risk | High | Low | Your capital exposure is halved. |

For a startup, saving over $40,000 in initial capital is a massive advantage. That money can be used for a bigger marketing budget, hiring a sales team, or simply extending your company's financial runway. You are achieving your production goal without putting the company's future at high risk.

The Operational Advantages: Flexibility and Redundancy

The benefits of the "Twin" strategy go far beyond the initial cost savings. They create a more robust and agile manufacturing operation.

Unmatched Redundancy: This is the most critical advantage. If your single fully-automatic line goes down for maintenance or an unexpected repair, your entire production stops. You are at 0% capacity. With the "Twin" setup, if one line needs maintenance, the other one keeps running. You are still at 50% capacity (300 BPH). You can still fulfill orders for your most important clients. This operational insurance is invaluable.

Ultimate Flexibility: What if a new client wants a 12L bottle, or a bottle with a different neck finish? With a single full-auto line, you have to stop all production to perform a time-consuming mold changeover. With the "Twin" strategy, you can run two different products simultaneously.

- Line A: Produces your standard 15L bottle.

- Line B: Produces a custom 12L bottle for a new client.

This allows you to say "yes" to more opportunities. You could explore different bottle shapes using a flexible PET bottle mold design guide or cater to clients who need a specific finish by following a guide on how to choose the right preform neck size. This agility can be a significant competitive advantage.

Gradual Scaling: The "Twin" strategy doesn't have to be implemented all at once. You can start with one semi-auto line (~$22k). Once you've built your customer base and maxed out its capacity, you can seamlessly add the second line (~$22k) to double your output. This is a much more organic and financially responsible way to scale, matching your investment directly to your revenue growth.

The "Twin Semi-Auto" strategy is the perfect middle ground. It's an intelligent solution that mitigates risk, enhances flexibility, and provides a clear, affordable path to scaling your production to 600 BPH and beyond. It requires you to manage two operators instead of one, but for most startups, the immense benefits in cost savings and operational resilience are well worth the trade-off.

Beyond the Blower: Why You Must Factor in the Total Project Cost?

You've analyzed the blowing machines, you've compared the costs, and you may even be leaning towards a specific path. But a critical mistake many startups make is fixating only on the price of the blower. They forget that a blow molding machine, by itself, is useless. It’s like buying a high-performance engine without the rest of the car.

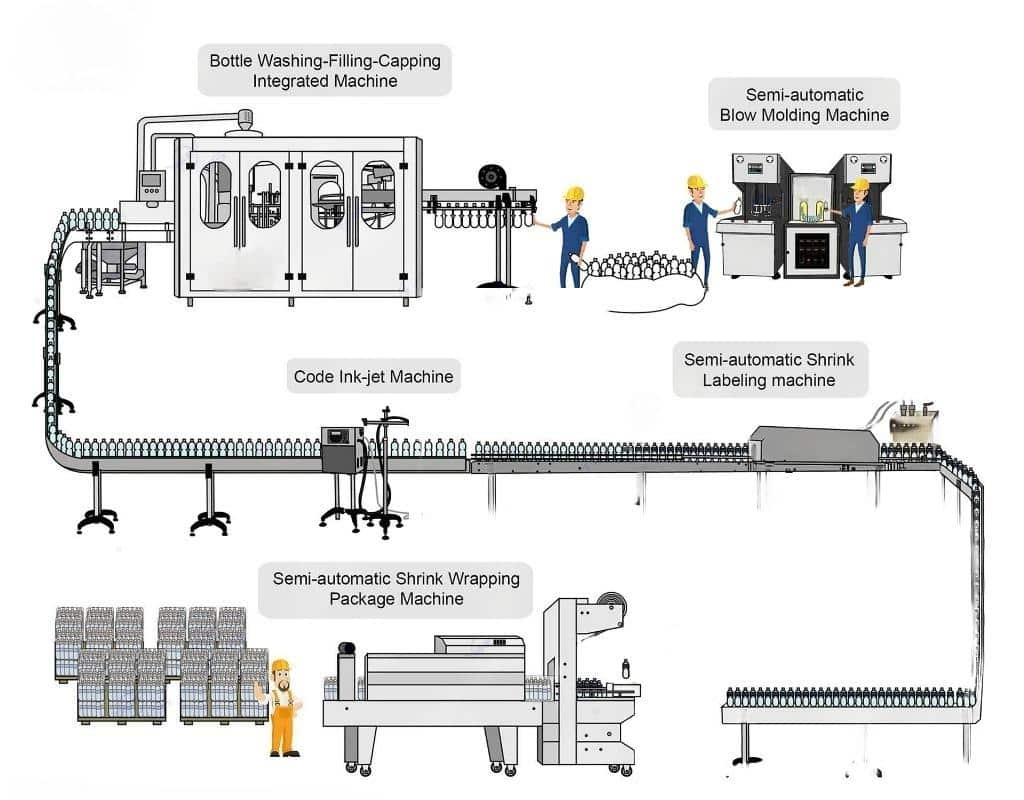

The blow molding machine is just one part of a complete production system. Your choice of blower directly dictates the speed, complexity, and cost of the required downstream equipment, including the filler, capper, and labeler. You must budget for the total project cost, not just one machine.

Thinking about the entire line from the start prevents costly bottlenecks and surprise expenses down the road. It ensures you are building a balanced, efficient factory, not just a collection of mismatched parts.

The Blower Sets the Pace for the Entire Line

The output of your bottle blowing machine is the heartbeat of your plant. Every other piece of equipment must be able to keep up with it.

- If you choose a 300 BPH semi-automatic blower: You can pair it with a more affordable, lower-speed filling and capping machine. The entire line is simpler and less expensive.

- If you choose a 600 BPH fully-automatic blower: You now must invest in a faster, more complex, and significantly more expensive filling and capping machine. Buying a slow filler would be like putting bicycle wheels on a race car – you've completely wasted the potential of your expensive engine.

This ripple effect applies to everything: the conveyors need to be longer and faster, the labeling machine needs to handle a higher throughput, and even your water treatment system needs to be able to supply purified water at a higher rate.

Sample "All-In" Investment for a Complete Plant

To make this tangible, let's look at a rough estimate of the "all-in" investment for a complete, basic bottling plant. These are estimates and can vary, but they illustrate the massive difference in total capital required.

| Equipment Category | Semi-Auto Path (300 BPH) | Full-Auto Path (600 BPH) | Key Difference |

|---|---|---|---|

| Blow Molding System | ~$22,000 | ~$85,000 | The core choice we've been discussing. |

| Water Treatment System | ~$10,000 | ~$15,000 | Higher flow rate requires a more robust system. |

| Filling & Capping Machine | ~$15,000 | ~$40,000 | Speed is the biggest cost driver here. This is a major jump. |

| Conveyors & Accumulation Table | ~$5,000 | ~$10,000 | Faster lines require more conveyor length and buffer zones. |

| Labeling & Date Coding | ~$8,000 | ~$15,000 | Higher speed and automation increase the price. |

| Essential Auxiliaries | Included in blower system | Included in blower system | Remember the importance of a good chiller and air compressor. |

| ESTIMATED TOTAL | ~$60,000 | ~$165,000 | The total investment difference is over $100,000. |

As the table clearly shows, the initial ~$63,000 price difference between the blowers balloons into a total project cost difference of over $100,000.

The Strategic Advantage of Gradual Investment

This is another area where the semi-automatic path shines for a startup. It allows for a more gradual and affordable investment across the entire plant. You can start with a ~$60,000 line that is balanced and efficient. As your business grows, you can add a second semi-automatic line (the "Twin" strategy) and a second affordable filling line.

This modular approach allows your capital expenditure to grow in lockstep with your revenue. The fully-automatic path requires the massive ~$165,000+ investment upfront. This is a significant financial burden and risk for a new company.

Before you make your final decision, look beyond the blower. Map out the cost of your entire production line. This total project cost is the true number you need to have in your budget. Making this calculation will give you a realistic understanding of the capital required and will almost certainly influence your choice of which path is right for you.

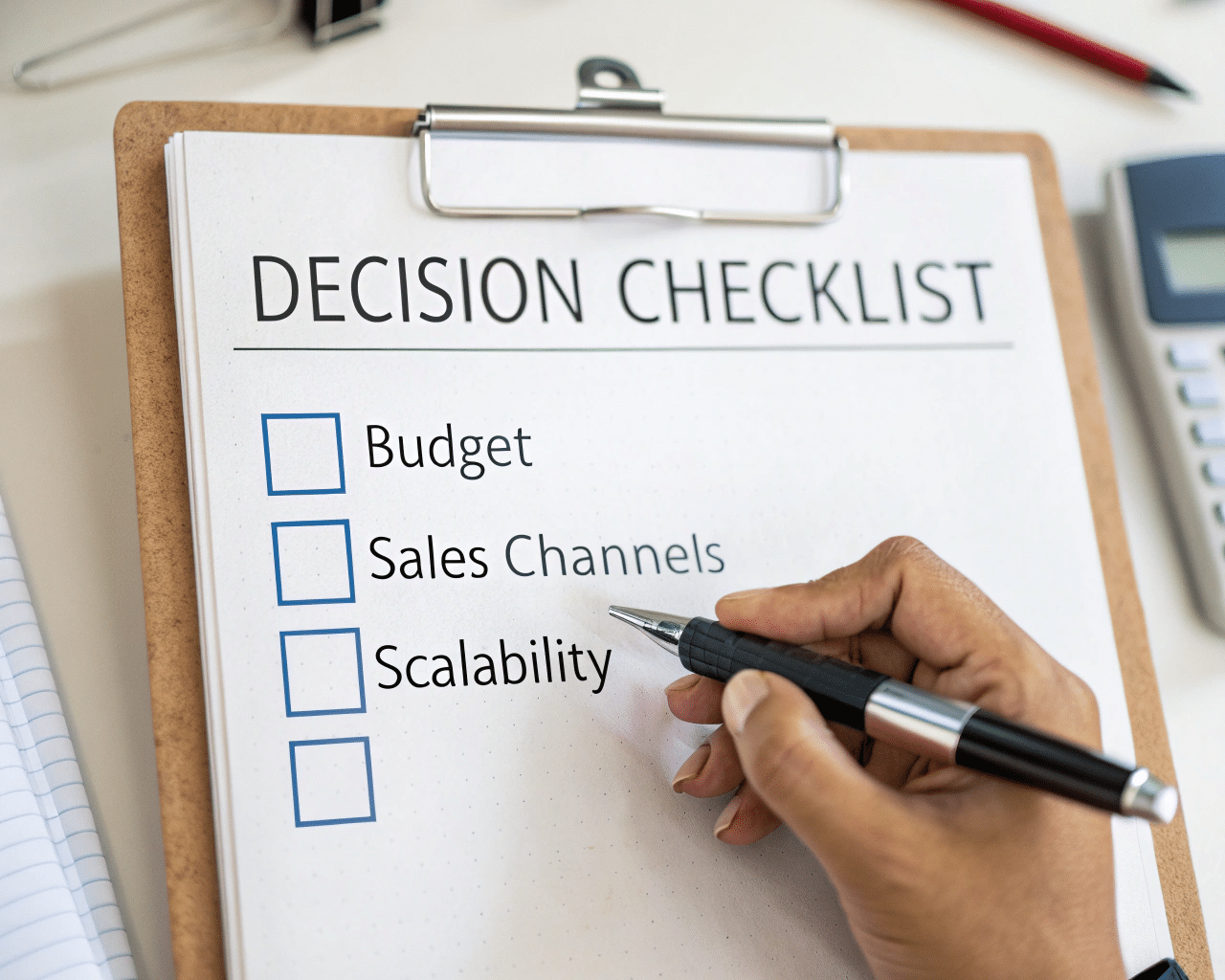

Final Verdict: Which Decision Framework is Right for Your 15L Venture?

We've covered a lot of ground. We've analyzed the market, dissected the costs, compared the strategies, and looked at the total project investment. Now it's time to bring it all together into a simple, actionable framework to help you make your final decision.

The right choice is not about which machine is "better," but which strategy best aligns with your company's specific financial situation, market position, and tolerance for risk. This final checklist will help you self-assess and choose your path with confidence.

Answer the following questions honestly. Your answers will point you directly to the most logical starting point for your 15L water bottle venture.

A Decision-Making Checklist

1. What is your total realistic budget for the entire production line (blower, filler, etc.)?

- A) Under $75,000: Your decision is clear. The Semi-Automatic path is the only viable option to build a complete, balanced line within your budget.

- B) $75,000 - $150,000: You are in the flexible zone. The "Twin Semi-Auto" strategy is a very strong contender, offering high output for a moderate investment.

- C) Over $150,000: You have the capital required to properly implement the Fully-Automatic path.

2. What is the status of your sales channels?

- A) I'm just starting out, building my client list from scratch. The Semi-Automatic path allows you to start small and grow organically with your sales.

- B) I have letters of intent and strong interest, but no signed contracts. The "Twin Semi-Auto" strategy provides a scalable path. Start with one line and add the second once contracts are signed.

- C) I have large, signed contracts with distributors or retailers. The Fully-Automatic path is necessary to meet this guaranteed high-volume demand.

3. What is your comfort level with operational complexity and technical staff?

- A) I prefer simple, mechanical systems and want to minimize the need for specialized technicians. The Semi-Automatic path is the most straightforward to operate and maintain.

- B) I am willing to manage a slightly larger team of operators to gain flexibility. The "Twin Semi-Auto" strategy fits this profile perfectly.

- C) My priority is minimizing labor through automation, and I can afford to hire a skilled engineer. The Fully-Automatic path aligns with your goal of a highly automated factory.

Your Recommended Path

Based on your answers, here is your final verdict:

Choose the Semi-Automatic Path if:

You answered mostly (A). Your initial budget is under $75,000, you are new to the market, you value operational simplicity, and you want maximum flexibility with minimum risk. This is the classic lean startup approach.

Choose the "Twin Semi-Auto" Strategy if:

You answered mostly (B). You have a moderate budget, a clear path to scaling your sales, and you value redundancy and flexibility. This is the savvy investor's choice, offering the best balance of risk, cost, and output.

Choose the Fully-Automatic Path if:

You answered mostly (C). You have a budget over $150,000 for the full line, you have secured large sales contracts, and your top priority is achieving high-speed automation to minimize long-term labor costs. This is the aggressive growth strategy.

No matter which path you choose, you are now equipped with the data and the strategic framework to make an informed decision. You understand the true costs, the operational realities, and the long-term implications of your choice.

Conclusion

Choosing between a semi-automatic and a fully-automatic line is your first major strategic decision. Base it on your capital, market certainty, and growth plan to build a successful 15L water bottle business.

Frequently Asked Questions (FAQs)

1. Is buying a used fully-automatic machine a better investment than a new semi-automatic one?

This is a very common question, and it's tempting. You might see a used European fully-automatic machine for the price of a new semi-automatic line. However, this is often a trap for startups. A used machine comes with significant hidden risks:

- No Warranty: When it breaks, you are 100% responsible for the cost of repairs and parts, which can be very expensive.

- Wear and Tear: You don't know the machine's history. Key components like seals, bearings, and electronics could be near the end of their life, leading to unexpected and costly downtime.

- Lack of Support: The original manufacturer may no longer support the model or could be difficult to deal with for technical help. With a new machine from a reputable supplier, you have a direct line for support and training.

- Compatibility Issues: A used machine might have unique specifications. You might even find yourself in a situation where you're worried about blow mold fit, which can be a major headache.

In almost all cases, a new semi-automatic machine with a full warranty and support is a much safer and smarter investment for a startup than a used fully-automatic machine.

2. How do I calculate the break-even point where labor savings justify the higher price of a fully-automatic machine?

You can use a simple break-even calculation. Let's make some assumptions:

- Investment Difference: $85,000 (Full-Auto) - $22,000 (Semi-Auto) = $63,000

- Labor Difference: A semi-auto line needs 1 dedicated operator. A full-auto line does not.

- Local Labor Cost (including taxes/benefits): Let's assume $15 per hour.

The calculation is:

Investment Difference / Hourly Labor Savings = Break-Even Hours

$63,000 / $15 per hour = 4,200 operating hours

If you run the machine for one 8-hour shift, 5 days a week, that's 40 hours per week.

4,200 hours / 40 hours per week = 105 weeks, which is approximately 2 years.

So, in this scenario, it would take about 2 years of continuous single-shift operation for the labor savings of the fully-automatic machine to pay back its higher initial investment. You need to decide if your business can support the higher upfront cost for a two-year payback period.

3. If I start with a semi-automatic machine, can it be upgraded or integrated into an automated line later?

A semi-automatic machine itself cannot be "upgraded" to become fully automatic. They are fundamentally different in their design and construction. However, your initial investment is absolutely not wasted. This is where the "Twin Semi-Auto" or a hybrid strategy comes in. As your business grows, you can purchase a fully-automatic line and have it work alongside your original semi-automatic machine. Many businesses do this. The full-auto line handles the high-volume, standard products, while the semi-auto line is used for smaller runs, new product development, or as a backup. Your first machine remains a valuable, flexible asset in your factory.

4. Besides cost savings, what are the main operational advantages of the "Twin Semi-Auto" strategy?

The operational advantages are arguably even more important than the cost savings:

- Production Redundancy: This is the biggest one. If one machine is down for maintenance, you are still producing. This prevents you from ever having to tell a major client you can't deliver.

- Simultaneous Production: You can run two completely different bottle types at the same time. This allows you to serve a wider range of customers without the downtime associated with mold changes. For example, you could run 15L bottles on one and 10L bottles on the other.

- Simplified Maintenance: You have two identical, simple machines. Your maintenance team only needs to learn one system and can stock one set of common spare parts. This is much easier than managing one simple and one highly complex machine.

- Staggered Investment: You don't need all the capital upfront. You can buy the first line, start generating revenue, and then buy the second line with the profits from the first. This is a much healthier way to manage cash flow.

5. What is the rough "all-in" investment for a complete plant for both the ~$22k semi-auto line and the ~$85k fully-auto line?

As we detailed in the "Beyond the Blower" section, the blower is just the start. A realistic "all-in" budget for a complete, basic but functional plant is crucial for planning. Based on our experience, here are some practical budget ranges to consider:

- For the ~$22k Semi-Automatic Blower Path: A startup should budget for a total project cost in the range of $60,000 to $80,000. This would cover the blowing system, a suitable water treatment system, a semi-automatic filling and capping line, and basic conveyors and labelers.

- For the ~$85k Fully-Automatic Blower Path: A company choosing this path should be prepared for a total project investment in the range of $165,000 to $200,000+. This higher amount accounts for the much more expensive high-speed filling, capping, and labeling equipment required to keep up with the blower's output.

Having these realistic total budget numbers is critical for creating a solid business plan and securing the necessary funding.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr