Struggling with blow molding machine choices? Overwhelmed by technical terms and uncertain about the best fit for your production? You need a clear path to an efficient, cost-effective solution.

The best choice between equal and variable distance 2L 4-cavity blow molding machines depends on your specific needs. Variable distance often offers higher efficiency and flexibility for diverse bottle sizes, while equal distance provides simplicity and lower initial cost, suitable for straightforward, consistent production runs.

Choosing the right blow molding machine is a big decision. It impacts your production speed, costs, and the types of bottles you can make. I've seen many businesses grapple with this, especially when looking at 2L 4-cavity machines. The market is evolving fast. Fully automatic blow molding machines are common now. We mainly see linear machines and rotary machines. Linear machines can be semi-automatic or fully automatic. The fully automatic ones often feature either equal distance heating or variable distance heating. Currently, variable distance heating is very popular with mid-to-high-end customers. This is because variable distance blow molding machines are much cheaper than rotary machines, the process is not as complex, and the output is high. Let's dive deeper into the specifics to help you choose wisely.

What is the difference between equal distance and variable distance blow molding?

Are you finding it hard to grasp blow molding jargon? Unsure what "equal" versus "variable" distance really means for your operations? A clear understanding is key to smart investments.

Equal distance systems keep preforms at a fixed spacing throughout heating and blowing. Variable distance systems adjust preform spacing, typically closer for heating and wider for blowing, optimizing each step.

To really understand these systems, we need to look at how they work. I always tell beginners to visualize the preform's journey.

Equal Distance (Fixed Pitch) System

In an equal distance system, the preforms maintain the same center-to-center distance from the moment they are loaded into the heating oven until they enter the blowing mold.

- Working Principle: Preforms are carried on mandrels that are equidistant on a chain or transport system. The heating lamps are arranged to provide uniform heating to these evenly spaced preforms. The blowing mold also has cavities spaced at this same fixed distance.

- Simplicity: This design is mechanically simpler. There are fewer moving parts involved in adjusting the pitch.

- Constraint: The pitch is usually determined by the bottle diameter in the mold or the preform diameter, whichever requires wider spacing. This can sometimes lead to inefficiencies in the heating oven if preforms are small but need to be spaced out for larger bottles.

Variable Distance (Adjustable Pitch) System

A variable distance system changes the spacing between preforms. Typically, preforms are kept closer together in the heating oven and then spaced further apart before entering the blow mold.

- Working Principle: Specialized mechanisms, often involving servo motors or pneumatic actuators, adjust the distance between preform holders. This allows for a denser preform arrangement in the oven, leading to a smaller, more energy-efficient oven. Before blowing, the pitch is increased to match the larger cavity spacing in the blow mold, which is necessary for larger bottles.

- Optimization: This allows for optimization of both the heating process (tighter spacing for better heat utilization) and the blowing process (correct spacing for the mold).

Here's a simple table to highlight the main differences:

| Feature | Equal Distance System | Variable Distance System |

|---|---|---|

| Preform Spacing | Fixed throughout process | Changes between heating & blowing |

| Heating Oven | Can be larger, less dense | More compact, denser preforms |

| Mechanical Parts | Simpler, fewer adjustments | More complex, pitch adjustment |

| Flexibility | Less flexible for varied sizes | More flexible for varied sizes |

| Typical Use | Simpler, dedicated production | High efficiency, varied production |

Understanding these basic definitions and working principles is the first step to making an informed decision for your factory.

How can variable distance improve bottle blowing efficiency?

Is slow production a bottleneck for your business? Frustrated by cycle times that limit your output and profit? You need a system that maximizes every second.

Variable distance systems boost efficiency by optimizing preform spacing for heating and then for molding. This intelligent adjustment shortens mold open/close times and speeds up the overall cycle, significantly increasing production capacity.

When I talk about efficiency in blow molding, it's not just about how fast one bottle is made. It's about the overall throughput and how consistently the machine runs. Variable distance technology, especially what some call "intelligent variable distance," plays a big role here.

Shortened Mold Open/Close Times

One key aspect is how preforms are presented to the mold.

- Optimized Transfer: In a variable distance setup, preforms can be heated very close to each other. This means the heating oven can be shorter, or more preforms can be heated in the same oven length, leading to better energy efficiency.

- Quick Pitch Adjustment: After heating, the system quickly adjusts the pitch of the preforms to match the wider pitch of the blow mold cavities. This adjustment is often done using precise servo motors. Because the preforms are already aligned and ready for the mold's specific spacing, the transfer into the mold and the clamping action can be faster. The mold doesn't have to accommodate a less-than-ideal preform presentation.

Increased Cycle Speed and Production Capacity

The overall cycle time in blow molding is a sum of several steps: preform loading, heating, transferring, blowing, cooling, and ejection.

- Reduced Dead Time: Variable distance systems reduce "dead time" during transfers. The quick and precise adjustment of preform pitch means less time is wasted.

- Higher Output: Even a small reduction in cycle time per bottle can lead to a significant increase in output over a shift or a day. For a 4-cavity machine, saving half a second per cycle means an extra 2 bottles every cycle. Over thousands of cycles, this adds up substantially. For example, if a cycle is 5 seconds, you produce 8 bottles (2 cycles x 4 cavities). If you reduce it to 4.5 seconds, in 9 seconds you produce 8 bottles with equal distance, but 10 bottles (2.5 cycles approx) with variable distance. This might seem small but scales up quickly.

In my experience, factories that switch to variable distance machines often report a noticeable jump in their production numbers, sometimes by 15-25%, depending on the bottle type and previous setup. This efficiency gain is a major reason for its growing popularity.

Is a variable distance blow molding machine more expensive?

Worried about high initial investment costs? Concerned that advanced technology means unaffordable prices and complex upkeep? You need to weigh the cost against the long-term benefits.

Yes, variable distance blow molding machines typically have a higher upfront purchase price. This is due to more complex mechanics, sophisticated control systems, and potentially more intricate mold designs.

It's a common question I get: "Will this advanced machine break my budget?" And it's a fair one. Let's break down the cost factors.

Equipment Price

The machine itself is usually more expensive.

- Mechanical Complexity: Variable distance systems require additional mechanisms to change the pitch of the preform holders. This can involve servo motors, precision guides, and more robust transfer systems. These components add to the manufacturing cost.

- Control System Sophistication: Managing the variable pitch accurately requires a more advanced PLC (Programmable Logic Controller) and potentially more sensors. The programming and integration of these systems also contribute to the cost.

Mold Design Complexity

While the molds themselves might not be drastically different in terms of the cavity, the interface with the variable pitch system can sometimes add complexity.

- Interfacing: The mold needs to align perfectly with the preforms whose pitch has just been adjusted. This might require more precise alignment features or a more robust mold clamping system to handle the dynamic nature of the preform presentation.

- Flexibility Cost: If the machine is designed to handle a wide range of pitch adjustments for maximum bottle size flexibility, the overall system supporting this will be more engineered and thus costlier.

Is the Investment Worth It?

This is the crucial question. A higher initial price doesn't automatically mean it's a worse deal.

- Return on Investment (ROI): The increased efficiency and higher output from a variable distance machine can lead to a faster ROI. If you can produce more bottles per hour, you can meet demand better, reduce per-bottle cost, and increase profits.

- Reduced Operational Costs: As we'll discuss later, potential energy savings can also offset the initial cost over time.

- Future-Proofing: Investing in a more flexible and efficient machine can be a way to future-proof your production capabilities, allowing you to adapt to changing market demands for different bottle sizes more easily.

So, while the sticker price is higher, I advise clients to look at the total cost of ownership and the potential gains in productivity. For many, especially those with high volume or diverse product needs, the extra investment pays off.

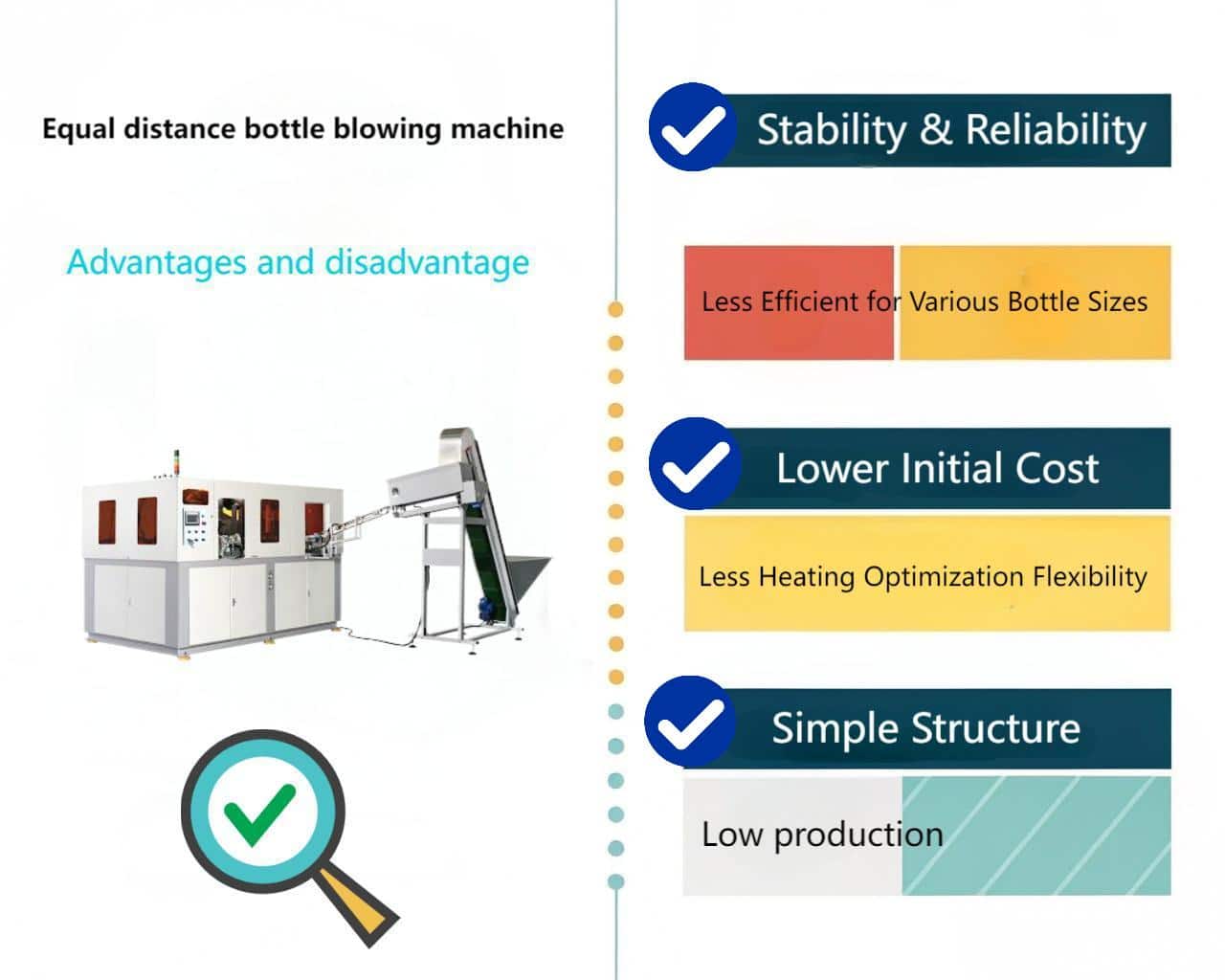

What are the advantages and disadvantages of an equidistant system?

Are you considering an equidistant system for its simplicity? Unsure if its limitations might hinder your future growth or efficiency? A balanced view is essential for decision-making.

Equidistant systems are known for their structural simplicity, stability, and lower maintenance and initial costs. However, they can be less efficient for varied bottle sizes and may offer less optimization in preform heating.

Equidistant, or fixed-pitch, systems have been the workhorse of the industry for a long time, and for good reasons. But they also have their drawbacks, especially when compared to newer technologies.

Advantages of Equidistant Systems

Stability and Reliability:

- With fewer moving parts involved in pitch adjustment, these machines often have a reputation for being very stable and reliable. The simpler mechanics mean there's less that can go wrong.

- I've seen many older equidistant machines still running strong after years of service, which speaks to their robustness.

Structural Simplicity:

- The design is straightforward. Preforms are loaded, heated, and blown at the same pitch. This makes the machine easier to understand, operate, and often, to manufacture.

- For factories with less experienced technical staff, this simplicity can be a big plus.

Lower Initial Cost:

- Generally, equidistant machines are less expensive to purchase than their variable distance counterparts. The simpler design translates to lower manufacturing costs.

- For startups or businesses with limited capital, this can be a very attractive feature.

Lower Maintenance Costs:

- Fewer complex mechanisms mean fewer specialized parts that might need replacement or intricate servicing. Maintenance routines are often simpler and less costly.

Disadvantages of Equidistant Systems

Lower Efficiency for Varied Bottle Sizes:

- The fixed pitch is often a compromise. If you're producing small bottles, the preforms might be spaced further apart in the oven than optimal, leading to energy wastage or a larger oven. If producing large bottles, the pitch is set by the bottle diameter, which is fine for blowing but might not be ideal for heating density.

- This lack of optimization can lead to lower overall production efficiency compared to variable distance systems, especially if you change bottle types frequently.

Less Flexibility in Heating Optimization:

- Because the preforms are at a fixed distance, you have less control over optimizing the heating process by adjusting preform density in the oven.

Potentially Larger Machine Footprint for Heating:

- To achieve adequate heating for preforms that are already spaced out to match the blow mold pitch, the heating oven might need to be longer, thus increasing the machine's overall footprint.

Here's a summary table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Cost | Lower initial cost, lower maintenance | |

| Operation | Simpler structure, easier to operate | Less flexible for different bottle sizes |

| Efficiency | Good stability and reliability | Potentially lower heating and overall cycle efficiency |

| Space | Might require larger oven/footprint |

For a company producing a single type of bottle in very large, consistent volumes, and where initial cost is the primary driver, an equidistant system can still be a very sensible choice.

Can variable distance technology reduce energy consumption?

Are rising energy bills eating into your profits? Wondering if advanced machinery can actually lead to operational savings? It's crucial to see if new tech offers greener, cheaper production.

Yes, variable distance technology can contribute to reduced energy consumption. This is mainly through more efficient preform heating in compact ovens and potentially optimized use of servo motors, leading to lower electricity and compressed air costs.

Energy consumption is a big concern for plastics processors. Electricity for heating and machine operation, plus compressed air for blowing, are major operational expenses. So, can variable distance machines help here? I believe they can, in a few ways.

Electrical Consumption

More Efficient Heating Oven:

- Variable distance systems allow preforms to be placed much closer together during the heating phase. This means the heating oven can be smaller and more compact for the same number of preforms.

- A smaller oven volume generally means less energy is required to maintain the heating temperature. Heat is more concentrated on the preforms, leading to less wasted energy. I've seen designs where the oven length is significantly reduced, directly impacting power draw.

- Some systems also optimize lamp positioning relative to the denser preforms, further enhancing heating efficiency.

Servo Motor Usage:

- Many modern variable distance systems use servo motors for the pitch adjustment mechanism and sometimes for mold clamping and stretching. Servo motors are known for their energy efficiency compared to traditional hydraulic systems or even some older pneumatic systems. They only draw significant power when performing work, unlike hydraulic pumps that might run continuously.

- While servos add to the machine's complexity, their precise control and energy-on-demand nature can contribute to overall lower electricity usage.

Compressed Air Consumption

This is a bit more indirect, but still relevant.

- Optimized Process: While variable distance itself doesn't directly reduce the volume of air needed to blow a specific bottle, the overall optimization it brings can play a role. More consistent and optimal preform heating can lead to a more stable blowing process, potentially reducing the instances of poorly formed bottles that might need higher pressures or longer blowing times to correct (or result in scrap).

- Reduced Air Leakage in Shorter Cycles: Faster cycle times mean less overall time during which minor air leakages in the system (if any) can contribute to waste. This is a smaller factor but can add up.

The primary energy saving with variable distance comes from the heating oven optimization. If the preforms are heated more efficiently, it not only saves electricity but also ensures that preforms enter the mold at the ideal temperature profile. This leads to better material distribution, potentially allowing for slightly lighter bottles without compromising strength, which also saves material costs. These indirect savings all contribute to lower operational costs, making the technology more attractive despite a higher initial outlay.

Is variable distance suitable for all bottle types and mold designs?

Do you produce a wide variety of bottles? Concerned if variable distance technology has limitations or requires complex mold changes? Knowing its applicability is key to leveraging its benefits.

Variable distance is highly suitable for a wide range of bottle types, especially when producing bottles where the diameter is significantly larger than the preform. However, it might have limitations for extremely small preforms, and mold designs need to accommodate the pitch change.

Variable distance technology is very versatile, but it's not a universal magic bullet. Its benefits shine brightest in certain situations.

Applicable Bottle Type Range

- Ideal for Larger Diameter Bottles: The core advantage of variable distance is optimizing the heating of preforms (closely spaced) and then adjusting them to the wider pitch needed for blowing larger diameter bottles. Think of 2L water bottles, juice containers, or wide-mouth jars. For these, the difference between preform pitch in the oven and cavity pitch in the mold is significant, and variable distance excels.

- Flexibility for Multiple Sizes: Machines with a good range of variable pitch adjustment are excellent for companies that produce many different bottle sizes on the same machine. It allows for quick changeovers and optimized setups for each size.

- Complex Shapes: While not directly tied to variable distance, the precision of modern servo-driven variable distance machines often goes hand-in-hand with capabilities to produce more complex bottle shapes that require very accurate preform conditioning and positioning.

Potential Limitations

- Extremely Small Preforms/Bottles: For very small bottles where the preform diameter is already close to the bottle diameter, the benefit of variable pitch is reduced. The preforms might already be optimally spaced for heating, or the mechanical complexity of varying a very small pitch might not provide a significant return in efficiency. In such cases, a simpler equidistant machine might be more cost-effective.

- Specific Niche Applications: There might be some highly specialized bottle types or production methods where the existing equidistant systems are deeply entrenched and optimized, and the benefits of variable distance might not outweigh the cost of change.

Requirements for Mold Design and Modification

- Standard Mold Interface: Generally, the molds themselves (the cavities) don't need radical redesign. However, the mold base and its interface with the machine's clamping and transfer system must be compatible with how the variable pitch system presents the preforms.

- Alignment Precision: Molds need to be designed and manufactured with high precision to ensure proper alignment with the preforms whose positions are actively changing. Any misalignment could lead to production issues.

- No Major "Retrofit" for Molds Typically: You wouldn't usually "modify" an existing mold designed for an equidistant machine to work optimally on a variable distance machine without significant rework of the mold base or transfer system. It's more about ensuring new molds are designed for the specific variable distance machine's parameters.

I usually tell clients that if their production involves a mix of bottle sizes, especially if they are going up to 2L or similar capacities from smaller preforms, variable distance is a strong contender. The key is to match the machine's capabilities with your product portfolio.

How to choose the right distance system according to your production needs?

Feeling unsure how to weigh all these factors for your specific business? Need practical advice to select the system that truly matches your goals? Let's make this choice clearer.

Choose based on production volume, bottle complexity, budget, and labor. High volume or varied/large bottles favor variable distance if budget allows. Simple, consistent runs can use cost-effective equal distance systems.

Selecting the right distance system is a strategic decision. There's no single "best" answer; it's about what's best for your specific situation. I always walk my clients through a few key considerations.

Just last week, I was talking to a client in Turkey. They currently have five 4-cavity equidistant blow molding machines, which can produce bottles up to 600ml. They are planning to add a new product line with bottles up to 2000ml (2L). This meant their existing machines wouldn't work for the new, larger bottles. They needed to buy new equipment. After I compared the pros and cons of equidistant and variable distance systems for them, focusing on their new 2L requirement, they decided to purchase one 4-cavity 2L variable distance blow molding machine to start. Their main reasons were the reasonable price for a high-output machine, the high production capacity, and the wide range of bottle volumes it could handle effectively.

Here’s a breakdown of how you can approach this decision:

1. Production Scale and Volume

- High Volume, Continuous Production: If you're running multiple shifts and need maximum output, the efficiency gains from a variable distance system can quickly justify its higher initial cost. The increased throughput means more products out the door.

- Lower Volume, Intermittent Production: If your production runs are smaller or less frequent, the higher capital cost of a variable distance machine might be harder to recoup. A robust equidistant machine could be more economical.

2. Bottle Type Complexity and Variety

- Multiple Bottle Sizes/Shapes: If you produce a wide array of bottles, especially if they vary significantly in diameter or require frequent changeovers, a variable distance machine offers much greater flexibility and efficiency. The ability to optimize the pitch for different preform-to-bottle size ratios is key.

- Single, Consistent Bottle Type: If you are dedicated to producing one or very few bottle types with similar dimensions, and you don't foresee much change, an equidistant machine optimized for that specific product can be very effective and cost-efficient.

3. Budget Constraints

- Initial Investment: Variable distance machines are more expensive upfront. If your capital budget is tight, an equidistant machine is a more accessible option.

- Total Cost of Ownership (TCO): Consider long-term operational costs. Variable distance can offer savings in energy and potentially higher output, which can lower the per-bottle cost over time. You need to calculate if these savings will offset the higher initial price within a reasonable timeframe for your business.

4. Labor and Technical Expertise

- Availability of Skilled Technicians: Variable distance machines, with their more complex mechanisms (like servo systems), may require more skilled technicians for maintenance and troubleshooting.

- Ease of Operation: While modern machines are highly automated, the underlying simplicity of an equidistant machine might be preferable if your workforce is less experienced with complex automation.

Here’s a simplified decision guide:

| Factor | Leans Towards Equal Distance | Leans Towards Variable Distance |

|---|---|---|

| Production Volume | Low to Medium | Medium to High |

| Bottle Variety | Low (few, similar types) | High (many different types/sizes) |

| Bottle Size | Smaller bottles, or where preform/bottle diameter ratio is low | Larger bottles (e.g., 2L), wide-mouth, significant preform expansion |

| Initial Budget | Primary Constraint | More Flexible / ROI focused |

| Operational Efficiency | Secondary to cost | Primary Goal |

| Energy Savings | Less critical | Important for cost reduction |

| Technical Staff Skill | Basic to Intermediate | Intermediate to Advanced |

My Turkish client's situation was a classic case: they needed to produce larger bottles (2L) than their current machines could handle, wanted high output, and appreciated the flexibility for future products, all while keeping the price reasonable compared to even more complex rotary systems. The variable distance linear machine was the sweet spot for them.

Think carefully about your current needs and your future growth plans. This will guide you to the most suitable and profitable choice.

Conclusion

Choosing between equal and variable distance systems hinges on your specific production needs, volume, bottle diversity, and budget. Variable distance often wins for efficiency and flexibility.

I hope this detailed look helps you make a more informed decision. The right machine is out there!

📖 Learn More About PET Blow Molds and Blow Molding Machines

To better understand how PET blow molds and blow molding machines work together, explore the following resources:

Blow Molding – Wikipedia

Learn about various blow molding processes including extrusion and injection stretch blow molding.PET Blow Molds – iBottler

Discover our custom PET blow molds designed to fit your production needs.Bottle Blowing Machines – iBottler

Explore automatic and semi-automatic machines compatible with your mold designs.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr