Are you planning to invest in a PET bottle production line but feel confused by the complex cost calculations? The fear of miscalculating, leading to budget overruns or mismatched equipment, is a concern for every investor. In reality, the core of all calculations should begin with one question: What is your daily output target?

To accurately calculate the investment cost for PET bottle production, you must first determine your daily output. This key metric directly dictates whether you need a small-scale, semi-automatic solution or a large-scale, fully-automatic line that includes in-house preform manufacturing, which in turn impacts the total investment amount.

I've met too many clients who are holding a stack of quotes from different suppliers, yet they can't make a decision because they haven't thought through their most fundamental production needs. This article will strictly follow the steps of investment planning to dissect, point by point, how to build a clear and reliable cost budget based on your daily output.

Why Is Daily Output the Key Factor in Determining Investment Scale?

Before choosing equipment, are you torn between buying a 2-cavity or a 4-cavity machine? The root of this confusion is that you've skipped the most important step: defining your daily output requirement. Daily output isn't just a number; it's the foundation of your entire business plan. Any quote you receive is meaningless for comparison without this clear target.

Before diving into specific equipment and costs, we must first clarify two core issues. These relate to your investment risk and future operational model. Later, I will share a real client case study where a mistake in this area had a painful lesson, almost turning his custom equipment into a pile of scrap metal.

Self-Use vs. For Sale: Two Radically Different Risk Models

Are you producing bottles for your own products or selling them to others? This determines your risk exposure. In a self-use model, you control the demand and bottle design, making the risk manageable. In a sales model, your fate is tied to your customers' orders.

Table 1: Production Mode Comparison Analysis

| Consideration Factor | Self-Use Model | For Sale Model |

|---|---|---|

| Demand Stability | High. Based on your own production plan, highly predictable. | Uncertain. Completely dependent on client orders, high volatility. |

| Bottle Design | Stable. You decide, with a one-time investment in mold costs. | Variable. Requires frequent changes or new molds for different clients. |

| Investment Risk | Lower. Tied to the success of your own primary business. | Extremely High. If a client cancels, custom equipment and molds may become obsolete. |

| Core Objective | Control packaging costs, secure the supply chain. | Generate profit, but must bear significant risk of client churn. |

For factories selling bottles, the question "Are the orders long-term and stable?" is a matter of survival. How long will it take to get a return on the production line you invested heavily in? This depends entirely on the continuity of customer orders. Investing in a brand-new line for a client who only commits to a few months of orders is undoubtedly a huge gamble.

10,000 Bottles/Day: How to Start and Configure Equipment with the Lowest Cost?

If your target market is still uncertain or you wish to start with minimal risk, small-scale production is an ideal choice. Setting a clear goal, such as 10,000 bottles per day, makes cost estimation very specific. For this output level, the core principle is "asset-light, high flexibility," avoiding any unnecessary heavy investments.

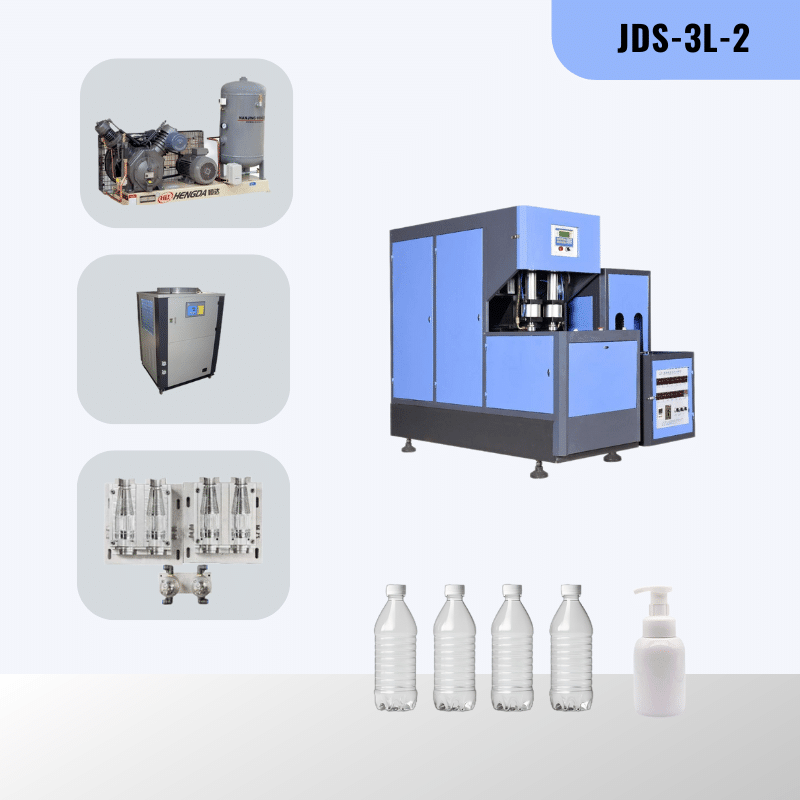

The most classic configuration is "one two-cavity semi-automatic blow molding machine + a basic set of auxiliary equipment." This solution has been proven by countless small and medium-sized enterprises worldwide and is the best choice for starting a project. It strikes a perfect balance between cost and efficiency. Semi-automatic means manual intervention is needed (placing preforms into the heater, then moving them to the blowing station), but this is precisely what gives it the advantages of low cost and operational flexibility.

Let's use a table to clearly list the components of this startup capital:

Table 2: 10,000 Bottles/Day · Initial Investment Cost Estimation Table

| Cost Item | Detailed Configuration / Description | Estimated Amount (USD) | Notes |

|---|---|---|---|

| Core Blowing Equipment | One two-cavity semi-automatic bottle blowing machine | $4,000 - $5,000 | The heart of the production line, highly cost-effective. |

| Essential Auxiliary System | High-pressure air compressor, water chiller, air tank, filters, etc. | $4,500 | The "logistics support" that ensures the blower runs properly. |

| Initial Raw Material Stock | Purchase of 18g preforms, stocked for one month's usage (300,000 pcs) | ~$9,000 | Calculated at $0.03/pc, turning fixed investment into variable cost. |

| Mold Cost | One set of a blow bottle mold for a standard bottle shape | $1,000 - $2,000 | Cost is lower for simpler bottle designs. |

| Estimated Total | Excludes factory rent, labor, and electricity | $18,500 - $20,500 | This is the core hardware and material investment needed to start production. |

As seen from the table, by adopting semi-automatic equipment and purchasing preforms, you can keep the entry barrier relatively low. This investment allows you to quickly enter the market for validation. Even if the project doesn't succeed, the loss is controllable. This is much wiser than investing over a hundred thousand dollars in a fully automatic line from the very beginning.

How to Reduce Initial Investment Pressure by Purchasing Preforms?

For any new PET bottle production project, controlling upfront investment is key to success. Among the many cost items, the method of acquiring preforms is a strategic choice that can make a huge difference. The most direct and effective cost-reduction strategy is: in the initial phase of the project, resolutely choose to purchase preforms from professional external manufacturers instead of investing in producing them yourself. This can help you save over 70% of the equipment investment.

Many beginners fall into the trap of thinking that an "all-in-one" production line is the most cost-effective. But at the small-scale production stage, this idea is fatal. Making your own preforms means you need to invest in an entire additional injection molding system, which is a massive expense, including a costly PET-specific injection machine (approx. $35,000 - $40,000) and a set of precision multi-cavity preform molds (approx. $20,000 - $30,000).

By purchasing preforms, you not only avoid this huge investment but also gain other benefits:

- Quality Assurance: Established preform suppliers have more stable processes and quality control systems. As a newcomer, the preforms you produce yourself might initially face various quality issues like inconsistent weight, pinholes, or bubbles. Directly purchasing high-quality preforms allows you to produce top-quality bottles from day one.

- Simplified Operations: You don't need to be distracted by managing a series of complex tasks like PET raw material procurement, drying, injection process debugging, and mold maintenance. You can focus all your energy on the core process of "bottle blowing" and serving your end customers well.

80,000 Bottles/Day: Investment Estimation and Core Configuration for a Large-Scale Line?

When your business takes off and your order volume stabilizes at 80,000 bottles per day (approx. 2.4 million per month) or higher, your cost structure and investment logic need a complete upgrade. At this scale, "efficiency is life, and cost is the weapon." The core of your investment will shift to high automation and vertical integration to achieve ultimate economies of scale.

At this point, building your own preform production line is no longer an option but a necessity. Relying on external purchasing is not only more expensive but also threatens your production security due to potential supply instability. What you need is a golden combination of a "fully-automatic blowing machine + automatic feeding system + in-house injection production line."

Table 3: 80,000 Bottles/Day · Large-Scale Investment Cost Estimation Table

| Cost Item | Detailed Configuration / Description | Estimated Amount (USD) | Notes |

|---|---|---|---|

| Fully-Automatic Blowing System | One six or eight-cavity fully-automatic bottle blowing machine | $50,000 - $60,000 | Core capacity guarantee, capable of 24/7 operation. |

| High-Performance Auxiliary System | Higher power air compression, cooling, and drying systems | $20,000 - $25,000 | Provides stable support for high-intensity, continuous production. |

| Preform Injection System | One PET-specific injection molding machine | $35,000 - $40,000 | Key to achieving an autonomous and controllable supply chain. |

| Core Molds | One set of multi-cavity preform molds (e.g., 16/32-cavity) | $20,000 - $30,000 | Mass-produces preforms to lower the unit cost. |

| Estimated Total | Excludes factory rent, labor, and electricity | $125,000 - $155,000 | This is a heavy asset investment aimed at building a long-term cost advantage. |

This huge investment buys you absolute control over the entire production process. You can directly purchase PET raw materials from the source, minimizing preform costs. Meanwhile, a fully automatic line drastically reduces labor costs and human error, ensuring high consistency in product quality. Under the amortization of high output, the steep equipment depreciation will be covered by a powerful cost advantage.

Besides Equipment, What Other Running Costs Need to be Calculated?

Equipment investment is a one-time expense, but factory operating costs occur every single day. Overlooking these ongoing expenses is the most common and fatal mistake when budgeting. They are like the part of the iceberg submerged underwater; though unseen, they determine whether your business can be profitable.

- Labor Costs: Your level of automation directly determines your labor needs. A small-scale semi-automatic line might require 2-3 operators, while a large-scale automatic line may only need one supervisor, but you might need more highly skilled maintenance engineers and mold technicians.

- Electricity: This is one of the largest operating expenses. A fully automatic line running at 80,000 bottles/day, along with its injection molder and air compressor, can easily consume thousands of kilowatt-hours of electricity per day. The local industrial electricity rate must be a core consideration when choosing a location.

- Factory Rent: The scale of the production line determines the factory space you need. A fully automatic line that includes injection, blowing, warehousing, and office areas might require over a thousand square meters.

- Maintenance & Depreciation: Machines and molds require regular maintenance and parts replacement. More importantly, any unexpected downtime means lost production capacity and delayed order delivery. A sufficient budget for preventive maintenance is "insurance" against larger losses.

How to Create a Flexible Investment Plan to Safeguard Your Project?

In the PET bottle production industry, especially when providing custom services for other clients, the biggest risk is a client changing their mind. Now, let me share the real client case study I mentioned earlier. This story profoundly reveals how fragile an investment without risk control can be.

I have a Russian client I've worked with for many years. A few years ago, he landed a huge contract. This single customer's purchase volume was projected to account for 60% of his total business. Thrilled by the unique bottle design and massive order volume, he invested heavily, purchasing a custom bottle blowing machine and several expensive, dedicated blow bottle molds from us specifically for this client. The factory was set up, the machines were installed and commissioned, and everything looked perfect.

However, the nightmare began just two months into production. His major client suddenly terminated the cooperation agreement, citing market changes, and cancelled all future orders. My client was instantly thrown into a desperate situation. The machine, optimized for a specific bottle, and those precision molds were useless for any other customer. They sat silently in his workshop, depreciating every day, unable to generate a single cent of revenue. He was under immense financial and psychological pressure, barely sleeping at night.

In the end, to save himself, he had to spend more money to have us modify the existing molds—altering them into a new, more generic bottle shape without infringing on the original client's design patent—and then painstakingly search for new buyers in the market. This painful lesson highlights the critical importance of a flexible investment plan.

What can we learn from this case?

- The Client MUST Pay for the Molds: This is the golden rule. For any custom bottle shape, the client must pay for the mold development costs upfront. This is the most direct safeguard for your initial investment.

- Set Up an Order Volume Rebate Clause: To foster cooperation, you can agree with the client to rebate the mold fee, in installments or in full, once their purchase volume reaches a certain level (e.g., 1 million or 5 million bottles). This secures your initial investment while incentivizing a long-term relationship.

- Sign Legally Binding Long-Term Supply Contracts: The contract must specify a minimum purchase quantity and cooperation period, and stipulate penalties for breach of contract. While this cannot completely eliminate risk, it at least provides a legal basis for seeking compensation if the worst happens.

Conclusion

In summary, accurately calculating the investment cost of PET bottle production begins and revolves around your daily output target. It dictates your equipment selection, cost structure, and risk control strategy. Clear planning, step-by-step execution, and arming yourself with smart contracts are the keys to investing wisely and establishing a strong position in this market.

Frequently Asked Questions

1. What is the biggest financial mistake new PET bottle producers make?

The most common mistake is investing in equipment blindly before defining a clear daily output and securing stable orders. This often leads to buying equipment that is either oversized, causing waste, or undersized, leading to missed opportunities, especially without conducting a thorough risk assessment when producing for others.

2. Should I choose a semi-automatic or fully-automatic blowing machine to start?

Choose based on your daily output target. If your goal is 10,000-20,000 bottles per day, a semi-automatic machine is the low-risk, high-value choice. Only consider investing in a fully-automatic line when you have stable, high-volume orders (e.g., 80,000+ bottles per day).

3. When should I consider making my own preforms?

You should only consider making your own preforms when your production reaches a large scale (typically meaning stable high output, like 80,000+ bottles/day) and you want to further reduce costs and control your supply chain. In the initial project phase, purchasing preforms is the smarter choice.

4. How can I mitigate risk if a client wants a custom bottle shape?

Adhere to the principle: "He who customizes, pays for the mold." Require the client to pay for the custom blow bottle mold upfront. You can simultaneously sign an agreement to rebate the mold cost after a certain purchase quantity is reached to lock in long-term orders and protect both parties' interests.

5. Is buying used machinery a good way to save money? Is it a good investment?

While used machinery is attractively priced, it carries high risks. You may face equipment aging, no warranty, and a higher frequency of breakdowns. Unless you have a very professional technician who can thoroughly inspect the machine, buying new equipment with factory support is the safer and, in the long run, more cost-effective choice for a new project.

🔗 Learn More about Blow Molding Technology

To better understand the core components of a 6-cavity automatic blow molding machine, here are some useful resources:

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Semi-Automatic Blow Molding Machines – iBottler

Ideal solutions for startups and small-scale PET bottle production.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr