Switching bottle designs creates production headaches. You try new settings, but get bad bottles, wasting time and material. A clear, systematic approach is what you need to succeed.

The key is to methodically adjust heating, pre-blowing, stretching, and main blowing parameters based on the new bottle's size, weight, and shape. Start with the heating profile, make one change at a time, test the result, and document everything for future use.

I've been in the PET packaging industry for 16 years and have helped over 300 clients. A common challenge I see is the difficulty they face when adjusting parameters for a new bottle type. When we ship a bottle blowing machine, we pre-tune it for the customer's specific bottle and preform. We set the heating temperatures, blowing times, and clamping speeds. This gives them a great starting point, only needing minor tweaks for local temperature differences. But when they introduce a completely new bottle, the real challenge begins. It requires a new way of thinking and a solid process to get it right. This guide will walk you through that process, just as I would with my own clients.

When Should You Adjust Parameters on a PET Blow Molding Machine?

Ready to launch a new bottle but not sure if you need to tweak the machine? Using your old settings is a recipe for failure. This leads to costly production halts.

You must adjust parameters whenever you change the bottle's fundamental characteristics. This includes switching the size (e.g., from 300ml to 500ml), changing the preform weight, altering the shape, or even using a different neck finish.

In my experience, operators often underestimate how sensitive the blow molding process is. They think a small change won't matter, but it almost always does. You can't expect the settings for a small, lightweight bottle to work for a large, heavy one. The physics are completely different. The machine needs to be told how to handle the new material and shape. Let's break down the specific triggers that demand a parameter adjustment.

Key Triggers for Parameter Adjustment

Changing Bottle Volume: This is the most obvious trigger. Moving from a small bottle to a large one requires a complete overhaul of the settings. A larger bottle needs more material to be stretched over a greater surface area. This means you'll need more heat, a slower and more controlled stretch, and adjusted blowing pressures to ensure the material distributes evenly. Going from large to small is just as critical; using settings for a large bottle on a small one will likely result in overheating and defects.

Changing Preform Weight: The weight of the preform, which you select based on your bottle's requirements, is directly tied to its wall thickness. A heavier preform from a new preform mold has thicker walls and requires significantly more heat energy to reach the ideal blowing temperature. If you use the same heating profile as a lighter preform, the outside will get hot but the inside will remain too cool, resulting in poor stretching and defects like haziness.

Changing Bottle Shape: A simple round bottle is much easier to blow than a square bottle or one with complex, decorative ribs. I had a client in Chile switch from a 300ml ribbed water bottle to a 550ml smooth, round bottle. Smooth bottles are very challenging because any heating imperfection shows up as ugly visual ripples on the surface. They initially used their old parameters and the results were terrible. The shape dictates how the material flows into the corners and flat panels of the blow bottle mold, so the pre-blow and main blow settings must be adapted to control this flow.

Changing Neck Finish: While the neck of the preform is not heated, changing the neck finish can sometimes require minor adjustments. The preform holder (mandrel) might be different, and the way the preform sits in the heating oven could change slightly, affecting the temperature profile near the top of the bottle. It's a less common trigger, but still one to be aware of.

Key Parameters That Impact Bottle Formation Quality?

Are you getting bottles that are cloudy, weak, or deformed? You are likely overlooking the core settings that control quality. This leads to high rejection rates and wasted plastic.

The most critical parameters are the heating temperature profile across different zones, the pre-blow pressure and timing, the speed of the stretch rod, and the final high-pressure blow. Mastering these four areas is the key to perfect bottles.

Think of these parameters as the four main ingredients in a recipe. If one ingredient is off, the whole dish is ruined. On a bottle blowing machine, each parameter controls a specific stage of the bottle's transformation from a small, thick preform into a large, thin container. I always teach my clients to focus on understanding what each parameter does before they start changing things randomly. A methodical approach saves time and prevents even more problems.

The Four Pillars of Bottle Quality

The journey from preform to bottle happens in a fraction of a second, but it's a carefully choreographed dance. Here’s what each key parameter controls:

1. Heating Temperature Profile

The preform oven is not just one big heater. It's divided into multiple vertical zones with several lamps in each. This allows you to apply different amounts of heat to different parts of the preform body.

- Why it's important: You need the preform to be heated to a precise, non-uniform temperature. The area that will become the bottle's base needs to be hotter than the area that will form the walls, for example.

- How to adjust: You increase or decrease the power output (usually a percentage) for the lamps in each zone.

- Common Problems & Adjustments:

| Defect Observed | Potential Cause | Heating Zone to Adjust |

|---|---|---|

| Pearlescence / Haziness in Base | Base is too hot or stretched too late. | Decrease temperature in bottom heating zones. |

| Thin Walls, Thick Base | Body is too hot compared to the base. | Increase temperature in bottom zones, decrease in middle zones. |

| Horizontal Ridges / Ripples | Uneven heating across the body. | Check for faulty lamps or adjust zone temperatures for uniformity. |

2. Pre-Blow Settings

After leaving the oven, the hot preform enters the mold. The pre-blow is a short burst of low-pressure air that happens just as the stretch rod begins to push down.

- Why it's important: It centers the preform in the mold, preventing it from touching the cold mold walls too early. It also starts to expand the preform into a bubble, beginning the material distribution process before the main stretch.

- Parameters: You control the start time (delay after mold close) and the pressure.

- Impact: An early pre-blow can make the top of the bottle thin. A late pre-blow can cause a thick base.

3. Stretch Rod Speed

The stretch rod is a metal rod that pushes down from the top, mechanically stretching the hot preform vertically.

- Why it's important: This action, called axial stretching, is what gives the bottle its vertical strength and helps determine the wall thickness.

- Parameters: You control the speed of the rod's movement. On advanced machines, this is controlled by a servo motor for extreme precision.

- Impact: A fast stretch speed tends to pull more material towards the base, making the walls thinner. A slower speed leaves more material in the upper body and shoulder.

4. Main Blow Pressure & Time

Once the stretch rod reaches the bottom of the blow bottle mold, a blast of high-pressure air is injected. This is the main blow.

- Why it's important: This high pressure forces the plastic to expand horizontally (radial stretching) and conform to the final shape of the mold cavity. It defines the bottle's final details, corners, and panels.

- Parameters: You control the final pressure (typically 30-40 bar) and the duration of the blow.

- Impact: Insufficient pressure or time will result in a poorly defined shape and soft spots. Too much pressure isn't usually the issue, but incorrect timing relative to the stretch and heat can cause problems.

Adjusting Parameters on Semi-Automatic PET Blow Molding Machines?

Working with a semi-automatic machine can feel like frustrating guesswork. You keep making manual changes with poor results. This costs you valuable time, materials, and energy.

On semi-automatic machines, the process is very hands-on. You physically adjust the distance of the heating lamps, manually set timers for stretching and blowing, and personally load each preform. Success comes from careful, small, and patient adjustments.

Semi-automatic machines are the workhorses for smaller production runs or startups. They lack the fancy touchscreens of their fully automatic cousins, but they operate on the exact same principles. The key difference is that you are the control system. This is where experience and a good "feel" for the process become invaluable. When I was helping my Chilean client with their new 550ml smooth bottle, they were using a semi-automatic machine. I couldn't just give them numbers to type in. I had to teach them how to see and feel the changes.

A Hands-On Guide to Semi-Automatic Adjustments

Adjusting a semi-automatic bottle blowing machine is an art form guided by science. You must be patient and methodical.

1. Adjusting the Heating Oven

This is the most critical and most manual step. The goal is to get the preform to the right temperature profile before it goes into the mold.

- Lamp Distance and Height: The heaters are on racks. You can physically move the entire rack closer to or further from the preforms. You can also adjust individual rows of lamps up or down. For a longer preform, you may need to add or reposition lamps to cover its entire length.

- The "Feel" Test: This is a trick I always teach. After a preform completes its heating cycle, take it out (with heat-proof gloves!). Gently squeeze it. It should feel soft and pliable, like a firm piece of licorice, but not floppy or sticky. You should be able to feel if there are hard, cool spots or overly soft, hot spots. My Chilean client mastered this, learning to feel when the thicker 22g preform was properly heated through.

- Rotation: Ensure the preforms are rotating consistently as they pass through the oven. If they stop rotating, one side will burn while the other stays cool.

2. Setting the Timers

Your control panel will have a set of simple timers, usually controlled by dials or basic digital inputs. These control the sequence inside the mold.

Stretch Delay: This is the pause between when the mold closes and when the stretch rod starts moving down. A longer delay allows heat to soak into the preform a bit more, which can help with base thickness.

Pre-Blow Time: The duration of the low-pressure pre-blow. A short time is usually sufficient, just enough to center the preform.

Main Blow Time: The duration of the high-pressure blow. This needs to be long enough for the bottle to form completely and cool slightly against the mold walls.

3. Mechanical Adjustments

Stretch Rod Position: You may need to mechanically adjust the stop position of the stretch rod to ensure it goes to the bottom of the new, different-sized blow bottle mold.

Clamping Pressure: Ensure the clamping unit that closes the two mold halves is set correctly to withstand the high blowing pressure without leaking air.

Making these adjustments requires a "one change at a time" approach. Adjust one thing—for example, move the lamps 5mm closer—and then blow a bottle. See the result, then decide on the next change. It's a slower process, but it's the only way to achieve mastery on these machines.

Adjusting Parameters on Fully Automatic PET Blow Molding Machines?

A fully automatic machine presents a complex screen of options. You are afraid to touch the wrong setting and cause a major issue. Your production suffers because you're stuck using a generic, suboptimal recipe.

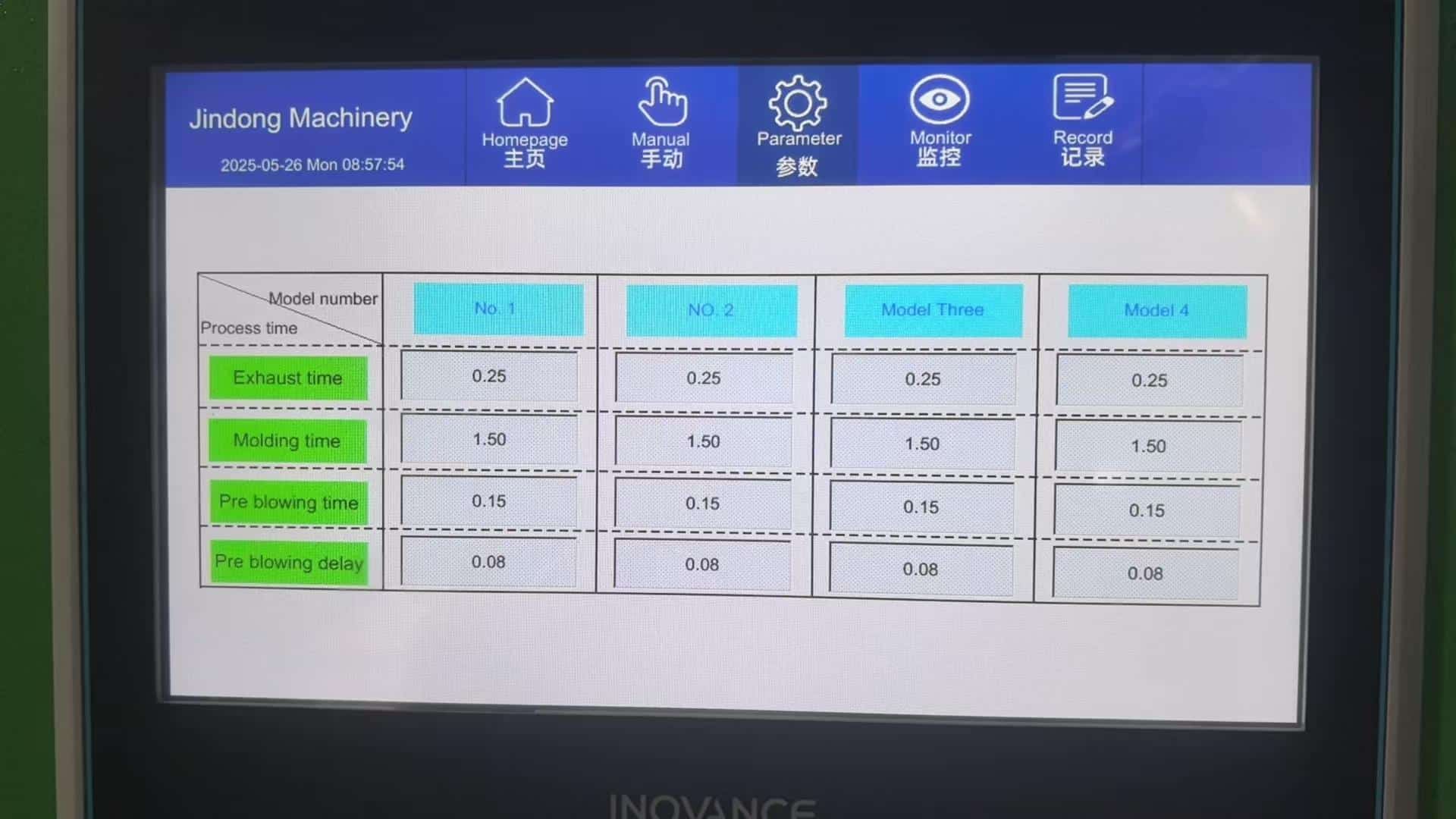

On fully automatic machines, all adjustments are made through a digital touchscreen, the Human-Machine Interface (HMI). You can precisely control heating zone percentages, pressures, servo motor speeds, and timings, and most importantly, save these settings as recipes for instant recall.

When a client invests in a fully automatic, high-speed bottle blowing machine, they are paying for precision, speed, and repeatability. The intimidating control panel is actually your greatest tool. Unlike a semi-automatic machine, where settings can be inconsistent, a fully automatic machine allows you to enter the exact same parameters every single time. The key is understanding what the numbers on the screen correspond to in the physical world. Once you master this, you can achieve incredibly efficient and consistent production.

Leveraging the Power of Digital Control

The HMI is the brain of the operation. Let's walk through how you use it to dial in a new bottle.

1. The Recipe Management System

This is the most powerful feature. Every time you perfect the settings for a specific bottle, you save them under a unique name (e.g., "550ml_Round_22g").

- Creating a New Recipe: When starting with a new bottle, don't start from scratch. Load the recipe from the most similar bottle you have in your library. If you're making a 500ml bottle, load the recipe for your 450ml bottle, not your 1.5L bottle. This gives you a much better starting point.

- Saving Changes: As you fine-tune the parameters, keep saving the recipe under a new version (e.g., "550ml_v2"). This allows you to go back if a change makes things worse.

2. Programming the Heating Profile

Instead of physically moving lamps, you simply type in a percentage of power for each heating zone.

- Precision Control: You can adjust the heat in tiny increments, perhaps changing Zone 3 from 65% power to 66%. This level of precision is impossible on a semi-automatic machine.

- Ventilation Control: The HMI also allows you to control ventilation fans that can cool the preform's neck or other specific areas to prevent unwanted deformation.

3. Digital Control of Stretching and Blowing

This is where servo motors show their value.

- Servo Stretching: You don't just set a single speed for the stretch rod. You can program a speed profile. For example, it can start slow, accelerate in the middle, and then slow down again just before it hits the bottom of the mold. This gives you ultimate control over vertical material distribution.

- Electronic Pressure Regulators: Pre-blow and main blow pressures are set digitally. You can also precisely control the timing, setting delays and durations down to the hundredth of a second. This allows for advanced techniques like a two-stage blow, which is very useful for large or complex bottles.

When you have a new blow bottle mold installed, the process is straightforward: load a similar recipe, adjust the heating for the new preform from the preform mold, and then start making small, digital adjustments to the stretching and blowing profiles, testing after each change. The ability to save your work means that the next time you run this bottle, the changeover will be incredibly fast.

Dealing with Heavier Preforms: Heating and Blowing Considerations?

You've switched to a heavier preform for a stronger bottle, but now your bottles are cloudy or have thick, un-stretched spots. Your old heating settings simply can't penetrate the thicker plastic, resulting in wasted, low-quality bottles.

Heavier preforms need more overall heat and a longer heating time for the energy to soak through the thicker PET material. You must increase lamp temperatures and potentially slow the machine's cycle time to ensure the preform is heated evenly from outside to inside.

This is one of the most common challenges I help my customers solve. It was the exact problem my Chilean client faced when they switched from a 10g preform to a much thicker 22g preform for their new bottle. They kept their old heating settings and the bottles were a disaster. The outside of the preform was getting hot, but the core remained too cool to stretch properly. It's like trying to cook a thick steak on very high heat; the outside burns before the inside is cooked. The same principle applies to heating a heavy preform from a preform mold.

Strategy for Heating and Blowing Thick-Walled Preforms

You can't rush the heating of a heavy preform. It requires a more intense, yet more patient, approach.

1. Rethinking the Heating Profile

The goal is deep, even heat penetration.

- Increase Overall Lamp Power: Your first step is to increase the power percentages on your heating lamps. But do this incrementally, maybe 5% at a time.

- Increase Soak Time (Slow Down): This is a critical step that is often missed. On a fully automatic bottle blowing machine, you can slightly decrease the overall machine speed (bottles per hour). This makes the preforms travel through the heating oven more slowly, giving them more time to "soak" in the heat. This allows the heat to penetrate to the core of the plastic.

- Zonal Adjustments: A thicker preform may require you to change the balance of heat. You might need to apply significantly more heat to the sections that will become the base and body, as there is more material to move there.

Use the Hand Test (Carefully): Just like on a semi-automatic machine, you can feel the result. A properly heated heavy preform will feel uniformly soft and pliable, without a hard, cool center. This is what I coached my client to do over video calls until they developed a feel for it.

2. Adjusting the Blowing Parameters

More plastic mass requires more force to move and shape it.

- Slightly Higher Pressures: Once the preform is properly heated, it will be soft enough to blow. However, you may find you need a small increase in pre-blow or main blow pressure to properly define the details in the blow bottle mold.

- Focus on the Pre-Blow: The pre-blow is very important for heavy preforms. It needs to be robust enough to start moving that thicker material and position it correctly before the main blow locks it into place. You might need to experiment with starting the pre-blow slightly earlier or with a bit more pressure.

By combining more intense heating with a longer soak time, you give the thick preform the energy it needs to stretch correctly. This combination is the key to turning a heavy preform into a crystal-clear, strong bottle.

Blowing Large Bottles: How to Prevent Deformation and Wall Thickness Issues?

You're excited about your new large-capacity bottles, but they keep coming out sagging or with paper-thin walls. The plastic just isn't distributing correctly across the larger surface area, leading to bottles that fail even basic quality control checks.

For large bottles (typically 1.5L and up), you need to slow down the entire process. This means longer heating, slower and more controlled stretching, and optimized mold cooling to manage the larger mass of hot plastic and prevent defects.

Blowing a large bottle is a completely different game than blowing a small one. The sheer amount of plastic you need to stretch and control is much greater. Gravity becomes a noticeable enemy. A large, hot preform from a heavy preform mold will want to sag under its own weight before it even gets into the mold. If you use the same speeds and timings as a small bottle, you are guaranteed to have problems with material distribution, leading to weak spots and deformation. I always tell my clients that for big bottles, "slow is smooth, and smooth is fast." A slower, more controlled process yields good bottles, which is much faster than running at high speed and producing nothing but rejects.

Techniques for Flawless Large-Format Bottles

Mastering large bottles requires a focus on control over speed.

1. Longer, More Intense Heating

Just like with heavy preforms, large bottles start from large, heavy preforms. They require a significant amount of heat energy.

- Increase Heating Time: You must slow down the oven cycle to give the preform enough time to absorb heat evenly.

Optimize Heat Zones: You need to ensure the entire length of the long preform is heated correctly. Pay special attention to the area that will form the base, as it needs to be hot enough to stretch across a wide diameter.

2. Slow and Controlled Stretching

This is arguably the most critical step for large bottles.

Reduce Stretch Rod Speed: On your bottle blowing machine, you must slow down the servo or pneumatic cylinder that controls the stretch rod. A fast stretch on a large bottle will immediately create thin, weak walls because the plastic doesn't have time to flow and orient itself properly. A slow, steady stretch pulls the material down evenly, maintaining better thickness control.

Delayed Stretch: You might experiment with a slightly longer delay before stretching begins. This allows the preform to equalize its temperature for a moment inside the closed mold, which can help prevent sagging.

3. Optimized Blowing and Cooling

Two-Stage Blowing: Many large bottles benefit from a modified blowing sequence. Instead of just a pre-blow and a main blow, you can use a lower-pressure "forming blow" for a slightly longer duration to push the material to the mold walls gently, followed by the final high-pressure blow to set the details.

Enhanced Mold Cooling: A large bottle contains a lot of heat. The blow bottle mold needs to remove that heat quickly to solidify the bottle and prevent it from shrinking or deforming after it's ejected. Ensure your mold cooling channels are clean and your chilled water supply is at the correct temperature and flow rate. Inadequate cooling is a major cause of post-mold deformation in large bottles.

By adopting a slower, more deliberate approach, you can successfully control the plastic flow and produce large, strong, and beautifully clear bottles.

Testing and Fine-Tuning After Parameter Changes?

You've changed the settings on the machine, but how do you know if they're really right? Just guessing and hoping for the best can lead to an unstable process that causes major problems during a long production run.

After every single parameter change, you must test systematically. Produce a small handful of bottles, perform detailed inspections for defects, cut them apart to check wall thickness, and record your findings before making the next small adjustment.

This is the part of the process where discipline pays off. Over my 16 years, I've seen countless operators get frustrated because they change five things at once. The bottle might look better, but they have no idea which of the five changes was the one that actually helped. They've learned nothing. I always insist that my clients follow one golden rule: make only one change at a time. It might feel slower, but it's the only way to truly understand cause and effect. This methodical process of adjusting, testing, and documenting is how you build a stable, repeatable process for every blow bottle mold in your factory.

The Adjust-Test-Document Cycle

Follow this professional workflow to ensure you are always moving in the right direction.

1. The "One Change at a Time" Rule

This is non-negotiable. If you think the base is too thick, you might decide to increase the heat in the bottom zone. Increase the temperature by a small amount (e.g., 2-3%), then run 5-10 bottles. Don't touch any other setting. Now you can analyze the result of that single change.

2. Visual Inspection Checklist

Have a standard checklist next to the machine. For every test bottle, inspect it for common defects.

| Defect to Check For | Yes/No | Notes |

|---|---|---|

| Haze / Pearlescence (White spots) | Usually in the base. Caused by overheating or over-stretching. | |

| Off-Center Gate | The small dot on the bottom isn't centered. Caused by bad pre-blow. | |

| Water Ripples / Lines | Uneven heating. The problem my Chilean client had. | |

| Thin/Weak Shoulders or Panels | Poor material distribution. Adjust heating zones or stretch speed. | |

| Deformation / Rocker Bottom | Bottle is unstable. Caused by bad heating or poor cooling. |

3. Section Weight Analysis (The Professional Method)

Looking at a bottle is good, but cutting it up tells the real story of material distribution. This is how the pros do it.

- Get a Hot Wire Cutter: Use a specialized cutter to get clean, repeatable cuts.

- Cut the Bottle: Cut the bottle into at least three sections: Top (shoulder), Body (sidewall), and Base. Some processes require five sections.

- Weigh Each Section: Use a precision scale to weigh each piece.

Analyze the Data: Your goal is to have weights that match your target specification. If the base is too heavy and the walls are too light, you know exactly what the problem is. This data tells you precisely how your parameter changes are affecting the bottle.

4. Keep a Detailed Logbook

For every new bottle setup, you should have a logbook or a digital file. Write down every single change, no matter how small, and the result it produced. "Increased Zone 4 temp from 70% to 72%. Result: Base weight decreased by 0.2g, slight haze appeared." This logbook becomes your most valuable asset. It's the history of your learning process for that specific bottle on that specific bottle blowing machine.

Expert Tips for Efficient Bottle Changeovers?

Does every new bottle setup mean hours of frustrating downtime? A chaotic and inefficient changeover process costs you thousands in lost production and wages. This inefficiency is a direct hit to your bottom line.

The fastest way to improve changeover efficiency is to build and save a digital parameter recipe for every single bottle you produce. This creates a repeatable, one-click starting point. Combine this with good physical organization of your tools and molds.

After helping hundreds of clients, I can tell you that the difference between a profitable factory and a struggling one often comes down to efficiency. A bottle changeover is a planned event; it should not be a moment of panic. The goal is to make the process as fast and repeatable as possible. A team that can switch from a 500ml water bottle to a 1L juice bottle in under an hour is going to be far more productive than a team that takes half a day. It all comes down to preparation and creating systems.

Strategies for Slashing Changeover Time

Here are the most effective tips I share with my clients to make their changeovers faster and more consistent.

1. Build Your Digital Parameter Library

This is the single most important tip for anyone using a fully automatic bottle blowing machine.

- Save Every Recipe: Once you have perfected the parameters for a bottle, save the recipe with a clear, descriptive name (e.g., "1L_Square_Juice_35g"). Don't just save one "good enough" version. As you improve it, save the new versions.

- Use as a Starting Point: The next time you need to run that 1L juice bottle, you simply load the recipe. This immediately gets you to a 95% perfect state. You may only need to make very minor tweaks for the day's ambient temperature or humidity.

For Semi-Automatic Machines: You can't save a digital recipe, but you can create a physical one. Use a detailed logbook or a laminated sheet with all the timer settings, photos of the lamp positions, and notes. This "recipe card" serves the same purpose.

2. Organize Your Physical Hardware (SMED Principles)

SMED (Single-Minute Exchange of Die) is a manufacturing philosophy focused on reducing setup times. You can apply its basic principles easily.

- Prepare in Advance: The next blow bottle mold should be clean, inspected, and waiting near the machine before you stop production on the current bottle.

- Create a Changeover Cart: Don't have your operators searching for tools. Have a dedicated cart with every single tool needed for the changeover: wrenches, bolts, hoses, cleaning supplies, etc. Everything should have its place.

Train the Team: A changeover should be like a pit stop. Everyone on the team should have a specific role and know exactly what to do. One person removes the old mold while another prepares the new one. Practice makes perfect.

3. Start from a Known Good Point

When you are developing parameters for a brand-new bottle you've never made before, don't start from zero. Find the most similar bottle in your library (similar volume, weight from the preform mold, and shape) and load its recipe. This will save you hours of initial guesswork. You are starting the tuning process from a much more advanced position. By combining these digital and physical strategies, you can transform your changeovers from a major source of downtime into a quick, efficient, and stress-free part of your daily operations.

Conclusion

Adjusting blow molding parameters is a skill. It combines technical knowledge with hands-on experience. By following a systematic process of small, deliberate changes, testing, and documentation, you can master any bottle changeover.

Frequently Asked Questions (FAQ)

1. Why is my PET bottle hazy or white at the bottom?

This is almost always a sign of crystallization, which happens when the plastic is either too hot or it's stretched too slowly at a high temperature. Try lowering the temperature of the heating zones that target the bottle's base or increase the stretch rod speed slightly.

2. How do I fix thin walls in the middle of my bottle with a thick base?

This is a classic material distribution problem. The material isn't being carried down the bottle properly during the stretch. To fix this, you generally need to make the base hotter and the body cooler. Increase the temperature in your lower heating zones and decrease it in the middle zones. You could also try slowing down the stretch rod to allow the walls to form more fully.

3. What's the very first parameter I should change for a completely new bottle?

Always start with the heating. The preform's weight and thickness are the most important factors. If you're moving to a heavier preform, you know you will need more heat. Adjust your heating profile first to get the preform to a soft, pliable state. Don't even try to adjust blowing or stretching until the heating is in the right ballpark.

4. Can I use the same parameters for a 15g preform and a 25g preform, even if the bottle shape is similar?

Absolutely not. A 25g preform is significantly thicker than a 15g one. If you use the 15g settings, the 25g preform will be severely underheated. You will need to increase the heating energy and likely slow the cycle down to allow that heat to penetrate the thicker plastic.

5. How long should a full bottle changeover take?

For a well-trained team running a bottle for which they already have a saved recipe, a full changeover (including swapping the blow bottle mold) can take less than an hour. However, for a brand-new bottle that requires developing parameters from scratch, the process of testing and fine-tuning could take several hours or more. The key is creating that recipe so future changeovers are fast.

【Final Complete Version】Parameter Tuning Summary & Quick Reference Guide

To consolidate the principles discussed in this article, we have created the following quick-reference chart. This table is intended to provide experienced operators and technical engineers with a logical baseline of starting parameters when commissioning new molds for common bottle types.

Disclaimer: The data below represents industry-standard starting points under typical production conditions and should not be considered absolute. The optimal parameters for your operation will vary based on factors such as preform resin brand, colorant, ambient temperature and humidity, and the specific model and condition of your equipment. The true art of process tuning lies in starting with a solid baseline, carefully observing the final product, and making precise, incremental adjustments.

Parameter Starting Guide for New Water Bottle Molds

| Bottle Specification | Machine Type | Key Parameter Group | Recommended Starting Parameters & Tuning Notes |

|---|---|---|---|

300ml Standard Water Bottle

| Semi-Automatic | 1. Heating |

|

| 2. Blowing |

| ||

| 3. Cycle |

| ||

| Fully-Automatic Servo (4-Cavity) | 1. Heating |

| |

| 2. Blowing |

| ||

| 3. Cycle |

| ||

500ml Standard Water Bottle

| Semi-Automatic | 1. Heating |

|

| 2. Blowing |

| ||

| 3. Cycle |

| ||

| Fully-Automatic Servo (4-Cavity) | 1. Heating |

| |

| 2. Blowing |

| ||

| 3. Cycle |

| ||

750ml Standard Water Bottle

| Semi-Automatic | 1. Heating |

|

| 2. Blowing |

| ||

| 3. Cycle |

| ||

| Fully-Automatic Servo (4-Cavity) | 1. Heating |

| |

| 2. Blowing |

| ||

| 3. Cycle |

|

Final Thought: The Bottle is the Only Standard

This table provides a solid starting point, but always remember that the quality of the final bottle is the only true measure of correct parameters. A skilled engineer never relies solely on fixed numbers; they build a logical feedback loop connecting the machine's settings, its behavior, and the finished product. The core essence of the PET blow molding process lies in observing the bottle's clarity, wall thickness distribution, and base formation, then using that information to fine-tune the parameters.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

📞 Contact: Vivian

🏭 Zhongshan Jindong Machinery Co., Ltd.

🌍 www.ibottler.com

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr