Struggling to find the right bottle size for the Thai market? You've noticed a gap between small bottles and large family packs, but introducing a new size feels risky and complicated.

The 750ml bottle is your answer. It perfectly meets the demand for all-day personal hydration, offering better profit margins and shelf presence. It's the ideal size for consumers who want more than a small drink but don't need a large, heavy bottle for their daily activities.

I recently worked with a client from Thailand who wanted to expand his bottled water line. He saw an opportunity with the 750ml size, a category that is surprisingly popular in Southeast Asia but less common in China. He had many questions about creating a custom mold, from design to production. This experience gave me a deep insight into the specific challenges and opportunities of launching this particular product in the Thai market. I want to share what I learned to help you navigate this process smoothly.

Why is 750ml Bottled Water Gaining Popularity in the Thai Market?

Wondering why 750ml bottles are suddenly everywhere in Thailand? You see them on convenience store shelves and in the hands of consumers, filling a specific niche you might have overlooked.

This size hits the sweet spot for Thai consumers. It’s large enough for extended outings or moderate hydration needs without being bulky. It bridges the gap perfectly between smaller 500ml bottles and large 1L family-size packs, catering to individual consumers in outdoor or on-the-go scenarios.

My Thai client pinpointed this exact trend. He noticed his customers were often buying two smaller bottles at a time. A 750ml bottle offers them a more convenient, single-purchase solution. For retailers, this size is also a winner. It occupies a unique space on the shelf, providing better visual impact and often yielding a higher profit margin compared to the more common, smaller sizes. This isn't just about quenching thirst; it's about providing a product that fits seamlessly into the modern Thai lifestyle—perfect for a day at the office, a trip to the gym, or navigating a busy city. This growing demand makes investing in a custom 750ml blow mold a strategic move for any beverage company in the region.

| Bottle Size | Target Scenario | Consumer Profile | Retail Advantage |

|---|---|---|---|

| 500ml | Quick thirst quench | On-the-go, short trips | High volume, low margin |

| 750ml | All-day hydration | Office workers, commuters, gym-goers | Fills market gap, better margin |

| 1L+ | Home/Office use | Families, group consumption | Bulk purchase appeal |

What Are the Design Trends for 750ml PET Bottles in Southeast Asia?

Thinking about your bottle design? You know it needs to look good, but you're unsure what specific styles appeal to consumers in Southeast Asia. A bad design can make your product disappear on the shelf.

Consumers in this region prefer tall, slender bottles with a curved waist. This shape is not only elegant but also easy to hold. A clean, transparent look with a large label area is also crucial for effective branding and standing out among competitors.

When I was developing the bottle for my Thai client, we focused heavily on these trends. He wanted a bottle that felt premium but was still practical. We settled on a design that was lightweight yet firm, avoiding the flimsy feeling that can make a product seem cheap. The key is to balance material cost with consumer perception. People want a bottle that is light enough to carry around all day but sturdy enough that it doesn't collapse in their hand. Getting this right is a huge part of a successful PET bottle mold design. A well-designed bottle feels good to hold, looks great on the shelf, and communicates the quality of the water inside before the customer even takes a sip. It’s an essential investment in your brand's identity.

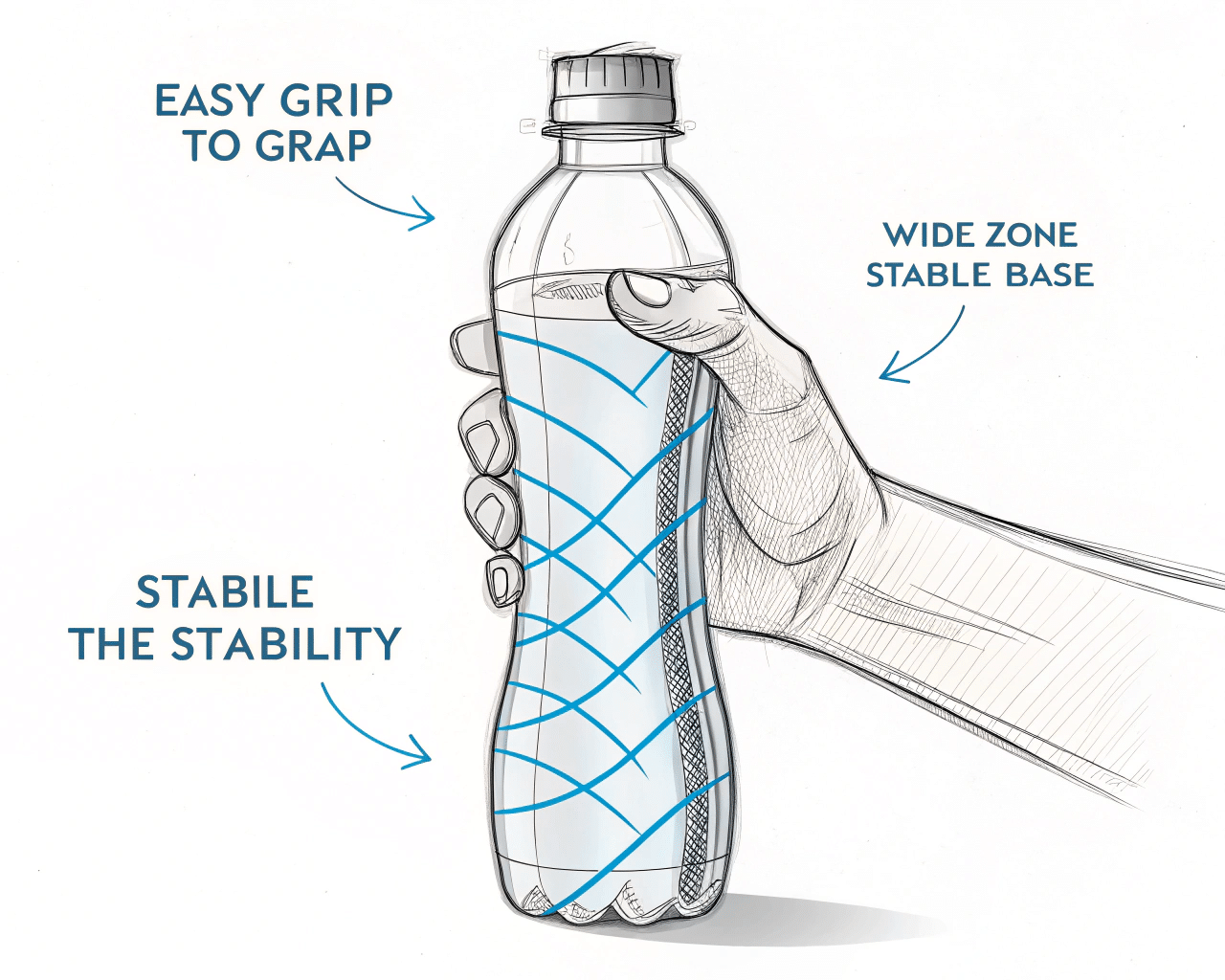

How Does Ergonomics Affect Bottle Shape Design?

Have you considered how your bottle feels in a customer's hand? A bottle that is awkward to hold, unstable, or difficult to transport can create a negative experience, no matter how good the water is.

Ergonomics is critical. The design must feel natural to grip, with a well-placed waist. The bottle's base needs to be wide and stable to prevent it from tipping over easily, both on the production line and on a customer's desk.

I remember a project where the initial design looked fantastic in 3D renderings, but it was a disaster in practice. The base was too narrow, causing bottles to constantly fall over on the conveyor belts of the filling line. We had to modify the mold, which cost the client time and money. For my Thai client’s 750ml bottle, we made sure the ergonomics were perfect from the start. We tested the grip for various hand sizes and simulated its stability. We also considered logistics. The bottle's height and diameter were optimized for standard shipping crates to maximize space and minimize transport costs. A thoughtful ergonomic design ensures a positive user experience and prevents costly production and logistical headaches down the road. You can even use 3D printed samples to physically test these factors before committing to the final mold.

How Can You Maximize Label and Branding Area on Thai Shelves?

Is your bottle’s label working hard enough for your brand? If the label area is too small, curved, or poorly placed, your branding will lose its impact on crowded retail shelves, making your product invisible.

To maximize visibility, your bottle design must include a large, flat, and smooth area specifically for the label. This ensures the label applies cleanly without wrinkles or distortion, presenting your brand professionally. A high-quality, highly transparent PET material will also enhance your brand's perceived quality.

For the 750ml bottle project in Thailand, we designed a specific label panel with a height of 90mm. This provided ample space for my client’s bold branding. We ensured the surface was perfectly cylindrical, not tapered, which is a common mistake that causes labeling machines to struggle. The clarity of the PET material was another priority; we chose a grade that was crystal clear and had a high gloss finish. This made the bottle sparkle under store lights and gave the entire package a premium feel. When your bottle looks good, customers assume the product inside is high quality too. Don’t let a poor label area undermine your branding efforts. It’s a simple detail that can make all the difference in a competitive market.

What's the Right Neck Finish and Cap for the Thai Market?

Are you sure the bottle you design will work with your filling machine? Choosing the wrong neck finish is a costly and easily avoidable mistake. It can lead to incompatible caps and major production shutdowns.

You must match the neck finish to your existing or planned bottling equipment. Common standards for still water in Thailand are PCO 1881, 30/25 and 29/25, as these are compatible with most mainstream filling lines. The cap type should also be considered for features like tamper evidence and leak prevention.

This was the most critical checkpoint for my Thai client. Before we even started the 750ml blow mold design, I asked him for the specifications of his capping machine. We confirmed he was using a standard 30/25 neck finish. This simple step saved us from a potential disaster. Imagine ordering a mold, only to find the bottles it produces don't fit your capper. It's a nightmare. We also discussed cap options, settling on a simple, lightweight screw cap with a tamper-evident ring, which is standard for bottled water. Always confirm compatibility first. It's the most important question to answer before you spend a single dollar on a new mold. For more details, a comprehensive guide on preform neck sizes can be an invaluable resource.

| Neck Finish | Common Use | Cap Type | Key Consideration |

|---|---|---|---|

| PCO 1881 | Carbonated Drinks, Water | Screw Cap | Lightweight, good for pressure |

| 30/25 | Still Water | Screw Cap | Very common, cost-effective |

| 29/25 | Still Water | Screw Cap | Similar to 30/25, slightly lighter |

| 38mm | Juices, Dairy | Screw Cap | Wider mouth for thicker liquids |

What Material Is Best for Water Bottle Blow Molds?

Confused about which metal to choose for your blow mold? You want a mold that is durable and produces high-quality bottles, but you also need to manage costs. The wrong choice can lead to poor performance or a short lifespan.

For most water bottle projects, 7075 aviation aluminum is the best choice for value. It offers excellent thermal conductivity for fast cycle times and is durable enough for high-volume production. For maximum longevity, S136 stainless steel is the premium option.

When quoting the 750ml bottle mold for my Thai client, I presented him with both options. His estimated production volume was high, but he also wanted to keep the initial investment reasonable. We decided on 7075 aluminum. It allowed him to get a high-quality mold with a fast production cycle, which is crucial for profitability. The faster you can cool the bottle, the more bottles you can make per hour. While S136 steel is harder and will last longer, the higher cost wasn't necessary for his specific goals. The choice of material should always be a balance between your budget, your expected production volume, and the specifications of your blow molding machine. A good supplier will help you weigh these factors to make the right decision.

What Should You Prepare Before Ordering a Custom 750ml Mold from China?

Ready to order your mold but worried you might forget a critical piece of information? Sending incomplete or incorrect details to a manufacturer can cause long delays, misunderstandings, and a final product that doesn't meet your needs.

To ensure a smooth process, you need to provide a clear and complete technical file. This includes a detailed bottle design, your production targets, and the specifications of your machinery. The more information you provide upfront, the better.

Before I create a mold for any client, I give them a simple checklist. This is exactly what I sent my Thai client to ensure we were perfectly aligned. Preparing this information in advance will make the entire process faster and more accurate. It eliminates guesswork for the mold maker and ensures the mold you receive will be a perfect fit for your factory. Don't forget, ensuring mold and blowing machine compatibility from the start is the most important step.

Pre-Order Checklist:

- Bottle Design: A 2D/3D drawing or a physical sample with dimensions, weight, and volume.

- Production Needs: Your target output (e.g., bottles per hour). This helps determine the number of cavities the mold needs.

- Blow Molding Machine Specs: The brand, model, and technical parameters of your machine. This dictates the mold's physical size and mounting.

- Filling Line Info: Key details like the filling nozzle diameter and height requirements.

- Preform Details: The neck finish and weight of the PET preform you will be using.

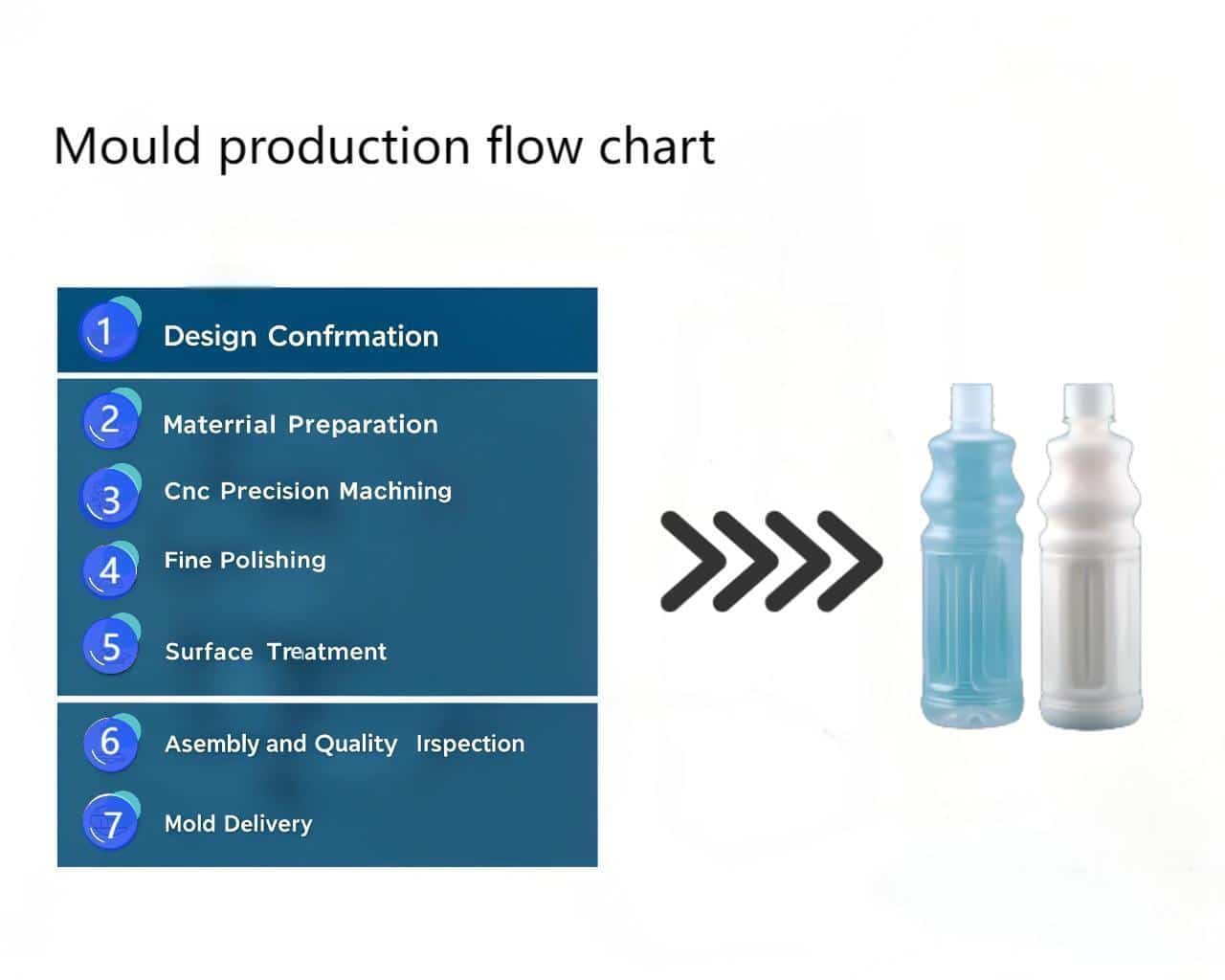

What Are the Lead Time, Price, and MOQ When Sourcing Molds from China?

Wondering how much a custom mold will cost and how long it will take? Uncertainty about price, delivery time, and minimum order quantities (MOQ) can make it difficult to plan your project and budget effectively.

For a standard 1- or 2-cavity 750ml bottle mold, you can expect a price between $2,500 and $4,000 USD. The typical lead time is about 25 to 30 days. The minimum order is almost always one set.

Let's break down the timeline for my Thai client’s project, which is very typical. After he confirmed the design, the process looked like this: 3D mold design and confirmation took 2 days. CNC machining of the mold parts took about 18 days. Finally, assembly, polishing, and testing took another 2 days. In total, the mold was ready to ship in about 18-25 days. The price depends on the number of cavities and the complexity of the design. A simple, single-cavity mold will be at the lower end of the price range. While the MOQ for the mold itself is one set, remember you will also need to source the right preform molds or preforms themselves. It's also crucial to remember that your production line needs more than just a blower and a mold; you'll need a reliable chiller and an efficient air compressor system to ensure everything runs smoothly and you avoid common bottle defects.

Conclusion

Launching a 750ml water bottle in Thailand is a smart move. By focusing on ergonomic design, branding, and technical compatibility, you can successfully capture this growing market segment.

FAQ

1. What is the most common reason for a new custom mold to fail in production?

The most common reason is a mismatch between the mold and the client's existing machinery, especially the blow molding machine's mounting specifications or the capping machine's neck finish requirements. This is why providing detailed technical specifications of your equipment is the most critical step. We always advise clients to check our guide on mold and blowing machine compatibility before placing an order.

2. How can I be sure the bottle design will look and feel right before I pay for the expensive metal mold?

You should request a 3D printed physical sample. This allows you to hold the bottle, test its grip, check its stability, and even apply a test label to see how your branding looks. Validating the design with a 3D printed sample is a small, inexpensive step that can save you from a costly mistake with the final mold.

3. If I provide a bottle sample from a competitor, can you copy it exactly?

Yes, we can replicate an existing bottle shape. We would 3D scan the sample to create a precise digital model. However, we always recommend making slight modifications to avoid any potential patent infringement issues and to add your own unique branding elements to the design. This is a core part of our PET bottle mold design service.

4. What's more important: the bottle's weight or its stiffness?

They are both important, but for different reasons. The weight directly impacts your material cost per bottle—lighter is cheaper. Stiffness, however, impacts consumer perception of quality. A bottle that is too flimsy feels cheap. The goal is to find the perfect balance: a bottle that is as light as possible without sacrificing the sturdy feel that consumers expect. This is often achieved through smart structural design, like adding reinforcing ribs.

5. Do I need a different mold for every bottle size?

Yes, you need a dedicated blow mold for each unique bottle shape and size. The mold cavity is machined to the exact dimensions of the final bottle. However, if multiple bottle designs share the same neck finish, you may be able to use the same preform molds and caps, which can save costs on that part of the process.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr