Struggling with a new bottle design? You have the perfect shape in mind, but now you worry that your existing preforms will become useless, forcing a costly change.

The answer is: not always, but it depends heavily on the design changes. For minor tweaks, your current preform might work. However, significant changes in height, shape complexity, or capacity will almost certainly require a new, specifically designed preform to ensure quality and avoid production failures.

Changing your bottle's design is an exciting step. It can refresh your brand, improve functionality, or cut costs. But this excitement can quickly turn into frustration if you overlook a critical component: the PET preform. Many people think a blow mold is all that matters, but the preform is the true foundation of your final bottle. Getting this wrong leads to costly delays, high scrap rates, and a product that doesn't live up to your vision. I want to walk you through the key things to consider, based on my 16 years in the PET mold industry. This will help you make the right call and ensure your new bottle launch is a success from the start.

Key Takeaways

| Factor | When You Likely Need a New Preform | When You Might Use the Original Preform |

|---|---|---|

| Height Change | Significant increase affecting the stretch ratio. | Minor height reduction or small adjustments. |

| Shape Complexity | Adding complex curves, embossing, or panels. | Simple, cylindrical shape with minor texture changes. |

| Bottom Design | Switching to a specialized base (e.g., for carbonation). | Sticking with a standard petaloid or flat base. |

| Wall Features | Adding integrated handles, grips, or deep grooves. | The bottle wall remains smooth and uniform. |

| Capacity Change | Increasing or decreasing volume by more than ~20%. | Minor volume tweaks within the preform's range. |

| Minor Tweaks Only | This is the ideal scenario for reusing preforms. | Not applicable if major changes are involved. |

| Mold Optimization | When mold adjustments alone cannot compensate. | If slight changes to mold cooling or venting suffice. |

| Professional Testing | Testing shows a clear mismatch in heating or stretching. | Testing confirms the original preform works perfectly. |

Does a major change in bottle height affect the stretch ratio?

You have a new, taller bottle design that looks fantastic. But using your old, shorter preform creates a major risk. The plastic might stretch too thin, creating weak spots.

Yes, a significant height increase directly impacts the stretch ratio. This can lead to an unstable blowing process, thin walls, and a weak bottle base. You will likely need a new, longer preform to match the new bottle's proportions and maintain structural integrity.

Dive Deeper: Understanding the Core Principle of Stretching

In the world of blow molding, the "stretch ratio" is a fundamental concept that dictates the success of your entire operation. It's not just a piece of industry jargon; it's the mathematical relationship between the preform and the final bottle. Getting it right is everything. I've seen countless projects succeed or fail based on this single principle. Let's break it down so it's perfectly clear.

What Exactly is the Stretch Ratio?

The stretch ratio is actually two different calculations that work together:

- Axial Stretch Ratio (Vertical): This measures how much the preform stretches in length.

- Formula:

Axial Ratio = Final Bottle Height / Preform Body Length

- Formula:

- Hoop Stretch Ratio (Horizontal): This measures how much the preform expands in diameter.

- Formula:

Hoop Ratio = Final Bottle Diameter / Preform Diameter

- Formula:

The combination of these two gives you the Overall Stretch Ratio, which tells you how much the material has thinned out in total. A balanced ratio is key. If you stretch too much in one direction and not enough in the other, you get problems. Think of it like stretching a piece of dough. If you only pull it longways, the middle becomes paper-thin and weak. You have to stretch it evenly in all directions to get a good, consistent base.

How a Taller Bottle Design Disrupts the Balance

When you introduce a much taller bottle design but try to use your old, shorter preform, you throw the axial stretch ratio way off. The bottle blowing machine has to stretch that limited amount of plastic over a much greater distance.

This causes several issues:

- Excessive Thinning: The material in the middle and bottom of the bottle gets stretched too thin. It might look clear, but it lacks the strength needed to hold the product or withstand pressure.

- Weak Base: The base of the bottle is often the most critical area for strength. If the axial stretch is too high, there isn't enough material left to form a robust, stable base. This is especially true for carbonated beverages.

- Process Instability: The blowing process becomes very sensitive. Small changes in temperature or pressure can cause bottles to burst inside the mold, leading to high scrap rates and production downtime.

I remember a client who wanted to launch a new line of tall, elegant 750ml water bottles. They wanted to use their existing preforms from a shorter, stockier 500ml bottle to save money. We ran the numbers, and the axial stretch ratio was nearly double the recommended limit. I advised them that it wouldn't work. They insisted on a trial run. As predicted, we couldn't produce a single stable bottle. The bottoms were paper-thin, and most of them burst during blowing. It was a clear demonstration of why the stretch ratio cannot be ignored. They ultimately invested in a new, longer PET preform mold and the problem was solved immediately.

Signs Your Stretch Ratio is Off

You can often see the problems with your own eyes. If you're experiencing any of these issues, a mismatched preform and bottle height is a likely culprit:

- Pearlescence: A pearly or hazy appearance in the bottle walls, indicating the material has been over-stressed.

- Thin Bottoms: The base feels flimsy and can be easily pushed in.

- Stress Cracking: Tiny cracks appear over time, especially in the base, as the material struggles to hold its shape.

- Inconsistent Wall Thickness: Some parts of the bottle are thick, while others are dangerously thin.

If you see these signs, you should check our guide on common PET blow molding defects for more detailed solutions.

The Solution: A New Preform

When your bottle height increases significantly, the only reliable solution is to use a preform that is designed for it. This usually means a preform that is physically longer. This reduces the axial stretch required, allowing the plastic to be distributed more evenly. It ensures you have enough material to form a strong base and consistent walls, resulting in a high-quality, durable bottle that performs as expected. Don't let a desire to reuse old inventory compromise the quality of your new product.

If the bottle's shoulder or shape gets more complex, is the original preform enough?

You've designed a beautiful bottle with stylish curves or a unique shoulder. But using a standard preform on a complex shape can lead to disaster. The plastic may not fill the mold properly.

No, a standard preform is often insufficient for complex designs. Intricate shapes like curved shoulders, embossed logos, or decorative panels require precise material distribution. A generic preform can result in incomplete forming, wrinkles, or weak spots in these detailed areas.

Dive Deeper: Material Flow is King for Complex Shapes

When you move from a simple cylindrical bottle to one with artistic flair, you are fundamentally changing the path the plastic must travel during the blowing process. It's no longer a straight, even stretch. The material has to flow into sharp corners, wrap around curves, and fill detailed engravings. This is where a generic preform shows its limitations. I always tell my clients to think of the preform as a block of clay. You need the right size and shape of clay to sculpt your masterpiece.

Why Complex Geometries Demand More

A standard preform is designed for efficiency and general use. It typically has a uniform wall thickness from the neck down to the base. This works perfectly for simple bottles because the material stretches in a predictable way.

However, complex features disrupt this simple stretching:

- Shoulder Designs: A bottle with a sharp, defined shoulder or a dual-shoulder design requires more material in that specific area. A standard preform will stretch thin over this corner, leading to a weak, easily deformable shoulder.

- Embossed Logos or Textures: When you have a logo or pattern pressed into the bottle wall, the mold has recessed areas. The plastic needs enough pressure and volume to push into every tiny detail. If the preform wall is already too thin by the time it reaches that area, it won't fill the detail completely, resulting in a soft or incomplete logo.

- Asymmetrical Shapes: Bottles that are not perfectly round, such as a flask shape or one with an offset neck, create very different stretching patterns on each side. A standard preform will result in uneven wall thickness, with one side being thicker and the other dangerously thin.

A great PET bottle mold design guide will always emphasize planning for these features at the preform stage, not just the mold stage.

Customizing the Preform for a Perfect Match

To solve these problems, we don't just use a longer or heavier preform; we strategically redesign it. This is where true expertise comes in.

- Thickened Shoulder Regions: For bottles with complex shoulders, we can design a preform that has an intentionally thicker band of plastic in the shoulder area. When this preform is heated and stretched, this extra material flows directly into the shoulder mold, ensuring it's fully formed and strong.

- Localized Wall Thickness: For bottles with deep panels or grips on the side (think of a sports drink bottle), the preform can be designed with thicker walls in the corresponding sections. This ensures that these functional or aesthetic areas are robust and not weak points.

- Optimized Heating Profile: A custom preform is also designed with a specific heating profile in mind. We know certain areas need to be hotter (to flow into details) and others cooler (to maintain thickness). The preform's design and the heating settings on the blowing machine work together to achieve this.

I worked with a startup in the spirits industry that had a stunning rectangular bottle design with a deeply embossed crest on the front. They brought me their design and a standard preform they had sourced. I knew right away it would be a problem. We ran a simulation, and it confirmed that the crest would be blurry and the corners of the bottle would be weak. I recommended a custom preform with a thicker wall on the front face. It was a small additional investment, but the result was a bottle that looked as premium as the liquid inside. The crisp, clear crest became their key branding feature, all thanks to starting with the right foundation.

The Risk of Ignoring Complexity

Pushing ahead with a standard preform for a complex bottle is a gamble. You might get a few acceptable bottles, but your process will be unstable. You will fight against defects like:

| Defect | Cause with Standard Preform | Solution with Custom Preform |

|---|---|---|

| Wrinkles/Folds | Material bunches up because it can't flow smoothly into a sharp corner. | Preform shape guides the material flow more naturally. |

| Incomplete Forming | Preform wall is too thin when it reaches a detailed area of the mold. | Provides more material in targeted zones. |

| Weak Corners | Excessive stretching around sharp angles in the bottle shape. | Thicker preform walls in corner areas provide strength. |

Ultimately, trying to force a generic preform to work for a special design costs more in the long run through wasted material, lost production time, and a final product that doesn't meet quality standards.

Does a different bottle bottom design affect preform suitability?

You're switching from a water bottle to a soda bottle. The bottom design is completely different, but it's the same capacity. Surely the same preform will work, right?

This is a common mistake. Different bottom designs have vastly different requirements for material thickness and distribution. Using the wrong preform can lead to a base that can't withstand pressure or stand straight.

A different bottle bottom often requires a new preform. Designs for carbonated drinks need thick, strong bases (petaloid), while hot-fill bottles need special vacuum-absorbing bases. A generic preform cannot provide the specific material placement needed for these specialized, high-performance bottoms.

-1.jpg)

Dive Deeper: The Base is the Unsung Hero of the Bottle

The bottom of a PET bottle is an engineering marvel, and it's far from a one-size-fits-all component. It's responsible for stability, pressure resistance, and in some cases, withstanding vacuum forces. I've spent years helping clients understand that the base design is one of the most critical factors driving the choice of a preform. A failure at the base means a failure of the entire package.

A Closer Look at Common Bottom Designs

Let's examine a few common base types and why they have such different preform requirements:

- Standard Flat Base (for Water/Juice): This is the simplest design, used for non-pressurized products. It needs to be flat and stable. The preform's gate area (the very bottom tip) needs to be stretched out evenly to create a uniform, flat surface. A standard preform usually works well here, but the gate quality is still crucial.

- Petaloid Base (for Carbonated Drinks): This is the classic five-footed base you see on soda bottles. Each "foot" is a carefully designed curve that distributes the immense pressure from carbonation. To form this correctly, you need a preform with a very thick, robust gate area. During blowing, this concentration of material is forced into the complex mold shape to create strong, stiff feet. Using a preform with a thin base will result in weak feet, a wobbly bottle, or even a stress-crack failure where the bottle bursts.

- Hot-Fill Base (for Teas/Juices): These bottles are filled with hot liquid (around 85-95°C), and as the product cools, it creates a vacuum that will collapse a normal bottle. Hot-fill bottles have special bases with panels or unique geometries that are designed to flex inward and absorb this vacuum. This requires a preform that allows for very precise material distribution—not too thick, not too thin—in the base panels.

- Asymmetrical/Specialty Bases: Some bottles, for marketing or functional reasons, have unique bases. Think of bottles designed to sit at an angle or those with integrated grips at the bottom. These require a completely custom PET preform mold to place material exactly where it's needed to support these odd shapes.

The Critical Role of the Preform Gate

The "gate" is the small circular spot at the very bottom of the preform where the molten PET was injected. The design and thickness of this specific area are paramount for the final base quality.

| Base Type | Required Preform Gate/Base Characteristic | Consequence of Using Wrong Preform |

|---|---|---|

| Petaloid (CSD) | Very thick and robust gate area | Base bursts under pressure; "rocker bottom" (wobbly) |

| Hot-Fill | Controlled thickness, high crystallinity | Base collapses or distorts (panel failure) |

| Flat (Water) | Clean, centered gate for even stretching | Off-center gate leads to a tilted, unstable bottle |

I once had a client, a co-packer, who won a new contract for a carbonated soft drink. They had plenty of preforms on hand from their bottled water line and assumed they could use them. The bottle capacity and neck finish were the same. During the first production run, bottles started exploding on the filling line. The pressure was too much for the weak bases formed from the water bottle preforms. We had to rush-order a new set of preforms with a heavy-weight base designed for carbonation. It was a stressful lesson for them on how critical the base design is. This is a common story and a key reason we always insist on reviewing the full PET bottle mold design guide with clients before they commit to a preform.

A change in bottom design is not a minor tweak. It's a fundamental change to the bottle's performance characteristics. In almost every case where the function of the base changes—from non-pressurized to pressurized, from cold-fill to hot-fill—you absolutely must use a new preform designed for that specific application.

Is the wall thickness distribution enough for new functional areas like handles or grips?

Your new bottle design includes a cool integrated handle or some ergonomic grips. These are functional features that need to be strong. Can a simple, generic preform provide the necessary strength in these specific spots?

It's highly unlikely. Functional zones like handles, grips, or deep grooves require significantly more material to ensure they don't break or deform during use. These are high-stress areas that need targeted reinforcement.

A standard, uniform-wall preform will stretch thin over these complex features, rendering them useless and fragile. For any bottle with functional zones that require structural strength, a custom preform with intentionally thickened walls in those areas is non-negotiable for a successful product.

Dive Deeper: Functionality Demands Purpose-Built Preforms

When you add a feature to a bottle that the consumer will physically interact with—like a handle to lift a heavy container or a grip to hold it securely—you are moving beyond simple aesthetics. You are adding a mechanical requirement. The bottle must perform a job without failing. In my experience, this is one of the clearest cases where a custom preform is not just recommended, but essential.

The Physics of a Functional Zone

Let's consider a large 5-liter edible oil bottle with an integrated handle.

- Stress Concentration: The handle, especially where it connects to the main body of the bottle, becomes a major stress point. When someone lifts the bottle, the entire weight (over 5 kg) is concentrated on that small plastic handle.

- Material Requirement: To withstand this force repeatedly, the handle needs to be made of thick, well-distributed plastic. It cannot be a thin, stretched-out membrane.

- The Failure of a Standard Preform: If you try to blow this bottle shape from a standard preform, the plastic will stretch dramatically to form the large body and the protruding handle. The handle itself will be incredibly thin and brittle. It would likely snap the first time a consumer tried to lift it.

This same logic applies to other functional features:

- Deep Grip Panels: The recessed grooves on a sports drink bottle need to be stiff enough not to collapse when you squeeze the bottle.

- Stacking Features: Some bottles have features on the top and bottom that allow them to lock together for stable stacking. These areas need to be robust and precisely formed.

Designing a Preform for Strength

To create a strong functional bottle, we have to design the preform backwards from the final product. We identify the critical, high-stress areas and ensure they get enough material.

Here’s how it works for the handle example:

- Identify the Zone: We map the area of the preform that will stretch to become the handle.

- Add Material: In our PET preform mold design, we create a much thicker wall section in that specific zone of the preform. It might look like a raised band or a thicker region on one side.

- Control the Flow: During the blowing process, this extra "lump" of plastic is carefully heated and then flows directly into the handle cavity of the blow bottle mold.

- Result: The finished handle is thick, strong, and fully integrated, while the rest of the bottle body can have a standard, more economical wall thickness.

This table shows the clear difference in approach:

| Feature | Standard Preform Approach (Incorrect) | Custom Preform Approach (Correct) |

|---|---|---|

| Handle | Material stretches thin over the handle shape. | A pre-thickened section of the preform flows into the handle. |

| Outcome | Flimsy, unsafe handle that breaks easily. | Robust, reliable handle that meets safety standards. |

| Grip Area | Grooves are thin and collapse under pressure. | Thicker preform walls in the grip area create stiff, functional ribs. |

| Outcome | Bottle feels cheap and deforms easily. | Bottle feels sturdy and provides a secure grip. |

I vividly recall a project for a cleaning products company. They designed a 2-liter bottle with a very stylish but thin, looped handle. They were very budget-conscious and insisted on trying a generic, off-the-shelf preform. We molded some samples, and the bottle looked great—until you tried to pick it up. The handle would flex and bend alarmingly. We did a simple weight test, and it snapped with less than half the weight of the filled product. It was an immediate safety failure. The project was delayed by six weeks while we designed and produced a proper custom preform with a reinforced handle zone. This initial attempt to save a small amount on preforms ended up costing them far more in lost time.

For any bottle where a part of its design has a physical job to do, you cannot compromise. A custom preform is the only way to ensure these features are strong, safe, and truly functional.

Does the new bottle's capacity exceed the original preform's maximum blow-up ratio?

You want to be more efficient and use your 500ml bottle preforms to make new 1-liter bottles. It's just more air, right? This seems like a simple way to expand your product line without new tooling.

This is a dangerous assumption that often leads to catastrophic failure. Every preform has a maximum "blow-up ratio," a limit to how much it can be safely stretched. Exceeding this limit is a recipe for disaster.

Yes, if the new capacity is significantly larger, it will likely exceed the preform's blow-up ratio. Pushing a preform beyond its design limits (typically more than a 20% volume change) will cause the material to stretch too thin, leading to burst bottles, inconsistent volume, and extremely high scrap rates.

Dive Deeper: The Absolute Limit of Plastic

The blow-up ratio, or blow ratio, is a hard physical limit. PET is a remarkable polymer, but it can only stretch so far before its molecular structure breaks down. Trying to make a 1.5-liter bottle from a preform designed for a 500ml bottle is like trying to make a king-size bed sheet from a dish towel. There simply isn't enough material to cover the area.

Understanding the Blow-Up Ratio

The blow-up ratio is a measure of the total expansion of the preform. It's closely related to the stretch ratios we discussed earlier, but it's more focused on the overall volume change. A general rule of thumb in the industry is that you should not try to blow a bottle that is more than about 20% larger or smaller in volume than the preform's intended design capacity.

- Going Too Big: When you try to create a much larger bottle, the PET is stretched beyond its elastic limit. The polymer chains are pulled so far apart that they can no longer hold together.

- Going Too Small: While less common, trying to blow a much smaller bottle from a large preform is also problematic. The material doesn't stretch enough, resulting in a bottle with very thick, rigid walls, poor clarity, and wasted plastic.

Let's look at the consequences of exceeding the maximum blow-up ratio:

| Problem | Description | Why it Happens |

|---|---|---|

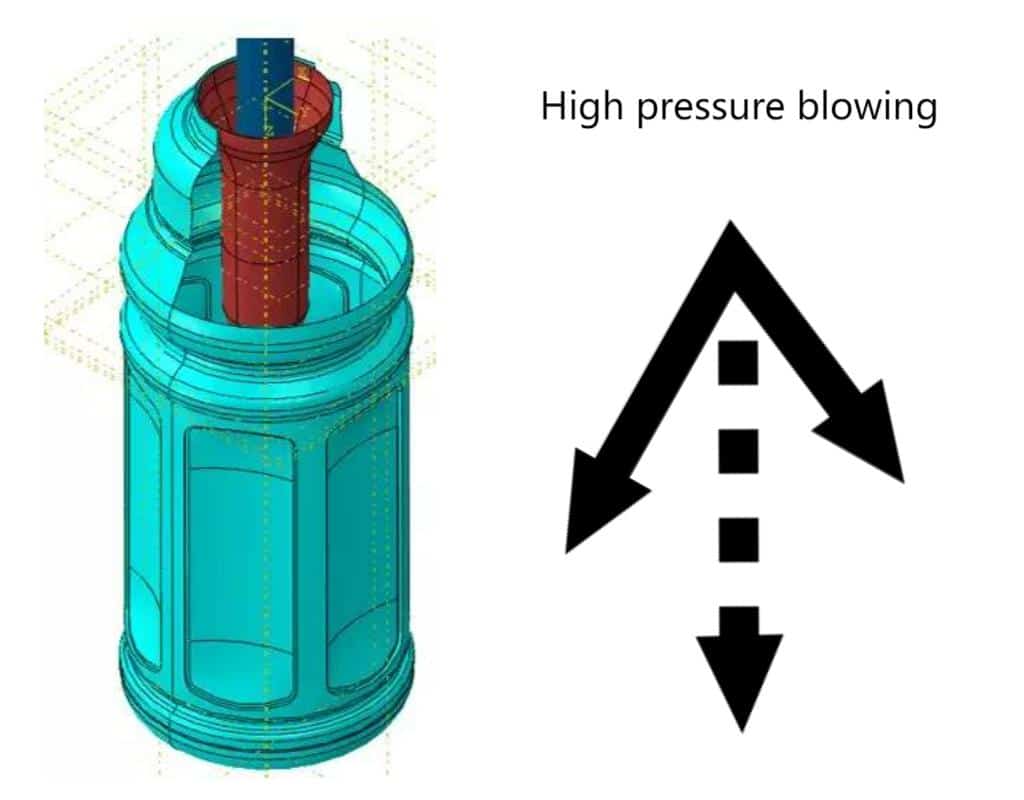

| Bottles Bursting | The most common and dramatic failure. The bottle explodes inside the mold during the high-pressure blowing stage. | The material becomes so thin that it cannot contain the blowing pressure (typically 40 bar / 580 psi). |

| Inconsistent Volume | The filled bottles do not hold the correct amount of product. Some might be 950ml, others 1050ml. | The process is so unstable that the material expansion cannot be reliably controlled from cycle to cycle. |

| Extreme Thinning | The bottle might form without bursting, but the walls are paper-thin, offering no structural integrity or barrier protection. | The limited amount of plastic has been stretched to its absolute maximum, covering a huge surface area. |

| High Scrap Rate | A huge percentage of the produced bottles have to be thrown away, wasting material, energy, and time. | The process window is practically non-existent. |

Why a Bigger Preform is the Only Answer

When you need to make a significantly larger bottle, you need more plastic. It's that simple. The solution is to use a preform that is heavier (contains more grams of PET) and often larger in physical size.

For instance, moving from a 500ml bottle to a 1.5L bottle would require a fundamental shift in the preform:

- Weight: A typical 500ml water bottle preform might weigh around 13-18 grams. A 1.5L bottle preform would be in the 28-35 gram range.

- Dimensions: The 1.5L preform will be longer and have thicker walls to provide the necessary material for the larger shape.

Trying to save money by using the wrong preform for a large capacity jump is one of the most common and costly mistakes I see new bottlers make. The material waste alone quickly surpasses the cost of buying the correct preforms. Furthermore, the entire production line becomes inefficient. To manage the unstable blowing, operators often have to slow down the bottle blowing machine, reducing output. You also need a robust air supply, and a cost-efficient air system becomes critical, as burst bottles and inefficiencies waste a lot of expensive high-pressure air.

I once consulted for a juice company that wanted to launch a "family size" 2-liter version of their popular 1-liter product. Their plant manager, trying to be clever, thought he could just use their existing 1L preforms and "turn up the pressure." The result was a complete mess. Their scrap rate was over 60%. The few bottles that did form were so flimsy they would collapse under their own weight. The project was dead on arrival until they invested in the proper, heavier preform designed for a 2-liter capacity. It's a foundational rule: the preform's weight must match the bottle's capacity.

What if the new bottle design only changes minor appearance details?

You want to make a small change to your bottle. Maybe you're shortening it by a few millimeters or adding a subtle texture. Do you really need to go through the expense and hassle of getting new preforms for such a tiny adjustment?

In this specific scenario, you are often in luck. Minor adjustments that don't fundamentally alter the bottle's core dimensions or performance requirements can frequently be made using your existing preforms.

If the changes are purely cosmetic and minor—like a slight height reduction or adding a shallow pattern—you can often use the original preform. This requires careful adjustment of the blowing process parameters and potentially some minor modifications to the blow bottle mold, but it can be a very cost-effective solution.

Dive Deeper: The Sweet Spot of Cost-Effective Modification

This is the situation every plant manager hopes for: the ability to refresh a product's look without a major investment in new primary tooling like a preform mold. It’s entirely possible, but it requires a good understanding of the process and a realistic view of the limitations. I've helped many clients navigate these "small" changes successfully, and it always comes down to careful management of the process variables.

When Can You Get Away With It?

You can typically reuse your existing preforms when the changes to the bottle design fall within these parameters:

- Minor Height Reduction: Shortening a bottle is much easier than lengthening it. You are using the same amount of plastic for a slightly smaller container. The main challenge is managing the excess material, which will result in slightly thicker walls.

- Adding Subtle Textures or Patterns: If you are adding shallow ribs, a light stipple texture, or a slightly recessed label panel, the material doesn't have to flow very far or stretch dramatically. A standard preform can often handle these minor deviations.

- Slight Diameter Changes: Small increases or decreases in the bottle's diameter (within the acceptable blow-up ratio) can also be accommodated.

This approach is perfect for budget-conscious projects, market trials for a new look, or when you need to make a quick change to solve a minor issue with an existing bottle.

The Key is in the Process Adjustment

Successfully using an existing preform for a slightly different bottle shape is less about the preform itself and more about fine-tuning the bottle blowing machine and the supporting equipment. This is where a skilled process technician is invaluable.

Here are the key adjustments we make:

- Heating Profile: The heating lamps in the oven are adjusted. For a shorter bottle, we might use less heat overall or change the heating zones to prevent the bottom from getting too hot, which could lead to an overly thick base.

- Blowing Pressures and Times: Both the pre-blow (which shapes the preform before high-pressure blowing) and the final blow pressures may need to be tweaked. Timings are adjusted by milliseconds to control exactly when and how the material expands.

- Stretch Rod Speed: The speed at which the stretch rod pushes the preform down into the mold can be changed to influence the vertical material distribution.

- Mold Cooling: This is critical. A change in wall thickness also changes the cooling time required. We always emphasize that PET blow molds need to be connected to a chiller to maintain a consistent mold temperature. For a thicker-walled bottle, you might need to increase the cooling time slightly or use colder water to ensure the bottle is stable when ejected.

A Real-World Example: The Label Panel Project

I worked with a beverage company whose marketing team wanted to switch from a wraparound paper label to a clear, pressure-sensitive label. To make the new label apply smoothly, they needed to add a flat, recessed panel to their existing bottle. The bottle's height, diameter, and capacity all remained the same.

This was a perfect case for reusing their existing preforms. The new feature was not a major structural change. We designed a new set of blow bottle mold cavities with the label panel feature. When it came to production, we didn't change the preform at all. Instead, our technician spent half a day fine-tuning the process. He slightly increased the heat in the zone corresponding to the panel and adjusted the pre-blow pressure. The result was a perfect bottle, and the client was thrilled to have refreshed their look with only the cost of the new mold cavities.

While this approach is great for saving money, it's important to be realistic. You are still forcing a preform to do something it wasn't perfectly designed for. The result might be a slightly heavier bottle or a process that is a little less stable than before. But for minor changes, it's often a very acceptable and intelligent trade-off.

Can you just optimize the mold locally to fit the original preform?

You're facing a situation where the preform isn't a perfect match for the new bottle design. But buying a new preform mold is a huge expense. Can't your mold maker just get creative and modify the blow mold to force the old preform to work?

Sometimes, this is a viable strategy to save costs, but it comes with significant compromises. You are essentially asking the mold to fix a problem that starts with the preform.

Yes, in some cases, the blow mold can be optimized to better accommodate a non-ideal preform. This involves modifying cooling channels, venting, or airflow paths within the mold. However, this is a workaround, not a solution. It may sacrifice bottle quality, leading to issues like uneven thickness or a less-defined shape.

Dive Deeper: The Art of Mold Compensation

When a client wants to avoid the cost of a new preform mold, my job as a mold maker shifts from straightforward design to creative problem-solving. We can't change the preform, so we have to change how the mold interacts with it. This is a delicate balancing act. We are trying to "trick" the plastic into flowing where we want it to go, even if the preform's natural tendency is to do something else.

Techniques for Mold Optimization

Here are some of the common tricks of the trade we use to compensate for a mismatched preform:

- Optimized Venting: Air that is trapped between the expanding preform and the mold surface can prevent the plastic from filling details completely. By adding or enlarging vents (tiny grooves that let air escape) in problem areas—like sharp corners or logos—we can help the plastic press firmly against the mold.

- Modified Cooling Channels: The temperature of the mold surface has a huge impact on how the plastic behaves. If a certain area of the bottle is too thin, we can make the corresponding area of the mold warmer by reducing the coolant flow there. This keeps the plastic softer for a fraction of a second longer, allowing it to stretch more. Conversely, to create a thicker section, we can try to cool that part of the mold faster. This is a core reason why understanding how a chiller connects to a PET blow mold is so important for process control.

- Altering Air Inlets: Sometimes, changing the shape or position of the air inlets at the bottom of the mold can change the way the high-pressure air inflates the "bubble," influencing the final material distribution.

- Base Mold Adjustments: We can make small mechanical adjustments to the base part of the mold to help center the preform better or to pre-shape the base slightly differently as it closes.

The Inevitable Compromises

While these techniques can work wonders in some situations, it's crucial to understand the trade-offs. You are asking the mold to do a job it wasn't designed for. This almost always leads to some sacrifice in quality or performance.

| Optimization Technique | Potential Positive Outcome | Potential Negative Consequence |

|---|---|---|

| Aggressive Venting | Fills sharp details and logos more effectively. | Can leave small lines or marks on the bottle surface. |

| Differential Cooling | Can help even out wall thickness. | May slow down the cycle time; can create internal stresses. |

| Mold Modifications | Can improve bottle stability or appearance. | May not fully solve the core issue; can weaken the mold. |

I always have a very frank conversation with my clients when we go down this path. I explain that we can try these optimizations, but I cannot guarantee a perfect bottle. The result might be a "good enough" bottle, but it won't be as robust or as aesthetically perfect as one made from a properly matched preform and mold.

This strategy is best suited for non-critical applications. For example, bottles for industrial chemicals or some household cleaning products where perfect clarity and flawless aesthetics are less important than cost. For a premium beverage or a cosmetic product, where the package is a key part of the brand's image, these compromises are usually unacceptable.

A few years ago, I had a client who had this exact issue. They had tens of thousands of preforms in stock but needed a slightly different bottle. To help them use their inventory, we modified the new blow bottle mold with extra venting and custom cooling circuits. It worked, and they were able to produce the bottle. However, their cycle time was about 10% slower, and the wall thickness variation was higher than on their other lines. For them, this was an acceptable trade-off to burn through old stock. But it's not a long-term solution for high-quality production.

What is the professional advice? Should I test preform compatibility before finalizing the bottle design?

You've spent weeks, maybe months, perfecting your new bottle design with your marketing team. It looks amazing on the computer screen. The temptation is to sign off on it and order the expensive production molds immediately.

This is one of the riskiest moments in the entire process. Finalizing a design without confirming it can actually be made with your chosen preform is a recipe for expensive rework and long delays.

Absolutely. The single most important piece of advice is to test the compatibility of your intended preform with your proposed bottle design before you finalize anything. A professional mold manufacturer can help you test and validate the combination, saving you from costly mistakes and production nightmares down the road.

-2.png)

Dive Deeper: Test Once, Produce with Confidence

In my 16 years in this business, the clients who have the smoothest, most successful product launches are always the ones who embrace the testing and validation phase. The clients who try to skip this step to "save time" are often the ones who end up with the biggest headaches. Committing to a multi-cavity production blow bottle mold can be a massive investment. You have to be certain it's going to work.

The Professional Validation Process

When a client comes to me with a new bottle design, we don't just start cutting steel. We initiate a formal validation process.

- Design Review: The very first step is for my engineering team to review the bottle design file. We use our experience to spot potential problem areas immediately—sharp corners, extreme stretch ratios, or features that will be difficult to form.

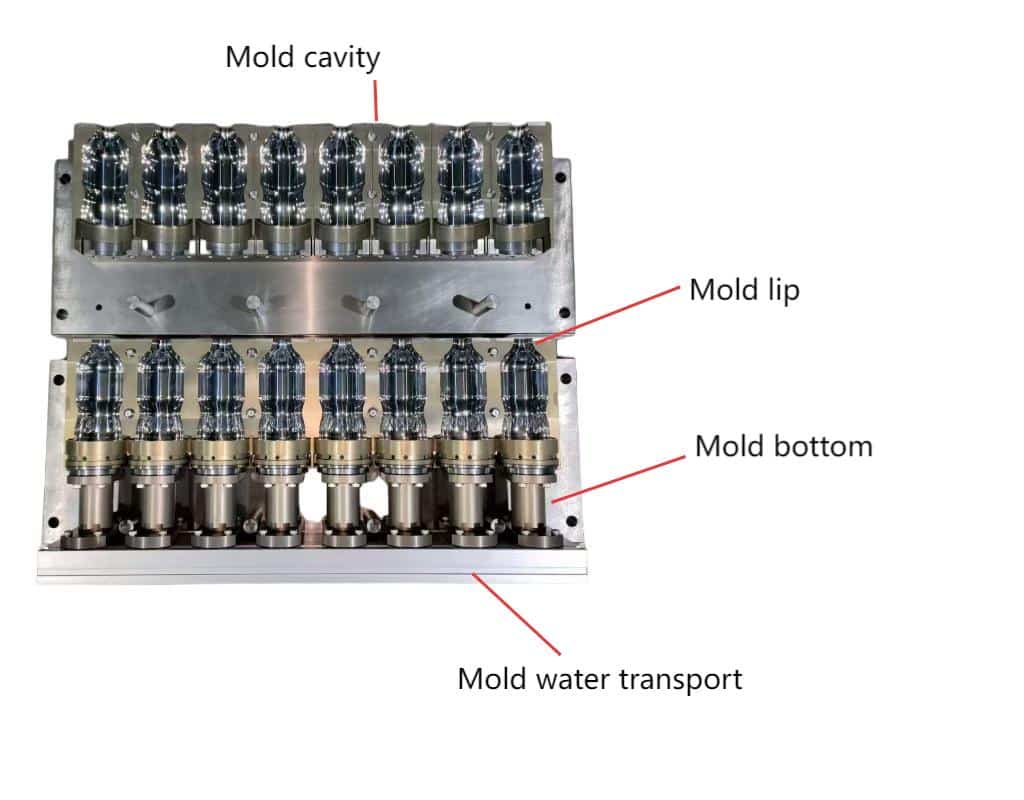

- Preform Selection/Analysis: We ask the client to send us samples of the exact preform they intend to use. We measure its weight, dimensions, and wall thickness distribution. If they don't have a preform, we recommend one based on the design. We also check the preform neck size to ensure it's compatible.

- Simulation (Optional but Recommended): For complex designs, we can run a blow molding simulation. This computer model predicts how the preform will stretch and where potential thin or thick spots will occur. It's a powerful tool for identifying problems before any metal is cut.

- Rapid Prototyping / 3D Printed Samples: This is a game-changer. We can create a 3D printed sample mold very quickly and cheaply. This allows us to blow actual sample bottles using the client's preform. They can hold the final bottle in their hands, check its dimensions, and test its strength.

- The Free Test Blow Service: We offer a service where we test a client's preform in a test mold in our facility. We analyze the stretch, the heating profile, and the overall compatibility. This provides concrete data. We can tell the client with high confidence: "Yes, this preform will work," or "No, this preform is not suitable, and here is why."

My Personal Guarantee: We Solve Problems Upfront

This brings me to a story I'm particularly proud of. I have a valued customer in the United States who purchased 30 sets of SACMI blow molds from us back in 2023. Earlier this year, in February 2025, they contacted me in a bit of a panic. One of their molds had been accidentally damaged—the mold bottom was unusable, and it had stopped their production line. They were worried because getting a local fix was proving difficult and expensive, and they feared a replacement from overseas wouldn't fit correctly.

This is a common fear, but it's one my company is built to eliminate. Because we keep meticulous records of every mold we've ever made, I was able to pull up their exact design files from 2023. I told him not to worry. We manufactured a brand new, identical mold bottom and shipped it to him. He received it, and it fit into his existing mold perfectly, like a key in a lock. His machine was back up and running in no time.

This story illustrates our philosophy. We aren't just selling a piece of metal; we're providing a long-term manufacturing solution. It also highlights the importance of working with a supplier who understands that blow mold fit and machine mounting dimensions are critical. Our upfront testing and meticulous record-keeping ensure that from the first sample to a replacement part years later, everything just works.

Investing a small amount of time and effort in upfront testing is the best insurance policy you can have. It confirms your design, validates your preform choice, and gives you the confidence to invest in full-scale production tooling without hesitation.

Conclusion

Changing your bottle design doesn't always mean changing your preform, but you must carefully consider height, complexity, and capacity. A small upfront analysis saves major production headaches later.

Frequently Asked Questions (FAQ)

1. What is the absolute biggest mistake I can make when changing my bottle shape?

The biggest mistake is assuming that if the bottle's volume and neck finish are the same, any preform will work. As we've detailed, factors like shape complexity, base design for carbonation, and even the location of a handle can dramatically affect whether a preform is suitable. Finalizing a bottle design and ordering expensive production molds without first validating it with the actual preform you plan to use is a costly and easily avoidable error.

2. I'm on a tight budget. What is the most cost-effective way to refresh my bottle's look?

The most budget-friendly approach is to make minor, cosmetic-only changes to your existing bottle. This could include a slight reduction in height, adding a subtle texture, or creating a recessed label panel without changing the core diameter or capacity. In these cases, you can often reuse your existing preforms and only need to invest in new, more affordable blow bottle mold cavities, not a whole new preform mold. The key is to keep the changes within the process window of your current preform.

3. How can I be 100% sure my new bottle will work before I spend thousands on molds?

You can achieve near-certainty by working with a mold supplier who offers robust testing and validation services. The ideal process involves:

- A professional design-for-manufacturing (DFM) review.

- Sending your preform samples to the supplier for analysis.

- Utilizing a 3D printed sample mold to create real, physical bottle samples.

This allows you to hold the bottle, test its strength, and approve the final product made from your exact preform before committing to the expensive, multi-cavity steel production molds. This upfront validation is the best insurance against costly errors.

4. My new bottle for carbonated juice keeps having a wobbly, unstable bottom. What's wrong?

This is a classic symptom of using the wrong preform for a carbonated beverage. You are likely using a standard preform designed for non-pressurized products like water. Carbonated drinks require a "petaloid" base with thick, strong "feet" to handle the internal pressure. This base can only be formed correctly from a preform that has a very thick, heavy gate area. Your current preform is stretching too thin at the bottom, creating a weak, rounded base (a "rocker bottom") instead of strong feet. You must switch to a preform specifically designed for CSD (carbonated soft drink) applications. You can learn more about this and other issues in our guide to fixing common blow molding defects.

5. How much can I change my bottle's volume before I absolutely need a new preform?

A good rule of thumb is the +/- 20% guideline. You can sometimes increase or decrease the bottle volume by up to 20% from the preform's original target volume, but this is pushing the limits. For example, you might be able to make a 400ml or 600ml bottle from a preform designed for 500ml, but it will require significant process adjustments. Anything beyond that, like trying to make a 750ml bottle from a 500ml preform, will almost certainly exceed the preform's maximum blow-up ratio, leading to burst bottles, thin walls, and a failed production run. A significant capacity change always requires a new, weight-appropriate preform.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr