Struggling with unexpected costs for your custom bottles? You finalize a design, then a large "mold fee" appears on the quote. Understanding this charge is crucial for protecting your brand and your budget.

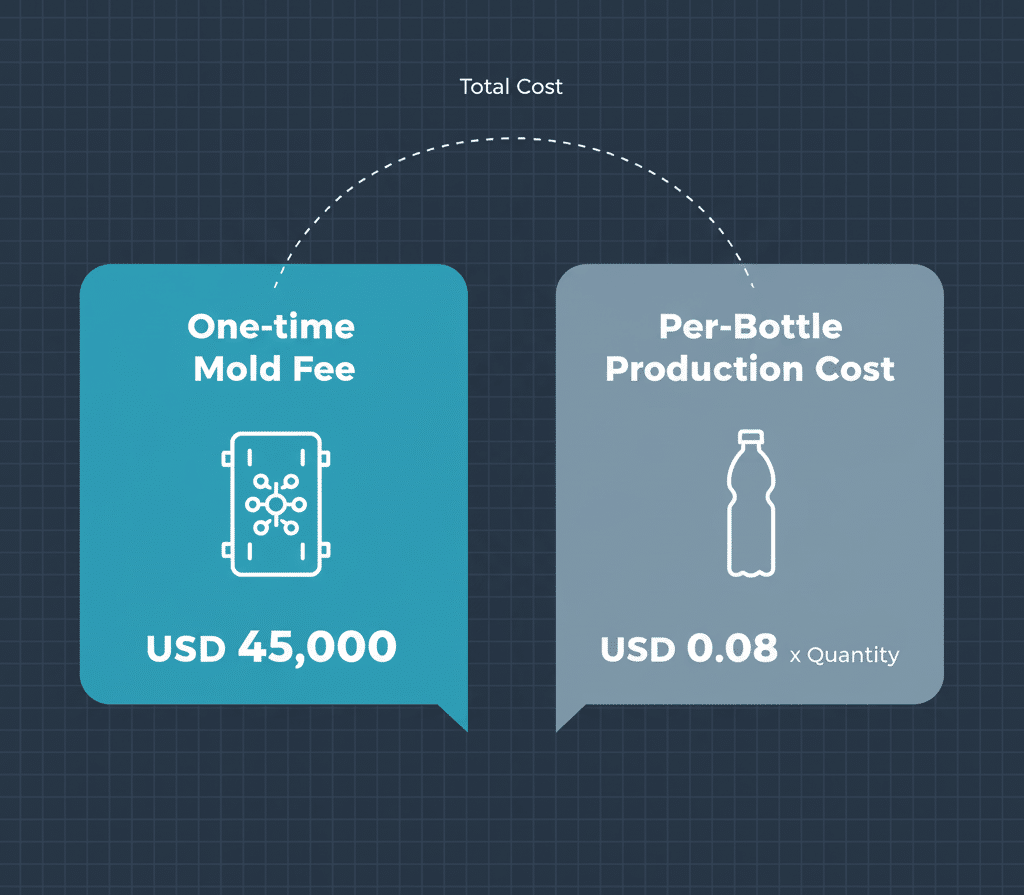

A blow mold fee is a one-time engineering cost to create the unique, physical tool required to produce your custom PET bottle. This fee is separate from the per-bottle price because it's an investment in a dedicated asset, not a consumable production expense.

This fee can be a source of confusion and friction between brands and their manufacturing partners. Many brand owners ask, "Why do I have to pay for this? Shouldn't the factory cover it?" This is a fair question, but the answer lies in understanding who truly benefits from the mold and what you're actually paying for. This article will walk you through every aspect of this critical cost. We will explore why you pay for it, what ownership really means, and how to protect this valuable asset. By the end, you will see this fee not as a burden, but as a strategic investment in your brand's future.

What is a "Mold Development Fee"? Why Is It Separate From Your Per-Bottle Price?

You are excited about your new bottle design, but the quote has a separate, large fee for "mold development." This feels like a hidden charge. This fee is actually your direct investment in a unique manufacturing tool.

A mold development fee is a one-time, non-recurring engineering (NRE) cost for the design, engineering, and fabrication of the specific blow mold for your bottle. It is separate from the per-bottle price, which covers the raw materials and ongoing production labor.

Diving Deeper into NRE vs. Production Costs

To truly grasp this concept, we need to distinguish between two types of costs in manufacturing: Non-Recurring Engineering (NRE) costs and recurring production costs.

Non-Recurring Engineering (NRE) Cost: This is a one-time charge to create a specific tool or process. In our case, the blow bottle mold is the tool. You pay for the engineering design, the high-grade steel or aluminum, the precision machining, and the assembly of this mold. Once it's paid for, this cost does not appear again for that specific design. Think of it as buying the fishing rod and reel.

Recurring Production Cost: This is the cost you pay for every single unit produced. It includes the PET plastic resin, the electricity to run the machines, the labor of the operators, and the factory's overhead. This is your per-bottle price. Think of this as paying for the bait and the fisherman's time for each fish you catch.

Here’s a simple table to break it down:

| Cost Type | What It Covers | Analogy | When You Pay |

|---|---|---|---|

| Mold Fee (NRE) | Design, steel, machining, assembly of the unique tool. | Buying the fishing rod. | Once, at the start of the project. |

| Bottle Price | Plastic, electricity, labor, factory overhead. | Paying for bait and labor per fish. | For every bottle you order. |

Why This Investment is Necessary

Without your specific mold, the factory simply cannot produce your bottle. A bottle blowing factory has a bottle blowing machine, but that machine needs a mold to form the plastic into a specific shape. It's like having an oven but no cake pan. The oven provides the heat, but the pan defines the cake's final shape. Your custom bottle design is unique, so it requires a unique mold that no one else has.

Factories do not keep an inventory of molds for custom projects because every client's design is different. Investing in your own mold ensures that the tool is built to the exact specifications of your PET bottle mold design. This guarantees quality and consistency for your product. It’s a foundational investment. The factory provides the production capability, but you provide the unique tool that makes your product possible. This separation ensures clarity and gives you, the brand owner, ultimate control over your physical asset.

"He Who Benefits, Invests": Why It's Standard for Brands to Pay the Blow Mold Fee?

You might wonder why the factory doesn't just pay for the mold. They are getting your business, after all. It seems unfair. However, this industry standard actually exists to protect you and your brand.

It is standard for brands to pay the blow mold fee because the mold is exclusive to their unique design and cannot be used for other clients. Paying the fee is the first step in establishing legal ownership and protecting your intellectual property from being copied.

Diving Deeper into a Fair Partnership

The core principle here is simple: "He who benefits, invests." Let's break down who really benefits from the creation of a custom mold and why your investment is critical.

The Mold's Exclusivity

Your custom bottle is a key part of your brand identity. The mold created for it is a tool that can only make your bottle. A contract manufacturer cannot use this mold to produce bottles for Coca-Cola, Pepsi, or any other client. For the factory, your mold is a dedicated piece of equipment that only serves one customer: you. If they were to pay for it, they would be investing thousands of dollars in an asset with no other commercial use. If you decided to stop production or switch suppliers, they would be left with a useless piece of expensive metal. Therefore, it is logical and fair for the party who solely benefits from the mold's existence—the brand—to cover its creation cost.

Protecting Your Intellectual Property (IP)

Your bottle's shape is a valuable piece of intellectual property. Paying for the mold is the most important action you can take to legally establish your ownership of that design. When you pay a clear, itemized invoice for "Mold Development," you have a legal and financial paper trail proving that you commissioned and funded its creation. This documentation is your first line of defense. It prevents a manufacturer from claiming the design is theirs and using it to produce knock-offs for a competitor. By investing in the tool, you are investing in the security of your brand identity.

Establishing a True Partnership

When a brand is unwilling to invest in the core tooling for their product, it can be a red flag for a manufacturer. It might suggest a lack of commitment to the project. Paying the mold fee demonstrates that you are serious and invested in a long-term relationship. This act transforms the dynamic from a simple client-vendor transaction to a more balanced partnership. You are not just a passive customer asking for a favor; you are an active partner who has invested in a key piece of the manufacturing process. This gives you more leverage and a stronger voice in discussions about quality, timelines, and price. It signals that you are a serious player, ready to build a successful product together.

I Paid for It, So Do I Own It? Demystifying Mold "Ownership" vs. "Right of Use"?

You paid the invoice. The mold fee is settled. So that physical mold is yours, right? You would think so, but a few tricky words in a contract can mean the difference between owning your asset and just borrowing it.

Yes, if you pay the full mold development fee, you should have 100% ownership of the physical mold. However, you must be cautious of contracts that only grant you an "exclusive right of use," which keeps the mold at the factory and prevents you from moving it.

Diving Deeper into Contractual Realities

The distinction between "ownership" and "right of use" is perhaps the single most important detail in your agreement with a contract manufacturer. Getting this wrong can cost you your business. Let's look at what these terms mean in the real world.

Full and Unambiguous Ownership

This is the ideal and proper arrangement. When you have full ownership, the mold is your property, your asset. It's like the title to a car. You paid for it, you own it. This means you have the right to:

- Inspect the mold: You can visit the factory and see your asset.

- Verify its condition: You can request maintenance records.

- Physically retrieve it: At any time (assuming you have paid all outstanding production invoices), you can arrange to have the mold picked up and moved to another facility of your choice.

To ensure this, your contract needs explicit language. It's not enough for it to be implied. I always advise my clients to insist on a clause that says something like:

"Upon full payment of all development fees, the blow mold (Serial #XXXX) becomes the sole and exclusive property of [Your Brand Name]. [Your Brand Name] retains the right to take physical possession of the mold at any time."

The "Exclusive Use" Trap

Here is where things get dangerous. Some factories, especially those that offer a discount on the mold fee, will use clever wording in their contracts. They might state that you have the "exclusive right to use the mold" at their facility. It sounds good. "Exclusive" feels protective. But what it really means is:

- The factory agrees not to use your mold for anyone else.

- BUT, the mold must remain on their premises.

- You do not have the right to move it. The factory retains physical possession, and often, legal ownership.

This is a trap. You've paid for a tool, but you don't own it in any practical sense. You have simply purchased a license to use that tool at one specific location. This arrangement heavily favors the factory and puts your brand in a very vulnerable position, which we will explore next.

The Risk of Being "Held Hostage": When Your Core Brand Asset Isn't Yours?

Imagine this: your supplier's quality starts to slip, or they suddenly announce a 30% price increase. If your mold isn't truly yours, you're stuck. You're effectively being held hostage by the one partner you're supposed to trust.

If you don't have clear ownership and the right to move your mold, you lose the freedom to switch suppliers. This gives the current factory total control over pricing, quality, and lead times, as they know replacing the mold is expensive and time-consuming for you.

Diving Deeper into the Hostage Scenario

This isn't just a theoretical risk. I see it happen to brands all the time. Just last month, in July, a client from Saudi Arabia called me in a panic. He needed to change his bottle supplier, Factory A, because of ongoing quality issues and missed deadlines. He asked them to prepare his mold for shipment to a new factory.

Factory A refused.

He told me, "I don't understand. I paid for that mold." I asked him to send me his contract. Buried in the terms was a clause he had overlooked. To get him to sign, Factory A had offered to "rebate" the mold fee if he ordered 5 million bottles from them. The contract didn't clearly state who owned the mold before that threshold was met. Now, because he hadn't reached the 5 million bottle target, Factory A claimed the mold was still their property and refused to release it. He was trapped. His choices were to either endure poor quality from Factory A or spend tens of thousands of dollars and several months building a new mold from scratch.

This story is a perfect illustration of the three key risks of not having clear mold ownership:

1. Losing the Freedom to Switch Suppliers

Your ability to change factories is your single greatest point of leverage. It keeps your supplier honest on price and motivated on quality. Without physical ownership of your mold, this freedom is gone. The cost and time required to create a new mold—often $5,000 to $20,000 and 8-12 weeks—creates a massive barrier to leaving. The factory knows this, and it changes the entire dynamic of your relationship.

2. Loss of Negotiating Power

Once a factory knows you cannot easily leave, they hold all the cards.

- Price Increases: They can impose price hikes with little justification, knowing your alternative is to re-invest in a new mold.

- MOQ Changes: They can increase the Minimum Order Quantity (MOQ), forcing you to tie up more cash in inventory.

- Longer Lead Times: Your orders can be de-prioritized in favor of other clients, leading to stockouts and lost sales.

You are no longer a valued partner; you are a captive customer.

3. Threats to Brand Security

This is the most extreme risk. If a factory has a dispute with you, and the mold ownership is unclear, what's to stop them from running extra shifts and selling your product on the grey market? Or even selling the mold itself to a competitor? While less common, it's a catastrophic risk that clear ownership completely eliminates. Your mold is a core brand asset, arguably as important as your trademark. You would never let someone else control your trademark, and you shouldn't let them control your mold.

Beware the "Free Mold" Trap: There's No Such Thing as a Free Lunch?

You're talking to a potential supplier and they make an incredible offer: "Sign with us, and we'll develop your mold for free!" This sounds like the perfect deal. But as the old saying goes, if it sounds too good to be true, it probably is.

"Free molds" are never truly free. The cost is amortized into a higher per-bottle price, meaning you pay more over time. Crucially, you will never own the mold, which permanently locks you in with that supplier and removes all your negotiating power.

Diving Deeper into the "Free" Mold's True Cost

Factories are not charities. They are businesses that need to make a profit on every component, including tooling. A "free mold" offer is simply a different financing strategy, one that is designed to benefit the factory, not you. Let's uncover the realities behind this tempting offer.

The Truth of Cost Amortization

The factory still has to pay its engineers and machinists. They still have to buy the expensive steel. That cost has to be recovered. Instead of billing you for it upfront, they add a small amount—perhaps a few cents—to the price of every single bottle you buy. It might not seem like much, but let's do some simple math.

Scenario Comparison:

| Feature | Option A: Pay for Mold | Option B: "Free" Mold |

|---|---|---|

| Upfront Mold Cost | $8,000 | $0 |

| Per-Bottle Price | $0.15 | $0.18 |

| Total Cost for 1,000,000 Bottles | $8,000 + (1,000,000 * $0.15) = $158,000 | $0 + (1,000,000 * $0.18) = $180,000 |

| Mold Ownership | You Own It | Factory Owns It |

As you can see, the "free" option ends up costing you $22,000 more over the life of the project. The factory not only recoups its mold cost but also builds in a handsome profit, all while you think you got a great deal.

The Ultimate Price: Permanent Lock-In

The financial cost is only part of the problem. The bigger issue, as we've discussed, is ownership. When you accept a "free mold," you are explicitly agreeing that the factory owns it. This is not a gray area; it's the fundamental basis of the deal. You are trading a short-term cash saving for a permanent loss of flexibility. You can never leave that supplier without abandoning the mold and starting from scratch. My Saudi client's story is a perfect example of a variation of this trap. His "rebate" was just a "free mold" deal in disguise, and it cost him his freedom.

A Simple Litmus Test

If you are ever presented with a "free mold" offer, there is one simple question you should ask the supplier directly. The answer will reveal everything you need to know.

Ask them: "Thank you for the offer. Just to be clear, if I accept this deal and we produce for one year, can I then take the mold you built and move it to a different factory for production?"

The answer will be a clear and immediate "No." This simple question cuts through all the marketing language and exposes the reality of the arrangement: the mold is theirs, not yours. You are not their partner; you are their permanent customer. While it might save cash upfront, the long-term cost and loss of control make the "free mold" trap one of the most dangerous pitfalls a brand can fall into.

Protecting Your Investment: 5 Key Clauses for Your Mold Development Contract?

Feeling nervous about the contract? That's a good thing. It means you understand the stakes. A well-written contract is your best tool to prevent future problems. It turns vague promises into legally binding commitments.

To fully protect your investment, your mold development contract must clearly define five key areas: unambiguous ownership, confidentiality (NDA), maintenance and storage duties, a mold release clause, and detailed technical specifications of the mold itself.

Diving Deeper into a Bulletproof Contract

A good contract doesn't need to be hundreds of pages long, but it does need to be precise. Think of it as the instruction manual for your partnership. Let's break down the five non-negotiable clauses you must include to safeguard your mold asset. I recommend having a lawyer review your contract, but understanding these points yourself is the first critical step.

Here is a summary of the essential clauses:

| Clause | Why It's Critical | Sample Wording Idea |

|---|---|---|

| 1. Clear Ownership | Prevents any dispute about who the mold belongs to. This is the foundation of your rights. | "The mold is the sole and exclusive property of [Your Brand Name]." |

| 2. Confidentiality (NDA) | Protects your unique bottle design from being shared with or copied by competitors. | "Manufacturer agrees not to disclose any designs, drawings, or specifications to any third party." |

| 3. Maintenance & Storage | Ensures the factory keeps your asset in good working order, preventing costly downtime or quality drops. | "Manufacturer is responsible for routine maintenance and proper storage of the mold at its own expense." |

| 4. Mold Release/Transfer | Guarantees your right to physically retrieve your property without hassle. | "Brand may retrieve the mold at any time after providing 7 days written notice." |

| 5. Detailed Specifications | Creates a technical record of what you paid for, ensuring quality and longevity. | "See Appendix A for mold specifications (steel type, cavity count, design life, etc.)." |

1. Clear Ownership Clause

We've covered this, but it bears repeating. This is the most important clause. It must explicitly state that upon final payment of the development fee, 100% of the title, rights, and interest in the mold transfers to you.

2. Confidentiality / Non-Disclosure Agreement (NDA)

Your bottle design is part of your competitive advantage. This clause legally obligates the manufacturer to keep your designs secret. It should state that they cannot use your designs, your mold, or any related information for any purpose other than fulfilling your purchase orders.

3. Maintenance & Storage Responsibility

A high-quality blow bottle mold can last for millions of cycles, but only if it's cared for. This clause should state that the factory is responsible for routine maintenance (cleaning, lubricating, minor repairs) and for storing the mold in a safe, dry environment when not in use. This prevents them from coming back to you later with a large bill for "mold refurbishment" or from letting your asset degrade through neglect.

4. Mold Release/Transfer Clause

This is the clause that gives your ownership teeth. It outlines the process for you to get your mold back. It should be simple and direct, stating that upon your written request (e.g., via email), the factory will make the mold available for pickup within a reasonable timeframe (e.g., 5-10 business days), provided your account is paid in full. Avoid clauses that add unreasonable conditions or fees for the release.

5. Detailed Mold Specifications

What are you actually buying? This clause, often included as an appendix, should detail the technical specifics of the mold. It should list the type of steel or aluminum used, the number of cavities, the estimated design life (e.g., "guaranteed for 1 million cycles"), and reference the final approved 3D design drawings. This ensures you get the quality you paid for and helps if you ever need to validate your blow mold design or move it to a new factory.

Demystifying Mold Costs: From Steel to Cavities, What Determines the Price?

Why did you get one quote for a mold at $4,000 and another at $12,000? This huge variation can be confusing. The price isn't arbitrary; it's directly tied to the complexity, productivity, and longevity of the tool you are commissioning.

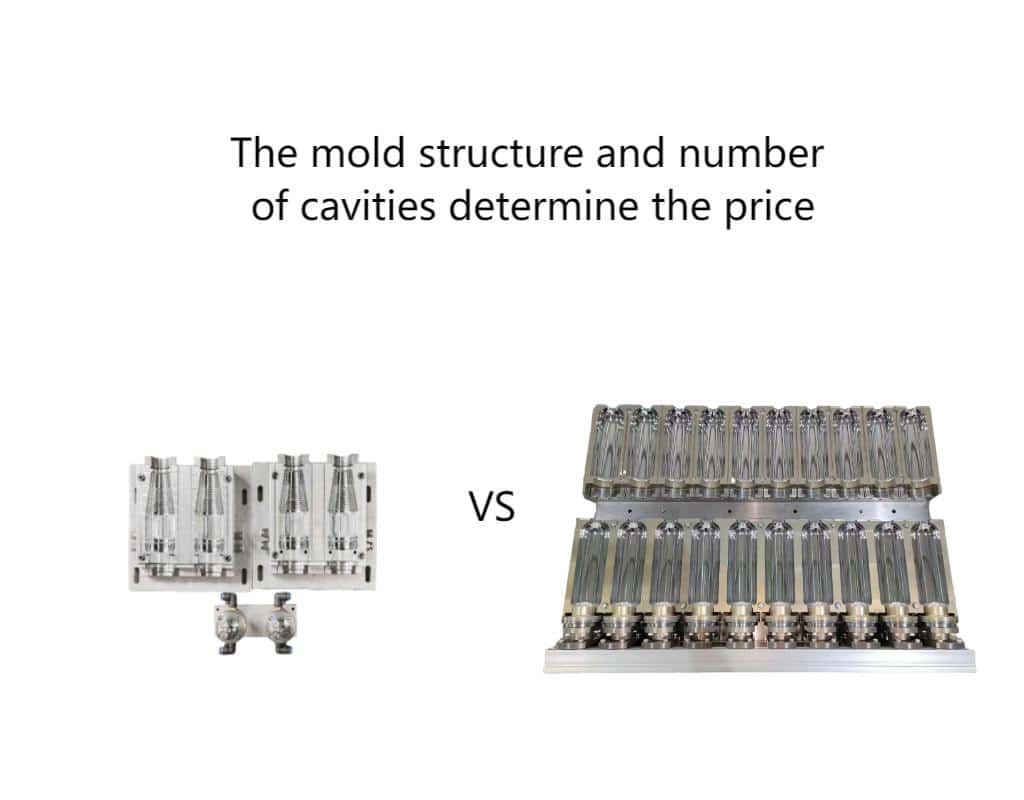

A blow mold's price is primarily determined by three factors: the complexity of the bottle design, the number of cavities in the mold (how many bottles it makes at once), and the grade of steel or aluminum used, which dictates its lifespan and durability.

Diving Deeper into the Price Tag

Understanding what drives the cost allows you to make informed decisions. You can work with your designer and mold maker to find the right balance between your vision, your production needs, and your budget. Let's break down the three main cost drivers.

1. Design Complexity & Bottle Structure

The simpler the bottle, the simpler the mold.

- Simple: A basic round or square bottle requires a relatively straightforward two-part mold. The machining is less time-consuming.

- Complex: A bottle with an integrated handle, an unusual shape (asymmetrical), or intricate embossed textures requires a much more complex mold. It might need additional moving parts (slides or inserts) to form these features and allow the bottle to be removed from the mold. This complexity adds significant hours to the design and machining process, directly increasing the cost. A good starting point is our PET bottle mold design guide, which can help you understand these trade-offs.

2. Number of Cavities

A mold's "cavity" count refers to how many bottles it produces in a single cycle of the blowing machine.

- 1-Cavity Mold: Produces one bottle at a time. It's smaller, uses less material, and is faster to machine. It's ideal for low-volume production runs or market tests.

- 4-Cavity (or 8, 16, etc.) Mold: Produces four bottles at a time. The mold itself is much larger, requires significantly more steel and machining time, and needs more complex systems to distribute the air and water evenly. The upfront cost is much higher, but it dramatically lowers your per-bottle production cost because you are making bottles four times faster. The choice depends on your sales forecast. A high-volume product will justify the investment in a higher cavity mold.

3. Steel Grade & Lifespan

This is a classic case of "you get what you pay for." The material used to make the mold is a huge factor in its cost and, more importantly, its useful life. Not all metals are created equal.

| Mold Material | Typical Use Case | Lifespan (Cycles) | Relative Cost | Key Advantage |

|---|---|---|---|---|

| P20 Steel | Prototyping, very low volume | 5,000 - 15,000 | Low | Fastest to machine, good for samples |

| 7075 /6061-T5 Aluminum | High volume production | 800,000 - 1,000,000 | High | Excellent polish, very durable |

| S136 Stainless | Medical/Food grade, PVC | 1,000,000+ | Very High | Corrosion resistant, best for clarity |

Choosing a cheap material like Aluminum for a high-volume product is a mistake; it will wear out quickly, forcing you to buy a new mold. Conversely, paying for high-end S136 stainless steel for a small, 50,000-unit run is unnecessary. Discussing your expected production volume with your mold maker is essential to selecting the right material for the job. It also ensures the mold you buy will correctly interface with the intended bottle blowing machine.

The Smart Choice: Viewing Your Mold Fee as a Controllable, Valuable Brand Investment?

After all this, the mold fee might still feel like a painful check to write. It's a significant upfront cost. But you can shift your mindset. Instead of seeing it as a problem, view it as a strategic investment that buys you control, flexibility, and long-term security.

Don't see the mold fee as a sunk cost. Instead, treat it as a controllable, strategic investment in your brand's core infrastructure. By making smart design choices and partnering with a transparent expert, you can optimize this cost and turn it into a valuable, protected asset.

)

Diving Deeper into a Strategic Mindset

Viewing the mold as a strategic asset changes everything. It's no longer just a line item on an invoice; it's a piece of your company's foundation. Here’s how to actively manage and control this investment.

A Necessary Mindset Shift

First, you must shift from "cost" to "investment." A cost is something you want to minimize at all times. An investment is something you manage for the best possible return. Your return on the mold investment is:

- Flexibility: The absolute freedom to choose the best manufacturing partner for your needs at any given time.

- Control: Power over your production schedule, quality standards, and pricing.

- Security: The peace of mind that comes from owning a critical asset and protecting your intellectual property.

When you see the mold fee through this lens, paying for a high-quality tool with a clear ownership contract becomes the obvious, smart business decision.

How to Control and Optimize Your Investment

Viewing it as an investment doesn't mean writing a blank check. You can and should control this cost intelligently.

- Engage Experts Early: Talk to a mold manufacturer like us at iBottler during your bottle design phase. We can look at a preliminary design and say, "This sharp edge will be difficult to machine and might cause quality issues. If we soften this curve slightly, it won't change the look, but it will reduce the mold cost by 15% and improve the bottle's strength."

- Simplify for Cost-Effectiveness: Don't add complex textures or features unless they are absolutely essential to your brand identity. Every extra curve and line adds machine time and cost.

- Validate with Prototypes: Before you cut steel, which is expensive and permanent, you can use modern tools to be certain of your design. We help clients move from 3D printed samples to production, allowing you to hold a physical version of your bottle in your hands for a fraction of the cost of a pilot mold. This confirms ergonomics, aesthetics, and even label fit before you commit to the main investment.

Finding a Partner You Can Trust

Ultimately, the best way to protect and optimize your investment is to work with the right people. You need a partner who is transparent about costs, an expert in mold making, and who respects your ownership. At iBottler, our entire business is built on this transparency. We can build a world-class mold for you, provide all the documentation for your records, and then you are free to take that mold to any contract manufacturer you choose. We even have a massive library of specifications to ensure that the blow mold we build will fit the blowing machine at your chosen factory.

Whether we are your primary mold maker or a consultant on your project, our goal is the same: to empower you to make smart, informed decisions that protect your brand and turn a potential "hidden cost" into your most valuable physical asset.

Conclusion

Understanding your blow mold fee is not just about avoiding hidden costs. It is about taking control of your brand's future, ensuring your flexibility, and owning your most critical physical asset.

Frequently Asked Questions (FAQ)

1. What happens if the mold I paid for breaks or wears out?

If you have a proper contract, it should specify the mold's expected lifespan (e.g., 1 million cycles) and the factory's maintenance responsibilities. If it wears out from normal use within that lifespan, the original manufacturer may have some warranty obligation. If it breaks due to the factory's negligence, they should be responsible for the repair. If it simply reaches the end of its natural life after millions of bottles, the responsibility to invest in a new one is yours, as the owner of the asset.

2. How much should a custom PET blow mold really cost?

There is no single answer, but a typical range for a single-cavity mold for a standard 500ml bottle is between $500 and $800. A multi-cavity mold can cost anywhere from $1,000 to $10,000 or more. The final price depends heavily on the bottle's complexity, the number of cavities, and the grade of steel used, as we detailed in the article. Always get a detailed quote that breaks down these factors.

3. Is a "free" mold ever a good idea?

Almost never. It is only viable in a very rare scenario where you need an extremely small test run (e.g., 10,000 bottles) and you are absolutely certain you will never produce the bottle again. For any brand building a long-term product, the loss of ownership and negotiating power far outweighs the short-term cash saving. The higher per-bottle price will eventually cost you more money.

4. Can I use my PET blow mold to make bottles from other plastics like HDPE or PP?

No. Blow molds are designed for specific materials and processes. A PET blow mold is part of a two-step "stretch blow molding" process that uses a pre-made preform mold and specific heating/stretching techniques. Other materials like HDPE use different "extrusion blow molding" processes and completely different types of molds. They are not interchangeable.

5. If I own my mold, can I show up at the factory and take it tomorrow?

Legally, yes, but practically, you need to follow the "Mold Release/Transfer Clause" in your contract. This usually requires giving written notice (e.g., 5-10 business days) to allow the factory to finish any current production runs, properly prepare the mold for transport, and ensure your account is fully paid. This professional courtesy ensures a smooth transition and prevents operational chaos for both parties.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr