Struggling to make your product stand out? Your current packaging is boring and gets lost on the shelf. You need a design that captures attention and drives sales instantly.

The solution is a PET Bearbrick bottle. This unique shape turns a simple product into a viral sensation. It combines high-quality PET material with a trendy, collectible design, ensuring your product gets noticed and desired by consumers, especially the younger generation who value personality and shareability.

In recent years, I've seen a massive shift in the market. Standard bottles just don't cut it anymore. Brands are fighting for every inch of consumer attention. The winners are those who innovate not just the product, but the entire experience. The PET Bearbrick bottle is a perfect example of this. It's more than a container; it's a statement piece, a toy, and a powerful marketing tool all in one. This article will break down everything you need to know about this trend. We will go from the initial design challenges to the final market success. I will share insights from my 20 years of experience to guide you through this exciting opportunity.

The Rise of Novelty Bottles: Why Does the "Bearbrick" Shape Ignite the Beverage and Candy Market?

Your product tastes great, but sales are flat. Competitors with bland packaging are somehow still on the shelf. You need a way to create an instant connection with customers.

The Bearbrick bottle shape is the key. It's not just a container; it's a pop culture icon that makes your product an instant must-have. This design leverages social media trends and the collector mindset, transforming your beverage or candy into a viral sensation and a collectible item.

The power of a unique shape can't be overstated. I remember a client from Thailand who came to me a couple of years ago. They were launching a new line of fruit juices. The market was incredibly crowded. They knew they needed something special. We decided to develop a custom PET Bearbrick bottle for them. The result was phenomenal. Their colorful juices looked amazing inside the crystal-clear bear-shaped bottles. Tourists and local young people started posting pictures of the bottles on Instagram and TikTok. The product went viral not because of a massive advertising budget, but because the packaging itself was the advertisement. It became a must-have item, a souvenir. This experience taught me a valuable lesson: in today's market, the bottle is as important as the beverage inside it. It's the first handshake with your customer.

The Social Media Engine

In our visually-driven world, a product's "shareability" is a core asset. Platforms like Instagram, TikTok, and Pinterest are digital shelves where consumers discover and validate new products. A standard round or square bottle might hold liquid efficiently, but it will never stop someone's scroll. The PET Bearbrick bottle, however, is designed to be photographed. Its distinct, playful silhouette stands out against any background. When a consumer buys your Bearbrick-bottled drink, they're not just buying a drink; they're buying a photo prop, a piece of content for their own social media feed. This user-generated content is a form of free, authentic marketing that is far more powerful than traditional ads. Each post acts as a personal recommendation, building brand awareness and driving curiosity among the user's followers. This viral loop—purchase, post, share, discover, purchase—is the engine that can launch a brand from obscurity to stardom.

Tapping into Gen Z and Millennial Psychology

Younger consumers, particularly Gen Z and Millennials, have different purchasing drivers than previous generations. They seek products that reflect their identity, offer a unique experience, and have a story. The Bearbrick bottle taps directly into these desires:

- Personalization and Identity: The bottle's shape is associated with "coolness," art, and street culture. Owning it is a subtle way for consumers to signal that they are in the know and have a unique taste.

- Collectibility: The Bearbrick figure itself is a highly collectible item. This "collector's mindset" easily transfers to the bottle. Consumers are motivated to buy different colors or variations, not just for the product inside, but to complete a set. This encourages repeat purchases and builds incredible brand loyalty.

- Fun and Novelty: In a world of serious news and daily pressures, consumers crave moments of fun and lightheartedness. A playful, bear-shaped bottle provides a small dose of joy. It's an emotional purchase, not just a functional one.

Turning a Commodity into a Premium Product

Let's be honest. Water is water. Juice is juice. Candy is candy. For many of these products, the market is commoditized, and brands are forced to compete on price. Unique packaging is the most effective way to break this cycle. The PET Bearbrick bottle instantly elevates the perceived value of its contents. It transforms a simple beverage into a high-value gift item or a personal treat. This allows you to command a premium price. The consumer isn't just paying for 300ml of juice; they are paying for the design, the brand experience, and the collectible bottle they can keep long after the product is gone. I've seen this happen. My Thai client was able to price their Bearbrick juices 40% higher than competitors in standard bottles, and they still flew off the shelves. The investment in a custom mold paid for itself in months, not years. That's the power of strategic packaging.

The Core Challenge: What Technical Hurdles Must Be Overcome to Design a Perfect PET Bearbrick Bottle Mold?

You have a great idea for a Bearbrick bottle, but you're worried about production. How can such a complex shape be made without defects? The risks of a bad mold are high.

Designing a perfect PET Bearbrick bottle mold requires mastering three key areas: complex curves for easy release, uniform wall thickness for strength, and precise parting lines for a flawless, leak-proof finish. Neglecting any of these can lead to costly failures and production delays.

Designing a mold for a shape like a Bearbrick is where our 20 years of experience really count. It’s not like making a simple water bottle. Every curve and corner presents a challenge. I recall a project where a new client came to us after a failed attempt with another supplier. Their first batch of Bearbrick bottles had major issues: the ears were too thin and brittle, and there were visible scuff marks on the arms from the mold. They were frustrated and had already lost money. We started from scratch. My team and I spent days analyzing the 3D model, focusing on the problem areas. We knew that a successful design required a deep understanding of how PET plastic behaves under pressure and heat. It's a puzzle of physics and engineering. In the end, a successful mold is a perfect balance of art and science, and that's a process you can only master with time and countless trials. If you want to learn more about the fundamentals, our PET bottle mold design guide is a great starting point.

Mastering Complex Curves and Draft Angles

The iconic shape of the Bearbrick is its biggest appeal and its greatest manufacturing challenge. The head, the distinct ears, the rounded belly, and the arms and legs all involve complex, multi-dimensional curves. The most critical factor here is the draft angle. A draft angle is a slight taper applied to the vertical surfaces of the mold. Without it, the cooled, rigid plastic bottle would be impossible to eject from the metal mold without scratching, deforming, or getting stuck.

- The Ears: The ears are particularly tricky. They are relatively small and have sharp angles at their base. The draft angle must be optimized to be large enough for a clean release but subtle enough not to distort the iconic shape.

- The Arms and Body: The area under the arms is a classic "undercut" problem area. The mold has to be designed to open in a way that allows this part of the bottle to be released without being torn or stretched. This often requires more complex mold actions, like side-cores or a multi-part cavity design.

Getting these angles right is a meticulous process that involves computer simulations (mold flow analysis) and the intuition of an experienced mold designer.

Achieving Uniform Wall Thickness

In blow molding, a heated plastic tube (a parison) or a preform is inflated to fill the mold cavity. With a simple round bottle, it's relatively easy to get an even wall thickness. With the Bearbrick, it's much harder. The plastic has to stretch more to form the corners of the feet or the tips of the ears than it does to form the flat stomach area. This uneven stretching can lead to critical defects:

- Weak Spots: If the wall becomes too thin in certain areas (like the ears or shoulders), the bottle will be fragile and can easily break during filling, capping, or transport.

- Material Waste: If you try to compensate by making the overall bottle heavier, you waste material and increase costs.

The solution lies in a combination of preform design and blow molding process control. The preform itself can be designed with varying thickness to provide more material to the areas that need to stretch more. During blowing, advanced techniques like preferential heating (heating specific bands of the preform more than others) are used to precisely control how the plastic stretches. This ensures that even the most complex parts of the bottle have a strong, uniform wall.

Perfecting Parting Lines and Venting

Every mold has to open to release the part, and the line where the mold halves meet is called the parting line. The placement and quality of this line are crucial for two reasons:

- Aesthetics: A poorly placed or highly visible parting line can ruin the look of the bottle, making it look cheap. For the Bearbrick bottle, the parting line is usually run down the sides, blending in with the natural silhouette of the figure to be as inconspicuous as possible.

- Sealing: A perfect, flash-free parting line is essential for a good seal at the neck of the bottle. Any imperfection can lead to leaks.

Venting is just as critical. As the hot plastic inflates, the air already inside the mold needs to escape. If it can't escape quickly and completely, it gets trapped between the plastic and the mold wall, causing defects like bubbles, burn marks, or incomplete formation of details. Vents are tiny channels cut into the parting line of the mold. They must be large enough to let air out but small enough to prevent the plastic from flowing into them. For a detailed shape like the Bearbrick, numerous vents must be strategically placed, especially around detailed areas like the face and limbs.

| Technical Hurdle | Key Consideration | Impact of Failure | iBottler's Solution |

|---|---|---|---|

| Draft Angles | Optimizing taper on ears, arms, and legs. | Scratches, deformation, bottle stuck in mold. | 3D analysis and iterative design based on 20 years of experience. |

| Wall Thickness | Controlling plastic stretch during blowing. | Fragile spots, breaks during filling/shipping. | Custom preform design and preferential heating process control. |

| Parting Line | Placement for aesthetics and function. | Visual defects, poor sealing, product leaks. | Strategic side placement and high-precision CNC machining. |

| Venting | Allowing trapped air to escape the mold. | Unfilled details, burn marks, surface bubbles. | Micro-venting technology placed in high-detail areas. |

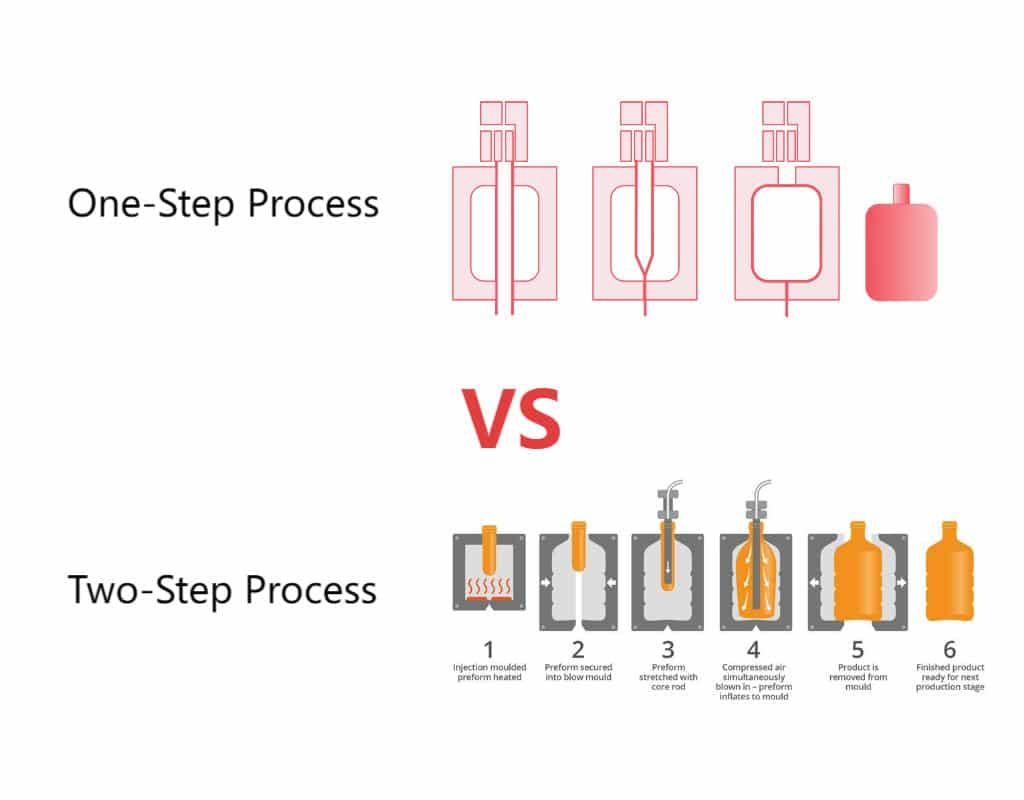

From Blueprint to Reality: Comparing One-Step vs. Two-Step Production Processes for Bearbrick Bottles?

You know you need a Bearbrick bottle, but which production method is right? Choosing the wrong process can lead to high costs, low quality, or an inability to scale up later.

The choice depends on your project's scale and quality needs. The one-step process offers higher precision for smaller, premium batches, while the two-step process provides speed and cost-efficiency for large-scale production. Understanding the trade-offs is key to making a smart investment.

Choosing between the one-step and two-step process is a critical decision that I walk my clients through all the time. There's no single "best" answer; it's about what's best for your specific project. I often compare it to cooking. The one-step method is like a master chef carefully preparing a gourmet meal from scratch in one continuous process—it's all about control and perfection. The two-step method is like a high-volume professional kitchen that prepares ingredients (the preforms) in advance and then assembles the final dishes (the bottles) to order. Both can produce excellent results, but they are designed for different scales and priorities. We have a wide range of bottle blowing machine options to suit either process, ensuring we can match the technology to your business goals.

The One-Step Process: Injection Stretch Blow Molding (ISBM)

The one-step process, as the name implies, does everything in a single machine. It goes from raw PET resin to a finished, blown bottle without any intermediate steps.

- Injection: The machine melts PET resin and injects it into a mold to form a preform. This preform is still hot and connected to a core rod.

- Conditioning: The preform is temperature-conditioned to the ideal profile for stretching.

- Stretching and Blowing: While still on the same core rod, the preform is moved into the bottle mold. The rod stretches it vertically while high-pressure air inflates it horizontally to fit the shape of the mold.

- Ejection: The finished bottle is ejected from the machine.

Advantages:

- High Precision: Since the preform is never released and cooled, you have incredible control over its temperature. This is fantastic for achieving blemish-free surfaces and high clarity, which is perfect for a premium product like the Bearbrick bottle.

- Good for Complex Shapes: The level of control makes it well-suited for non-standard, asymmetrical designs.

- No Scuffing: The preform isn't handled or transported, so there's no risk of scratches or damage before blowing.

Disadvantages:

- Slower Cycle Times: Combining three processes into one machine means the cycle time is limited by the slowest step (usually the injection molding). This results in lower output per hour compared to the two-step method.

- Higher Equipment Cost: One-step machines are generally more complex and expensive.

- Less Flexible: The machine is a single, integrated unit. You can't make preforms and store them for later, or use preforms from another supplier.

The Two-Step Process: Reheat and Blow Molding (RHB)

The two-step process separates the manufacturing into two independent stages. This is the most common method for producing PET bottles worldwide, especially for beverages.

- Step One (Injection Molding): PET resin is melted and injected into a multi-cavity mold to produce finished preforms. This is typically done on a massive scale. These preforms look like thick-walled test tubes with the final threaded neck already formed. They are cooled and can be stored or transported. We offer a variety of preform mold options for this stage.

- Step Two (Reheat and Blow): The preforms are loaded into a reheat blow molding machine. They pass through an oven with infrared heaters that soften the plastic to the optimal blowing temperature. Then, they are quickly transferred to the bottle mold, stretched with a core rod, and inflated with high-pressure air, just like in the one-step process.

Advantages:

- High Speed and Volume: Because the two steps are separate, they can both be optimized for maximum speed. Reheat and blow machines can produce tens of thousands of bottles per hour.

- Cost-Effective for High Volume: The high output and efficiency lead to a lower cost per bottle, making it ideal for large production runs.

- Flexibility: You can produce preforms in one location and blow them in another. You can also buy standard preforms on the open market if your design allows it, reducing your initial mold investment.

Disadvantages:

- Potential for Defects: The preforms are handled and stored between steps, which can lead to scuffs or dust contamination if not managed properly.

- Process Control is Key: Reheating the preform evenly is a major challenge. Uneven heating can lead to inconsistent wall thickness, a common problem that we detail in our guide to common PET blow molding defects.

How to Choose the Right Process for Your Bearbrick Bottle

So, which path should you take? Here’s the advice I give my clients:

| Factor | Choose One-Step (ISBM) If... | Choose Two-Step (RHB) If... |

|---|---|---|

| Production Volume | You have lower volume needs (e.g., up to 1-2 million bottles/year), or are launching a pilot product. | You anticipate high volume needs (several million bottles or more per year). |

| Quality Requirements | You need the absolute highest level of clarity and a blemish-free surface. It's a super-premium, top-shelf product. | Standard high quality is acceptable. You need a robust, functional, and beautiful bottle at a high rate of speed. |

| Budget | You have a higher initial capital budget for equipment but want to minimize tooling complexity. | You need the lowest possible cost per bottle at scale and can invest in separate injection and blowing capabilities. |

| Flexibility | You are only producing one specific bottle design. | You want the option to produce multiple bottle types or source preforms from different suppliers. |

For most of my clients starting out with a custom Bearbrick bottle, the two-step process often hits the sweet spot. It offers a good balance of quality and the scalability needed for a successful consumer product. We can design a highly optimized custom preform and a blow bottle mold that gives you excellent results while positioning you for growth.

Material is Fundamental: Why is High-Clarity PET the Best Choice for Bearbrick Bottles?

You want your Bearbrick bottle to look premium, be safe for consumers, and not harm the environment. Choosing the wrong plastic can compromise all three, ruining your brand's image.

High-clarity Polyethylene Terephthalate (PET) is the ideal material. It offers exceptional transparency to showcase your product, the toughness to form complex shapes perfectly, and it's a food-safe, 100% recyclable plastic that meets modern consumer demands for sustainability.

When people ask me why we almost exclusively use PET for products like this, my answer is simple: it delivers on every front. It’s the total package. Other plastics might be cheaper or easier to work with in some cases, but they come with trade-offs. PVC has environmental concerns. Polypropylene can be hazy. PET, especially the high-clarity grades we use, gives you that glass-like look with the durability and design freedom of plastic. It’s the material that allows a concept like the Bearbrick bottle to exist. The material choice also directly impacts other design decisions. For example, the grade of PET can influence how you design the neck finish. I always advise clients to review our guide on how to choose the right preform neck size, as it’s a critical detail that depends heavily on the material's properties and the intended use of the bottle.

Unmatched Transparency and Gloss

The primary job of a package is to sell the product inside. PET excels at this. Its properties are very similar to glass in terms of clarity and gloss, but without the weight and fragility.

- Showcasing the Product: For a Bearbrick bottle filled with colorful candies, vibrant juice, or even a clear spirit, PET's crystal-clear nature makes the product itself the hero. The colors appear brighter and more appealing. This visual appeal is a powerful purchasing trigger for consumers Browse a store shelf.

- Premium Feel: The high gloss surface of PET gives the bottle a premium, high-quality feel. It doesn't look like a cheap, disposable plastic. It looks like a durable, well-made object, which reinforces the value of the brand and justifies a higher price point. This glass-like appearance elevates the entire consumer experience. When a customer picks it up, it feels substantial and well-crafted.

Excellent Formability and Toughness

A complex design like the Bearbrick bottle is only possible because of PET's unique behavior during the stretch blow molding process.

- Superior Stretchability: When heated to the right temperature, PET becomes highly malleable. It can be stretched and inflated to conform to the most intricate mold details—like the sharp corners of the Bearbrick's ears or the defined shape of its feet—without tearing or creating weak spots. This is known as its strain-hardening property, which allows for the creation of thin yet strong walls.

- Impact Resistance: Despite being lightweight, a well-designed PET bottle is incredibly tough and shatter-resistant. This is a huge advantage over glass, especially for products aimed at children or for use in environments where breakage is a concern (like parties, beaches, or sports venues). This durability ensures the product reaches the consumer intact and can even be reused by the consumer, extending its life and the brand's visibility. This toughness is a result of the biaxial orientation of the polymer chains that occurs during the stretch blow molding process, aligning the molecules for maximum strength.

The Clear Choice for Food Safety and Sustainability

In today's market, safety and environmental responsibility are not optional; they are requirements. PET is a leader on both fronts.

- Proven Food-Safe: PET is globally recognized by health and safety agencies, including the FDA in the United States and the EFSA in Europe, as a safe material for food and beverage contact. It's stable, non-toxic, and does not leach harmful substances into its contents. This gives brands and consumers complete peace of mind.

- 100% Recyclable: PET is one of the most recycled plastics in the world. It carries the #1 recycling code. Post-consumer PET bottles are collected, cleaned, and re-melted to create new products, including new bottles (rPET), polyester fiber for clothing and carpets, or strapping for packaging. By choosing PET, you are choosing a material that is part of a well-established circular economy. Communicating this to your customers can significantly enhance your brand's reputation and appeal to environmentally-conscious shoppers. Many of my clients are now actively marketing the recyclability of their PET packaging as a key brand benefit.

Quality Control: How to Detect and Avoid Common Defects in Bearbrick Bottle Production?

You've invested in a mold, but now you worry about production flaws. Defects like bubbles, thin spots, or leaks can ruin an entire batch, costing you time and money.

Effective quality control is a system, not an accident. It involves identifying potential defects, implementing specific preventive measures during production, and running rigorous final checks. This ensures every bottle meets your high standards and protects your brand's reputation.

Quality control is something I am obsessed with. A single, visible defect can undermine all the effort and investment put into a beautiful design. Over the years, I've seen it all. I believe that the best approach to quality is prevention, not just detection. It's about setting up the process correctly from the very beginning. This means a perfectly designed mold, a well-maintained blowing machine, and high-quality raw materials. We've compiled our decades of troubleshooting experience into a detailed guide on our website. If you're facing any issues, I highly recommend checking out our comprehensive article on common PET blow molding defects and how to fix them. It’s a practical resource that can save you a lot of headaches.

Identifying and Preventing Common Defects

The first step in quality control is knowing what to look for. For a complex shape like a PET Bearbrick bottle, certain defects are more common. Here’s a breakdown of the main culprits and how we prevent them:

| Defect | Description | Common Cause(s) | Prevention Strategy |

|---|---|---|---|

| Haze / Cloudiness | The bottle is not crystal clear; it has a milky or hazy appearance. | Improper heating of the preform (too hot or too cold); moisture in the PET resin. | Precise oven temperature control; drying PET resin thoroughly before processing. |

| Pearlescence | A whitish, pearly appearance, usually in the base or walls. | Over-stretching the material; preform temperature is too low. | Adjusting blow pressure and stretch rod speed; increasing preform temperature slightly. |

| Thin/Weak Spots | Areas of the bottle wall (e.g., ears, corners) are dangerously thin. | Uneven preform heating; incorrect stretch ratio. | Using preferential heating to target specific zones; optimizing preform design for the shape. |

| Parting Line Flash | A thin ridge of excess plastic along the seam of the bottle. | Mold halves not closing perfectly; excessive blow pressure. | High-precision mold manufacturing; regular mold maintenance; optimizing blow pressure. |

| Bottom Blowout | The base of the bottle bursts during the blowing process. | Preform gate area is too hot; excessive blow pressure. | Adjusting heating profile to cool the gate area; reducing primary blow pressure. |

| Scuffs & Scratches | Marks on the surface of the bottle. | Rough handling of preforms or finished bottles; drag marks during ejection from mold. | Careful automated handling systems; ensuring proper draft angles and a polished mold surface. |

The iBottler Quality Inspection Process

Prevention is key, but verification is mandatory. Every production run must be validated with a rigorous inspection process. At my factory, we use a multi-stage approach that I've refined over many years. This isn't just about looking at the final bottle; it's about checking every step of the process.

- Raw Material Inspection: Every batch of PET resin is checked for its intrinsic viscosity (IV) and moisture content. Using off-spec material is the first step toward failure.

- Preform Inspection: Preforms are regularly checked for clarity, color consistency, weight, and dimensional accuracy, especially the critical neck finish.

- In-Process Checks: During the production run, our operators perform checks every 30 minutes. They pull sample bottles and perform a series of tests:

- Visual Inspection: Checking for any of the defects listed in the table above.

- Dimensional Checks: Using calipers and gauges to ensure the height, diameter, and neck dimensions are within tolerance.

- Weight Check: Verifying the bottle weight is consistent, which is a good indicator of wall thickness consistency.

- Leak Test: Bottles are pressurized underwater to ensure there are no microscopic leaks, especially around the parting line and gate.

- Final Batch Testing: Before a batch is approved for shipping, we conduct more rigorous tests on a statistical sample:

- Top Load Test: We measure the force required to crush the bottle vertically. This ensures it can withstand the pressures of capping, stacking, and shipping.

- Drop Test: We fill bottles and drop them from a specified height to simulate real-world accidents, ensuring they don't break or leak.

- Seal Integrity Test: We cap the bottles and use specialized equipment to test the seal between the bottle's neck finish and the cap.

This systematic process ensures that when you receive a shipment of Bearbrick bottles from us, you can be confident that they are not only beautiful but also robust and reliable. They are ready for your filling line and your customers.

Cost vs. Benefit: Analyzing the Real ROI of Investing in Bearbrick Bottle Molds and Production Lines?

You see the potential of a Bearbrick bottle, but you're concerned about the upfront cost. Is the investment in a custom mold and production line really worth it?

The initial investment is only half the story. A unique bottle like the Bearbrick creates value far beyond its cost by enabling premium pricing, increasing sales velocity, and building lasting brand equity. The real ROI is found in long-term market advantage, not short-term savings.

I have this conversation about return on investment (ROI) every week. Many potential clients focus solely on the initial mold cost, which is understandable. A high-quality, multi-cavity blow bottle mold is a significant investment. However, I always encourage them to think like an investor, not just a buyer. The mold isn't a cost; it's an asset. It is a tool that will generate revenue for years. The key is to shift the perspective from "How much does it cost?" to "How much will it make me?". Part of this calculation includes the entire production ecosystem. For example, the efficiency of your blowing line is critical. This means considering if your air system can run efficiently with one compressor or understanding why your PET blow molds need a chiller. These elements are part of the total ROI equation.

Breaking Down the Initial Investment

First, let's be transparent about the costs. A custom project for a PET Bearbrick bottle typically involves several key investments:

- Mold Development & Manufacturing: This is the largest upfront cost. It includes the design, engineering, CNC machining, polishing, and assembly of the blow mold. The cost varies based on:

- Number of Cavities: A 2-cavity mold is less expensive than a 6-cavity mold but produces fewer bottles per cycle.

- Mold Material: High-quality steel or aircraft-grade aluminum. Steel is more durable for very high volume, while aluminum offers faster heat dissipation for quicker cycle times.

- Complexity: The intricate details of the Bearbrick shape require more complex machining and skilled hand-polishing than a simple bottle.

- 3D-Printed Samples: Before cutting steel, it's wise to invest in validating the design. We offer a service for rapidly validating designs with 3D-printed samples, which allows you to hold a physical model of your bottle and test its ergonomics and shelf presence for a fraction of the cost of a pilot mold.

- Auxiliary Equipment: If you are setting up a new production line, you need to account for the blowing machine, air compressors, and chillers. However, if you are working with a manufacturing partner like us, you are leveraging our existing infrastructure, so this may not be a direct cost for you.

Calculating the Long-Term Benefits and Value

Now, let's look at the other side of the ledger—the return. This is where the Bearbrick bottle truly shines.

- Increased Unit Price (Premiumization): As discussed with my Thai client, the unique bottle allows you to break free from commodity pricing. If a standard bottle of juice sells for $1.50, the Bearbrick bottle version can command $2.50 or more. That extra $1.00 in margin goes directly to paying back the mold investment and then to your bottom line.

- Increased Sales Velocity: A "viral" product sells faster. The unique shape creates buzz and drives impulse purchases. A product that flies off the shelves means more revenue, better relationships with retailers (who love fast-moving products), and a more efficient supply chain.

- Brand Building and Loyalty: The bottle becomes a symbol of your brand. Consumers don't just remember the juice; they remember the "cool bear bottle." This builds a powerful brand identity that is difficult for competitors with generic packaging to replicate. The bottle is a long-lasting advertisement that sits on a consumer's desk or shelf for months.

- Marketing Asset: The bottle itself is a marketing tool. The money you might have spent on traditional ads can be reduced because the product generates its own organic buzz through social media.

Case Study: A Simplified ROI Analysis

Let's imagine a hypothetical brand, "Beary Good Juice Co."

| Investment & Costs | |

|---|---|

| Custom 4-Cavity PET Bearbrick Mold | $20,000 |

| Cost of Goods per Unit (juice + standard bottle) | $0.50 |

| Cost of Goods per Unit (juice + Bearbrick bottle) | $0.60 |

| Incremental Cost per Unit | $0.10 |

| Revenue & Profit | |

|---|---|

| Sale Price (standard bottle) | $1.50 |

| Profit per Unit (standard bottle) | $1.00 |

| Sale Price (Bearbrick bottle) | $2.50 |

| Profit per Unit (Bearbrick bottle) | $1.90 |

Analysis:

Each Bearbrick bottle sold generates an additional $0.90 in profit compared to the standard bottle.

To pay back the $20,000 mold investment, the company needs to sell:

$20,000 / $0.90 per unit = 22,222 units

If the company sells just 5,000 units per month, the mold is paid for in less than 5 months. After that, the extra $0.90 per unit is pure additional profit, a direct return on the initial investment. This calculation doesn't even include the likely increase in total units sold due to the bottle's popularity. This is how a strategic investment in packaging can fundamentally change the financial trajectory of a product.

Why Choose iBottler? How Our 20 Years of Experience Safeguards Your Project?

You're ready to start, but you need a partner you can trust. A complex project like a Bearbrick bottle has many risks. Choosing an inexperienced supplier can lead to delays, poor quality, and wasted investment.

Choosing iBottler means choosing peace of mind. Our 20 years of specialized experience provides a one-stop solution, deep technical expertise for complex designs, and reliable support, ensuring your project is a success from concept to launch.

When a client chooses to work with us, they're not just buying a mold or a set of bottles. They're buying a partnership. They're tapping into two decades of my life's work, filled with both successes and challenges that have taught me invaluable lessons. I've seen firsthand what works and what doesn't. This experience is particularly crucial for complex, novelty shapes. It’s one thing to make a simple round bottle; it’s another thing entirely to produce millions of perfect Bearbrick bottles. One of the biggest fears for clients is compatibility. They worry, "If I buy a mold from you, will it fit my machine?" This is a valid concern, which is why we've built a massive database. We have the mounting dimensions for 80% of blow molding machines worldwide, so we can guarantee a perfect fit. This is the kind of practical expertise that safeguards your investment.

Your One-Stop Solution Partner

For many brands, especially startups or companies launching a new product category, managing multiple suppliers is a nightmare. You have to find a designer, then a mold maker, then a production facility, and make sure they all communicate perfectly. It's inefficient and risky. We eliminate that headache. We offer a true one-stop, "concept-to-container" solution:

- Design Consultation: We start with your idea. We help you refine the design of your Bearbrick bottle for optimal aesthetics and, more importantly, for manufacturability.

- Mold Manufacturing: Our in-house team designs and builds your custom blow bottle mold, using our deep expertise to tackle the challenges of the Bearbrick shape.

- Machine Matching: We ensure the mold we build is perfectly compatible with your existing bottle blowing machine or recommend the right equipment for your needs.

- Mass Production: We can manage the entire production run for you, delivering high-quality, finished bottles ready for your filling line.

This integrated approach saves you time, reduces coordination costs, and ensures a single point of accountability. We take full responsibility for the final result.

Deep Technical Expertise in Complex Molds

The PET Bearbrick bottle is the perfect example of a project where experience matters. An inexperienced manufacturer will struggle and likely fail. Our 20 years in the business have been spent specializing in these kinds of challenging projects.

- Problem Solving: We know the common failure points for novelty shapes. We anticipate issues with wall thickness in the ears or draft angles under the arms before they happen. We design the mold and the process to prevent these problems from the start.

- Material Science: We understand the nuances of different PET grades and how they behave under heat and pressure. We select the precise material that will give your bottle the best clarity, strength, and performance.

- Precision Engineering: Our facility uses state-of-the-art CNC machines and EDM technology, but more importantly, we have technicians who are masters of their craft, especially in the critical final stages of hand-polishing the mold to achieve a flawless surface finish. It is this combination of technology and human skill that allows us to deliver on the promise of a perfect bottle.

Reliable After-Sales Service and Support

Our relationship doesn't end when we deliver your mold or your first batch of bottles. We see ourselves as your long-term production partner.

- Mold Maintenance: Blow molds are high-performance tools that require maintenance. We provide clear guidelines and support for maintaining your mold to ensure its longevity and consistent performance over millions of cycles.

- Technical Guidance: If you are running production in-house and encounter an issue, our team is here to help. We can provide remote troubleshooting and technical advice to help your team solve problems quickly, minimizing downtime.

- Responsive Communication: You will have a dedicated contact person on my team. We believe in clear, prompt communication. When you have a question or a concern, you will get a fast, straight answer. We know that in business, time is money, and we respect yours. Your success is our success, and this philosophy is at the core of everything we do.

Take Action Now: Start Your Custom Bearbrick Bottle Project?

Feeling inspired but not sure where to begin? The gap between a great idea and a real product can seem huge, filled with technical questions and uncertainty. Don't let that stop you.

The first step is a simple conversation. We make it easy to get started with a free design evaluation and a clear, transparent process. Let us show you how we can turn your vision for a custom Bearbrick bottle into a market-ready reality.

Every successful product started with a single step. I've had the privilege of being part of that first step for hundreds of clients. I know it can be intimidating, especially with a unique and custom project. That's why my goal is to make the process as clear and risk-free as possible for you. We remove the guesswork. We can even create a physical prototype for you before you commit to the full mold investment. Using our service to go from 3D-printed samples to production is the best way to validate your concept and gain confidence. Let's build something amazing together.

Step 1: Free Consultation & Design Evaluation

You have an idea, a sketch, or maybe just a question. That's all you need. Reach out to my team. We will schedule a free, no-obligation consultation to discuss your project.

- What we'll discuss: Your product, your target market, your desired volume, and your vision for the bottle.

- What you'll get: Our initial expert feedback on your design's manufacturability. We'll point out potential challenges and suggest improvements based on our 20 years of experience. We'll be honest and transparent about what it will take to succeed.

Our goal in this first meeting is to provide you with genuine value and a clear understanding of the path forward.

Step 2: Request Samples & A Detailed Quotation

Words are one thing, but quality is something you need to see and feel. We encourage potential clients to take the next step:

- Request Samples: We can send you samples of similar PET bottles we have produced. You can examine the clarity of the material, the quality of the finish, and the robustness of the construction. This helps you understand the high standard we hold ourselves to.

- Get a Detailed Quote: Based on our initial consultation, we will prepare a comprehensive quotation. This will not just be a single number. We will break down the costs for you, including mold development, sampling, and unit price per bottle at different volume levels. We believe in full transparency so you can make an informed business decision.

Step 3: Our Simple and Professional Collaboration Process

If you decide to move forward, we follow a structured process to ensure your project stays on track and you are informed every step of the way.

| Phase | Key Activities | Your Involvement | Outcome |

|---|---|---|---|

| 1. Design & Engineering | 3D model refinement, mold flow analysis, detailed mold design (DFM). | Review and approve final 3D bottle design. | A production-ready mold design optimized for quality and efficiency. |

| 2. Mold Manufacturing | CNC machining, EDM, mold fitting, polishing. We provide progress updates. | Minimal involvement needed. | A high-quality, precision-engineered blow mold. |

| 3. Sampling (T1) | We produce the first samples from the new mold. | You receive physical samples for final approval. | Approval of the final bottle before mass production begins. |

| 4. Mass Production | We launch full production, implementing our rigorous QC process. | Receive regular updates on production status. | High-quality bottles delivered on time and on budget. |

Taking action is simple. Contact us today to start the conversation. Let's explore how a custom PET Bearbrick bottle can become your brand's next big success story.

Conclusion

Creating a successful PET Bearbrick bottle is a journey. It requires mastering design, choosing the right production process, and committing to quality. With the right expert partner, this iconic shape can transform your product into a market leader.

Frequently Asked Questions (FAQ)

1. What is the typical cost for a custom PET Bearbrick bottle mold?

The cost varies significantly based on complexity and the number of cavities, but a high-quality, multi-cavity mold is a significant investment. A smaller, 2-cavity pilot mold might start in the low five figures ($10,000 - $15,000), while a high-volume, 6 or 8-cavity production mold made from premium steel can range from $25,000 to over $50,000. We provide detailed quotes based on your specific design and volume requirements.

2. What is the minimum order quantity (MOQ) for custom Bearbrick bottles?

The MOQ is largely determined by the production method. Because of the setup costs involved in mass production, a typical MOQ for a custom bottle run using the two-step process would be around 50,000 to 100,000 units. For smaller, more specialized projects using a one-step process or for initial pilot runs, a lower MOQ might be negotiable.

3. How long does it take to go from the final design to having finished bottles?

The entire process can be broken down into two main phases. First, mold manufacturing typically takes 3 to 4 weeks from design approval to having a finished mold. Second, once the mold is complete and samples are approved, the first mass production run can usually be scheduled and completed within 2 to 3 weeks. Therefore, a realistic timeline from project start to having bottles in hand is approximately 6 to 8 weeks.

4. Can you help me design the bottle if I only have a basic concept?

Absolutely. This is a core part of our one-stop solution. Many of our clients come to us with just an idea. Our design and engineering team will work with you to turn that concept into a fully realized, 3D model that is not only visually appealing but also optimized for the blow molding process. We will guide you on aspects like draft angles, wall thickness, and parting line placement.

5. Besides the bottle, can you also help with sourcing caps and closures?

Yes. While our core business is the bottle and the mold, we have a vast network of trusted partners in the packaging industry. We can certainly assist you in sourcing the right caps, closures, or even labeling and decoration services that will perfectly complement your custom PET Bearbrick bottle. Our goal is to make your product launch as seamless as possible.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr