Are you watching your material costs rise? Wondering how to gain a competitive edge in the crowded beverage market? The answer might be smaller than you think.

The PCO 1881 neck finish is the future because it significantly reduces PET resin usage, lowering production costs and carbon footprint without compromising performance. This lightweight standard, already adopted by industry giants, offers a clear path to enhanced profitability and brand sustainability for beverage producers.

I have spent over 16 years in the PET packaging machinery industry. I have seen trends come and go. But the shift from the PCO 1810 to the PCO 1881 neck finish is not just a trend; it is a fundamental evolution. It represents a smarter way to produce bottles. For any business owner, production manager, or brand strategist, understanding this change is not just useful—it is essential for future success. This article will explore this transition in detail, showing you why a few millimeters can make a massive difference to your bottom line and your brand's place in the market. Let's dive in.

PCO 1810 vs. 1881: More Than Just a 4mm Difference in Height?

Struggling to see how a tiny change in a bottle neck can have a big impact? You see two standards, and the difference seems minor, almost academic.

The PCO 1881 isn't just shorter; it's a complete redesign for efficiency. It uses less material, weighs less, and is engineered to maintain or even exceed the sealing performance of the older PCO 1810 standard, making it a strategic choice for modern production.

In my 16 years in this industry, I've seen many clients initially overlook the significance of the neck finish. They focus on the bottle's body, the label, the cap color. But the neck finish is the heart of the bottle's efficiency. The transition from PCO 1810 to PCO 1881 is a story about precision engineering meeting economic and environmental necessity. Let's break down the real differences and why they matter so much.

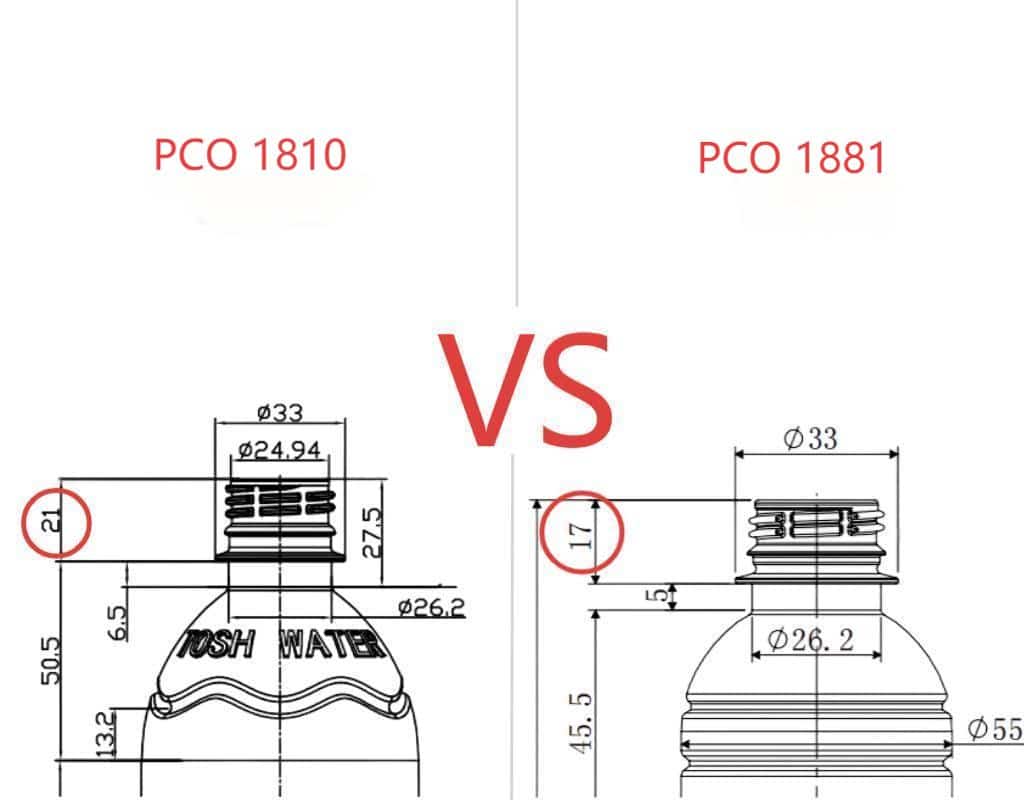

A Detailed Technical Comparison

At first glance, the change seems trivial. The "1881" is shorter than the "1810". But the engineering goes much deeper. The International Society of Beverage Technologists (ISBT) did not simply chop off the top of the old standard. They re-engineered the entire system.

| Parameter | PCO 1810 (Traditional Standard) | PCO 1881 (Modern Standard) | Key Advantage of 1881 |

|---|---|---|---|

| Neck Height | Approx. 21 mm | Approx. 17 mm | Less material, shorter cycle times |

| Typical Weight | Approx. 5 grams | Approx. 3.7 grams | ~26% weight reduction per neck |

| Thread Turns | 2.5 turns | 1.5 turns | Faster capping application |

| Design Focus | Robustness, traditional compatibility | Lightweighting, performance, sustainability | Optimized for modern efficiency |

| Primary Use | Formerly standard for CSD and water | Now the dominant standard for CSD & water | Lower cost, better eco-profile |

This table shows more than just numbers. It shows a philosophy shift. The PCO 1810 was designed in an era where "stronger" meant "more material." The PCO 1881 was born from the need to be smarter, leaner, and more responsible. The reduction in thread turns, for example, doesn't just save a tiny bit of plastic; it allows for faster capping speeds on the production line, a small but significant boost to overall equipment effectiveness.

The Evolution from an Industry Need

The PCO 1810 was the workhorse for a long time. It was reliable. But as raw material prices, especially for PET resin, began to fluctuate and trend upwards, the industry felt the pressure. Every gram of plastic on a bottle became a cost center. Simultaneously, consumers and governments started demanding more sustainable practices. The beverage industry needed a solution.

The ISBT stepped up. Their goal was clear: create a new neck finish standard that would:

- Significantly reduce the amount of PET resin used in the bottle neck and the matching cap.

- Maintain or improve the performance characteristics, especially for carbonated soft drinks (CSD) which require high-pressure retention.

- Be easily adoptable by existing manufacturing infrastructure with minimal, manageable changes.

The result was the PCO 1881. It wasn't just an update; it was a direct response to the core challenges facing the beverage industry: cost and sustainability. Its development marked a pivotal moment where the industry collectively decided to pursue efficiency at a micro-level to achieve macro-level benefits. This is a crucial point to understand, especially if you are considering which standard to use for a new product line. Your choice of neck finish is a strategic decision that impacts your entire value chain.

The Cost Driver: How Does PCO 1881 Really Save Money for Your Production Line?

Are you constantly looking for ways to cut operational expenses? The rising cost of PET resin eats directly into your profit margins, making every gram count.

The PCO 1881 neck finish directly attacks this problem. Its lighter weight design saves significant amounts of PET resin and plastic for caps, translating into substantial, measurable financial savings on every single bottle you produce.

I always tell my clients, especially those just starting out, that the most obvious savings are not the only ones. The switch to PCO 1881 presents a compelling financial case that extends beyond just the raw material. Let's quantify these savings and look at the bigger picture of your return on investment.

Quantifying the Raw Material Savings

This is the most direct and impactful financial benefit. The PCO 1881 neck finish is, on average, 1.3 grams lighter than its PCO 1810 counterpart. The corresponding 1881 cap is also lighter than an 1810 cap. Let's put this into a real-world scenario.

Imagine your company produces 50 million bottles a year.

- Weight saving per bottle (neck only): 1.3 grams

- Total annual weight saving: 50,000,000 bottles * 1.3 g/bottle = 65,000,000 grams

- Total saving in kilograms: 65,000 kg

- Total saving in metric tons: 65 metric tons

Now, let's talk money. The price of PET resin fluctuates, but let's use a conservative estimate of $1,500 per metric ton.

- Annual savings on PET resin: 65 tons * $1,500/ton = $97,500

This is nearly one hundred thousand dollars in savings, year after year, from a single, small change. This calculation doesn't even include the savings from the lighter-weight caps. For a large-scale producer, this number can easily run into the millions. When I lay out these numbers for clients, the strategic value of PCO 1881 becomes immediately clear. You can see how this one choice can free up significant capital for marketing, R&D, or other growth initiatives.

The Ripple Effect: Lower Transportation and Storage Costs

The savings don't stop at the factory gate. Lighter bottles mean lighter shipments. While the saving per bottle is small, it accumulates across pallets and truckloads.

- Reduced Shipping Weight: A truckload of bottles will be significantly lighter. This can lead to fuel savings and potentially allow for more units per shipment without exceeding weight limits, lowering the cost per unit transported.

- Warehouse Efficiency: While the bottle dimensions are similar, the lighter weight can have minor benefits in handling and stacking within a warehouse. More importantly, preforms for PCO 1881 are shorter. This means more preforms can fit into a standard shipping container or pallet box. This directly reduces the inbound freight cost of your primary raw material. When you're ordering millions of preforms, fitting 10-15% more into a container is a massive logistical saving.

Analyzing the Long-Term Return on Investment (ROI)

Of course, switching from PCO 1810 to 1881 isn't free. There is an initial investment. The primary cost is the new set of preform molds required for the 1881 neck finish. Depending on the size and complexity, this can be a significant capital expenditure. You may also need to make minor adjustments to your capper and potentially update your blow molds.

This is where a clear ROI calculation is essential.

| Investment Cost (Example) | Description | Estimated Cost |

|---|---|---|

| New Preform Mold | A 48-cavity PCO 1881 preform mold. | $50,000 - $80,000 |

| Capper Adjustments | New chucks or guides for the shorter cap. | $5,000 - $15,000 |

| Contingency/Labor | Installation, testing, and process optimization. | $5,000 |

| Total Estimated Investment | $60,000 - $100,000 |

Using our previous example of $97,500 in annual raw material savings, the payback period for this investment is incredibly fast.

- Payback Period: Total Investment / Annual Savings = $100,000 / $97,500 ≈ 1.02 years

In just over a year, the investment pays for itself. After that, the $97,500 in savings goes directly to your profit, every single year. This is why the transition isn't an expense; it's a high-return investment in the financial health of your production line.

Embracing Sustainability: How Does Light-weighting Enhance Your Brand Image?

Do you feel pressured to make your brand more "green"? Consumers are skeptical of vague environmental claims and want to see real, tangible action.

Adopting the PCO 1881 standard is a concrete, measurable step in sustainability. It directly reduces plastic consumption, lowers your carbon footprint, and provides a powerful, authentic story to share with environmentally-conscious consumers.

Over the years, I've seen a dramatic shift. "Eco-friendly" has gone from a niche marketing angle to a core consumer expectation. Brands are no longer just selling a beverage; they are selling their values. A lighter bottle is not just a technical detail; it's a public statement of your commitment to the planet, and it's a statement that resonates deeply with today's buyers.

Reducing Your Carbon Footprint, One Bottle at a Time

The most direct environmental benefit of the PCO 1881 standard is the reduction in plastic use. As we calculated earlier, a medium-sized production line can save 65 metric tons of PET resin annually. But what does that mean in terms of overall environmental impact?

- Less Fossil Fuel Consumption: PET is derived from petroleum or natural gas. Using less PET means consuming less of these non-renewable resources.

- Lower Energy in Manufacturing: Manufacturing PET resin is an energy-intensive process. By reducing the amount of resin needed, you are also reducing the total energy consumed upstream in your supply chain.

- Reduced Greenhouse Gas Emissions: The entire lifecycle of that "saved" plastic—from resource extraction to polymerization to transportation—generates greenhouse gases. The U.S. EPA's greenhouse gas equivalency calculator can help put this into perspective. The production of 65 metric tons of PET can generate roughly 150 metric tons of CO2 equivalent. Saving this amount is like taking over 30 gasoline-powered passenger vehicles off the road for a year. This isn't a vague claim; it's a quantifiable reduction in your company's carbon footprint.

Meeting the Modern Green Consumer

Today's consumers are savvy. They read labels, they research brands online, and they are increasingly making purchasing decisions based on a company's environmental and social policies.

- A Tangible Message: It's much more powerful to say, "We redesigned our bottles to use 26% less plastic in the neck, saving 65 tons of plastic every year," than to use a generic slogan like "We love the planet." The specificity of the PCO 1881 transition provides a credible and easy-to-understand sustainability message.

- Appealing to Millennials and Gen Z: Younger demographics, in particular, show a strong preference for sustainable brands. A 2021 study by Simon-Kucher & Partners found that 34% of consumers are willing to pay more for sustainable products, and this trend is growing. Aligning your packaging with these values can build powerful brand loyalty with the next generation of consumers.

- Competitive Differentiation: In a crowded shelf space, a small callout on your label like "New Eco-Friendly Lighter Bottle" can be the deciding factor for a consumer choosing between two similar products. It signals that your brand is modern, responsible, and forward-thinking.

A Powerful Story for Your CSR Report

Corporate Social Responsibility (CSR) is no longer a "nice-to-have." For investors, partners, and even employees, a strong CSR profile is a sign of a well-managed, future-focused company. The switch to PCO 1881 is a perfect addition to any CSR report or sustainability disclosure.

It demonstrates a proactive approach to:

- Resource Management: You are actively working to reduce your consumption of raw materials.

- Waste Reduction: Lighter bottles contribute less to the post-consumer waste stream.

- Climate Action: You are taking measurable steps to lower your carbon footprint.

Instead of being a dry technical specification, the PCO 1881 standard becomes a cornerstone of your environmental narrative. It's proof that your company is not just talking about sustainability, but is actively investing in technologies and processes to make it a reality. This builds trust and enhances your corporate reputation in a way that traditional advertising simply cannot.

Technical Transition Concerns: What Changes Does My Production Line Need to Switch from 1810 to 1881?

Are you worried that upgrading to PCO 1881 will mean a massive, complicated overhaul of your entire production line? The fear of downtime and compatibility issues can be paralyzing.

The transition is manageable and primarily involves three key areas: preform molds, capper adjustments, and blow molding process tuning. With expert guidance, these changes can be implemented efficiently, minimizing disruption to your operations.

This is where my team and I spend most of our time with clients who are making the switch. The fear of the unknown is often the biggest hurdle. "Will my existing bottle blowing machine work? How much will new molds cost? How long will my line be down?" These are the practical questions that every plant manager asks. The good news is, the path is well-trodden, and the challenges are well-understood.

The Core Change: New Preform Molds

Let's be perfectly clear: this is a non-negotiable step. You cannot make a PCO 1881 preform with a PCO 1810 mold. The geometry of the neck finish, including the threads, height, and support ledge, is fundamentally different.

- Why is a new mold necessary? The mold cavity is what shapes the molten PET into the preform. To get the shorter neck and different thread profile of the 1881 standard, you need a mold with a cavity machined to those exact specifications.

- Investment and Opportunity: While this requires investment, it's also an opportunity to upgrade. Modern preform molds often feature improved cooling channels, better steel alloys, and more efficient hot runner systems. So, you're not just changing the neck finish; you're likely upgrading to a mold that can run faster and last longer. This is a core part of what we do at iBottler—providing high-precision, durable molds that make the transition seamless.

Adjusting Your Capping Equipment

The next critical area is the machine that applies the caps. Because the PCO 1881 neck and cap are shorter, your capper needs to be told how to handle them.

- Modern Capping Machines: For most modern rotary cappers, the adjustment is relatively simple. It typically involves changing out the "chucks" (the heads that grip and twist the caps) and adjusting the height of the cap sorter and chute. The machine's program will also need to be updated with the new torque and application angle specifications. This can often be done in a single day by a skilled technician.

- Older Equipment: Very old or less flexible capping machines might present more of a challenge. In some rare cases, a full replacement of the capping turret might be more cost-effective than a complex retrofit. Part of a smooth transition is a thorough audit of your existing equipment. We often help clients assess their cappers to determine the most efficient path forward.

Fine-Tuning the Blow Molding Process

The preform is different, so the way you blow it into a bottle needs to be adjusted. The main body of your blow bottle mold might not need to change if the bottle shape remains the same, but the blowing process itself requires fine-tuning.

- Heating Profile: The PCO 1881 preform has a different mass distribution in the neck area. This means the heating profile in your blow molder's oven needs to be adjusted. You may need to slightly change the lamp settings to ensure the preform is heated evenly to the ideal temperature without overheating the new, shorter neck.

- Stretching and Blowing Parameters: The stretch rod parameters and the timing of the pre-blow and high-blow air might need small adjustments. The goal is to ensure that the plastic distributes correctly throughout the bottle's body, maintaining wall thickness and preventing defects. This is a process of small, incremental changes and quality checks. It's one reason why having a partner who understands both molds and the blowing process is so important. When we deliver a new mold, we also provide the starting parameters to minimize this tuning phase for our clients. A related component is the chiller, which must maintain the mold at a consistent temperature for optimal bottle quality.

The transition is a project, not a crisis. By breaking it down into these three areas and working with an experienced partner, you can manage the change smoothly and start reaping the cost and sustainability benefits much faster than you might think.

Performance Anxiety: Will a Shorter Neck Compromise Product Sealing and Safety?

Are you worried that a lighter, shorter neck is a weaker neck? It's a natural concern: if you're saving material, are you sacrificing the safety and integrity of your product?

No. The PCO 1881 standard was specifically engineered to provide sealing performance and safety that is equal to or better than the PCO 1810. Its advanced design ensures product integrity, even for high-pressure carbonated beverages.

I understand this concern completely. For 16 years, I've stressed to my clients that product safety is paramount. No amount of cost savings is worth a leaking bottle or a recall. The beauty of the PCO 1881 standard is that it was designed by beverage technologists who share this priority. They didn't just remove plastic; they re-imagined the seal. Let's look at the engineering that makes this possible.

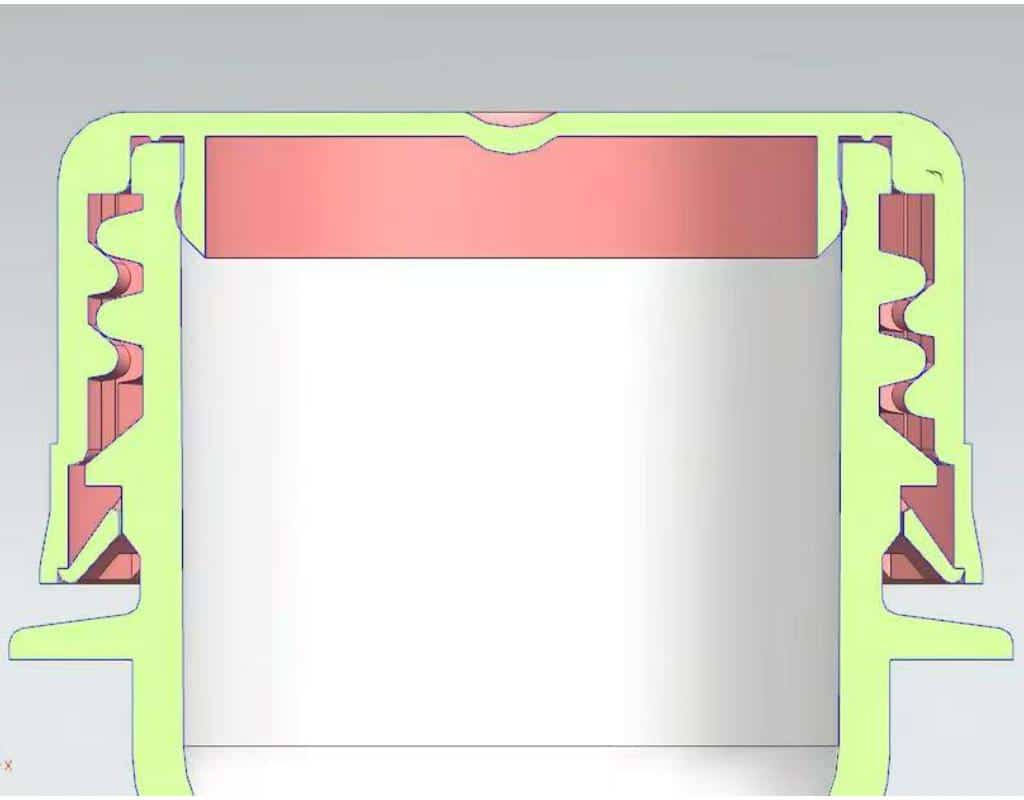

Advanced Thread Design for a Superior Seal

It seems counterintuitive. The PCO 1810 has more threads, so it should have a better grip, right? Not necessarily. The PCO 1881 leverages smarter engineering, not just more material.

- Optimized Thread Engagement: The 1881's threads are designed for more precise and effective contact with the cap. The shape and pitch of the threads create a tight, consistent seal with less rotation. This efficiency means a secure seal is achieved faster and more reliably on the capping line.

- Top-Seal vs. Side-Seal: Many PCO 1881 caps utilize a "top-seal" design. Instead of relying solely on the friction of the threads along the side of the neck (a side-seal), a sealing ring inside the top of the cap presses firmly and evenly against the flat surface of the bottle's rim. This creates a highly effective primary seal that is less dependent on the exact torque of the cap, reducing the chance of leaks caused by minor variations in the capping process. This robust design is one of the key reasons we can confidently recommend it to clients. Understanding these mechanics can help prevent many common PET blow molding defects related to the neck finish.

Engineered for Carbonation

The biggest performance test for any bottle neck is holding the pressure of a carbonated soft drink (CSD). This was a primary design constraint for the creators of the PCO 1881.

| Performance Feature | How PCO 1881 Achieves It | Result for Carbonated Beverages |

|---|---|---|

| Stress Crack Resistance | The 1881 neck design distributes stress more effectively around the finish. Thicker material is kept only where it's structurally needed. | Greatly reduces the risk of cracks forming at the base of the neck, a critical failure point for CSDs under pressure. |

| Gas Retention (CO2) | The combination of a precise thread profile and effective top-sealing cap creates a very low permeability barrier. | Ensures the beverage maintains its desired level of carbonation throughout its shelf life, preserving the consumer experience. |

| Pressure Holding | The design has been rigorously tested to withstand pressures well above those found in typical CSDs, even in hot conditions. | Peace of mind that your product will remain safely sealed from the factory to the consumer's hands. |

The world's largest beverage companies have put the PCO 1881 through millions of dollars in testing. They would not have adopted it for their flagship cola brands if it presented any risk to carbonation retention. Their widespread adoption is the ultimate proof of its performance.

The Reliability of the Tamper-Evident Band

The final piece of the security puzzle is the tamper-evident (TE) band. Will the shorter neck make it less effective? Again, the answer is no. The design has been adapted for the new standard.

The TE band on an 1881 closure is designed to mate perfectly with a specific groove, known as the support ledge, on the 1881 neck finish. When the cap is screwed on, the band slides over this ledge. When the consumer first opens the bottle, the band is designed to break away cleanly and visibly, providing clear evidence of tampering. The geometry is different from the 1810, but the function and reliability are the same. It is a complete, secure system, engineered from the ground up to provide total product safety.

Supply Chain Synergy: The Importance of Matching Caps and Preforms?

Have you ever thought that a preform is just a preform, and a cap is just a cap? Sourcing them from different, unverified suppliers to save a few cents might seem tempting.

This is a huge risk. The PCO 1881 system relies on precise tolerances between the neck finish and the cap. A mismatch can lead to catastrophic failures like leaks, contamination, and production line shutdowns, costing far more than any initial savings.

This is a lesson I've had to teach many times over my career, sometimes the hard way. I recently worked with a client from Denmark. He was starting a new mineral water brand and was very focused on keeping his initial costs down. He understood the benefits of PCO 1881 but was confused by the number of different suppliers for preforms and caps. He asked, "Can't I just buy the cheapest preform from this supplier and the cheapest cap from that one?"

I explained that the PCO 1881 standard, while universal, allows for tiny variations between manufacturers. A cap designed for Supplier A's preform might not create a perfect seal on Supplier B's preform. The risk of slow leaks or caps coming loose during transport was too high. After we discussed the importance of a matched system, he understood. He chose to source his preforms from a supplier we recommended who works closely with a specific cap manufacturer, ensuring a perfect fit. He made the right choice, opting for security over a tiny, risky saving. This is where a good guide on choosing the right preform neck size becomes invaluable.

The Critical Need for Strict Tolerance Matching

The PCO 1881 is a high-performance system. Like any high-performance system, its components need to work in perfect harmony. We're talking about measurements at the micron level.

- "T" Dimension (Thread Outer Diameter): If the preform's thread diameter is at the low end of the tolerance range, and the cap's inner thread diameter is at the high end, the fit can be loose. This can lead to caps vibrating loose during shipping or failing to hold pressure.

- "E" Dimension (Thread Root Diameter): A similar mismatch here can affect how the cap seats and seals.

- Neck Height and Top Surface: The height of the neck and the flatness of the sealing surface are critical for top-sealing caps. A poorly molded preform with a warped top surface will never seal correctly, no matter how good the cap is.

The ISBT provides the specifications, but manufacturing processes have slight variations. A reputable preform maker will control their process to stay within a very tight tolerance window. A reputable cap maker will do the same. The best suppliers often test their caps on preforms from major manufacturers to guarantee compatibility.

The Advantage of One-Stop Sourcing or Vetted Partners

This is why simplifying your supply chain is so important. When you work with a partner like iBottler, we're not just selling you a mold. We're providing a complete solution.

- Guaranteed Compatibility: We design our preform molds to the exact ISBT PCO 1881 standard. We can also recommend cap suppliers whose products we know are manufactured to the same exacting standards and are proven to work with preforms made from our molds.

- Reduced Risk: This eliminates the guesswork. You don't have to become an expert in neck finish tolerances. You can trust that the components have been vetted to work together, so you can focus on making your beverage.

- Simplified Troubleshooting: If a sealing issue does arise, there is no finger-pointing between a cap supplier and a preform supplier. You have a single point of contact who can help analyze the entire system—preform, bottle, and cap—to find a solution quickly.

Avoiding Common and Costly Mismatch Errors

Here are the real-world consequences of a mismatch, which I have seen happen:

| Mismatch Error | Consequence | Financial Impact |

|---|---|---|

| Using an 1810 cap on an 1881 neck | It may seem to twist on, but it will not seal. The threads are incompatible. | 100% product loss due to leakage or contamination. Potential for a massive recall. |

| Using a poorly made 1881 cap on a good 1881 neck | Slow leaks, loss of carbonation, TE band not breaking properly. | Customer complaints, damaged brand reputation, potential for retailer rejection of stock. |

| Using a poorly molded 1881 preform | Inconsistent wall thickness, warped sealing surface, bottles failing pressure tests. | High scrap rates on the production line, line stoppages, risk of product failure in the market. |

The synergy between the cap and the preform is not an optional extra. It is the foundation of a safe, reliable, and efficient packaging system.

The Choice of Global Giants: Why are Brands like Coca-Cola and Pepsi Leading the 1881 Trend?

Do you ever wonder if a new technology is truly proven? Seeing small companies adopt it is one thing, but when the global leaders make a change, it signals a major shift.

The world's largest beverage companies, like Coca-Cola and PepsiCo, have overwhelmingly transitioned to the PCO 1881 standard. They did this for two simple reasons: massive cost savings at scale and a powerful commitment to global sustainability goals.

When I talk to clients who are hesitant about the PCO 1881 standard, I often point to the big players. These companies do not make changes lightly. They have multi-million dollar research and development departments. Their supply chains are global and incredibly complex. If they have chosen to re-tool hundreds of factories around the world to adopt PCO 1881, it's because the business case is not just strong; it's undeniable. Their choice validates the technology for the entire industry.

Cost-Effectiveness Magnified at Scale

We previously calculated that a company making 50 million bottles could save around $97,500 annually in PET resin. Now, let's apply that logic to a global giant.

- Coca-Cola's Production: The Coca-Cola system sells more than 1.9 billion servings of its drinks per day. While not all are in PET bottles, a huge percentage are. Let's conservatively estimate they produce 100 billion PET bottles annually worldwide.

- Saving per bottle: 1.3 grams of PET from the neck alone.

- Total Annual Weight Saving: 100,000,000,000 bottles * 1.3 g/bottle = 130,000,000,000 grams

- Total Saving in Metric Tons: 130,000 metric tons of PET resin.

Now, let's apply the same conservative cost of $1,500 per ton.

- Annual Savings for a Global Giant: 130,000 tons * $1,500/ton = $195,000,000

That's nearly two hundred million dollars. Annually. Just from the neck finish. This doesn't include the savings on lighter caps, reduced transport costs, or improved production efficiency. When you operate at this scale, a saving of 1.3 grams isn't a small optimization; it's a monumental financial lever. This is the primary driver. The economics are simply too powerful to ignore.

Fulfilling Global Sustainability Pledges

Beyond the direct financial incentive, these multinational corporations are under intense public and regulatory pressure to become more sustainable. They have all made bold public commitments to reduce their use of virgin plastics and lower their carbon footprint.

- The "World Without Waste" Initiative: Coca-Cola has a goal to make 100% of its packaging recyclable globally by 2025 and to use at least 50% recycled material in its packaging by 2030.

- PepsiCo Positive (pep+): PepsiCo has pledged to cut virgin plastic per serving by 50% by 2030.

How can they possibly achieve these ambitious goals? Through actions, not just words. The transition to the PCO 1881 neck finish is one of the most significant and impactful single initiatives they can undertake to reduce plastic use. The 130,000 tons of plastic saved by our estimate is a massive, concrete step towards meeting those public pledges. It's a key part of their sustainability story, demonstrating to investors, governments, and consumers that they are serious about their commitments.

The Demonstration Effect for the Entire Industry

When a company like PepsiCo or Coca-Cola adopts a new standard, it sends a powerful message to the rest of the industry.

- Technical Validation: It proves that the technology is robust, safe, and reliable at the highest possible scale. All the performance questions have been answered.

- Supply Chain Maturity: It ensures that a global and competitive supply chain for high-quality PCO 1881 preforms and caps will exist. Suppliers rush to meet the demand from the giants, which benefits smaller players as well.

- Sets the Benchmark: It effectively makes PCO 1881 the new de facto global standard. Sticking with the older, heavier PCO 1810 now looks outdated and inefficient. New bottling lines are almost exclusively being set up for the 1881 standard.

For a small or medium-sized company, following the lead of the giants is a low-risk, high-reward strategy. The path has been cleared, the technology has been proven, and the supply chain is in place. The decision is no longer about "if," but "when."

How Can iBottler Help You Smoothly Transition to the New PCO 1881 Standard?

Are you convinced of the benefits of PCO 1881 but feel overwhelmed by the process of making the change? You need a partner, not just a supplier.

iBottler offers end-to-end support to ensure your transition to PCO 1881 is seamless, efficient, and successful. From initial assessment to high-precision mold manufacturing and ongoing technical support, we manage the complexities so you can focus on your business.

After 16 years of helping businesses navigate the complexities of PET packaging, I know that a successful transition is built on trust and expertise. It's not just about delivering a piece of steel. It's about understanding your specific production environment, anticipating challenges, and providing solutions every step of the way. Our goal is to make this powerful upgrade feel less like a daunting project and more like a smart, controlled step forward for your company.

Expert Technical Assessment of Your Line

The first step is to understand exactly where you are starting from. We don't believe in one-size-fits-all solutions.

- Free Consultation: We begin with a detailed discussion about your current production line. We'll ask about your bottle blowing machine, your capper, your current preform, and your production goals.

- Feasibility Analysis: We provide a clear-eyed assessment of what needs to change. We'll identify the necessary mold changes, analyze your capping equipment's compatibility, and outline the required process adjustments. We have extensive data on machine compatibility, including the mounting dimensions for 80% of blow molding machines worldwide, which drastically reduces uncertainty.

- Cost & ROI Projection: Based on this assessment, we provide a transparent proposal outlining the investment required and a projection of your potential ROI based on your production volume. This gives you the clear business case you need to make an informed decision.

High-Precision Mold Customization

The quality of your bottle starts with the quality of your mold. This is the core of our expertise.

- Design Excellence: We don't just copy a standard design. We design your PCO 1881 preform mold or blow bottle mold for optimal performance. This includes designing for efficient cooling, durability, and perfect material flow. Our process often starts with a detailed PET bottle mold design guide to align with your vision.

- Advanced Manufacturing: We use high-quality, durable steel and advanced CNC machining to create molds with exacting tolerances. This precision ensures that every preform and every bottle you produce is consistent and meets the highest quality standards.

- Rapid Validation: We can even accelerate your design process. We can go from 3D printed samples to production, allowing you to touch and feel a prototype of your new bottle design before committing to the final production mold.

Full-Process Technical Support and Training

We believe our job isn't done when the mold is shipped. We are your partner until your line is running smoothly and efficiently.

- Installation and Commissioning: Our support extends to the installation of the mold and the initial setup. We provide the starting parameters for heating and blowing, which drastically cuts down on your team's trial-and-error time.

- Process Optimization: We help your team fine-tune the process to achieve the best bottle quality at the fastest possible cycle time. We can also provide support for ancillary equipment, like ensuring your air system is adequate for the job.

- Ongoing Partnership: We remain available for troubleshooting and support long after the installation. If you face a challenge, you have a direct line to an expert who knows your mold and your process. This long-term relationship is what truly defines the iBottler experience.

Conclusion

The shift from PCO 1810 to 1881 is the clear future. It offers undeniable cost savings, enhances your brand's sustainability, and is backed by the entire global beverage industry.

Frequently Asked Questions (FAQs)

1. What is the single biggest reason for me to switch from PCO 1810 to PCO 1881?

The single biggest reason is direct cost reduction. The PCO 1881 standard uses significantly less PET resin per bottle, which translates into substantial annual savings on your most significant raw material cost. For any business, this direct impact on profitability is the most compelling driver.

2. Will I have to replace my entire bottling line to make the switch?

No, in almost all cases you will not need to replace the entire line. The core changes are specific: you will need a new preform mold, and your capping machine will need adjustments (like new chucks). Your existing blow molder, conveyors, and labeler will typically not require major changes. Our technical assessment can give you a precise list of what's needed.

3. Is the PCO 1881 neck finish strong enough for my carbonated drinks?

Absolutely. The PCO 1881 standard was designed and rigorously tested specifically for its performance with carbonated soft drinks. Its advanced thread design and top-sealing mechanism ensure excellent gas retention and pressure resistance, performance that has been validated by its use on billions of bottles by global brands like Coca-Cola and Pepsi.

4. Can I buy PCO 1881 preforms from one supplier and caps from another to save money?

While you can, it is highly risky. The PCO 1881 system's reliability depends on very tight tolerances between the preform neck and the cap. A mismatch between two different manufacturers can lead to leaks, pressure loss, and line stoppages. It is much safer to use a preform and cap combination that is proven to work together, ideally sourced through a partner who can vouch for their compatibility.

5. How long does the transition process typically take from start to finish?

The timeline can vary, but a typical project can be broken down. The longest lead time is usually for the manufacturing of the new preform mold, which can take 8-12 weeks. The on-site installation and line adjustments can usually be completed in just a few days to minimize downtime. So, a typical project timeline from order to full production is about 3-4 months.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr