You signed the contract. The machine is on its way. But that warranty clause feels like a distant promise. How do you ensure it becomes a reality when you need it most?

The warranty is your production line's insurance. A good supplier treats it as a partnership commitment, providing proactive remote support, a comprehensive knowledge base, and a rapid spare parts system to guarantee your uptime.

That piece of paper in your contract is more than just a legal requirement. It's the foundation of your relationship with the supplier. It represents their promise to stand by their product, not just on the day of sale, but for years to come. The real challenge, especially for overseas buyers, is stress-testing that promise before a crisis hits. You need to move beyond the text and evaluate the systems and people that turn words into action. This guide will walk you through exactly how to do that, ensuring your investment is protected by a service that is as reliable as the machine itself.

The "Paper Promise" Problem: Why Overseas Buyers Are Right to Be Skeptical?

You've heard the stories, or maybe lived one yourself. A critical machine part fails, and the supplier who promised "24/7 support" is suddenly silent. The warranty is just paper.

This skepticism is valid. Many overseas buyers get burned by warranties that are not honored due to distance, time zones, or a supplier's lack of a real service infrastructure. True service commitment overcomes these barriers.

I see this problem all the time. A few months ago, a new client from Canada reached out to me. He was in a terrible position. His fairly new bottle blowing machine was down, and it was still under warranty. However, his original supplier was giving him the runaround. They refused to send a replacement part under the warranty terms. When my Canadian client offered to pay for the part just to get his production running again, the supplier quoted him an outrageous price. It felt like a punishment. He was stuck, thousands of miles away, with a useless warranty and a silent production line. This isn't just a business problem; it's a breach of trust.

This "Paper Promise" problem is why so many international buyers are hesitant. You are right to be skeptical. The challenges are real:

- Geographical Distance: A supplier on the other side of the world can't just send a technician over in the afternoon.

- Time Zone Differences: Your 9 AM crisis is their 9 PM, making real-time communication difficult.

- Cultural and Language Barriers: Misunderstandings can turn a simple request into a major issue.

But here is the truth: these are challenges, not excuses. A professional and committed supplier anticipates these issues and builds a robust service system specifically to overcome them. They understand that their reputation is built not on the sales contract, but on their response when things go wrong. The purpose of this article is to give you a clear framework. I want to show you how to look past the promises on the page and identify the suppliers who have invested in the infrastructure and mindset to provide real, tangible support from anywhere in the world. It’s about learning to spot the difference between a supplier who sells you a machine and one who enters into a partnership to ensure your success.

| Feature | The "Paper Promise" | The "Real Partnership" |

|---|---|---|

| Communication | Slow or no response; limited to email. | Fast, multi-channel (WhatsApp, Zoom); guaranteed response time. |

| Troubleshooting | "It's your operator's fault." | Collaborative problem-solving; remote diagnostics. |

| Spare Parts | Unavailable or overpriced; slow shipping. | Clear list and prices; fast international shipping. |

| Knowledge | Basic, poorly translated manual. | Detailed manuals, video tutorials, and training resources. |

| Goal | To close the sale. | To ensure your long-term production uptime. |

My Canadian client’s story had a positive turn. We were able to identify the faulty part, provide him with a fair and transparent price, and ship it to him via express courier. We also gave him access to our video tutorials to guide his team through the installation. He’s running again, but the experience was a powerful lesson. A warranty is only as good as the company that stands behind it.

Step 1: Fortify the Promise Itself – What to Look for in Your Warranty Contract?

Your contract is the foundation. A weak, vague warranty clause leaves you exposed. You need clear, specific language that defines responsibilities and eliminates ambiguity before you ever sign on the dotted line.

A strong warranty contract clearly defines coverage for core vs. wearing parts, specifies the duration for each, and outlines the exact process for initiating a service request. It is your primary legal protection.

Before you can even think about the service team or spare parts, you must analyze the document itself. A good supplier will have a standard warranty that is already clear and comprehensive. A supplier who offers a vague, one-sentence warranty is waving a major red flag. They are leaving room for interpretation, which they will almost always interpret in their favor. Think of the contract as the rulebook for your partnership. If the rules are unclear, the game is rigged.

When I review a purchase contract, I zoom in on the warranty section. I am not just looking for a time period, like "one-year warranty." That's not nearly enough information. I am looking for the details that will matter when a machine is down and pressure is high. Here’s how you can break down the contract to ensure your promise is fortified.

Key Elements of an Enforceable Warranty

You need to move beyond a simple "1-Year Warranty" statement. A truly protective warranty clause is detailed and leaves no room for doubt.

1. Clear Coverage: What Is and Isn't Included?

A bottle blowing machine has hundreds of components. A good warranty distinguishes between them.

- Core Components: These are the major, non-consumable parts of the machine. The contract should explicitly list what is considered a core component. This includes things like the main frame, clamping unit, PLC controller, main motors, and heating ovens. These items should have the longest warranty period, typically one to two years.

- Wearing Parts / Consumables: These are parts that are expected to wear out with normal use and need regular replacement. The contract must be just as clear about what is not covered. This list usually includes seals, heaters, filters, belts, and certain pneumatic components. A trustworthy supplier will provide a "Recommended Spare Parts List" alongside the contract, so you know exactly what these parts are and can plan for their replacement.

- Third-Party Components: The contract should also specify how components from other manufacturers (e.g., a specific brand of PLC or valve) are handled. Usually, these are covered by their original manufacturer's warranty, and your machine supplier should act as the facilitator to process that claim.

2. Specific Duration: How Long is the Coverage?

The warranty period should not be a single, blanket statement.

- Tiered Durations: Look for different warranty periods for different components. For example, you might see "24 months for core mechanical components, 12 months for electrical and pneumatic components." This level of detail shows the supplier has thought through the lifecycle of their machine.

- Start Date: The contract must clearly state when the warranty period begins. Is it the date of shipment from their factory (Bill of Lading date)? Or is it the date of installation and commissioning at your facility? The latter is always preferable for the buyer, as it accounts for shipping and installation time.

3. Defined Process: How Do You Make a Claim?

This is perhaps the most critical part. A warranty is useless if you don't know how to use it. The contract should outline the step-by-step process.

- Initiation: Who do you contact? What information do you need to provide (e.g., machine serial number, photos, videos of the issue, error codes)?

- Response Time: A strong contract might include a clause like, "Supplier commits to acknowledging the service request and providing an initial diagnosis within 24 hours." This prevents your request from falling into a black hole.

- Resolution Path: What are the steps the supplier will take? Usually, it follows a logical progression: remote diagnosis first, then shipping of replacement parts, and in rare cases, sending a technician. The contract should briefly mention this process.

Here is a sample table comparing a vague clause with a fortified one, which you can use as a reference.

| Aspect | Vague Clause (Red Flag) | Fortified Clause (Green Flag) |

|---|---|---|

| Coverage | "Machine is covered by warranty." | "Core components (defined in Appendix A) are covered. Wearing parts (defined in Appendix B) are excluded." |

| Duration | "1-year warranty." | "24 months on Frame & Clamping Unit, 12 months on Electricals. Warranty begins on date of successful commissioning." |

| Process | "Contact us for service." | "To initiate a claim, email service@supplier.com with S/N, photos, and video. Initial response guaranteed within 24 hours." |

| Costs | Not mentioned. | "Supplier covers the cost of the replacement part. Buyer covers the cost of express shipping." |

Asking your supplier to clarify these points in the contract before you sign is not being difficult; it's being a smart business partner. A supplier who is confident in their product and their service will have no problem providing this level of detail. A supplier who resists is telling you everything you need to know about their "paper promise."

Step 2: Translate Words into Action – The Four Pillars of "Real Service"?

A strong contract is your starting point, but it's not the end goal. A document cannot fix a machine. You need a supplier with a robust system designed to bring that promise to life.

"Real service" is an active support system built on four essential pillars: responsive remote support, an empowering knowledge base, a rapid spare parts system, and a transparent vetting process you can use before buying.

Over the years, I've seen countless suppliers talk about their great service. But when you look closer, their "service" is often just one engineer's email address. That's not a system; it's a gamble. A genuine service commitment is a core part of the supplier's business operations. It's as important as their R&D or their manufacturing process. It's a machine built to support your machine.

I've structured my own company's service philosophy around what I call the "Four Pillars." These are the non-negotiable elements that must exist to provide effective support to an overseas buyer. When these four pillars are in place, the warranty document is transformed from a static piece of paper into a dynamic, active partnership. It ensures that when you face a production challenge, you are not just sending an email into the void; you are activating a well-oiled machine designed to get you back online as quickly as possible. Let’s briefly introduce these pillars before we dive deep into each one.

Proactive & Responsive Remote Support: This is your first line of defense. It's about having immediate access to expert help that can diagnose and often solve problems without the need for physical parts or on-site visits. In today's connected world, this is the fastest way to solve the majority of issues.

An Empowering Knowledge Base: The best service is the service you don't need to use. A supplier who empowers you with the knowledge to handle routine maintenance and minor troubleshooting yourself is a true partner. They are giving you control over your own production. This is about providing the tools for self-sufficiency.

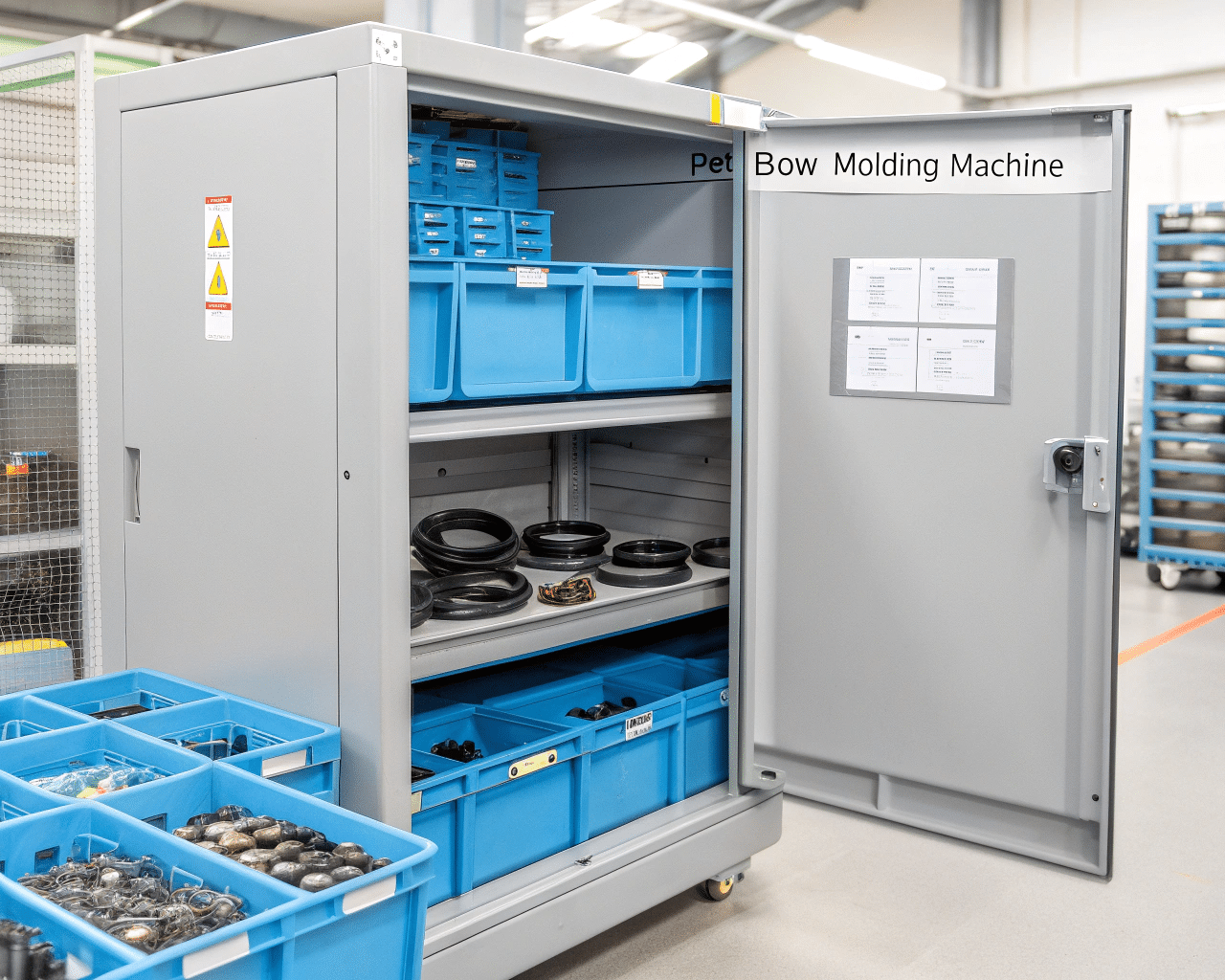

A Transparent and Rapid Spare Parts System: For problems that do require a physical part, the speed and efficiency of the supply chain are paramount. This pillar is about having the right parts in stock, clear pricing, and a streamlined logistics process to minimize your downtime. This is where my Canadian client's supplier failed so spectacularly.

A Pre-Purchase Vetting Process: This isn't a service you use after the sale, but it's a critical part of the framework. It's about the supplier being transparent enough to let you "look under the hood" of their service operations before you commit. A confident supplier will gladly show you proof of their capabilities.

These four pillars work together to create a safety net for your investment. They replace uncertainty with a predictable, professional process. The next sections will explore each of these pillars in detail, giving you the specific questions to ask and the red flags to watch for. This is how you move beyond the paper promise and find a partner committed to your uptime.

Pillar 1: Proactive & Responsive Remote Support?

When your machine stops, the clock starts ticking. Every minute of downtime costs you money. You don't have time to wait for an email response that might come two days later.

Modern remote support uses technology to bridge any distance. A top-tier supplier offers real-time video calls, PLC remote diagnostics, and a dedicated support team with a guaranteed response time, solving issues in hours, not days.

The old model of flying an engineer across the world for every problem is obsolete, slow, and incredibly expensive. The first and most important pillar of modern after-sales service is a fast, effective remote support system. This is your direct line to the experts who designed and built your machine. It's about leveraging technology to put their brain right next to your machine, instantly.

I remember a client in Mexico who called me in a panic. An error on their HMI screen had halted production, and they couldn't figure it out. Instead of a long chain of emails, we immediately set up a WhatsApp video call. Their operator showed me the screen and the sensors in the machine. Within 15 minutes, we identified a misaligned sensor. I guided their operator on how to adjust it, step by step, while watching on the video. In less than half an hour, their machine was running again. That's the power of responsive remote support. It saved them what could have easily been a full day or more of lost production. This is how you solve many of the common PET blow molding defects and how to fix them quickly.

The Components of a World-Class Remote Support System

A great remote support system is more than just a phone number. It’s a multi-faceted approach designed to diagnose and resolve issues with speed and precision.

1. Multi-Channel, Real-Time Communication

A professional supplier won't limit you to email. They will offer a range of communication tools to suit the situation.

- Instant Messaging (WhatsApp/WeChat): Perfect for quick questions, sharing photos of parts, or sending short videos of a problem.

- Video Calls (Zoom/Skype): Essential for real-time troubleshooting. It allows the supplier's engineer to see what your operator sees and provide live guidance.

- Dedicated Support Hotline/Email: A centralized point of contact that ensures your request is logged, tracked, and assigned to the right person.

2. PLC Remote Access & Diagnostics

This is a game-changer for troubleshooting complex electrical or programming issues. Modern blow molding machines should have the capability for secure remote access to their PLC (Programmable Logic Controller).

- How it Works: With your permission, an engineer from the supplier's office can log into your machine's control system over the internet.

- The Benefits: They can view error logs, check the status of sensors and outputs, analyze the program's logic, and identify the root cause of a problem with 100% accuracy. They can even make minor programming adjustments remotely to optimize performance or fix a bug. This eliminates guesswork and is the fastest path to a solution for any non-mechanical issue.

3. A Structured and Accountable Team

You need to know who you're talking to and that they are empowered to help.

- Guaranteed Response Time (SLA): A serious supplier will commit to a Service Level Agreement (SLA). This could be something like "Initial response within 4 hours, action plan within 24 hours." This holds them accountable.

- English-Speaking Engineers: There should be no language barrier. The support team must have engineers fluent in English who can understand your technical descriptions and communicate solutions clearly.

- Case Tracking System: Every support request should be logged as a "case" or "ticket." This ensures your issue is tracked from start to finish and won't be forgotten.

Here's a comparison of what to look for versus what to avoid:

| Feature | Excellent Remote Support | Poor or Non-Existent Support |

|---|---|---|

| Availability | Multiple channels (Video, PLC, IM), clear hours, SLA. | Single email address, slow replies, no time guarantee. |

| Personnel | Dedicated, English-speaking support engineers. | A salesperson trying to answer technical questions. |

| Technology | PLC remote diagnostics, AR support tools. | Relies solely on photos and emails. |

| Process | Ticket system, clear escalation path. | Ad-hoc, disorganized, depends on who you can reach. |

When you are vetting a supplier, don't just ask "Do you have remote support?" Ask them to describe their system. Ask about their response time guarantee. Ask if their machines are equipped for PLC remote access. Ask them to share a success story, like the one I had with my Mexican client. Their answers will reveal whether their support is a true pillar of their business or just another paper promise.

Pillar 2: An Empowering Knowledge Base That Puts You in Control?

Relying on a supplier for every question is inefficient. True partnership means the supplier equips you with the tools and knowledge to handle your own machine confidently and competently.

An excellent knowledge base, including detailed English manuals and comprehensive video tutorials, is a sign of a supplier invested in your autonomy. It empowers your team to solve 80% of daily issues independently.

The goal of a great after-sales service program shouldn't be to make you dependent on the supplier. It should be to make you as self-sufficient as possible. A supplier who truly wants you to succeed will invest heavily in creating high-quality documentation and training materials. They understand that if your team can handle routine maintenance, simple troubleshooting, and common procedures like a mold change, it benefits everyone. You have less downtime, and their expert engineers are free to focus on the truly complex issues. This is about transforming service from a reactive "firefighting" model to a proactive "fire prevention" model.

I believe in the principle of "teaching you how to fish." That’s why we put so much effort into our documentation. Our goal is that for any common task, from daily lubrication to changing a blow bottle mold, your team should be able to do it perfectly by following our guides, without ever needing to contact us. This not only saves time but also builds confidence and expertise within your own staff.

What Does a Great Knowledge Base Contain?

A cheap, poorly translated manual is a major red flag. A world-class knowledge base is a suite of resources designed for clarity and ease of use.

1. The Comprehensive Technical Manual

This is the bible for your machine. It should not be a short pamphlet. It should be a detailed, professionally written document.

- Clear Language and Diagrams: It must be in fluent, technical English. Every instruction should be accompanied by clear diagrams, schematics (mechanical, electrical, pneumatic), and high-resolution photos.

- Structured Sections: It should be easy to navigate, with clear sections for Installation, Operation, Maintenance, and Troubleshooting.

- Detailed Procedures: For a task like daily maintenance, it shouldn't just say "lubricate machine." It should show a diagram of every lubrication point, specify the type of lubricant, and state the required frequency. The same detail should apply to all procedures. It should be a complete guide, much like our PET bottle mold design guide from concept to production provides every necessary detail for that process.

2. A Library of Video Tutorials

In today's world, video is often the best way to learn a physical task. A forward-thinking supplier will have a library of short, focused video tutorials covering the most common operations.

- Key Topics: Essential videos include step-by-step guides for mold changes, daily/weekly/monthly maintenance routines, and troubleshooting common error messages. Imagine being able to see a perfect mold change, with every step explained, before your team ever attempts it.

- Accessibility: These videos should be easily accessible, perhaps on a private YouTube channel or a customer portal. They can be downloaded and used to train new operators, ensuring consistency and quality for years to come. This is also a great way to show how auxiliary equipment, like a chiller, should be properly connected, a topic we cover in our article on why PET blow molds need a chiller.

3. An Exhaustive Troubleshooting Guide

This section of the manual is your first stop when something goes wrong. It empowers your team to be detectives before they become callers.

- Symptom/Cause/Solution Format: A good guide is structured intuitively. It lists potential symptoms or error codes. For each symptom, it lists the possible causes, and for each cause, it provides a clear solution or action to take.

- Flowcharts: For more complex problems, visual troubleshooting flowcharts can be incredibly effective, guiding an operator through a series of yes/no questions to isolate the root cause of an issue.

Before you buy, ask for a sample of the machine's manual. Ask if they have video tutorials and if you can see one. The quality of these materials is a direct reflection of the supplier's commitment to your success. A supplier who has invested the time and resources to create a top-tier knowledge base is a supplier who is building a partnership, not just making a sale. They are giving you the keys to your own machine.

Pillar 3: A Transparent and Rapid Spare Parts System?

Even with the best support and knowledge base, parts will eventually wear out or fail. When that happens, your entire production line can be held hostage by a single, small component.

A reliable spare parts system is defined by its transparency and speed. A great supplier provides a priced parts list from day one and uses express couriers to get you what you need, fast.

This is the pillar that completely failed my Canadian client. His machine was down, he knew which part he needed, but his supplier created a roadblock. First, they refused to honor the warranty. Then, they quoted an absurd price. Finally, they were slow to even process the order. This is a nightmare scenario for any operations manager. A world-class supplier understands that the spare parts process is just as critical as the machine itself. Their system should be designed for speed, clarity, and fairness.

The moment you sign a purchase contract, you should already know how you will get spare parts for the next 10 years. There should be no mystery, no hidden costs, and no delays. A breakdown in the spare parts supply chain is a breakdown in the fundamental trust between you and your supplier. It turns a partner into an adversary at the worst possible moment. That's why we operate with a philosophy of complete transparency. Our customers receive a detailed list of recommended spare parts with their initial quote, and every part has a clear part number and price.

Characteristics of a Dependable Spare Parts System

When evaluating a supplier, you need to look for evidence of a professional, well-managed parts system.

1. A Proactive and Detailed Spare Parts List

This should be provided to you before you even purchase the machine. It's a critical planning tool.

- Categorization: The list should be broken down into at least two categories:

- Critical Spares: A small set of essential parts that you should keep in your own stock on-site. These are items that, if they fail, will stop your machine instantly and are crucial for immediate replacement (e.g., specific sensors, seals, heaters).

- Recommended Spares: A broader list of parts that have a longer lifespan but are good to have on hand or know you can get quickly.

- Clear Identification: Every single part must have a unique part number, a clear description, and a photo or diagram. This eliminates any confusion when ordering.

- Transparent Pricing: The price for each part should be listed. There should be no "call for price" games. This allows you to budget for future maintenance and ensures you will not be price-gouged in an emergency.

2. Inventory and Logistics Management

Having a list is one thing; having the parts in stock and being able to ship them is another.

- In-Stock Commitment: The supplier should commit to keeping all critical spare parts in stock at their facility, ready for immediate dispatch.

- Partnership with Global Couriers: The supplier must have established relationships with reliable international couriers like DHL, FedEx, or UPS. These couriers specialize in fast, trackable, door-to-door international shipping.

- Streamlined Process: How quickly can they get a part from their shelf to the courier? A good supplier should be able to process and ship an in-stock emergency part within 24 hours.

3. Post-Warranty Fairness

The supplier's attitude toward parts shouldn't change the day your warranty expires.

- Continued Availability: They should guarantee the availability of spare parts for a long period, typically 10 years or more after the machine purchase.

- Fair Pricing: The prices should remain consistent with the initial list. A supplier who dramatically inflates prices after the warranty period is not a long-term partner. This was the second major failure in my Canadian client's case.

Here is a checklist you can use when discussing spare parts with a potential supplier:

| Question to Ask | Good Answer (Green Flag) | Bad Answer (Red Flag) |

|---|---|---|

| Can I see a recommended spare parts list with prices? | "Yes, here is the full list with part numbers, descriptions, and prices for your machine model." | "We will tell you the price when you need a part." |

| Which parts do you keep in stock? | "We stock all critical electrical and pneumatic parts, seals, and heaters for immediate shipment." | "We have to order most parts from our own suppliers." |

| How quickly can you ship an emergency part? | "We can typically dispatch in-stock parts via DHL within 24 hours of confirming the order." | "It usually takes a few days to get things ready." |

| Who do I contact to order parts? | "We have a dedicated parts manager. Here is their direct email and contact number." | "Just send an email to our general sales address." |

A reliable supply of parts is the physical manifestation of a supplier's commitment. It proves they are prepared to support you not just with advice, but with the tangible components needed to keep you in business.

A Pre-Purchase Checklist: How to Vet a Supplier's Service Commitment Before You Sign?

You now understand what constitutes real service. The final step is to actively investigate a potential supplier's capabilities before any money changes hands. Don't take their word for it; ask for proof.

A confident supplier will welcome your due diligence. Use a pre-purchase checklist to request documents, samples, and references. This process separates suppliers with genuine service systems from those with empty promises.

Everything we've discussed—the strong contract, the remote support, the knowledge base, the parts system—can and should be verified. The vetting process is your opportunity to be a journalist, to dig deeper than the sales brochure and see the real operational capacity of the company you are about to partner with. A supplier who is proud of their service infrastructure will be happy to open their doors and show you how it works. A supplier who makes excuses or is hesitant to provide proof is likely hiding the fact that their "system" is just a paper promise.

This is the most empowering stage for you as a buyer. You are in control. By asking specific, evidence-based questions, you shift the dynamic from being sold to, to actively choosing a partner. I always encourage potential clients to ask me these tough questions. It builds trust and shows them from the very beginning that we are committed to transparency and have the systems to back up our promises. This is also the stage where you should discuss the full scope of your project, including how their machine will fit with your existing setup. Verifying things like mold and machine compatibility is a key part of this; as we note, we have mounting dimensions for 80% of blow molding machines worldwide, which is a detail we share upfront.

Your Actionable Vetting Checklist

Use this checklist as a guide during your evaluation process. Go through it point by point with any supplier you are seriously considering.

1. Scrutinize the Documents:

- [1] Ask for their standard warranty document. Don't just wait for it to appear in the final contract. Review it early. Look for the clear coverage, specific durations, and defined processes we discussed in Step 1.

- [2] Ask for their recommended spare parts list—with prices. Analyze it. Does it seem comprehensive? Are the prices reasonable? Is it professionally formatted with clear part numbers?

- [3] Ask for a sample of the machine's technical manual. Request a specific chapter, perhaps the daily maintenance or a troubleshooting section. Is it in clear, fluent English? Are there helpful diagrams? Is it detailed enough for your team to actually use?

2. Verify the Support System:

- [1] Ask about their remote support process. Who is the direct contact? What is their guaranteed response time? Do they use a ticketing system?

- [2] Ask for a demonstration. This is a powerful test. Say, "Could one of your engineers spend 15 minutes on a Zoom call with me to walk me through the machine's HMI control screen?" Their ability and willingness to do this will tell you a lot.

- [3] Ask about their support team. How many dedicated service engineers do they have? What are their backgrounds? Are they fluent in English?

3. See the Knowledge Base in Action:

- [1] Ask if they have video tutorials. If so, ask for a link to one or two samples. Are they clear, well-produced, and easy to follow?

- [2] Ask how they train customer operators. Do they offer training at their facility before shipment? Do they provide on-site training during commissioning? A commitment to training is a strong indicator of a partnership mentality. This is also where discussions about optimizing the whole system, like implementing a cost-efficient air system, can highlight their expertise.

4. Seek Social Proof:

- [1] Ask for customer references, preferably in your region. Don't just get a name; get a contact number or email. A supplier with happy customers will have no problem providing this.

- [2] Prepare specific questions for the reference. When you contact the reference, don't just ask if they are "happy." Ask targeted questions:

- "Have you ever had to use their after-sales support? How was the experience?"

- "How would you rate the quality of their technical manual?"

- "Have you ever had to order spare parts? How quickly did they arrive?"

Completing this checklist will give you a multi-dimensional view of the supplier's commitment. The documentation proves their preparation, the support demo proves their capability, the knowledge base proves their investment in your autonomy, and the references prove their track record. By the end of this process, you won't be guessing if their warranty is real. You will have the evidence to know for sure.

Conclusion: A Warranty Isn't a Document, It's a Partnership?

A warranty is not just ink on paper; it's a supplier's active pledge to ensure your production runs smoothly. It's the foundation of a long-term partnership built on trust and mutual success.

Frequently Asked Questions (FAQs)

1. What specific clauses should I add to my purchase contract to make the warranty more enforceable?

To make a warranty more "enforceable," you need to add specificity. Insist on clauses that clearly define key terms and processes. For example, add an appendix that lists all "Core Components" versus "Wearing Parts." Specify the warranty start date as the "Date of Commissioning Acceptance" instead of the "Bill of Lading Date." Most importantly, add a "Service Level Agreement (SLA) for Technical Support" clause. This could state: "Supplier guarantees an initial response to any technical support request within 4 hours and a proposed action plan within 24 hours." This turns a vague promise of "support" into a measurable, contractually obligated deliverable.

2. For a critical machine failure, what is a reasonable "guaranteed response time" to expect from an overseas supplier?

A reasonable expectation should be tiered. For a critical, production-stopping failure, you should expect:

- Initial Acknowledgement: Within 2-4 hours. This confirms they have received your request and are looking into it.

- Initial Diagnosis & Action Plan: Within 24 hours. This should be a detailed response after they have reviewed photos, videos, or PLC data. The plan should state whether the issue can be solved remotely, if a part needs to be shipped, or the next steps.

- Part Shipment: For in-stock critical parts, shipment should occur within 24-48 hours.

This tiered approach is the hallmark of a professional support system.

3. Besides customer references, what other proof can a supplier offer to demonstrate their remote support capabilities?

Excellent question. Ask for a live demonstration. A confident supplier should be willing to schedule a 30-minute video call where one of their engineers shares their screen and walks you through their remote diagnostic process. They could show you an anonymized service ticket from a past issue, demonstrating how they log, track, and resolve problems. They could also show you a recording of a remote access session into a test machine in their factory, proving the technology works and their team is proficient with it.

4. How does the warranty work if a problem is caused by a third-party component (like a mold or preform) and not the machine itself?

This is a critical area where a true partner shines. A poor supplier will immediately play the "blame game." A great supplier will act as a consultant to help you diagnose the root cause, even if it's not their machine. Their warranty should state that while they are not responsible for replacing third-party components, their technical support team will assist in the troubleshooting process. For example, if you have bottle defects, they should help you determine if it's a machine parameter, a preform mold issue, or related to the preform's neck size. Their expertise is valuable, and their willingness to help you solve the entire problem, regardless of its source, is a key indicator of a partnership mentality.

5. How much more should I be willing to pay for a machine with a proven, comprehensive after-sales support system?

This isn't a cost; it's an investment in Total Cost of Ownership (TCO). While the exact percentage varies, consider this: a single week of unplanned downtime could easily cost you more than the 5-10% price premium of a machine from a top-tier supplier. Think of the higher upfront price as an insurance premium against future losses. You are buying not just a machine, but guaranteed uptime, peace of mind, and access to expertise that will make your operation more efficient for years to come. The cheapest machine is often the most expensive one in the long run.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

📲 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr