Are you trying to enter the profitable Tritan bottle market but feel lost? The high investment costs and complex technology can be confusing. It's a big risk.

The best way for newcomers to start is with the two-step reheat and blow process. This method has a much lower initial investment. It also gives you more production flexibility compared to the one-step method. It's the ideal choice to begin your Tritan bottle business.

I’ve seen many people get stuck at the very first decision. The world of plastics manufacturing is full of technical terms and big machines with even bigger price tags. It's easy to feel overwhelmed. A few years ago, I spoke with a client from Kenya who was in this exact situation. He saw the huge demand for stylish, durable sports water bottles and knew Tritan was the material to use. But he thought his only option was a massive, expensive one-step machine. He was ready to take out a huge loan, a decision that could have sunk his business before it even started. This conversation is what inspires me to write this guide. I want to show you a smarter, safer path into this market. Let’s walk through the process step-by-step, so you can make an informed decision with confidence.

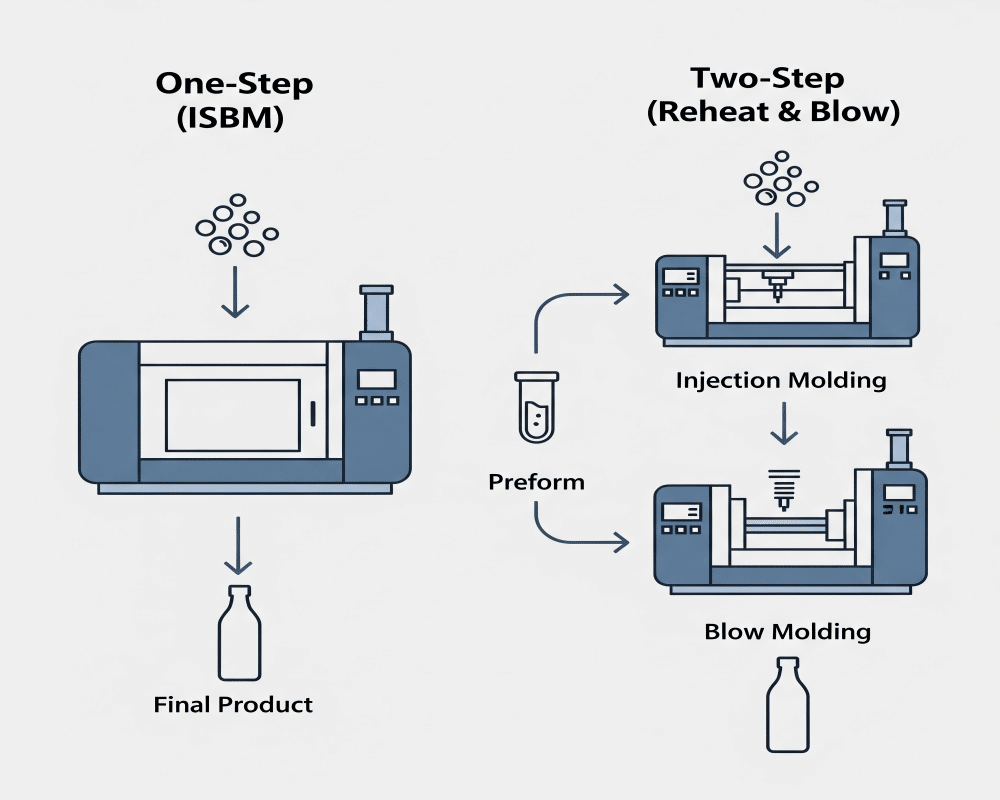

Two Process Options to Understand Before Investing in a Tritan Production Line?

Choosing a production process can feel like a massive gamble. A wrong move could mean spending hundreds of thousands of dollars on the wrong equipment. I'll clarify the two main options for you.

The two main methods are one-step Injection Stretch Blow Molding (ISBM) and the two-step reheat and blow process. The one-step method is best for huge, single-product runs. The two-step process offers much more flexibility and lower initial costs, making it a smarter choice for most new businesses.

When you decide to produce Tritan bottles, the very first technical question you face is "how?" The answer lies in choosing between two fundamentally different manufacturing philosophies: the "all-in-one" approach or the "divide and conquer" strategy. Let's break them down in simple terms.

The One-Step (ISBM) Process: The All-in-One Powerhouse

Think of the one-step Injection Stretch Blow Molding (ISBM) machine as a complete factory in a single box. You pour raw Tritan resin pellets in one end, and a finished, ready-to-ship bottle comes out the other. The machine performs three actions sequentially on a single platform:

- Injection: It melts the resin and injects it into a mold to form a "preform." A preform looks like a thick test tube with the final threads of the bottle neck already formed.

- Conditioning & Stretching: While the preform is still hot and soft from the injection process, it's moved to a conditioning station. Here, its temperature is optimized. Then, a stretch rod pushes down, stretching it vertically.

- Blowing: In the final station, high-pressure air is blasted into the stretched preform, inflating it like a balloon to fit the shape of the final bottle blow mold.

This process is incredibly efficient for massive production volumes of a single bottle design. Think of a company like Coca-Cola that needs millions of identical bottles every day. The main advantage is that since the preform is never fully cooled, you save the energy required to reheat it. However, this efficiency comes at a very high price. The machines are extremely complex and the initial investment can easily run into many hundreds of thousands, if not millions, of dollars. For a new business or a company looking to produce a variety of bottle shapes, this is often an unnecessarily large and inflexible investment.

The Two-Step (Reheat and Blow) Process: The Flexible & Smart Approach

The two-step process, as the name suggests, divides the manufacturing into two separate, independent stages. This is the approach I recommend to 95% of the clients who are new to Tritan.

- Step 1: Preform Production. A standard (but specially configured for Tritan) injection molding machine is used to produce the preforms. These preforms are then fully cooled and can be stored, packed, and even sold as a separate product. This stage uses a dedicated preform mold.

- Step 2: Reheat and Blow. The cooled preforms are fed into a separate bottle blowing machine. Inside this machine, the preforms travel through a heating oven with infrared lamps that soften them to the perfect temperature. They then move into the blowing station where, just like in the one-step process, they are stretched and blown into their final shape.

The beauty of this method is its modularity and flexibility. You can start small, scale up, and adapt to market changes easily. The initial cost is a fraction of the one-step method, making it far more accessible.

To make the choice clearer, let's compare them side-by-side:

Comparison Table: One-Step vs. Two-Step for Tritan Production

| Feature | One-Step (ISBM) Process | Two-Step (Reheat and Blow) Process | My Recommendation for Newcomers |

|---|---|---|---|

| Initial Investment | Very High ($$$$$) | Low to Medium ($$) | Two-Step |

| Production Flexibility | Low (Tied to one machine) | High (Separate processes, easy to change) | Two-Step |

| Ideal Production Scale | Massive, continuous runs | Small to large, varied runs | Two-Step |

| Mold Complexity & Cost | High (Complex multi-stage mold) | Lower (Separate, simpler molds) | Two-Step |

| Technical Complexity | Very High (One complex system) | Medium (Two simpler, standard systems) | Two-Step |

| Energy Consumption | Lower per bottle (uses residual heat) | Higher per bottle (requires reheating) | - |

| Entry Barrier | Extremely High | Low | Two-Step |

As you can see, unless you have a guaranteed contract for millions of a single type of Tritan bottle, the two-step process is the logical, financially sound, and flexible choice. It allows you to enter the market without betting the entire farm on one machine.

Why the Two-Step Process is Ideal for Newcomers (A Cost & Flexibility Analysis)?

Starting a new production line is a huge financial risk. You worry about tying up too much money before you even make your first sale. Let me show you a safer, more flexible path.

The two-step process is perfect for new businesses because the initial investment is much lower than the one-step method. It gives you amazing flexibility. You can start by just blowing bottles from preforms you buy, and then scale up when you're ready.

When I advise new investors, my primary goal is to help them succeed long-term. Success often means starting smart and managing risk. This is where the two-step process truly shines as the superior strategy for anyone entering the Tritan bottle market. Let's dig deeper into the two pillars of this strategy: cost and flexibility.

The Overwhelming Cost Advantage

Let's talk numbers, because that's what matters most when you're starting. A one-step ISBM machine capable of producing Tritan bottles is a highly specialized piece of equipment. You are essentially buying an injection molding machine and a blow molding machine fused into one complex unit. The engineering required to make this work seamlessly is significant, and the price tag reflects that. We are often talking about an initial outlay of $300,000 to over $1,000,000. For a startup, this is a monumental barrier.

Now, consider the two-step approach. You are buying two separate, more standard machines:

- An Injection Molding Machine: This is a workhorse of the plastics industry. While you need one with a special screw for Tritan, it's still a relatively common piece of equipment.

- A Reheat Blow Molding Machine: This is our specialty. Our machines are specifically engineered with the heating capacity and control needed for Tritan.

The combined cost of these two machines is a fraction of the one-step alternative. You get the same high-quality output but without the terrifying upfront investment. The mold costs are also more manageable. A complex, multi-station mold for a one-step machine is a huge engineering project. Separate, simpler molds for injection and blowing are more affordable and faster to produce. This isn't just about saving money; it's about reducing your financial risk and improving your cash flow from day one.

The Game-Changing Flexibility

This, for me, is the most powerful argument for the two-step process. It gives you options and allows your business to grow organically. I call it the "Phased Investment Model."

Phase 1: Enter the Market with Minimal Risk

You don't even need to buy both machines at the start! The smartest way to begin is to purchase only our iBottler Tritan bottle blowing machine. You can then buy high-quality Tritan preforms from a specialized supplier. I can even help you find reliable sources. This approach allows you to:

- Minimize Initial Capital: Your first investment is only the blowing machine and the bottle mold.

- Test the Market: Start producing bottles and building your customer base without the pressure of a massive bank loan.

- Learn the Blowing Process: Focus on mastering one part of the production chain first.

Phase 2: Scale Up and Control Your Supply Chain

Once your bottle business is established and you have consistent sales, you can move to Phase 2. Now you invest in an injection molding machine and a preform mold. This brings production in-house. The benefits are huge:

- Lower Costs: Producing your own preforms is cheaper than buying them.

- Full Quality Control: You control the entire process from raw material to finished product.

- Become a Supplier: Here's the brilliant part. You can run your injection machine for more shifts and produce more preforms than you need. You can then sell these extra preforms to other smaller companies who are in Phase 1. You've just created a brand new, profitable revenue stream!

This is exactly the path my Kenyan client took. He started with a small, semi-automatic blowing machine from us. He bought preforms for the first 18 months. As his brand grew, he invested in an injection line. Today, he not only dominates his local market for Tritan bottles but is also the primary preform supplier for several other companies in the region. He built an empire, one smart step at a time.

Here’s how the investment can be staged:

| Investment Phase | Equipment Needed | Primary Activity | Capital Outlay | Risk Level |

|---|---|---|---|---|

| Phase 1: Market Entry | Tritan Reheat Blow Molding Machine | Blowing bottles from purchased preforms | Low ($) | Very Low |

| Phase 2: Vertical Integration | Injection Molding Machine & Preform Mold | Producing own preforms, blowing bottles | Medium ($$) | Low |

| Phase 3: Market Expansion | (Additional Capacity) | Selling excess preforms to others | (Self-funded) | None |

This phased approach simply isn't possible with a one-step machine. With one-step, you're all in, right from the start. The two-step process gives you control, reduces risk, and provides a clear, manageable path to growth.

Step 1: The Injection Molding Machine & Mold for High-Quality Tritan Preforms?

The quality of your final bottle is decided the moment your preform is made. A flawed preform will always result in a flawed bottle. This wastes material, time, and money. Let's get this first step right.

To make top-quality Tritan preforms, you must use an injection molding machine with a screw designed specifically for Tritan. The preform mold is just as vital. It needs to be made from high-grade steel and have a precision hot runner system and an excellent cooling design.

In the two-step process, creating a perfect preform is the foundation of your entire operation. You can have the best blowing machine in the world, but if you feed it bad preforms, you'll get bad bottles. Many people new to Tritan underestimate the science behind this first step, assuming it's just like working with PET. It's not. Tritan has its own unique personality, and you need the right equipment to handle it properly.

The Injection Molding Machine: It's All About the Screw

The heart of the injection molding machine is the screw. This is the component that transports, melts, and pressurizes the plastic resin pellets. For a material like Tritan (a copolyester), you cannot use a standard screw designed for PET or other common plastics.

Why? It comes down to two things: viscosity and processing temperature. Tritan has a different melt viscosity than PET and is more sensitive to overheating.

- Standard PET Screw: A screw with a compression ratio designed for PET will generate too much shear heat when processing Tritan. This extra heat can degrade the material, causing it to turn yellow or become brittle. It can also lead to "black specks" in the preform, which are tiny bits of burnt plastic.

- Tritan-Specific Screw: A screw designed for Tritan has a lower compression ratio and specific geometry. This design ensures the material is melted gently and uniformly, without any hot spots. It plasticizes the material perfectly, delivering a homogenous, stable melt to the mold.

When you're sourcing an injection molding machine, you must be clear with the supplier that you will be processing Tritan. Insisting on the correct screw configuration is non-negotiable. It's the single most important factor in the machine itself for ensuring preform quality.

The Preform Mold: Where Precision Engineering Pays Off

The mold is where the magic happens. A well-designed and well-built preform mold is a long-term asset that will produce millions of identical, high-quality preforms. A cheap, poorly made mold will cause endless headaches and production defects. Here are the critical components of a great Tritan preform mold:

- Mold Steel: The core and cavity of the mold should be made from high-grade, hardened stainless steel, like S136. This type of steel can be polished to a mirror finish, which is essential for the glass-like clarity of Tritan. It's also highly resistant to corrosion, ensuring a long lifespan even with demanding production schedules.

- Hot Runner System: This is a network of heated channels within the mold that delivers the molten plastic from the machine's nozzle to each individual cavity. For Tritan, a high-quality hot runner system with valve gates is ideal. Valve gates provide precise control over the injection process, ensuring each cavity fills evenly and cleanly. This results in consistent preform weights (crucial for the blowing stage) and a clean gate mark on the preform base, which prevents defects in the final bottle.

- Cooling System: This is one of the most underrated aspects of mold design. A network of channels circulates chilled water throughout the mold to cool the plastic preform rapidly and evenly. The faster you can cool the preform, the shorter your cycle time, and the more preforms you can produce per hour. An optimized cooling design is the key to profitability. Poor cooling leads to long cycle times, inconsistent preform quality, and potential defects like warping. Connecting your mold to a properly sized water chiller is absolutely essential.

Thinking about the preform neck is also very important. The neck finish must be perfect from the injection stage. I recommend reading this guide on how to choose the right preform neck size, as the principles apply to Tritan as well. Investing in a high-quality machine and mold for Step 1 is the best insurance policy for a smooth and successful Step 2.

Step 2: Selecting the Right Reheat Stretch Blow Molding Machine for Tritan?

You've made perfect preforms, but the wrong blowing machine will turn them into scrap. Don't let this final, critical step become your point of failure. Let's look at what your blowing machine truly needs.

A blowing machine for Tritan needs a more powerful and finely controlled heating system than a standard PET machine. It must have more infrared lamps to properly heat the thicker preform and a smart control system to guarantee perfect, crystal-clear results every time.

This is where my company, iBottler, focuses its expertise. We have spent years perfecting our reheat bottle blowing machines to handle the specific challenges of Tritan. Many people make the costly mistake of assuming that a machine that blows PET bottles can also blow Tritan bottles. This is technically true in the same way that a family car can technically drive on a racetrack. It will work, but the performance will be terrible, and you'll likely end up with a wreck.

The Critical Challenge: Heating the Tritan Preform

The single biggest difference between blowing PET and blowing Tritan is the heating process. This is where 90% of problems occur. Here's why Tritan is so much more demanding:

- Thickness: Tritan preforms for durable sports bottles are often significantly thicker and heavier than preforms for disposable PET water bottles. This thickness acts like an insulator, making it much harder for the heat from the infrared lamps to penetrate all the way to the core of the preform.

- Heat Absorption: Tritan material absorbs infrared energy differently than PET. It requires more energy, applied over a slightly longer period, to reach its optimal stretching temperature (around 110-120°C).

- Narrow Processing Window: Tritan has a narrower "sweet spot" for temperature. If it's too cool, it won't stretch properly, resulting in a white, hazy appearance (a defect called pearlescence). If it's too hot, it can become too fluid, leading to sagging or blowouts.

A standard PET blowing machine's heating oven is simply not equipped for this task. It doesn't have enough lamps or enough control to heat a thick Tritan preform evenly and consistently. The result is a preform that is hot on the outside but still too cold on the inside. When this improperly heated preform is stretched and blown, defects are inevitable.

The iBottler Solution: An Oven Engineered for Tritan

We understood this challenge from day one. That’s why our Tritan-ready blowing machines feature a completely redesigned heating system.

1. More Heating Power: We install a higher density of high-quality infrared heating lamps in our ovens. This provides the raw energy needed to penetrate the thick-walled Tritan preforms effectively.

2. Precision Control: Power is useless without control. Our machines feature multiple heating zones. Each zone's temperature can be adjusted independently via a simple PLC touchscreen. This allows you to create a precise heating "recipe" for your specific preform. You can, for example, apply more heat to the thicker body section and less heat near the neck area.

3. Enhanced Ventilation: We've also optimized the ventilation system within the oven. This system prevents the outer surface of the preform from overheating while the core is still coming up to temperature. It ensures a stable and uniform heat distribution.

Beyond Heating: The Importance of Mechanical Control

Once the preform is perfectly heated, the mechanical actions of stretching and blowing must also be precise.

- Servo-Driven Stretching: Our more advanced machines use servo motors to control the stretch rod. This allows for precise control over the speed and position of the stretch rod. Why does this matter? For a sports bottle with a thick base, you might want the stretch rod to move slower at the beginning to form a solid foundation before accelerating to stretch the walls. This level of control is key to achieving perfect material distribution and consistent bottle thickness.

- High-Pressure Blowing System: A robust two-stage blowing system is crucial. A low-pressure "pre-blow" first inflates the preform slightly to orient the material, followed by the high-pressure main blow that forces the material into every detail of the bottle blow mold. Our machines are equipped with high-quality, fast-acting valves to make this process sharp and repeatable.

Choosing the right blowing machine isn't about just buying a piece of equipment. It's about investing in a solution that has been specifically designed to overcome the known challenges of the material you want to work with.

Case Study: An Investment Estimate for Starting a Tritan Bottle Production Line?

The numbers can look scary when you're just starting out. You need a clear budget to make real plans. Let's create a realistic example to make the investment concrete and understandable.

For a two-step production line making about 10,000 Tritan sports bottles per day, a complete investment might range from $75,000 to $145,000. This estimate includes the injection machine, preform mold, blowing machine, bottle mold, and essential auxiliary equipment.

Theory is good, but real-world numbers are what help you make a business plan. Let's build a hypothetical but very realistic case study for a startup company aiming to enter the Tritan sports bottle market. This will give you a tangible idea of the capital you would need for a two-step production line.

The Project Scenario:

- Product: A 750ml (25 oz) Tritan sports water bottle.

- Bottle Weight: 85 grams (a nice, sturdy feel).

- Target Production: 10,000 finished bottles per 10-hour working day.

To achieve this, we need to work backward to figure out the specifications for each piece of equipment.

Step 1: The Injection Molding Side

To produce 10,000 preforms in 10 hours, we need a certain cycle time. Let's aim for a 4-cavity preform mold.

- Production required per hour: 1,000 preforms

- Cycles required per hour (with 4 cavities): 1,000 / 4 = 250 cycles

- Cycle time per shot: 3600 seconds / 250 cycles = 14.4 seconds. This is very achievable.

Based on an 85-gram preform and 4 cavities, the total shot weight is 340 grams. This calculation, along with the mold size, tells us we need an injection molding machine of around 200 tons clamping force.

Step 2: The Blow Molding Side

To blow 10,000 bottles in 10 hours, we can use a 2-cavity semi-automatic blowing machine.

- Production required per hour: 1,000 bottles

- Cycles required per hour (with 2 cavities): 1,000 / 2 = 500 cycles

- Cycle time per blow: 3600 seconds / 500 cycles = 7.2 seconds. This is a comfortable speed for a semi-automatic machine, where an operator loads preforms and removes bottles.

Now, let's put some estimated costs to this equipment. These are realistic market ranges for good quality, reliable machinery – not the cheapest, and not the most expensive European brands.

Estimated Investment Breakdown

| Equipment / Item | Specification Example | Estimated Cost Range (USD) | Key Notes and Considerations |

|---|---|---|---|

| Injection Molding Machine | 200 Ton clamping force, with specialized Tritan screw | $40,000 - $70,000 | This is the largest single equipment cost. Brand, features, and level of automation affect the price. |

| Tritan Preform Mold | 4-cavity, S136 steel, quality hot runner system | $10,000 - $20,000 | Mold quality is critical. Don't cut corners here. This is the heart of your preform quality. |

| Reheat Blow Molding Machine | iBottler 2-cavity semi-automatic, Tritan-optimized oven | $15,000 - $25,000 | Our specialty. This provides the best value and performance for this production scale. |

| Bottle Blow Mold | 2-cavity, high-grade aluminum or P20 steel | $3,000 - $8,000 | Aluminum is good for prototypes and shorter runs. Steel is for high-volume, long-term production. |

| Air Compressor System | High-pressure (30-40 bar) & Low-pressure (8-10 bar) | $5,000 - $15,000 | Absolutely essential. You need both for blowing and for machine movements. A reliable system is a must. See our guide on air systems. |

| Water Chiller | Sized for both injection and blow molds (~5HP) | $2,000 - $7,000 | Non-negotiable for maintaining mold temperature, ensuring fast cycle times and high-quality products. |

| Total Estimated Investment | Complete Production Line | $75,000 - $145,000 | This is a realistic, all-in budget for a robust startup line. |

As you can see, for a total investment that is likely less than half the cost of just the machine in a one-step setup, you can have a complete, flexible, and high-capacity production line. This budget is achievable and allows for a much faster return on investment. It turns the dream of starting a Tritan bottle factory into a practical business plan.

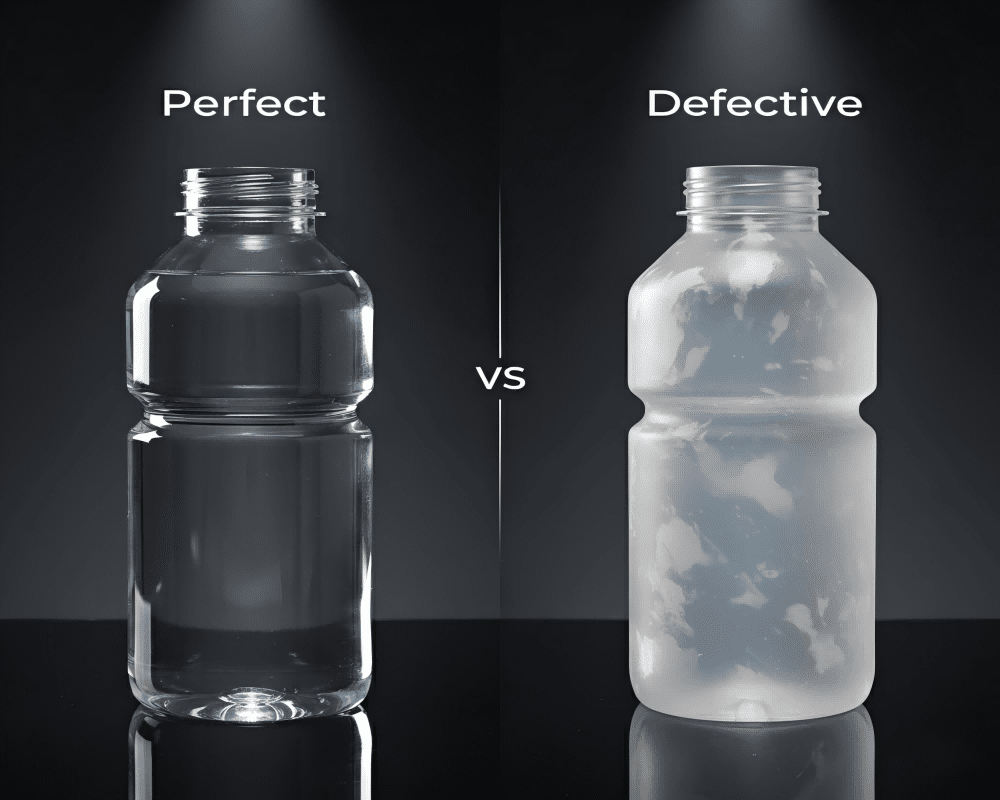

Common Misconception: Can I Use a Standard PET Blowing Machine for Tritan?

You might already have a PET blowing machine, and it's very tempting to try and save money by using it for Tritan. I must warn you, this is a path that often leads to a costly mistake.

The simple answer is no, you cannot reliably or efficiently use a standard PET blowing machine to produce high-quality Tritan bottles. The heating oven in a PET machine is not powerful enough to properly heat the thicker Tritan preforms, which will lead to a host of defects.

This is one of the most frequent questions I get, and I understand why. If you've already invested in equipment for PET production, you want to maximize its use. The idea of buying a whole new machine just for a different type of plastic can be frustrating. However, trying to force a PET machine to do a Tritan machine's job is a classic example of being "penny wise and pound foolish." Let me explain exactly why it doesn't work.

The Science of Heat: A Simple Analogy

Imagine you are a chef. You have a microwave oven designed to perfectly heat up a cup of soup in 60 seconds. One day, someone asks you to use that same microwave to perfectly roast a thick, 2-inch steak. What would happen? You could turn the microwave on for a long time. The outside of the steak would become rubbery and overcooked, while the inside would remain cold and raw. The tool is simply not designed for the task.

This is a perfect analogy for using a PET oven for Tritan preforms.

- PET Preform = The Cup of Soup: It's thin, heats up quickly, and the standard microwave (PET oven) is perfectly tuned for it.

- Tritan Preform = The Thick Steak: It's thick, dense, and requires a different kind of heat – a more intense, penetrating heat applied evenly over time – to cook it properly. A microwave just can't do it.

A PET machine's oven has fewer heating lamps, spaced further apart. It is designed to quickly heat the surface of a thin PET preform. When you put a thick Tritan preform in that oven, the surface gets hot very fast, but the core remains cool. The machine's control system doesn't know the difference; it only sees that the surface is at temperature. It then sends this improperly heated preform to be blown. The result is a disaster.

The Cascade of Defects

When you try to stretch and blow a preform that is hot on the outside and cold on the inside, you will encounter a predictable set of problems. These issues lead to massive amounts of wasted material, wasted electricity, and wasted time.

- Pearlescence (Whiteness/Haze): This is the most common defect. The cold, under-heated parts of the preform don't stretch properly. Instead of the polymer chains aligning smoothly to create a clear bottle, they are violently torn, causing micro-fractures and crystallization. This turns the plastic a milky white color, completely ruining the desired glass-like clarity of Tritan.

- Blowouts and Bursting: The uneven heating creates severe weak spots in the preform. When the high-pressure air hits, the hot spots stretch too thin while the cold spots don't stretch at all. The bottle simply bursts inside the mold.

- Poor Material Distribution: Even if the bottle doesn't burst, you will get very inconsistent wall thickness. You might end up with a paper-thin body and a giant, heavy blob of plastic at the base. This makes the bottle structurally unsound and unusable.

- Incomplete Formation: The bottle may not fully form to the shape of the mold, resulting in soft details, rounded corners, and an overall poor appearance.

I have an extensive guide on common PET blow molding defects. While it's written for PET, the visual results of defects caused by poor heating are very similar, just far more pronounced and difficult to solve with Tritan on an improper machine. You will find yourself fighting a losing battle, constantly tweaking settings but never getting a good result, because the root cause is a fundamental hardware limitation. The money you think you're saving by not buying a proper Tritan-ready machine will be quickly lost in rejected products and production downtime.

From Preform to Product: Keys to Optimizing the Two-Step Process?

You have the right equipment in place. But how do you master the process to get beautiful, perfect bottles every single time? The small details are what separate the amateurs from the professionals.

To truly optimize the two-step process for Tritan, you need to focus on three areas: meticulous preform handling, creating a precise heating profile, and fine-tuning the mechanical stretching and blowing parameters. These adjustments are the key to maximizing quality.

Getting a 99% success rate in manufacturing isn't about one big secret; it's about doing a hundred small things correctly. Once you have your Tritan-ready injection machine and your iBottler blowing machine, the journey to becoming a top-tier producer begins. Let me share some of the "know-how" I've gained over 20 years of helping clients fine-tune their operations. These are the details that make a real difference.

Pre-Production: Handle Your Preforms Like Gold

The quality of your production run is determined before a single preform even enters the heating oven. Tritan, like many plastics, is hygroscopic, which means it absorbs moisture from the air.

- Storage is Crucial: Tritan preforms must be stored in a dry, climate-controlled room. They should be kept in sealed bags or containers, preferably with desiccant packs. If a preform absorbs moisture, that water will turn into steam inside the plastic during heating. This will cause splay marks or silver streaks, which are unacceptable visual defects.

- Keep Them Clean: The preform surface must be perfectly clean. Any dust, dirt, or oil from an operator's hands will burn in the high-temperature oven, leaving black spots or carbon deposits on your final bottle. Enforce clean handling procedures at all times.

In-Production: Mastering the Machine Settings

This is where art meets science. Every bottle design and preform weight will require its own unique "recipe" of settings. The key is to make small, methodical adjustments and observe the results.

1. Dialing in the Heating Profile

Your iBottler machine's PLC gives you precise control over the oven. Use it. Don't just set all the lamps to one generic temperature.

- Create Zones: Think of the preform in three sections: neck, body, and base. The body and base need the most heat. You can lower the power percentage for the lamps closest to the neck to prevent it from deforming.

- Adjust Fan Speed: The ventilation fans cool the outer surface of the preform. This is a powerful tool. If you're getting haze (pearlescence), it often means the inside is too cold. You can try increasing the fan speed slightly. This forces you to increase the lamp power to compensate, driving more heat into the core of the preform while keeping the surface stable.

- Document Everything: When you find the perfect settings, write them down! Create a recipe book for each product you run.

Here is a simplified guide to some starting parameters you can adjust:

| Parameter | Guideline for Tritan (vs. PET) | The "Why" Behind the Adjustment |

|---|---|---|

| Lamp Voltage % | Generally higher than for PET. Start around 70-90%. | You need more energy to penetrate the thick Tritan preform. |

| Heating Time | Longer than for PET. Often 40-60 seconds. | This gives the heat time to "soak" into the core evenly. Don't rush it. |

| Preform Rotation Speed | Slower than for PET. | Ensures each side of the thick preform gets adequate exposure to the lamps. |

| Ventilation Fan % | A key adjustment variable. Start around 50-70%. | Balances surface temperature with core temperature. Critical for clarity. |

2. Fine-Tuning the Blow & Stretch Parameters

Once the preform is perfectly heated, you can fine-tune the mechanical process.

- Stretch Rod Delay: Introducing a tiny delay (e.g., 0.1 seconds) between when the mold closes and when the stretch rod begins to move can sometimes help stabilize the preform.

- Pre-Blow Timing: Starting the low-pressure pre-blow just as the stretch rod is moving helps to center the preform and initiate uniform stretching. This is key to controlling wall thickness.

- Validate Your Design Early: Before you even cut steel for a production mold, we can help. Using services like 3D printed samples to validate designs, we can identify potential issues with stretching and material distribution at the concept stage, saving you thousands in mold rework later.

I once spent an entire day on-site with a client in Mexico. His bottles were coming out hazy 20% of the time. We didn't touch the lamp temperatures. We only worked on the fan speed and the pre-blow timing. By slightly increasing the fan speed and starting the pre-blow 0.2 seconds earlier, we took his success rate to 99.5%. It's this level of detail that turns a good operation into a great one.

iBottler: Your Expert for Cost-Effective Two-Step Tritan Solutions?

You now understand the process and the equipment, but finding a reliable partner is the final, crucial step. You don't just need a machine supplier; you need a team of experts to ensure your success.

iBottler specializes in providing complete, cost-effective, two-step Tritan production solutions. We deliver market-proven blowing machines optimized for Tritan, high-quality molds, and the comprehensive, hands-on technical support you need to launch and succeed.

The journey into manufacturing a new product can be intimidating. There are many variables, and it's easy to feel like you're on your own. My goal, and the mission of my entire team at iBottler, is to change that. We see ourselves as your partners, not just your suppliers. Our success is directly tied to your success. We've built our company around providing a complete, intelligent solution for people looking to enter the Tritan bottle market, based on the flexible and cost-effective two-step process.

More Than Just a Machine

When you work with iBottler, you get more than just a piece of equipment delivered to your door. You get a comprehensive solution designed to get you into production quickly and efficiently.

- Tritan-Ready Blowing Machines: We offer a full range of machines, from simple semi-automatic models perfect for startups, to fully automatic systems for when you're ready to scale up your production. Every machine we designate as "Tritan-Ready" features the specialized heating ovens and precision controls we've discussed. They are not simply re-branded PET machines; they are engineered for the task.

- High-Precision Molds: We can design and supply both the preform molds for your injection stage and the final bottle blow molds for the blowing stage. We use high-quality steel and advanced design principles to ensure longevity, fast cycle times, and flawless bottle quality. We also solve compatibility issues before they happen; we have the mounting dimensions for 80% of blow molding machines worldwide, ensuring our molds will fit your machine.

- Complete Line Integration Support: We don't just sell you a blowing machine and wave goodbye. We help you plan the entire production line. We'll advise you on the correct specifications for your injection molder, your high-pressure air compressor system, and your water chiller. We ensure all the pieces of the puzzle fit together perfectly.

- Unmatched Technical Support: This is what truly sets us apart. Our team has 20 years of hands-on experience blowing Tritan and other materials. We provide on-site installation and training to get your team up to speed. And our support doesn't stop there. When you run into a production challenge six months or two years down the line, you can call me. We will work with you to troubleshoot the problem and find a solution, just as I've done for hundreds of clients before.

The iBottler Advantage Summarized

| Our Advantage | What It Means For You |

|---|---|

| Low Barrier to Entry | You can start a professional Tritan production line for a fraction of the cost of a one-step system. |

| High Flexibility | Our two-step approach allows you to start small, test the market, and scale your investment as your business grows. |

| Proven Expertise | You get machines and molds specifically engineered for Tritan, backed by 20 years of real-world experience. |

| End-to-End Partnership | We support you from the initial planning stage through installation, training, and long-term troubleshooting. |

The demand for high-quality, reusable Tritan water bottles is only growing. Don't let uncertainty or the fear of high costs prevent you from capturing your share of this exciting market. The two-step method is the proven, smart way to begin.

Let's start a conversation about your project. Contact us today. I would be happy to personally review your requirements and help you configure a production line that fits your budget and your ambitions. Let's build your success story, together.

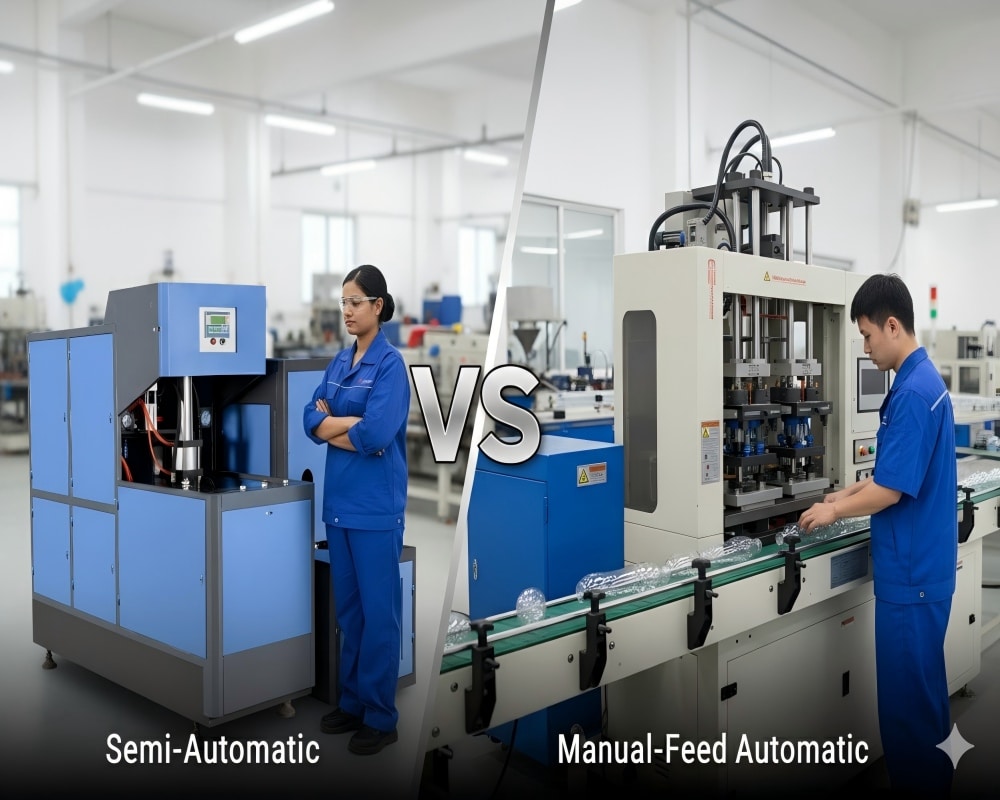

Final Summary: Choosing Your Ideal Two-Step Machine?

You're convinced the two-step process is the right path, but now you face another choice. Semi-automatic or fully automatic? Making the wrong decision here can impact your efficiency and product quality.

The best choice depends on your production needs. A semi-automatic machine offers the lowest investment. A manual-feed fully automatic machine provides higher output without risking scratches on your pristine Tritan preforms, which is a common issue with standard automatic loaders.

We've firmly established that for anyone new to Tritan bottle production, the two-step method is superior to the one-step method in terms of cost and flexibility. A complete two-step line might cost between $75,000 and $150,000, while a one-step machine alone can easily cost over $300,000. That part is a clear financial decision.

Now, let's zoom in on the heart of your new production line: the blowing machine itself. Within our recommended two-step process, you have two main choices: a semi-automatic machine or a fully automatic machine. From our experience, especially with a high-value, aesthetic product like a Tritan sports bottle, this choice requires careful consideration.

The Critical "Scratch" Problem with Fully Automatic Machines

In a standard fully automatic setup, preforms are dumped into a hopper and then unscrambled and oriented by an automatic loading system that feeds them into the oven. For PET soda bottles, this is perfectly fine. But for Tritan, it's a major risk. Tritan preforms are heavy and their surfaces are meant to be flawless. When they tumble against each other in a hopper and get pushed along metal tracks, they inevitably get scuffed and scratched. These tiny scratches, almost invisible on the preform, become magnified and very obvious on the final clear bottle. Your rejection rate will be high, and your product's premium feel will be lost.

Our Recommended Solution: The "Manual-Feed" Automatic Machine

Because of this scratch problem, we do not recommend multi-cavity, fully-automatic machines with standard loaders for high-clarity Tritan sports bottles. Instead, we have the perfect solution: a two-cavity, manual-feed fully automatic blowing machine.

This machine works brilliantly:

- An operator carefully takes two perfect, unscratched preforms and places them directly onto the holders by hand.

- From that point on, the machine is fully automatic. It carries the preforms through the optimized heating oven, transfers them to the mold, blows the bottles, and ejects the finished products automatically.

You get the speed and consistency of an automatic cycle without any risk of damaging the preforms. It's the best of both worlds for this specific application.

Comparison: Which Two-Step Machine is Right for You?

To make your decision easier, here is a direct comparison from my factory's point of view:

| Feature | Semi-Automatic Machine | Manual-Feed Fully Automatic Machine |

|---|---|---|

| Initial Investment | Lowest ($) | Low-Medium ($$) |

| Output (750ml bottle) | ~600-800 bottles per hour | ~1200-1500 bottles per hour |

| Labor Requirement | 1 Operator (Loads preforms AND removes bottles) | 1 Operator (Only loads preforms) |

| Process | Operator loads 2 preforms -> Machine heats & blows -> Operator removes 2 bottles | Operator loads 2 preforms -> Machine does the rest automatically |

| Key Advantage | Lowest possible startup cost, very simple to operate. | Higher efficiency, consistent cycle time, reduced operator fatigue. |

| Key Disadvantage | Lower output, cycle speed depends on operator consistency. | Slightly higher investment cost than semi-auto. |

| My Recommendation | Perfect for startups, small-scale production, or if your budget is extremely tight. | The ideal choice for growth, providing a major boost in output with a modest increase in investment while protecting bottle quality. |

From my perspective as a machine builder and a consultant to my clients, the choice is clear. If you are just starting and want the lowest possible entry cost, the semi-automatic machine is a safe and reliable workhorse. But if you have established demand and want the most efficient production line specifically for high-quality Tritan bottles, the manual-feed fully automatic machine is, without a doubt, the superior long-term investment. It offers the perfect balance of speed, quality control, and value.

Conclusion

The two-step process is the smartest, most flexible, and most cost-effective way to start producing Tritan bottles. With the right equipment and an expert partner like iBottler, your success is closer than you think.

Frequently Asked Questions (FAQs)

Q1: I heard that only expensive one-step machines can make good Tritan bottles. Is the two-step method really reliable?

A: This is a common misunderstanding. While one-step machines are excellent for specific high-volume scenarios, the two-step method is technically capable of producing Tritan bottles of equally high quality. The key to success is using equipment specifically optimized for Tritan's unique properties, particularly a blowing machine with an advanced heating system. Our two-step solutions are proven to be reliable and have the major advantages of lower investment and greater production flexibility.

Q2: If I choose the two-step method, do I have to buy an injection molding machine and a blowing machine at the same time?

A: Not at all, and this is the biggest advantage of the two-step process. In the initial phase of your project, you can minimize your startup capital by purchasing only our Tritan blowing machine. You can then source high-quality Tritan preforms from the open market to begin production immediately. Once your sales are stable and your business grows, you can then invest in your own preform production line.

Q3: What is the biggest technical challenge in producing Tritan with the two-step method, and how do you solve it?

A: The single biggest challenge is the precise heating of the preform. Tritan preforms are thicker than PET and are very sensitive to temperature. If not heated evenly, they will not blow correctly. Our blowing machines solve this challenge with a specially designed heating oven that features more heating lamps, multi-zone temperature control, and an optimized ventilation system. This ensures that every preform is heated uniformly to the perfect temperature for stretching, guaranteeing a very high success rate for the finished bottles.

Q4: What is a rough budget for a two-step Tritan production line, from equipment to commissioning?

A: Compared to one-step machines that can easily cost hundreds of thousands of dollars, the two-step method is far more accessible. A basic, complete production line—including a suitable injection molding machine, a preform mold, one of our blowing machines, and a bottle mold—can be established with a much more competitive investment. The exact budget depends on your desired production capacity and level of automation, but it's a fraction of the one-step cost. We welcome you to contact us for a detailed, customized quotation based on your specific needs.

Q5: After I purchase your equipment, will I get technical support if I run into problems with heating or forming the Tritan bottles?

A: Absolutely. We provide much more than just equipment; we provide a partnership. We have 20 years of experience in blow molding Tritan and other materials. Our engineers will provide comprehensive support, from the initial installation and commissioning to training your operators on process optimization. Any production challenges you encounter, we will be there with proven solutions to ensure your production runs smoothly and successfully.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr