Your production line is running, but you feel a constant drag. You suspect the mold that came with your machine is the cause. Is a specialist upgrade the answer?

A specialized PET blow mold is a smart upgrade. It solves quality issues and boosts efficiency beyond what a standard bundled mold can offer. A dedicated factory provides superior engineering, better materials, and tailored cooling systems, directly leading to a higher return on investment and better bottle quality.

I recently spoke with a client from Dubai. He was frustrated. He bought a new four-cavity automatic bottle blowing machine and it came with a bundled mold. The mold had constant problems. The bottle quality was just not there. He knew he needed a replacement, but he was worried. Could a new mold from a different factory really be better? Would it even fit his machine? And what about the cost? His story is not unique. Many businesses face this exact problem. They want to upgrade but are held back by valid concerns. This article is for them. I want to walk you through why moving to a specialized mold maker is not just a purchase, but a powerful upgrade for your entire operation.

The "Good Enough" Problem: When to Move Beyond Your Machine's Original Mold?

Your bundled mold works, but is it holding you back? Constant small issues and missed targets suggest it is time for an upgrade. Relying on "good enough" costs you money every day.

Moving beyond your original mold is necessary when you see consistent quality defects, slow production cycles, and high scrap rates. These issues indicate the bundled mold lacks the precision engineering and advanced cooling needed for optimal performance and profitability.

The idea of "if it ain't broke, don't fix it" is a dangerous one in manufacturing. Your original equipment manufacturer (OEM) mold, the one that came with your machine, might seem "good enough." It produces bottles, and the machine runs. But this mindset often hides significant hidden costs and missed opportunities. It creates a ceiling on your production's potential. My client in Dubai was living this reality. His machine was brand new, but the bundled mold was a constant source of headaches. He was trapped in the "good enough" problem, where the tool was functional but far from optimal. This is a critical turning point for any bottling business. Recognizing when to move on from this stage is the first step toward unlocking greater efficiency and higher profits. It's about shifting your thinking from just making bottles to making the best possible bottles in the fastest possible time.

Signs Your "Bundled" Mold is Underperforming

How do you know if your mold is the weak link in your production chain? The signs are often subtle at first but become more obvious as you look closer. You might not have a catastrophic failure, but a slow drain on your resources and quality. It’s crucial to identify these symptoms early.

- Uneven Wall Thickness: This is a critical indicator. In the two-step PET blowing process, the preform's weight is fixed, so the total weight of every bottle is the same. However, a poor mold design or inefficient cooling will cause uneven material distribution. This means some areas of the bottle are too thick while others are dangerously thin, creating structural weak points that can fail during transport or use.

- Visible Defects: Take a close look at your finished bottles. Are you seeing pearlescence (a milky appearance), haze, or small stress cracks? These are not just cosmetic issues. They are symptoms of molding problems. Our guide on common PET blow molding defects can help you identify these problems. These defects often stem from a mold that doesn't cool effectively or lacks the precise geometry for your specific PET preform.

- Longer-Than-Expected Cycle Times: Your machine has a theoretical maximum output, but can you actually reach it? If your cycle times are consistently longer than the machine's specification, the mold is often the bottleneck. The bundled mold's cooling system is typically basic, requiring more time for the plastic to solidify before ejection. A few seconds per cycle adds up to thousands of bottles lost per shift.

- High Scrap Rate: Every bottle you throw away is lost profit. If your scrap rate is creeping up beyond 1-2%, it's a major red flag. This waste could be due to bottles failing quality checks for the defects mentioned above, or from operational issues during ejection. A high-performance mold is built with tighter tolerances, reducing the likelihood of these failures.

- Frequent Downtime for Mold Maintenance: Are you constantly stopping production to clean, polish, or make minor adjustments to your mold? While all molds require maintenance, bundled molds often use softer steel or have less robust components. This leads to more frequent wear and tear, forcing you into unplanned downtime and reducing your overall equipment effectiveness (OEE).

The Hidden Financial Drain of an Inefficient Mold

The most significant impact of a "good enough" mold is on your finances. The costs are not always obvious on an invoice, but they are very real on your profit and loss statement. You are paying for that underperforming mold every single day.

Let's break down the costs using a simple table:

| Hidden Cost Category | How an Inefficient Mold Contributes | Estimated Financial Impact (Annual) |

|---|---|---|

| Material Waste | Higher scrap rates mean more wasted PET resin. | A 2% increase in scrap rate can cost thousands, even tens of thousands, of dollars in raw materials. |

| Energy Consumption | Longer cycle times mean your machine and auxiliary equipment (like the air compressor) run longer for the same output. | 5-10% higher energy bills, which can be a significant operational expense. |

| Lost Production | Every second added to the cycle time reduces your total output. | A 2-second reduction in cycle time can result in over 1 million extra bottles per year on a single machine. |

| Labor Costs | More downtime and manual quality checks require more operator intervention. | Increased labor cost per unit produced, reducing overall profitability. |

| Reputation Damage | Shipping inconsistent or low-quality bottles can lead to customer complaints and lost contracts. | The long-term cost of a damaged brand reputation is immeasurable. |

My client in Dubai was experiencing all of these. His team was spending too much time troubleshooting, his scrap bin was always full, and he was missing his production targets. The "free" mold that came with his machine was turning out to be one of the most expensive pieces of equipment in his factory. This is the reality of the "good enough" problem. The initial saving on the mold is quickly erased by ongoing operational inefficiencies.

First, Audit Your Current Production: What Problems Are You Trying to Solve?

You are losing efficiency but cannot pinpoint the cause. Is it the machine, the material, or the mold? A focused audit will reveal the true bottleneck in your production line.

Start by auditing your production data. Analyze scrap rates, cycle times, and bottle quality reports. This data will clearly identify the specific problems your bundled mold is causing and build the case for a targeted, high-performance upgrade that solves those exact issues.

Before you can find the right solution, you must fully understand the problem. Simply saying "we need a better mold" is too vague. You need to dig deeper and gather concrete data. This is the most critical step in the journey to upgrading your production. It’s not about blame; it’s about diagnosis. I always advise my clients, including the one in Dubai, to take a step back from the daily grind and look at their operation like a detective. What are the clues? Where is the evidence pointing? This audit process transforms a vague feeling of frustration into a clear, actionable plan. It provides the "why" behind your decision to invest in a custom blow mold and helps you define exactly what success will look like after the upgrade. Without this step, you risk buying a new mold that doesn't solve your core issues.

Collecting the Right Data: Your Production Story in Numbers

Your machines are telling you a story every day through data. Your job is to learn how to read it. You need to move beyond simple output counts and look at the key performance indicators (KPIs) that reveal the health of your molding process.

- Document Everything: For at least one full week, create a detailed log. Record the start and end time of each production run. Note every machine stoppage, the reason for it, and how long it took to resolve. This log will be your primary source of truth.

- Categorize Scrap: Don't just count reject bottles. Categorize them. How many were rejected for a thin wall? For a thick base? For pearlescence? Create specific categories. This detailed breakdown will point directly to potential mold design or cooling flaws. If 40% of your scrap is due to haze near the base, you have a clear indication of a cooling problem in that specific area of the mold.

- Measure Cycle Time Precisely: Use a stopwatch or the machine's own monitoring system to record the exact cycle time. Don't rely on the "target" time. What is the actual time, consistently, over hundreds of cycles? Record the cooling time portion of the cycle separately if your machine allows it. This is often where the biggest opportunities for improvement lie.

- Analyze Utility Consumption: Monitor the energy usage of the blow molder and the high-pressure air compressor. Correlate this data with your production output. Are your energy costs per bottle higher than industry benchmarks? This is a sign of inefficiency, often linked to long cycles or air leaks, which can sometimes be related to poor mold sealing.

From Data to Diagnosis: Connecting the Dots

Once you have this data, the next step is to analyze it to form a clear diagnosis. This is where you connect the symptoms you've recorded to their root causes.

Pinpointing the Bottleneck

Look at your downtime log. If a significant portion of your stoppages are related to "mold adjustments," "stuck bottles," or "quality holds," the mold is a primary suspect. Compare your actual cycle time to the theoretical minimum. If there's a large gap, and the cooling phase is the longest part of the cycle, you've likely identified an inefficient cooling system in your mold. A well-designed mold requires an efficient chiller to perform optimally, but the mold's internal channel design is the most critical factor.

Quantifying the Financial Impact

Now, turn these operational problems into financial figures. This is how you will build the business case for the upgrade.

- Cost of Scrap:

(Number of Scrap Bottles per Day) x (Cost per Preform) x (Number of Production Days per Year) - Cost of Lost Production:

(Target Bottles per Hour - Actual Bottles per Hour) x (Profit per Bottle) x (Operating Hours per Year) - Excess Energy Cost:

(Actual Energy Cost per Bottle - Target Energy Cost per Bottle) x (Total Bottles Produced per Year)

This kind of analysis makes the decision clear. It's no longer a vague "I think we need a new mold." It becomes "Our current mold is costing us over $50,000 a year in lost profit and wasted material." This data-driven approach was what convinced my Dubai client. When he saw the numbers, he realized he wasn't considering a cost, but an investment with a clear and rapid payback.

What to Expect from a Professional Mold Maker (That a Machine Supplier May Not Offer)?

You think a mold is just a block of steel. But a specialist offers so much more. What are the key differences that justify moving away from your original machine supplier for this critical part?

A professional mold maker offers deep specialization. Expect collaborative design, advanced material selection, superior cooling engineering, and dedicated after-sales support. These are services that a machine supplier, whose core business is machinery, often cannot match in depth or expertise.

When you buy a car, you don't expect the car dealership to be the world's leading expert on tire manufacturing. They provide a tire that works, but a dedicated tire company lives and breathes rubber compounds, tread patterns, and performance characteristics. The relationship between a bottle blowing machine supplier and a blow mold is very similar. The machine supplier provides a "bundled" mold that makes the machine functional. It's a package deal designed for convenience. A specialized mold factory, on the other hand, has a singular focus: designing and building the highest-performing PET blow molds possible. Their entire business, reputation, and engineering talent are dedicated to that one purpose. This fundamental difference in focus leads to a whole range of benefits that machine suppliers typically cannot offer. For my client in Dubai, this was a key realization. He was dealing with a machine company's sales team, not a mold engineer. He needed expert advice, not a part number from a catalog.

A Partnership in Design, Not Just a Transaction

One of the biggest differences is the collaborative process. A machine supplier often asks for your bottle drawing and gives you a price. A specialist mold maker engages you in a deep technical dialogue.

- Preform Optimization: A true specialist will ask for your preform drawing and weight. They will analyze it to ensure it's the right choice for your desired bottle. They might suggest a slight change to the preform design or weight that could dramatically improve the blowing process, reduce material usage, and enhance bottle strength. They understand the critical relationship between the preform and the final bottle. This expertise can be invaluable. For example, selecting the right preform neck size is a crucial first step that affects the entire project.

- Collaborative Bottle Design: They don't just take your design and machine it. They refine it. Their engineers will use simulation software (Finite Element Analysis - FEA) to predict how the plastic will stretch and flow into the mold cavity. They can identify potential weak spots, thin areas, or features that might be difficult to mold consistently. This proactive approach, guided by a comprehensive PET bottle mold design guide, prevents problems before the first piece of steel is even cut.

- Rapid Prototyping: Want to feel your new bottle design in your hands before committing to an expensive production mold? Many specialists offer services like 3D printed samples. This allows you to test the ergonomics, check the label area, and get marketing feedback on a physical model, de-risking the entire project.

Expertise in Materials and Manufacturing

A mold's performance and lifespan are directly tied to the materials it's made from and the precision with which it's machined. This is an area where specialists invest heavily.

| Feature | Standard OEM Mold | Specialist High-Performance Mold | Why it Matters |

|---|---|---|---|

| Mold Material | Standard P20 steel, often chrome-plated. | High-grade S136 Stainless Steel or 7075 Aircraft-grade Aluminum. | The chrome plating can wear and peel, and the P20 base steel rusts easily, shortening mold life and contaminating cooling channels. S136 and 7075 eliminate these problems. |

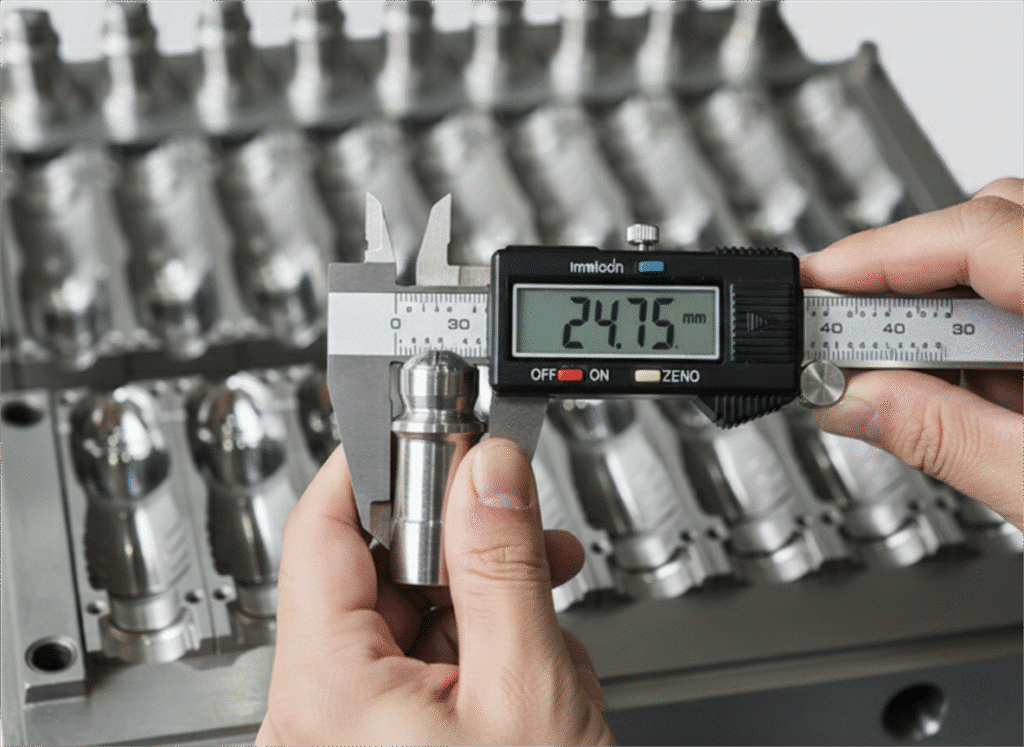

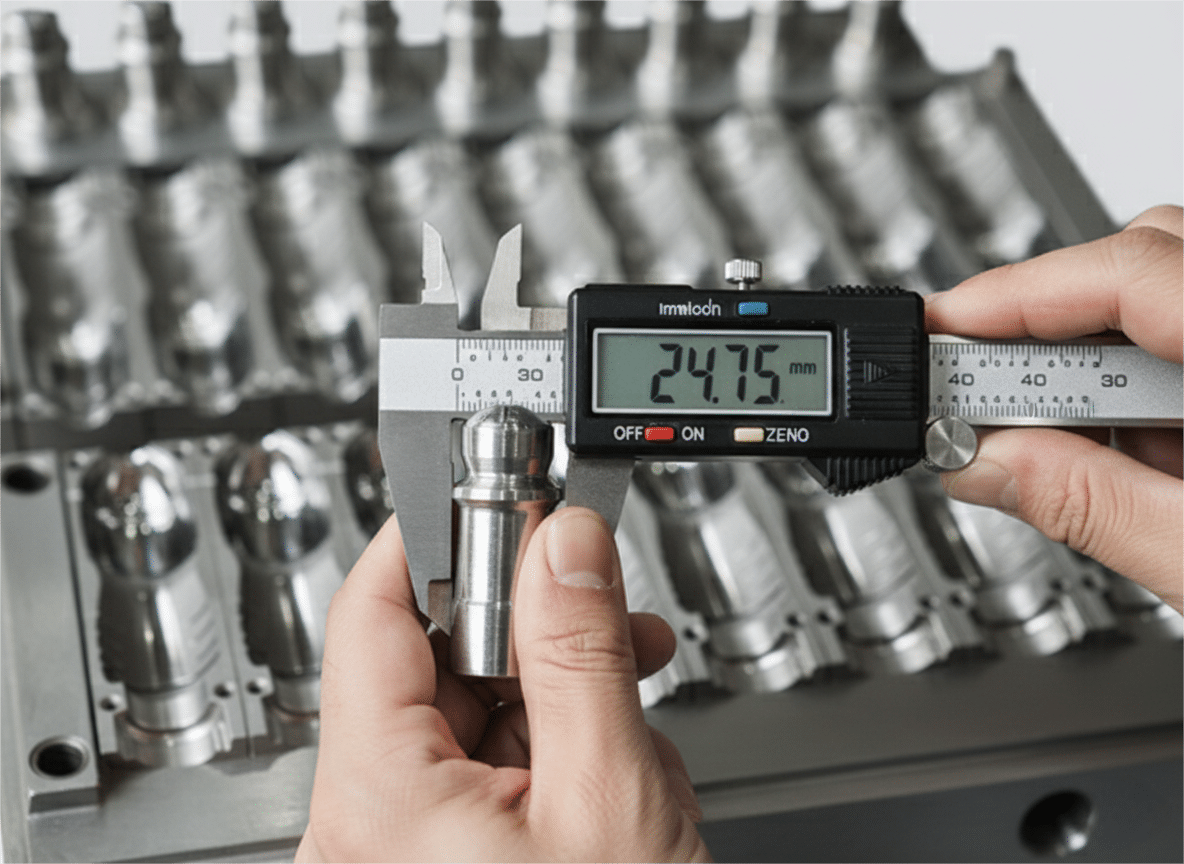

| Machining Tolerances | Standard industry tolerances | Ultra-high precision (often to within 0.01mm) using 5-axis CNC and EDM machines. | Tighter tolerances ensure perfect parting line matching and consistent bottle volume over millions of cycles. |

| Surface Finish | Standard polish | Optical or "diamond" mirror polish | A smoother surface improves material flow, enhances bottle clarity, and makes part ejection easier, reducing scuffing. |

A machine supplier's primary goal is to sell machines. They may outsource their mold making to the lowest bidder to keep the package price attractive. A specialist's reputation is built on the quality and longevity of their molds. They will never compromise on materials or manufacturing techniques because that is their core business. They are a true blow mold supplier.

The Key to Higher ROI: A Deep Dive into Advanced Cooling and Precision Engineering?

You know a new mold can be faster, but where does that speed actually come from? It seems like magic, but it is pure engineering. How do specialists achieve this performance boost?

The key to a higher ROI lies in advanced cooling and precision engineering. Specialized mold makers use scientific analysis to design complex cooling channels and use superior materials. This drastically cuts the cooling portion of the cycle time, which directly increases your output and profitability.

In PET blow molding, the single longest part of the production cycle is cooling. It can account for up to 70% of the total cycle time. The plastic is stretched into the mold shape at high temperature, and it must then cool down enough to become rigid before the mold can open and eject the bottle. If you can shorten this cooling time by even one or two seconds, the impact on your overall output is massive. This is where a specialist mold maker focuses the majority of their engineering firepower, and it's the core of achieving a fast 2.5-second cycle time. It's not about making the machine run faster; it's about making the bottle ready faster. This is the secret to unlocking the true potential of your blow molding machine. While the machine supplier's mold is designed to simply work, the specialist's mold is designed to work as fast and efficiently as humanly possible.

The Science of Heat Extraction

Think of your mold as a heat exchanger. Its job is to pull heat out of the molten plastic as quickly and evenly as possible. Uneven cooling leads to defects like warping or haze. Slow cooling leads to long cycle times.

Traditional vs. Advanced Cooling Channel Design

A standard bundled mold often has very simple cooling channels. They are typically straight lines drilled through the mold block. This is cheap and easy to manufacture, but it's not very effective. Hot spots can form in areas that are far from these channels, like sharp corners or the thick base of the bottle.

A specialist mold maker uses a much more sophisticated approach.

- Conformal Cooling: Using advanced manufacturing techniques, they can create cooling channels that follow the exact contour of the bottle cavity. This ensures that cooling water is flowing close to every surface of the bottle, eliminating hot spots and providing incredibly uniform heat extraction. This is a game-changer for bottles with complex shapes.

- Optimized Water Flow: They use fluid dynamics software to simulate the flow of water through the channels. They design the channels to maintain turbulent flow, which is much more efficient at transferring heat than smooth, laminar flow. They will specify the exact flow rate and pressure your chiller needs to provide to achieve this optimal state.

- Strategic use of High-Conductivity Materials: As mentioned before, they don't use just one type of metal. They strategically place inserts made of materials like Beryllium Copper in the areas that are hardest to cool, such as the thick gate area at the base of the bottle. This acts like a superhighway for heat, pulling it out of the plastic at an incredible rate.

Precision Engineering: The Foundation of Quality and Longevity

Beyond cooling, the sheer precision of the mold's construction plays a vital role in its performance and your ROI.

- Venting: When the preform is blown, the air already inside the mold cavity must escape instantly. If it gets trapped, it can cause burns on the plastic or prevent the bottle from forming completely. Specialist molds have microscopic vents machined into the parting line and other strategic areas. These are so small that plastic cannot flow into them, but air can escape freely. The design and placement of these vents is a science in itself.

- Interchangeability of Components: A high-performance mold from a specialist is built like a fine watch. Every component—cavity halves, neck rings, bottom inserts—is machined to such a high degree of precision that they are perfectly interchangeable. If one cavity gets damaged, you can often order a single replacement component that will drop in perfectly, minimizing downtime. With a cheaper bundled mold, the components are often hand-fitted, meaning a small amount of damage might require the entire mold to be sent out for extensive repairs.

- Surface Treatments and Coatings: To further enhance performance and lifespan, specialists often use advanced surface coatings. These can be ultra-hard coatings that prevent wear and scratching, or low-friction coatings that make bottle ejection smoother and reduce the chance of scuffing. These are treatments you will almost never find on a standard OEM mold.

This combination of advanced cooling science and meticulous precision engineering is what you are paying for when you invest in a high-performance PET mold. It's not just a block of steel; it's a highly engineered tool designed for one purpose: to make you more money. The ROI is not just theoretical; it's a direct result of these tangible engineering advantages.

Ensuring a Perfect Match: How to Guarantee Compatibility with Your Existing Machine?

You are convinced a new mold is better, but you have a major fear. What if it does not fit your machine? How can you be sure a mold from a different supplier will work perfectly?

Guaranteeing a perfect match involves a detailed technical exchange. A specialist mold maker will request specific mounting dimensions, technical drawings, and photos of your machine. They use a comprehensive database and a rigorous verification process to ensure 100% mechanical and operational compatibility.

This was the number one concern for my client in Dubai, and it's the question I get asked most often. It's a completely valid fear. Your blow molding machine is a complex piece of equipment, and the mold is its heart. A mismatch of even a few millimeters can lead to catastrophic damage or a mold that simply won't run. This is where the professionalism and experience of a specialized blow mold supplier truly shine. They understand that their job isn't just to make a great mold; it's to make a great mold that works flawlessly in your machine. They have a robust, multi-step process to eliminate any risk of incompatibility. This process is all about measurement, verification, and clear communication. Let me walk you through exactly how we ensure a perfect fit, every single time.

The Technical Information Exchange: A Two-Way Street

The process begins with a detailed information gathering phase. A professional mold maker will not just give you a quote based on a bottle drawing. They will send you a technical questionnaire or have a detailed call to gather critical data about your machine.

What We Need From You

To start, we need to know the basics:

- Machine Manufacturer and Model: Who made your machine and what is the exact model number? (e.g., Sidel SBO 14, Krones Contiform 3 Pro, etc.)

- Number of Cavities: How many bottles does your machine produce per cycle?

- Bottle Drawing and Preform Drawing: We need detailed technical drawings of both the bottle you want to produce and the preform you will be using.

But this is just the beginning. To guarantee the fit, we need to go deeper. We will often provide you with a diagram showing the exact measurements we need.

- Mounting Plate Dimensions: This includes the exact bolt hole pattern, the size and location of any guide pins or bushings, and the overall dimensions of the plate where the mold halves are mounted.

- Clamp Stroke and Shut Height: We need to know the minimum and maximum distance between the machine's platens when the clamp is open and closed. This ensures the mold is not too thick or too thin to fit and function correctly.

- Ejection System Details: How does your machine push the finished bottles out? We need to know the location and travel distance of any ejector pins or plates.

- Cooling Line Connections: Where are the inlet and outlet ports for the cooling water on your machine's platens? What type and size of fittings are used?

- Photos and Videos: A picture is worth a thousand words. We will ask for clear photos of your existing mold while it's in the machine, photos of the mounting platens with the mold removed, and sometimes even a short video of the machine in operation.

Our Verification Process: Cross-Referencing and Confirmation

This is where our expertise comes in. We take the information you provide and put it through a rigorous verification process.

The Power of a Global Database

A key advantage of working with a specialist who serves a global market is our extensive database. Over the years, we have built molds for hundreds of different machine makes and models. As I often tell my clients, we have mounting dimensions for 80% of blow molding machines worldwide. When you tell us your machine is a "SIG Corpoplast Blocmax 10," chances are very high that we already have the complete technical file for it in our system. We can then cross-reference the measurements you send us against our existing data. If there are any discrepancies, we know immediately to investigate further. This database is one of our most valuable assets and your biggest insurance policy against incompatibility.

The Final Confirmation Drawing

Once we have verified all the technical details, we don't just start cutting steel. We create a final "Mold Assembly and Mounting Drawing." This detailed technical drawing shows the complete mold assembly and, most importantly, superimposes it onto the critical mounting points of your specific machine model.

This drawing will clearly show:

- How the mold bolts onto your machine's platens.

- The location of all cooling and air connections.

- Clearance checks to ensure no part of the mold will interfere with the machine's operation.

We send this drawing to you for a final sign-off. You and your technical team can review it and compare it against your actual machine one last time. Only after you have given your final approval do we begin manufacturing. This multi-stage process of data collection, database cross-referencing, and final drawing confirmation removes all guesswork and ensures that when your new mold arrives, it will be a perfect, drop-in fit.

The Business Case: Calculating the Payback Period for a High-Performance Mold?

A new mold costs money. You see the price tag, but how do you justify it? How can you prove to yourself or your boss that this is a smart investment, not just an expense?

You calculate the payback period. By quantifying the financial gains from faster cycles, lower scrap rates, and reduced energy use, you can determine exactly how many months it will take for the high-performance mold to pay for itself. It is often much faster than you think.

Money talks. In any business, an investment must be justified by its return. A high-performance mold is no different. While we have discussed the technical benefits like better cooling and precision, the ultimate decision always comes down to the financial impact. The question my Dubai client eventually asked was, "Okay, I believe it's better, but when will I get my money back?" This is the most important question to answer. Calculating the payback period transforms the purchase from a gut feeling into a data-backed business decision. It is a simple but powerful tool that clearly illustrates the ROI of a new blow mold. The good news is that with realistic market pricing, the payback period for a high-quality mold is incredibly short.

Step 1: Calculate the Total Investment

First, you need to know the total upfront cost. We will use a realistic market price for this calculation.

- Mold Purchase Price: A high-performance 4-cavity blow mold is approximately $1,800 USD.

- Shipping and Logistics: Estimated at $500.

- Installation & Commissioning Labor: Estimated at $200.

- Total Initial Investment (I): $2,500

Step 2: Calculate the Monthly Financial Gain

Next, we need to calculate the new profit or cost savings the mold will generate each month, using modern, high-speed production figures.

Gain from Increased Production

This is usually the biggest contributor.

- Old/Inefficient Mold Cycle Time: 4.5 seconds (800 cycles/hour)

- New/High-Performance Mold Cycle Time: 2.5 seconds (1,440 cycles/hour)

- Increase in Hourly Output:

(1,440 - 800) cycles/hr * 4 bottles/cycle = 2,560 bottles - Assume a profit of $0.01 per bottle.

- Additional Profit per Hour:

2,560 bottles * $0.01/bottle = $25.60 - Assuming 400 operating hours/month (2 shifts/day, 6 days/week)

- Monthly Gain from Production (P): 400 hours x $25.60/hour = $10,240

Savings from Reduced Scrap

- Old Scrap Rate: 4%

- New Scrap Rate: 1%

- Reduction: 3%

- Total Monthly Production (New Rate):

1,440 cycles/hr * 4 bottles/cycle * 400 hrs/month = 2,304,000 bottles - Scrap Reduction (in bottles):

2,304,000 * 3% = 69,120 bottles - Assume a preform cost of $0.03.

- Monthly Savings from Scrap (S): 69,120 x $0.03 = $2,073.60

Savings from Energy and Labor

We can conservatively estimate this. Let's say the increased efficiency reduces energy and wasted labor costs by $200 per month.

- Monthly Operational Savings (O): $200

Now, we add up the monthly gains:

Total Monthly Gain (G) = P + S + O = $10,240 + $2,073.60 + $200 = $12,513.60

Step 3: Calculate the Payback Period

The final calculation is simple, but the result is powerful.

Payback Period (in months) = Total Initial Investment (I) / Total Monthly Gain (G)

Payback Period = $2,500 / $12,513.60 per month ≈ 0.199 months

What is 0.199 months? That is approximately 6 days. Yes, you read that correctly. Based on this calculation, your entire investment in the new high-performance mold can be paid back within the first week of production. This clearly shows that upgrading a mold is not a "cost" but one of the fastest, most direct-return investments you can make in your factory.

A "Supplier Switching" Checklist: 7 Advanced Questions to Ask a Potential Mold Partner?

You are ready to talk to new suppliers, but you want to go beyond the basic questions. How do you separate a truly expert mold maker from a standard machine shop?

Ask advanced questions. Inquire about their design process, material choices, cooling simulations, quality control procedures, and after-sales support. Their answers will reveal the true depth of their expertise and their suitability as a long-term partner for your business.

When you decide to source a critical component like a replacement PET blow mold from a new supplier, you are not just buying a product; you are starting a technical partnership. The quality of this partnership will directly impact your production for years to come. To ensure you choose the right partner, you need to ask questions that dig deeper than "How much does it cost?" and "How fast can you deliver?". You need to probe their processes, their philosophy, and their technical capabilities. These advanced questions are designed to test their expertise and see if they are a true specialist or just a general fabricator. Here are the seven questions I encourage all my clients to ask.

The Checklist: Questions to Identify a True Expert

Use this checklist during your initial calls or meetings with potential new mold makers. The quality and confidence of their answers will tell you everything you need to know.

| # | Question | What a Good Answer Looks Like | Red Flags |

|---|---|---|---|

| 1 | "Can you walk me through your mold design and validation process, from receiving my bottle drawing to final approval?" | They should describe a multi-stage process involving preform analysis, draft angle analysis, FEA simulation for material distribution, a formal cooling channel design phase, and a final assembly drawing for customer sign-off. They should mention specific software they use (e.g., Siemens NX, SolidWorks with MoldFlow). | "You send us the drawing, we make the mold." This indicates a lack of a rigorous, collaborative engineering process. |

| 2 | "What steel or aluminum alloys do you recommend for my specific application (bottle type, annual volume), and why?" | They should ask you about your expected annual volume and cycle time targets. They should be able to discuss the pros and cons of different materials like S136 stainless for durability vs. 7075 aluminum for high-speed applications. They should mention using Beryllium Copper for inserts. | "We use P20 steel for everything." This one-size-fits-all approach shows a lack of material science expertise. |

| 3 | "How do you design and verify the effectiveness of your mold's cooling system before manufacturing?" | A top-tier supplier will talk about using Computational Fluid Dynamics (CFD) or thermal simulation software to model heat transfer and water flow. They should talk about designing for turbulent flow and targeting specific cooling times. | "We drill as many lines as we can fit." This is a sign of guesswork, not engineering. |

| 4 | "What is your quality control process during manufacturing? What specific measurements and checks are performed?" | They should describe a detailed QC process, including CMM (Coordinate Measuring Machine) checks of all critical dimensions for cavities, hardness testing of materials, and surface finish verification. They should be able to provide a final QC report. | "Our machinists are very experienced." While experience is good, it's not a substitute for a documented, data-driven QC process. |

| 5 | "What spare parts do you recommend I keep in stock, and what is your procedure for ordering and delivering them?" | They should provide a recommended spare parts list (e.g., neck rings, seals, inserts) with the initial mold quote. They should have a clear system for quickly manufacturing and shipping dimensionally-guaranteed spare parts. | "Don't worry, our molds don't break." Or, "Just let us know if something goes wrong." This shows a lack of proactive planning for long-term maintenance. |

| 6 | "Can you provide case studies or references from clients running similar applications on my type of machine?" | A confident, experienced supplier will be happy to share (non-confidential) data on performance improvements or connect you with a current customer for a reference. This shows they have a track record of success. | Hesitation, inability to provide any examples, or vague claims without proof. |

| 7 | "What is your after-sales technical support process if we encounter issues during mold commissioning or operation?" | They should have a clear process, including a dedicated contact person, remote support via video call, and clear documentation. They should be able to explain how they help customers optimize machine parameters for the new mold. | "Just call our main number." This suggests a lack of a structured support system. |

Asking these questions fundamentally changes the dynamic of your conversation with a potential supplier. It shows that you are an educated buyer who values engineering excellence and long-term performance over a low initial price. The right partner will welcome these questions and be eager to demonstrate their expertise. The wrong partner will be evasive or unable to provide satisfactory answers. This checklist will give you the clarity and confidence to select a supplier who will be a true asset to your business.

Conclusion: Choosing Your Next Mold Isn't Just a Purchase, It's an Upgrade?

Moving from a bundled mold to a specialist-made one is more than a simple replacement. It's a strategic upgrade that boosts your efficiency, quality, and overall profitability for years.

Your next mold is a critical investment in your production's future. By choosing a specialized partner, you are not just buying a tool; you are upgrading your entire operational capability.

Frequently Asked Questions (FAQ)

1. Is it always cheaper to buy a PET blow mold from a specialized factory than from the original machine supplier?

Not always in terms of initial price. An OEM might offer a lower price for a bundled mold to make the machine package more attractive. However, a specialized factory provides a much higher value. The investment often results in a lower total cost of ownership due to significantly better performance, longer life, and higher efficiency. The ROI from a high-performance mold's faster cycle times and lower scrap rates means it quickly becomes the more profitable choice.

2. How do you guarantee that your custom mold will work perfectly with my existing machine, which is from a different brand?

We guarantee compatibility through a rigorous, multi-step process. First, we gather detailed technical data about your machine, including model number, mounting specifications, and photos. Second, we cross-reference this information with our extensive database of machine mounting dimensions from around the world. Finally, we provide you with a detailed mold assembly drawing for your final review and approval before any manufacturing begins. This process eliminates any risk of incompatibility.

3. What specific performance improvements (e.g., cycle time reduction in seconds) can I realistically expect from upgrading my mold?

The exact improvement depends on your current mold's quality and your bottle design, but realistic expectations are significant. For many clients, we see a cycle time reduction of 15-30%. For a 4.5-second cycle, a reduction to 2.5 seconds is entirely achievable. This is primarily achieved through advanced cooling design and the use of high-conductivity materials. Additionally, you can expect a reduction in scrap rate, often from 3-5% down to below 1%, and a marked improvement in wall thickness consistency and overall bottle quality.

4. What is the process for ordering an upgrade mold? What technical information do I need to provide about my current machine?

The process is collaborative and starts with a technical consultation.

- Initial Discussion: We discuss your goals, bottle design, and current production problems.

- Information Gathering: You will need to provide your detailed bottle drawing, preform drawing (or samples), and key information about your blow molding machine (manufacturer, model, number of cavities).

- Technical Verification: We will ask for specific machine dimensions (we provide a guide sheet) and photos to ensure a perfect fit.

- Quotation & Design: We provide a detailed quote. Upon agreement, our engineers begin the detailed mold design.

- Design Approval: You receive a final assembly drawing for your approval.

- Manufacturing & Delivery: We manufacture, test, and ship the mold.

5. What are the hidden costs or risks of continuing to use an old, underperforming "bundled" mold?

The hidden costs are substantial and accumulate over time. They include:

- Lost Revenue: Due to slower cycle times, you produce fewer bottles per shift, directly limiting your sales capacity.

- Wasted Material: Higher scrap rates mean you are literally throwing away money in the form of wasted PET resin.

- Excess Energy Consumption: Longer cycles mean your machine, air compressor, and chiller run longer to produce the same number of bottles, increasing your utility bills.

- Increased Labor Costs: Operators spend more time troubleshooting quality issues and dealing with mold problems instead of running production.

- Brand Damage: Inconsistent bottle quality (like uneven wall thickness leading to bottle failure) can lead to customer complaints and damage your reputation in the market.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

📲 WhatsApp: +86-13106288777

🚀 Let’s build your PET packaging project together!

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr