You're facing a tough choice for a new bottle mold. The quotes are in, but the price differences are huge. Is a cheaper mold really saving you money, or is it a hidden trap for future costs?

A high-quality bottle mold is not an expense; it's a profit-generating asset. The right bottle mold manufacturer delivers a tool that boosts your production efficiency, lowers scrap rates, and ultimately increases your return on investment (ROI) for years to come. This guide reveals the five key signs of such a partner.

It's easy to get lost comparing quotes from different plastic mold suppliers. Many focus solely on the initial price, but that number tells only a fraction of the story. I've seen companies choose the cheapest option only to face endless downtime, high defect rates, and maintenance nightmares that bleed money. The real value of a mold isn't in its purchase price, but in its performance over millions of cycles. Let's move beyond the price tag and explore what truly defines a top-tier mold making company that will genuinely improve your bottom line.

From Cost Center to Profit Center: Redefining Your Bottle Mold Investment?

Your budget is tight, and a low-cost mold seems like a smart financial move. But what if this initial saving leads to constant production headaches and hidden expenses down the line?

Investing in a high-quality mold from a reputable bottle mold maker transforms it from a simple cost into a core profit center. It's about shifting your mindset from short-term savings to long-term value creation and production efficiency.

For over 16 years, I've seen this scenario play out time and again. A client comes to me after a bad experience with a low-cost supplier. They were promised the world for a low price, but what they received was a mold that couldn't hold up. The material was subpar, the cooling was inefficient, and the parting lines were messy. The result? Their production line was constantly stopping for repairs, a high percentage of bottles had to be scrapped, and their energy costs were through the roof. They "saved" 20% on the initial purchase but lost far more in operational inefficiency within the first year.

This is why we must redefine how we view a custom blow mold. It’s not a disposable tool; it’s the heart of your production line. A superior mold, though potentially higher in initial cost, pays for itself many times over. It’s an investment in reliability, speed, and quality. A top-tier manufacturer understands this. They don't just sell you a piece of metal; they provide a solution engineered for maximum profitability. This article will walk you through the five undeniable hallmarks of a manufacturer who can deliver that kind of long-term value, helping you make an investment that generates returns instead of headaches.

The True Cost of a "Cheap" Mold

The initial price is just the tip of the iceberg. A poorly made mold introduces numerous hidden costs that accumulate over its lifespan.

- Increased Maintenance and Downtime: Low-quality materials and imprecise machining lead to frequent wear and tear. This means more time and money spent on repairs and more production downtime, which is often the biggest cost of all.

- Higher Scrap Rates: Inconsistent dimensions, poor venting, or flawed parting lines result in a higher percentage of defective bottles. Every scrapped bottle is a direct loss of raw material, energy, and production time.

- Lower Production Efficiency: Inefficient cooling channels are a common issue in cheap molds. This extends the cycle time for each bottle. In high-speed production where cycles are measured in seconds, any fractional delay results in massive output losses.

- Energy Inefficiency: A poorly designed mold may require higher clamping force or longer cooling times, leading to increased energy consumption from your bottle blowing machine and your industrial chiller.

Shifting to an Investment Mindset

Viewing your mold as a profit center means evaluating it based on its Total Cost of Ownership (TCO) and its potential to generate revenue.

| Factor | Low-Cost Mold (Cost Center) | High-ROI Mold (Profit Center) |

|---|---|---|

| Focus | Lowest initial price | Lowest cost per bottle produced |

| Lifespan | Short, 1-2 million cycles | Long, 5-10+ million cycles |

| Cycle Time | Slower, cannot match machine's best speed | Faster, optimized for efficiency |

| Quality | Inconsistent, higher scrap rate | Consistent, minimal scrap |

| Downtime | Frequent, unplanned stops | Minimal, scheduled maintenance |

| Supplier Role | Order taker | Engineering partner |

By investing in a high-ROI mold, you are buying uptime, speed, and quality. You are investing in a tool that will reliably produce millions of perfect bottles, allowing your business to grow without being held back by equipment failure. The conversation with your manufacturer should not be about "how cheap can you make it?" but "how can this mold make my operation more profitable?"

Hallmark 1: A Deep Commitment to Material Science, Not Just Material Grades?

You see "Imported Aluminum" or "S136 Steel" on a quote and assume it's good. But is that specific material truly the best fit for your bottle type, production volume, and end-use?

A top-tier bottle mold manufacturer doesn't just list material grades. They perform a scientific matching process, recommending the optimal combination of materials based on your specific needs—whether it's a standard water bottle or a corrosion-resistant chemical bottle—to ensure the best balance of performance and economy.

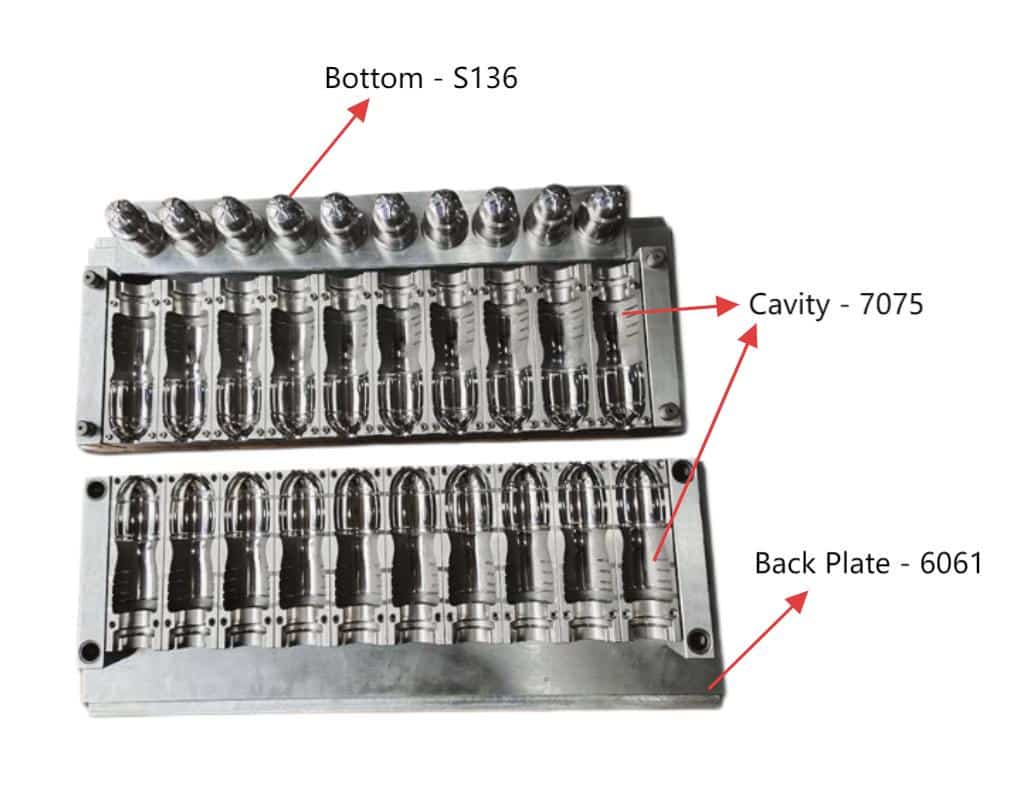

Any supplier can name the materials they use. But a true expert and partner goes much deeper. They act as a consultant, asking detailed questions about your production. For instance, standard PET water and beverage bottles prioritize maximum cooling efficiency to shorten the cycle time. In this case, aircraft-grade aluminum (like 7075) with its excellent thermal conductivity is the most cost-effective choice. It dissipates heat far more rapidly than steel, significantly boosting your production efficiency.

However, if you're producing bottles for 90°C hot-fill beverages or packaging for chemical products, the hardness and corrosion resistance of aluminum may not be sufficient for long-term use. A professional manufacturer will then explain why S136 stainless steel is necessary. Although it's more expensive and cools slower than aluminum, its superior corrosion resistance and high hardness ensure the mold maintains a high-polish finish in harsh production environments, leading to a much longer lifespan.

This application-based "material customization" is what separates an ordinary supplier from a professional partner. They don't just sell you a block of metal; they sell a well-thought-out production solution designed to create the most value for you.

Beyond the Name: How Material Choice Dictates Your Production Efficiency

Blow mold material selection is a balancing act between production efficiency, mold life, and cost. A professional manufacturer will clearly explain the pros and cons of different materials.

| Material Type | Key Properties | Best For | Why It Matters for ROI |

|---|---|---|---|

| Aircraft-Grade Aluminum (7075, 6061-T6) | Excellent thermal conductivity, lightweight, good machinability | Standard PET water/beverage bottles, medium-to-high volume | Boosts Efficiency: Superior heat transfer means faster cooling and shorter cycle times, directly increasing daily output. Lightweight nature simplifies mold installation and maintenance. |

| S136 Stainless Steel | High corrosion resistance, high hardness, excellent polishability | Hot-fill bottles, chemical/daily product bottles, PVC bottles, ultra-high volume | Ensures Quality & Lifespan: Resists corrosive materials; high hardness guarantees a very long life; achieves a perfect mirror finish, enhancing premium product appeal. |

| P20 Steel | Balanced properties, economical | Lower volume blow molding applications (e.g., HDPE), simpler bottle shapes | Balances Cost: Less expensive than S136, suitable for projects where extreme mold life or surface finish is not the top priority. An economical choice, but with lower thermal conductivity than aluminum. |

| Beryllium Copper (BeCu) Inserts | Thermal conductivity far superior to steel and aluminum | Complex areas requiring rapid cooling, like the base of the bottle | Ultimate Optimization: Used as inserts in critical areas (like base push-ups) to solve localized cooling issues, further reducing cycle time and improving bottle base quality. |

A top-tier manufacturer will analyze your bottle design to determine if embedding Beryllium Copper inserts in specific locations of an aluminum mold is necessary to overcome cooling "bottlenecks," thereby maximizing cycle time optimization. This deep, flexible understanding of material science is the foundation for ensuring you get the highest return on your investment.

Hallmark 2: An Engineering-First Approach to Design Optimization?

You have a final bottle design, so you just need a manufacturer to build the mold, right? But what if small, unseen design tweaks could make your production line 10% faster?

A great manufacturer doesn't just take your drawing and press "start." They act as your engineering partner, using advanced simulation and analysis to optimize the mold design for faster cycle times, lighter bottle weight, and superior performance.

The greatest value a bottle mold maker can provide is often before a single piece of metal is cut. This is where engineering excellence comes into play. Many suppliers are simply toolmakers; they will build exactly what you ask for. But an elite manufacturer is an engineering powerhouse. They scrutinize your bottle design not just for its looks, but for its manufacturability and efficiency. They see a bottle not as a static object, but as the result of a dynamic process involving heat, air pressure, and cooling.

I worked with a large beverage company that had an advanced high-speed blowing machine, but their old molds were creating a production bottleneck, preventing the machine from reaching its full potential. My engineering team didn't just replicate the old mold. We used CFD (Computational Fluid Dynamics) analysis to completely redesign the mold's cooling channels, especially optimizing heat dissipation in the bottle base. The new mold unlocked their machine's full capability, increasing their total production output by over 7%. That translated into millions of extra bottles per year, generating a massive return on their investment. This is the power of an engineering-first approach. It's about finding hidden opportunities for efficiency that you might not even know exist. For a deeper dive into this process, our PET bottle mold design guide is a great resource.

The Pillars of Engineering-Driven Mold Design

An engineering-first manufacturer uses a toolkit of advanced technologies to perfect your mold before it's built.

- Blow Simulation: This analysis predicts how the preform will stretch and form the final bottle shape, identifying potential thin spots or material distribution issues.

- Cooling System Optimization: The cooling phase is the most critical factor in a high-speed blow molding cycle. An expert engineer will design cooling channels that provide maximum, uniform cooling to the bottle surface. This is the single most important factor in reducing cycle time. Techniques include:

- Strategic Placement: Placing water channels closer to "hot spots" of the mold.

- High-Flow Design: Ensuring channel diameters and layouts allow for turbulent water flow, which is much more effective at removing heat.

- Conformal Cooling: Advanced designs where the cooling channels follow the exact shape of the bottle, providing unparalleled cooling efficiency. This is a key reason why a high-quality mold needs a dedicated chiller connection.

- Structural and Weight Optimization: Using Finite Element Analysis (FEA), engineers can analyze the stresses on a bottle during filling, stacking, and shipping. This allows them to remove unnecessary material (light-weighting the bottle) without compromising its structural integrity. Reducing bottle weight by even a fraction of a gram saves a significant amount on material costs over a production run of millions of units.

The Hot-Fill Challenge: A Case Study in Engineering

A powerful example of engineering expertise is in hot-fill bottle design, as I saw with a client from South Africa. They had two failed molds from other suppliers for their 90°C fruit juice. The first mold produced bottles that deformed after filling. The second produced bottles that didn't have enough volume. The problem was complex: hot-filling creates a vacuum as the product cools, which can collapse the bottle. Furthermore, PET plastic shrinks when heated.

Our engineering solution was multifaceted:

- Vacuum Panel Design: We designed special panels (negative windows) into the bottle body. These panels are engineered to flex inward as the vacuum forms, absorbing the pressure change and preventing the main body of the bottle from deforming.

- Shrinkage Compensation: Based on our experience, we knew exactly how much the PET would shrink. We calculated the required shrink ratio and designed the mold cavity to be slightly larger than the final desired bottle volume. After filling and cooling, the bottle shrank to the perfect size and volume.

This wasn't just about cutting metal. It was about applying a deep understanding of physics and material science to solve a complex production problem. That is the hallmark of a true engineering partner.

Hallmark 3: An Obsession with Precision in Machining and Finishing?

Every manufacturer claims they have "high precision." But what does that really mean for your final product? How does it affect the look and feel of your bottle on the shelf?

True precision is an obsession with micron-level tolerances. It's the combination of advanced machinery like 5-axis CNCs with the masterful craftsmanship of a polisher, ensuring perfect parting lines and a flawless finish that defines a premium product.

The difference between an average mold and a world-class mold often comes down to microns ($\mu m$). A micron is one-thousandth of a millimeter. To the naked eye, it's nothing. But in mold making, it's everything. This is where a manufacturer's commitment to quality is truly tested. It’s one thing to own a high-end 5-axis CNC machine; it's another to have the process, the people, and the culture to push that machine to its absolute limits of precision.

I always tell my clients to look at the details. Look at the parting line on a bottle. On a bottle from a superior mold, the line is almost invisible. It’s a clean, sharp seam. On a bottle from a mediocre mold, you'll see a noticeable ridge or even "flash"—a thin sliver of extra plastic that squeezed out. This flash is a direct result of imprecise machining where the two halves of the mold don't meet perfectly. This not only looks cheap but can also create sharp edges and requires a secondary trimming process, adding cost and time. This relentless pursuit of perfection in the physical manufacturing process is a non-negotiable hallmark of a top-tier mold making company.

The Technology of Precision

Achieving this level of quality requires a significant investment in technology.

- High-Speed 5-Axis CNC Machining: Unlike traditional 3-axis machines, a 5-axis machine can move a part or the cutting tool along five different axes simultaneously. This allows for the creation of highly complex shapes and contours in a single setup, which dramatically increases accuracy and reduces the chance of human error from repositioning the workpiece.

- Computer-Aided Manufacturing (CAM): Sophisticated CAM software translates the 3D design into precise instructions for the CNC machine. This ensures that the physical part is a near-perfect replica of the digital design.

- Coordinate Measuring Machines (CMM): After machining, a CMM is used for quality control. This device uses a highly sensitive probe to measure the geometry of the mold components down to the micron level, verifying that every dimension is within the specified tolerance.

The Craftsmanship of Finishing

Technology alone is not enough. The final surface of the mold cavity, which dictates the finish of your bottle, is often achieved through hours of skilled manual labor.

- Mirror Polishing: For products that require perfect clarity, like premium water or spirit bottles, the mold cavities must be polished to a mirror finish. This is an art form. A skilled technician will use a series of progressively finer abrasive compounds to meticulously polish the steel surface until it is flawless. Any tiny scratch or imperfection in the mold will be transferred directly to every bottle produced.

- Texturing: For matte finishes or intricate patterns, processes like chemical etching or laser texturing are used. Precision here is key to ensuring the texture is uniform and consistent across the entire mold surface.

- Parting Line Matching: The most skilled technicians spend hours manually fitting and "blueing" the two halves of the mold. They apply a special ink and press the halves together to identify high spots that are just microns off. These spots are then carefully stoned down until the fit is perfect. This painstaking process is what creates that invisible parting line.

A manufacturer who is truly obsessed with precision will proudly show you their quality control reports from their CMM and let you inspect their polished cavities. They understand that this dedication to the smallest details is what directly impacts the final "shelf appeal" and perceived quality of your product. It prevents common issues like PET blow molding defects and ensures your brand is represented perfectly.

Hallmark 4: A Transparent and Proactive Project Management Process?

You've placed your order, but now you're in the dark. Weeks go by with no updates, and you're left wondering if your project is on schedule or facing delays.

A top manufacturer provides more than just a mold; they provide peace of mind. They offer a transparent process with clear timelines, regular progress reports with photos and videos, and proactive communication to solve problems before they escalate.

This is often the biggest source of anxiety for clients, especially when working with an overseas supplier. The fear of the unknown can be stressful. Did they start machining yet? Did they encounter a problem? Is the project still on schedule for our product launch? A world-class bottle mold manufacturer understands this and builds their project management process around eliminating this uncertainty. They don't wait for you to ask for an update; they provide it proactively.

In my experience, transparency is the foundation of trust. At iBottler, we assign a dedicated project manager to every single mold build. Every week, without fail, that project manager sends the client a detailed progress report. This isn't just a one-line email saying "everything is fine." It's a structured update that includes:

- A percentage completion of each stage (design, rough machining, finish machining, assembly).

- High-resolution photos and short videos of their actual mold components being machined or assembled.

- A clear statement on whether the project is on, ahead of, or behind schedule. If it's behind, we provide an immediate explanation and a recovery plan.

This simple, consistent communication transforms the client experience. It removes anxiety and makes them feel like they are right there on the shop floor with us. It also fosters a collaborative environment. Once, during a progress update, a client noticed a small detail in a video of their mold core. It sparked a question about a potential change to the bottle's neck finish. Because we were in constant communication, we were able to address this early in the process, making a small adjustment that saved a huge headache later. Proactive management isn't a "nice to have"; it's an essential service.

Elements of a World-Class Project Management System

When evaluating a potential mold supplier, look for these specific project management practices.

| Process Element | What It Looks Like | Why It's Critical for ROI |

|---|---|---|

| Detailed Project Timeline | A Gantt chart or similar document provided at kickoff, outlining every major milestone from design approval to final shipment. | Sets clear expectations and provides a baseline to measure progress against. Prevents "schedule creep" that can delay your product launch. |

| Dedicated Point of Contact | A single project manager who speaks your language fluently and is responsible for all communication. | Prevents miscommunication and ensures you always know who to talk to. You get answers quickly without being passed around. |

| Regular, Scheduled Updates | Weekly or bi-weekly reports sent on a specific day, including visual evidence (photos/videos) of progress. | Builds trust and provides total transparency. You can visually confirm that your investment is being built to the right specifications. |

| Proactive Problem Solving | The supplier informs you of a potential issue and presents a proposed solution at the same time. | Shows ownership and expertise. It keeps the project moving forward instead of getting bogged down in finger-pointing or delays. |

| Digital Collaboration Tools | Use of modern platforms for sharing large design files, video conferencing, and tracking project milestones. | Makes remote collaboration seamless and efficient, which is crucial for international projects. |

The "No Surprises" Philosophy

Ultimately, a transparent project management process is about a "no surprises" philosophy. The final mold delivery should be a formality, not a moment of truth where you hope everything is correct. Throughout the entire process, you should feel informed, confident, and in control. This level of service separates the commodity suppliers from the true partners. It eliminates the risk and uncertainty from global sourcing and allows you to focus on what you do best: growing your business.

Hallmark 5: A "Partnership" Mindset for Long-Term Support?

Your new mold has arrived and is running. The transaction is over, right? But what happens in six months when a small component wears out, or you need help optimizing your process?

The best manufacturers don't see the sale as the end of the relationship. They see it as the beginning of a long-term partnership, offering comprehensive after-sales support, maintenance training, and strategic advice for the entire lifecycle of the mold.

The relationship with your mold maker shouldn't end when the final payment is made. A mold is a complex piece of equipment that will operate under intense pressure and high temperatures for millions of cycles. Wear and tear is inevitable. The critical question is: what happens when you need support? Will your supplier still be there for you? A manufacturer with a partnership mindset is focused on your long-term success, not just the initial sale. Their reputation is built on the performance of their molds years down the line.

I vividly recall a client in Mexico who bought a 12-cavity preform mold from us. About a year into production, they called us. One of the cavity inserts had been accidentally damaged by a new maintenance technician. Their entire production line was down. Because we view our clients as partners, we didn't just quote them a price for a new part. We had the CAD files and manufacturing records for their specific mold instantly accessible. We started machining a replacement insert that very same day and had it air-freighted to them within 72 hours. We also provided a video call with their maintenance team to walk them through the proper installation procedure. This is what a partnership looks like. It's about being responsive and reliable when your client needs you the most.

The Components of True Long-Term Support

After-sales support is more than just a warranty policy. It's a comprehensive system designed to maximize your mold's uptime and performance.

- Detailed Documentation and Training: A great partner provides a complete "owner's manual" for your mold. This includes:

- Final 2D and 3D mold drawings.

- A full Bill of Materials (BOM) with every component listed.

- A recommended spare parts list, categorized by wear-and-tear likelihood.

- Detailed instructions and videos on proper mold maintenance, disassembly, and assembly.

- Systematic Spare Parts Program: They don't just provide a list; they make it easy. They should keep critical data on file and be able to manufacture and ship standard wear parts (like seals and neck rings) quickly. Some even offer a consignment stock program for high-volume customers.

- Responsive Technical Support: When you have a problem, you need access to an expert who knows your mold. A partnership-focused company provides remote diagnostics via video call and has engineers available to help you troubleshoot issues with your process, not just the mold itself.

- Proactive Upgrade and Optimization Advice: As your business grows, your needs may change. A true partner keeps track of your mold's performance. They might contact you after a few years with suggestions for a new set of cores to produce a lighter-weight bottle or offer retrofitting services for a new design. They are actively thinking about how to improve your ROI over the long term.

Worrying about whether a new mold will fit your existing machinery is a common concern. A proactive partner addresses this early on. For instance, we maintain a massive library of mounting dimensions for over 80% of blow molding machines worldwide, ensuring a perfect fit from day one. This partnership mindset is the ultimate hallmark of a manufacturer who is invested in your success. They understand that if your production line is running smoothly and profitably, you will be a customer for life.

How These Hallmarks Directly Boost Your ROI?

You understand the signs of a quality manufacturer. But how do these abstract concepts like "engineering" and "partnership" translate into real, measurable dollars for your business?

Each of the five hallmarks directly impacts your bottom line by increasing revenue and decreasing costs. The connection is clear: better materials, design, precision, management, and support all lead to a significantly higher return on your investment.

The concept of Return on Investment (ROI) can sometimes feel abstract. Let's break it down into concrete financial benefits. When you invest in a mold from a top-tier manufacturer who embodies these five hallmarks, you are not just buying a piece of tooling. You are buying a more efficient, more reliable, and more profitable production system. The initial price difference between an average mold and a superior one is often insignificant when you look at the total value it creates over its lifetime.

Let's take the example of cycle time reduction again. On a high-speed production line, every action is measured in milliseconds. If a well-engineered mold can shave even a fraction of a second—say, 0.2 seconds—off a rapid cycle time, the impact is enormous. In a 24/7 operation, that translates to thousands, or even tens of thousands, of extra bottles per day. What is the profit margin on those extra bottles? Multiply that by 365 days, and the financial return becomes staggering. Suddenly, paying 20% more for the mold seems like one of the best business decisions you could have made. This is not a cost; it is a high-yield investment.

Connecting the Hallmarks to Financial Gain

This table clearly illustrates how each hallmark translates into tangible benefits that boost your ROI.

| Hallmark | Feature | Direct Impact on Operations | Tangible ROI Benefit |

|---|---|---|---|

| 1. Material Science | Using the right material (e.g., Aluminum for speed, Steel for life). | Cycle time reduced or mold lifespan dramatically extended. | Lower Cost Per Unit or Higher Revenue: Faster cycles boost output; longer life reduces capital cost per bottle. |

| 2. Engineering Design | Optimized cooling channels and structural analysis. | Cycle time reduced. Bottle weight minimized without losing strength. | Increased Revenue & Lower Material Cost: Faster cycles mean more units produced per day. Lighter bottles directly reduce resin costs. |

| 3. Precision Machining | Micron-level tolerances, perfect parting lines, mirror finish. | Near-zero scrap rate from flash or defects. Consistent bottle quality. | Reduced Waste & Higher Sell Price: Eliminates material loss from scrapped parts. Premium finish can command a higher price point. |

| 4. Project Management | Transparent communication and on-time delivery. | No production start-up delays. Predictable project timeline. | Faster Time-to-Market: You can launch your product and start generating revenue on schedule, avoiding costly launch delays. |

| 5. Partnership Support | Rapid spare part delivery and expert troubleshooting. | Minimized unplanned downtime. Faster recovery from maintenance issues. | Maximized Uptime: Less time spent waiting for parts or solutions means the production line is running and generating revenue more often. |

Ultimately, calculating the real ROI of a high-quality bottle mold requires you to look beyond the invoice. You need to factor in the gains from increased output, the savings from reduced waste and material usage, and the value of uninterrupted production. When you do the math, the conclusion is clear: investing in quality is the most profitable decision you can make.

The iBottler Standard: Where Expertise Meets ROI?

You've learned the five hallmarks of a top-tier mold manufacturer. Now, how do you find a partner who embodies all of them consistently?

The iBottler Standard is the practical application of these five principles. We combine deep material science, an engineering-first approach, precision obsession, transparent management, and a long-term partnership mindset to deliver molds that are not just tools, but powerful drivers of your profitability.

For over 16 years, I have dedicated my career to more than just making molds. My goal, and the core mission of iBottler, is to build partnerships that create tangible value for our clients. We have built our entire process around the five hallmarks discussed in this article because we have seen, time and time again, that they are the only path to delivering true, long-term ROI. Our standard is to be the engineering partner that helps you succeed, not just another supplier on a list.

We live by these principles every day. Our commitment to material science was demonstrated for our South African client with their hot-fill juice bottles. Our engineering-first approach is proven every time we reduce a client's cycle time or light-weight their bottle. Our obsession with precision is visible in the flawless finish and invisible parting lines of every mold we ship. Our transparent project management provides peace of mind to clients across the globe. And our partnership mindset means we are still there for you, years after the mold has been delivered.

Choosing a mold manufacturer is a critical decision that will impact your business for years. Don't let the initial price tag be the only factor. Look for the hallmarks of a true partner—one who is as invested in your production efficiency and profitability as you are.

Ready to invest in a mold that delivers real returns? Let's talk. Contact our team of experts today to discuss your project and discover how the iBottler Standard can transform your production.

Summary of Key ROI Drivers from a High-Quality Mold

| Hallmark | Key Action | Primary Benefit | Financial Impact |

|---|---|---|---|

| Material Science | Matching material (Aluminum or Steel) to the application. | Extended Mold Life or Shorter Cycle Time | Lowers capital amortization cost per unit or boosts output. |

| Engineering Design | Optimizing cooling and bottle structure. | Faster Cycle Time & Lighter Weight | Increases daily output and reduces raw material costs. |

| Precision Machining | Achieving micron-level accuracy and finish. | Near-Zero Defects | Eliminates scrap costs and improves brand image. |

| Project Management | Providing transparency and proactive updates. | On-Time Delivery | Enables faster market entry and revenue generation. |

| Partnership Support | Offering rapid response and long-term care. | Maximized Uptime | Reduces revenue loss from production stoppages. |

Frequently Asked Questions (FAQ)

Q: How does the choice of mold material directly impact my production cost over time?

A: The choice of mold material is one of the most critical factors in long-term production cost. For high-speed production of PET water or beverage bottles, aircraft-grade aluminum is often the best choice for its superior thermal conductivity. It allows for faster cooling, shorter cycle times, and more bottles produced per hour, which lowers the cost per unit. For applications like hot-fill or chemical products, durable and corrosion-resistant S136 stainless steel is required. While the initial cost is higher, it ensures the mold lasts for millions more cycles without degradation, which dramatically lowers the long-term capital cost amortized per bottle.

Q: What is "cycle time" and how can a better mold design reduce it?

A: Cycle time is the total time it takes to produce one batch of bottles. It includes closing the mold, blowing the bottle, cooling, opening the mold, and ejecting the bottle. In high-speed blow molding, the cooling phase is the most critical part of the cycle. A better mold design, created by an engineering-focused manufacturer, incorporates highly efficient cooling channels. By using simulations to place these channels strategically, they can extract heat from the plastic much faster. Reducing the cooling time, even by a fraction of a second, directly reduces the overall cycle time, allowing you to produce significantly more bottles per day and directly increasing your revenue.

Q: Is a more expensive mold always a better investment?

A: Not necessarily, but a mold that is engineered for high performance and longevity often has a higher initial price. The key is to look at value, not just price. A mold might be more expensive because it uses the correct material for the job (e.g., S136 steel instead of aluminum for a corrosive product), has a complex and highly efficient conformal cooling system, and has undergone hours of precision polishing. While its price tag is higher, this mold will run faster, last longer, and create less scrap. Conversely, a cheap mold can become a "money pit" of repairs and downtime. The best investment is the mold that delivers the lowest Total Cost of Ownership (TCO).

Q: How do I calculate the real ROI of a high-quality bottle mold?

A: Calculating the real ROI requires looking beyond the purchase price. A simplified formula is: ROI = (Gain from Investment - Cost of Investment) / Cost of Investment. The "Gain from Investment" includes multiple factors:

- Increased Revenue: (Extra bottles per day due to faster cycle time) x (Profit per bottle) x (Production days per year).

- Material Savings: (Grams saved per bottle) x (Number of bottles produced) x (Cost per gram of resin).

- Reduced Scrap Costs: (Reduction in scrap rate %) x (Total production volume) x (Cost per bottle).

- Downtime Savings: (Hours of downtime avoided) x (Cost of downtime per hour).

When you add all these gains together and compare them to the initial cost difference, you'll often find that a high-quality mold pays for itself very quickly.

Q: What kind of information do you need from me to start a mold design discussion?

A: To have a productive first discussion, it's helpful to prepare some key information. The more you can provide, the better we can understand your project and offer valuable insights. Here’s a good starting list:

- Bottle Drawing or Sample: A 3D file (STEP or IGS) is ideal, but a 2D drawing or even a physical sample works too. Our 3D printed samples can also be a great starting point.

- Bottle Material: Are you using PET, PP, HDPE, etc.?

- Bottle Application: What will the bottle hold? (e.g., water, CSD, hot-fill juice, chemicals).

- Target Bottle Weight: Do you have a specific weight in grams you are aiming for?

- Estimated Annual Production: How many bottles do you plan to produce per year? This helps determine the required mold cavitation and material type.

- Your Blow Molding Machine: The brand and model of your machine, so we can ensure the mold's mounting dimensions are a perfect match.

- Preform Information: If you already have a preform supplier, the preform drawing and weight are very important. We can also help you with preform neck size selection.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr