Starting a PET bottle production line feels overwhelming. You face complex machinery choices and a long list of confusing equipment. You worry about missing a critical component.

This ultimate checklist provides a clear, step-by-step guide to every piece of equipment you need. We will cover everything from the main machine to essential utilities, ensuring you are fully prepared and confident in your investment.

Setting up a new production line is a major project. It involves more than just buying a single machine. It's about creating a complete system where every part works together perfectly. Many people focus only on the main blow molding machine and forget the critical support systems. This guide will walk you through the entire process. We will look at each piece of equipment, one by one. This will help you understand its function and why it's important. My goal is to give you the knowledge to build a reliable and efficient production line from day one.

The Heart of Your Line: PET Blow Molding Machine & Molds?

Choosing your main production machine is a huge decision. It feels like the entire project's success rests on this single choice. The options seem endless and technical.

The core of your operation is the PET blow molding machine and its corresponding blow bottle molds. Your choice here directly impacts production speed, bottle quality, and operational cost. Select a machine that matches your output needs and a mold made from high-quality steel for longevity.

This is where the magic happens. The preform is heated and then blown into its final shape inside the mold. The machine and mold work together as a single unit. Getting this combination right is the most critical step in your entire setup process. I've seen many new businesses make mistakes here. They either buy a machine that is too big for their needs or too small to keep up with demand. Or they try to save money on the mold, which often leads to bigger problems later. Let's break down the details so you can make an informed decision.

Diving Deeper into Your Core Production Unit

The selection process for your main machine and molds requires careful thought. This combination dictates your production capacity, efficiency, and the quality of your final product. Let's explore the key factors you need to consider.

Choosing the Right Blow Molding Machine

Your first major decision is the type of blow molding machine. The main choice is between fully automatic and semi-automatic models.

- Fully Automatic Machines: These machines integrate preform feeding, heating, and blowing into one continuous, automated process. They are ideal for high-volume production. They require minimal operator intervention, which reduces labor costs and increases consistency.

- Semi-Automatic Machines: With these machines, an operator manually loads the heated preforms into the blowing station. They are a great entry-level option for startups, small-batch production, or custom bottle manufacturing. The initial investment is lower, but the output is dependent on the operator's speed and consistency.

Another critical factor is the drive system. Modern machines often use servo motors instead of traditional pneumatic or hydraulic systems.

| Drive System | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Servo | High precision, energy-efficient, low noise, fast | Higher initial investment | High-speed, high-precision applications |

| Pneumatic | Lower cost, simple mechanics | Higher energy consumption, noisier operation | Entry-level or less demanding applications |

From my experience, the energy savings from a servo-driven machine can often justify the higher initial cost over a few years of operation, especially in regions with high electricity prices. It also gives you much finer control over the stretching and blowing process, which is essential for lightweight or complex bottle designs.

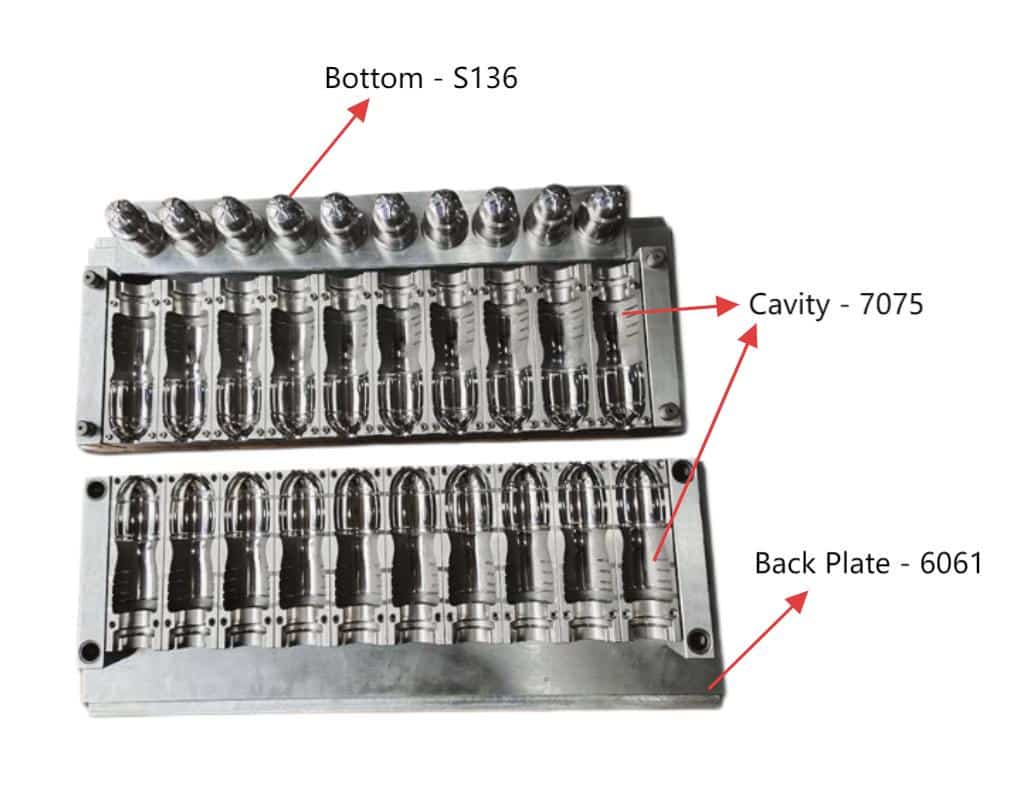

The Unsung Hero: Your PET Bottle Mold

The mold is just as important as the machine. A top-quality machine with a poorly made mold will produce nothing but scrap. As a client from Mexico once told me, "At first, I only focused on the machine price, but you advised me to upgrade the mold steel. Two years later, the machine is still running smoothly, while the cheaper mold on another line has been repaired three times." This proves that investing in your mold provides the highest long-term return.

Here’s what to look for in a mold:

- Number of Cavities: This determines how many bottles you produce in each cycle. A 4-cavity mold will produce four bottles at a time. The more cavities, the higher your output. However, the machine must have enough clamping force to handle the larger mold.

- Mold Material: The choice of material affects the mold's lifespan and the bottle's finish.

- S136 Stainless Steel: This is the premium choice. It's highly corrosion-resistant, which is great for humid environments. It can be polished to a mirror finish, resulting in crystal-clear bottles. It’s also very durable, perfect for high-volume production.

- 7075 Aircraft-Grade Aluminum: This material is excellent for prototyping or short production runs. It's easier to machine, so the lead time is shorter and the cost is lower. However, it's not as durable as steel.

- P20 Steel: A common, cost-effective choice for general-purpose molds. It offers a good balance of durability and cost but lacks the high polish and corrosion resistance of S136.

It is absolutely vital to ensure your chosen mold can be correctly installed on your machine. I always stress this point. We have compiled a comprehensive database of mounting dimensions for over 80% of blow molding machines worldwide to guarantee a perfect fit for our clients. There's nothing worse than receiving a new mold that you can't even mount on your machine.

The Starting Point: Preform Feeding & Heating System?

You have your main machine, but how do you get the raw materials into it? An inefficient feeding system can cause constant stops and ruin your production flow.

This system prepares the PET preforms for blowing. It consists of a preform hopper and elevator, an unscrambler to orient the preforms, and a heating oven. A stable, evenly heated preform is the foundation for a high-quality bottle.

Think of this stage as warming up before a race. If the warm-up isn't right, the final performance will suffer. The same is true for bottle blowing. Uneven heating is one of the most common causes of defects like inconsistent wall thickness or hazy spots. This initial stage is often overlooked, but its importance cannot be overstated. Let's look at each component of this critical system.

Diving Deeper into Preform Preparation

Stable and uniform preform heating is the prerequisite for blowing a qualified bottle. A well-designed heating oven, equipped with independent controls for multiple temperature zones, can significantly reduce the scrap rate. This is especially true when producing special-shaped or thick-walled bottles. I consider this one of the most easily overlooked yet crucial parts of the entire line.

The Components of the System

The feeding and heating system is not just one machine, but three components working in sequence:

Preform Hopper & Elevator: This is where the journey begins. Preforms are loaded in bulk into a large hopper at ground level. A cleated conveyor belt, or elevator, then transports them up to the next stage. The key here is a smooth, gentle transfer to avoid scratching or damaging the preforms. A variable speed control on the elevator is a valuable feature, allowing you to match the feeding rate to the machine's production speed.

Preform Unscrambler (Sorter): Once elevated, the preforms are dropped into a sorting mechanism. The unscrambler’s job is to orient all the preforms so they are facing the same direction, typically neck-up, before feeding them onto a rail that leads to the oven. An efficient unscrambler is essential for preventing jams and ensuring a continuous flow of preforms to the heating unit. In my experience, a poorly designed sorter is a common bottleneck that can bring a high-speed line to a halt.

Heating Oven (Heating Tunnel): This is the most technically critical part of the pre-blowing stage. Inside the oven, preforms travel past a series of high-intensity infrared (IR) lamps. The goal is to heat the preform body to the ideal molding temperature (typically around 100-120°C) while keeping the neck thread cool and stable.

Critical Features of a High-Quality Heating Oven

A modern, efficient oven will have several key features:

- Multiple Heating Zones: The oven should be divided into several zones, each with its own independent temperature control. This allows you to create a precise heating profile, applying more or less heat to different sections of the preform body as needed. This is crucial for achieving the desired material distribution in the final bottle. For example, the base of the preform often requires more heat than the upper body.

- Effective Ventilation: As the lamps heat the preforms, they also generate a lot of ambient heat. A good ventilation and cooling system is vital for two reasons. First, it protects the preform necks from deforming by directing a flow of cool air or chilled water across them. Second, it removes excess heat from the oven to maintain a stable environment and protect the lamps and internal components.

- Preform Rotation: The preforms must rotate as they travel through the oven. This ensures that all sides of the preform are heated evenly. Without proper rotation, you will have hot spots on one side and cold spots on the other, leading to inconsistent wall thickness in the blown bottle.

The choice of preform itself is also part of this system. The design, weight, and especially the neck size of the preform must be perfectly suited to your final bottle design and the heating capabilities of your oven.

The Powerhouse: Choosing Your Air Compressor System?

Your blow molding machine needs compressed air to function, but what kind? Choosing the wrong air system can lead to high energy bills and poor bottle quality.

You need a clean, stable supply of compressed air. There are two main setups: a traditional high and low-pressure combo, or a modern, integrated high-pressure system. Your choice depends on factory space, budget, and machine type.

Compressed air is the lifeblood of the blowing process. It's what shapes the bottle. But not just any compressed air will do. It needs to be at the right pressure, and it must be incredibly clean and dry. Any oil or moisture in the air can ruin your bottles and damage your machine. This is why the air compressor system is not just an accessory; it's a fundamental part of your production line. Let’s compare the two leading solutions.

Diving Deeper into Compressed Air Solutions

The blowing process requires two distinct types of compressed air. Low-pressure air (around 10-12 bar) is used to power the machine's pneumatic actions, like opening and closing the mold and operating cylinders. High-pressure air (from 30-40 bar) is used for the final blowing of the bottle. The market currently offers two mainstream configurations to meet this need.

Option A: Traditional High & Low-Pressure Combo

This is the classic, time-tested setup. It consists of two separate compressors working together.

- Configuration:

- One low-pressure screw air compressor (10-12 bar) to supply the machine's actions.

- One high-pressure piston booster or compressor (30-40 bar) specifically for blowing.

- A complete set of air storage tanks, refrigerated dryers, and precision filters for both pressure levels.

- Advantages:

- Mature Technology: This system has been used for decades and is well understood by technicians.

- System Flexibility: You can independently control and manage the low-pressure and high-pressure air circuits. If one compressor needs maintenance, the other might still be usable for certain tasks.

- Disadvantages:

- Larger Footprint: You need space for two compressors, two sets of tanks, and two sets of dryers/filters.

- More Complex Installation: The piping is more extensive, connecting two separate systems to the blow molder.

Option B: Integrated High-Pressure System

This is a more modern and streamlined approach, made possible by advancements in machine design.

- Configuration:

- One single high-pressure compressor (30-40 bar).

- A single set of air storage tanks, dryers, and filters for the high-pressure air.

- How it Works: The single high-pressure line is fed to the blow molding machine. Modern fully automatic machines have integrated pressure-reducing valves. The machine automatically taps into the high-pressure line and reduces it to a stable low pressure internally to supply its own actions.

- Advantages:

- Smaller Footprint: This system takes up significantly less floor space.

- Simplified Management: You only need to purchase and maintain one compressor system.

- Lower Initial Investment: The overall cost for one compressor and simplified piping is often lower.

I remember a startup client from Southeast Asia whose factory space was very limited. We recommended the "Integrated High-Pressure System" for him. It not only saved nearly 5 square meters of space compared to the traditional plan but also reduced the initial investment in piping. This experience taught me that the best solution is not always the same; it's the one that best fits your actual situation. You can read more about this in our cost-efficient air system guide.

Air Purity is Non-Negotiable

Regardless of the system you choose, air treatment is essential. A standard air treatment package includes:

| Component | Function |

|---|---|

| Air Receiver Tank | Stores compressed air, smooths out pressure fluctuations. |

| Refrigerated Air Dryer | Cools the air to condense and remove water vapor. |

| Pre-Filter | Removes larger solid particles and some water droplets. |

| Coalescing Filter | Removes fine oil aerosols and smaller particles. |

| Activated Carbon Filter | Removes any remaining oil vapor and odor, delivering pure air. |

Investing in proper air treatment protects your machine's sensitive pneumatic components from premature wear and ensures your PET bottles are free from contamination.

Keeping Cool: The Industrial Water Chiller System?

Your machine is running, but it's getting hot. Overheating can damage equipment and cause defects in your bottles, forcing you to slow down or stop production entirely.

An industrial water chiller is essential for temperature control. It circulates cool water to the mold and the machine's hydraulic system. This ensures consistent bottle quality, faster cycle times, and a longer lifespan for your equipment.

Heat is the enemy of stable production. The blow molding process generates a significant amount of heat, both from the machine itself and from the hot preforms entering the mold. If this heat isn't removed effectively, the mold temperature will rise. This can lead to a host of problems. A dedicated chiller system isn't a luxury; it's a necessity for any serious production line.

Diving Deeper into Cooling Systems

A stable mold temperature equals stable bottle quality and faster production cycles. Based on my 20 years of experience, many problems with bottle haze at the bottom or a lack of clarity in the body can be traced back to an insufficient cooling capacity or an unstable water temperature from the chiller. You must accurately match the cooling capacity to the machine model and your ambient factory temperature. This is why we have a detailed article explaining why PET blow molds need a chiller.

The Dual Role of the Chiller

The industrial water chiller serves two primary functions in a PET bottle production line:

- Mold Cooling: This is its most critical job. After the hot preform is blown, the mold must rapidly cool the newly formed bottle so it solidifies and can be ejected without deformation. Effective cooling is key to achieving fast cycle times. If the cooling is too slow, you have to extend the cycle time, which directly reduces your output. It also ensures the final properties of the PET material, like its clarity and strength, are optimal.

- Machine Cooling: Many blow molding machines, especially those with hydraulic systems, have an oil cooler. The chiller circulates water through a heat exchanger to keep the hydraulic oil at its optimal operating temperature. Overheated oil can lose its viscosity, leading to sluggish machine performance and potential damage to hydraulic components.

How to Select the Right Chiller

Choosing a chiller is not a one-size-fits-all situation. The main factor you need to determine is the required "cooling capacity," usually measured in tons or kilowatts (kW).

Calculating Cooling Capacity: A rough rule of thumb is to allocate 1 ton of cooling capacity for every 20-30 kg of PET processed per hour. However, a more precise calculation should be made by your equipment supplier. They will consider:

- The machine's maximum plasticizing capacity (kg/hr).

- The specific heat of PET material.

- The temperature difference between the molten plastic and the desired ejection temperature.

- The ambient temperature of your factory.

Air-Cooled vs. Water-Cooled Chillers: You also have a choice in how the chiller itself dissipates the heat it removes from your process.

| Chiller Type | How it Works | Pros | Cons |

|---|---|---|---|

| Air-Cooled | Uses fans to blow ambient air over a condenser coil to release heat. | Easy to install, self-contained, no cooling tower needed. | Less efficient in very hot climates, can add heat to the factory. |

| Water-Cooled | Circulates water to a separate cooling tower where heat is released via evaporation. | More energy-efficient, not affected by high ambient air temps. | Higher initial cost, requires a cooling tower and more complex plumbing. |

For most small to medium-sized PET blowing operations, an air-cooled chiller is the more common and practical choice due to its simplicity and lower initial setup cost.

Incorrect cooling is a direct cause of many common bottle problems. If you're seeing issues, it's often the first place to look. We've compiled a guide on how to fix common PET blow molding defects, and many solutions point back to optimizing the cooling process.

The Finishing Touches: Bottle Conveying & Leak Testing?

You are producing beautiful bottles, but how do you move them efficiently and ensure none are defective? Dropping them into a cardboard box is inefficient and risks contamination and damage.

You need an automated system for post-production handling. An air conveyor gently transports finished bottles to the next stage. An online leak tester automatically inspects every single bottle for microscopic holes, protecting your quality standard.

The work isn't done when the bottle is ejected from the machine. Getting the finished product from the blow molder to your storage or filling area requires a gentle and clean method of transport. Furthermore, you need a reliable way to check the integrity of every bottle. A single bottle with a pinhole leak can cause problems for your customers and damage your brand's reputation. This final stage is about quality assurance and efficiency.

Diving Deeper into Post-Mold Operations

These final steps are what separate a basic operation from a professional, high-quality production facility. They ensure the bottles you've worked so hard to produce are handled correctly and meet stringent quality standards.

Gentle Transport: The Air Conveyor

Once a bottle is ejected from the blow molding machine, the most common way to transport it is using an air conveyor.

- How it Works: The system consists of a neck guide rail and a plenum chamber with fans. The bottles hang by their neck rings on the guides. The fans generate a flow of filtered air inside the chamber, which pushes against the body of the bottles, propelling them smoothly along the track.

- Key Advantages:

- Hygienic: Since only the neck ring is touched by the guide rail, the body of the bottle remains untouched, which is critical for food and beverage applications.

- Flexible: Air conveyors can be easily routed around obstacles, elevated overhead to save floor space, and can span long distances. The speed is adjustable to match the output of the blow molder and the input of the next machine in the line (like a filler or a packer).

- Gentle Handling: The air cushion provides very gentle transport, preventing scratches or dents on the finished bottles.

The design of the air conveyor, especially the guide rails, needs to be matched to the specific neck finish of your bottles to ensure stability and smooth movement.

Quality Gatekeeper: The Online Leak Tester

An online leak tester is your investment in brand reputation. It can automatically check 100% of your products for microscopic holes and reject any defective ones, ensuring that every bottle leaving your factory is perfect. For clients who produce high-end products or are highly brand-conscious, this is a must-have.

- How it Works: Leak testing machines typically operate using the pressure decay method.

- A testing head descends and creates a perfect seal on the bottle's opening.

- A precise amount of pressurized air is injected into the bottle.

- The pressure inside the bottle is monitored for a very short period (fractions of a second).

- If there is a leak, the pressure will drop. The machine's sensor detects this drop and triggers a rejection mechanism (usually an air jet) that pushes the faulty bottle off the line.

- Why It's Critical:

- Protecting End-Users: For beverage or food products, a leak can compromise the product's sterility and safety.

- Preventing Filling Line Issues: Leaky bottles can cause spills and messes on an automated filling line, leading to costly downtime for cleaning.

- Maintaining Brand Trust: Shipping a product in a container that leaks creates a very poor customer experience and erodes trust in your quality.

While it is an additional investment, the cost of a single product recall or a damaged customer relationship is far greater than the cost of an online leak tester. It's the final quality check that provides peace of mind.

Essential Utilities: Power Supply & Water Piping?

Your new equipment is arriving soon, but your factory isn't ready. The wrong voltage or inadequate water supply can cause major delays and expensive modifications.

Before any equipment is delivered, you must prepare your factory's infrastructure. This includes ensuring you have the correct industrial voltage, sufficient total power capacity, and properly installed piping for the cooling water system.

This is the foundational work that has to be done right the first time. I've seen customers get excited about their new machines, only to face weeks of delays because the basic utilities were not correctly prepared. Getting these details right from the start will ensure a smooth and fast installation process. Think of it as building the foundation of a house before you put up the walls.

Diving Deeper into Factory Infrastructure

This is the behind-the-scenes work that is absolutely crucial for a successful startup. Neglecting these details can lead to severe consequences, from damaged equipment to safety hazards.

Electrical Power Supply

Getting the power supply right is a non-negotiable safety and operational requirement.

- Voltage, Frequency, and Phase: This is the most critical piece of information. You must confirm the exact electrical specifications of your factory and communicate them to your equipment supplier before signing any contract.

- Voltage: Different countries and regions use different industrial voltages (e.g., 380V, 415V, 220V, 480V).

- Frequency: Usually 50Hz or 60Hz.

- Phase: Industrial machinery typically requires a 3-phase supply.

I cannot stress this enough. As I always tell my clients, remember to double- and triple-check your factory's voltage and hertz with the supplier! This is a mandatory confirmation item in our process because incorrect electrical parameters will prevent the equipment from being used, and the subsequent modification costs are extremely high.

- Total Power Load: You need to calculate the total power consumption (in kW) of all the equipment running simultaneously—the blow molder, air compressors, chiller, conveyor, lighting, etc. Your main electrical panel and the wiring from the grid to your factory must be able to handle this total load safely. It's wise to plan for at least 20-25% extra capacity for future expansion.

- Power Stability: In some areas, the power grid may be unstable, with voltage fluctuations. These fluctuations can damage sensitive electronic components in modern machines. If this is a concern, you may need to invest in an industrial voltage stabilizer.

Water Piping and Circulation

This network of pipes is the circulatory system for your chiller.

- Closed-Loop System: The most efficient setup is a closed loop. Water flows from the chiller to the blow molding machine (and mold), absorbs heat, and then flows back to the chiller to be cooled and recirculated. This system minimizes water consumption and keeps the cooling water clean.

- Piping Material and Diameter: The pipes connecting the chiller and the machine must be of the correct diameter to ensure adequate water flow. The manufacturer will specify this. Common materials include PPR, PVC, or stainless steel, depending on the pressure and temperature requirements.

- Layout and Installation: Pipes should be laid out to be as short and direct as possible to minimize pressure loss. They should be properly insulated, especially the "cold" line going to the machine, to prevent condensation ("sweating") and maintain cooling efficiency.

Here is a simple pre-installation checklist for your utilities:

| Utility | Checklist Item | Status |

|---|---|---|

| Power | Confirmed factory voltage/frequency/phase with supplier (e.g., 380V/50Hz/3Phase). | ☐ Pending |

| Calculated total kW load for all equipment. | ☐ Pending | |

| Main panel and wiring rated for total load + 25% future capacity. | ☐ Pending | |

| Considered need for a voltage stabilizer. | ☐ Pending | |

| Water | Chiller location determined. | ☐ Pending |

| Piping route planned for minimal distance. | ☐ Pending | |

| Correct diameter pipes and fittings procured. | ☐ Pending | |

| Insulation for piping procured. | ☐ Pending | |

| Air | Compressor and dryer location determined. | ☐ Pending |

| Air piping route planned to the blow molding machine. | ☐ Pending |

Completing this checklist before the machines arrive will save you an immense amount of time and money.

A Complete Overview: Your Checklist in a Table?

You've learned about all the individual components. But how do you keep track of everything and compare offers from different suppliers? It's easy to lose sight of the big picture.

Here is a comprehensive checklist table. It summarizes every key piece of equipment, its function, and a key selection tip. You can use this to ensure no critical component is missed when planning your investment.

.png)

This table is your master plan. It brings everything we've discussed together into one easy-to-read format. I advise my clients to use this checklist when they receive quotes from different suppliers. It helps you compare apples to apples. You can clearly see where the differences in the quotes are, ensuring you don't pay for features you don't need or, more importantly, miss any essential equipment. This tool empowers you to have a more detailed and effective conversation with potential suppliers.

Diving Deeper into Your Master Checklist

Using a structured checklist is a professional approach to procurement. It helps you move from a general idea to a specific, actionable plan. It forces you and your suppliers to be detailed and transparent. When you request a quote, you can attach this list and ask them to provide specifications and pricing for each item. This structured approach simplifies the decision-making process. For example, when you are deep into the details, you may want to consult a comprehensive PET bottle mold design guide to ensure your core product is perfectly planned.

Here is the master checklist for your PET bottle production line:

| Equipment Category | Specific Item | Function | Key Selection Tip |

|---|---|---|---|

| 1. Core Production | PET Blow Molding Machine | Heats preforms and blows them into the final bottle shape. | Choose automation level (Full vs. Semi) and drive system (Servo vs. Pneumatic) based on your production volume and budget. |

| PET Bottle Mold | The tooling that forms the shape of the bottle. | Select mold steel (S136 for durability, 7075 for prototyping) and cavity count based on quality needs and output goals. | |

| 2. Preform Handling | Preform Hopper & Elevator | Stores and transports preforms in bulk to the unscrambler. | Ensure gentle handling to prevent scratches on the preforms. A variable speed motor is a plus. |

| Preform Unscrambler / Sorter | Orients preforms correctly (neck-up) before they enter the heating oven. | A reliable unscrambler is key to preventing jams and maintaining a continuous production flow. | |

| Heating Oven / Tunnel | Heats preforms to the optimal, uniform temperature for blowing. | Look for multiple, independently controlled heating zones and effective neck cooling. | |

| 3. Auxiliary Systems | High-Pressure Air Compressor | Provides high-pressure air (30-40 bar) to stretch and blow the preforms. | Must be oil-free. Sizing (m³/min) must match the machine's consumption. |

| Low-Pressure Air Compressor | Provides low-pressure air (10-12 bar) for machine movements (or use an integrated high-pressure system). | If using a combo system, ensure it's sized correctly for all pneumatic actions. | |

| Air Receiver Tanks (High & Low) | Store compressed air to buffer against pressure drops during peak consumption. | Tanks must be certified pressure vessels. Size them to handle at least 30 seconds of air consumption. | |

| Air Dryer (Refrigerated) | Removes moisture from the compressed air to prevent condensation and contamination. | Essential for both high and low-pressure lines to protect equipment and ensure bottle quality. | |

| Air Filters (Pre, Coalescing, Carbon) | Removes dust, oil, and vapor from the air to ensure it is perfectly clean. | A multi-stage filtration system is required for food-grade production. | |

| Industrial Water Chiller | Circulates chilled water to cool the mold and the machine's hydraulic oil. | Cooling capacity (tons or kW) must be accurately calculated based on machine size and ambient temperature. | |

| 4. Post-Production | Air Conveyor | Transports finished bottles from the blow molder using a cushion of air. | Hygienic and gentle. The design must match your bottle's neck ring. |

| Online Leak Tester | Automatically checks every bottle for pinhole leaks and rejects defective ones. | A critical quality assurance tool to protect your brand and your customers. | |

| 5. Infrastructure | Electrical Wiring & Panels | Provides the correct and stable power to all equipment. | Double-confirm Voltage/Hz/Phase with your supplier before ordering. |

| Water Piping & Insulation | Creates a closed loop for chilled water between the chiller and the machine. | Use correctly sized, insulated pipes to maintain efficiency and prevent condensation. |

This checklist is the foundation of your project plan. Review it carefully, and use it to build the perfect production line for your business.

Beyond the Checklist: Let Us Build Your Turnkey Solution?

You have the checklist, but sourcing each item, ensuring compatibility, and managing the installation is a massive project. It can feel like a full-time job on its own.

A turnkey solution from an experienced partner is the answer. We provide everything on the checklist and manage the entire project, from design to installation and training, delivering a fully operational production line.

Building a production line is a complex systems engineering project. If you want to skip the tedious process of matching and purchasing equipment and focus on your market, then a "turnkey" solution is the most efficient choice. We take responsibility for handing over a "bottle workshop" that can produce smoothly. This approach saves you time, reduces risk, and gets you to market faster.

Diving Deeper into the Turnkey Advantage

A turnkey project is a partnership. It's about leveraging our experience as equipment specialists so you can focus on your expertise: marketing and selling your product. We handle the technical complexities from start to finish.

What Does a Turnkey Solution Include?

When you choose a turnkey solution with us, you are getting more than just machines. You are getting a complete, integrated system and a comprehensive service package.

Consultation and Design: We start by understanding your goals. What kind of bottles do you want to make? What is your target production volume? What is your factory space like? Based on this, we design a complete line layout, optimizing the flow of materials and people for maximum efficiency. We can even help you rapidly validate your bottle ideas by going from 3D printed samples to production molds.

Equipment Sourcing and Integration: We select and provide every single piece of equipment from the checklist. Because we source everything, we guarantee 100% compatibility between all components. The blow molder will work perfectly with the compressor, the chiller will be correctly sized for the mold, and all the conveyors will connect seamlessly.

Project Management: You will have a single point of contact for the entire project. You don't need to coordinate with a dozen different suppliers, shipping companies, and technicians. We manage the entire timeline, from manufacturing and delivery to installation.

Installation and Commissioning: Our team of experienced engineers will come to your site to install and commission the entire line. We connect all the machines, run the power lines, hook up the water and air pipes, and test everything to ensure it runs smoothly and meets the specified production targets.

Training: We don't just leave you with a running machine. We provide comprehensive training for your operators and maintenance staff. They will learn how to run the line efficiently, perform routine maintenance, and troubleshoot common issues.

The True Value of a Turnkey Solution

The benefits go beyond just convenience.

| Benefit | Description |

|---|---|

| Reduced Risk | Compatibility issues are eliminated. The responsibility for making the entire system work lies with one supplier: us. |

| Faster Time-to-Market | The entire process is streamlined. With experienced project management, we can get your line up and running much faster than if you were coordinating it yourself. |

| Cost-Effectiveness | While the initial quote might seem higher than buying individual pieces, you save on hidden costs like project management time, troubleshooting, and potential delays. |

| Simplified After-Sales | If you have a problem, you make one phone call. You don't have to figure out if the issue is with the machine, the compressor, or the chiller. We support the entire system. |

Choosing a turnkey solution is an investment in efficiency and peace of mind. It allows you to launch your business with confidence, knowing that the technical foundation of your operation is solid, integrated, and fully supported.

Conclusion

Building a PET bottle line requires a complete system, not just one machine. From the blow molder to the air and water utilities, every part is critical for success.

Final Checklist Summary

| Category | Key Equipment |

|---|---|

| Core Production Unit | PET Blow Molding Machine, Custom PET Bottle Mold |

| Preform Handling System | Hopper, Elevator, Unscrambler, Heating Oven |

| Essential Utilities | High & Low-Pressure Air Compressors, Air Dryer, Filters, Water Chiller |

| Downstream & QA | Air Conveyor, Online Leak Tester |

| Factory Infrastructure | Correct Electrical Supply, Water Piping, Stable Foundation |

Frequently Asked Questions (FAQ)

Q: What is the approximate total cost for a basic PET bottle production line?

A: A basic, entry-level line can range from $50,000 to $150,000 USD. The final price heavily depends on the machine's automation level, bottle size, mold cavities, and the brands chosen for auxiliary equipment.

Q: How much factory space do I need for a complete production line?

A: For a standard automatic blowing line, we recommend a minimum of 100-150 square meters (approx. 1000-1600 sq ft). This allows for the equipment, as well as space for raw material storage, finished product area, and maintenance access.

Q: Do I have to buy all the equipment from one supplier?

A: You don't have to, but it is highly recommended. Sourcing from a single, experienced supplier like iBottler ensures all components are perfectly compatible, simplifies the installation process, and gives you a single point of contact for all after-sales support.

Q: What is the main difference between a high-pressure and low-pressure air compressor?

A: The low-pressure compressor (around 10 bar) powers the machine's pneumatic movements, like opening and closing the mold. The high-pressure compressor (up to 40 bar) provides the powerful burst of air needed to stretch the preform and blow it into the final bottle shape. Both are essential.

Q: How long does it take from ordering to starting production?

A: The lead time depends on the machine type. For semi-automatic machines, it's typically 15-20 days. For fully-automatic machines, it's about 30-45 days. Ocean shipping adds another 20-40 days. Therefore, a realistic timeline from order to production is about 2-4 months.

🔗 Learn More about Blow Molding Technology

Blow Molding – Wikipedia

A comprehensive overview of various blow molding processes, including extrusion, injection, and stretch blow molding.Injection Molding – Wikipedia

Important for understanding the production of preforms used in stretch blow molding.Stretch Blow Molding – Wikipedia

Explains how PET bottles are formed through axial and radial stretching processes.PET Bottle – Wikipedia

Background information on the materials and properties of typical PET bottles.Design of PET Bottles – Wikipedia

An introduction to the design considerations and geometry used in PET bottle manufacturing.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr