Your production line is fast, but profits are slowly leaking away. A few extra milliliters in every bottle add up to huge losses. You need a simple, reliable fix.

The best way to fine-tune CSD bottle volume is by using a mechanical system of high-precision volume adjustment spacers, or shims. This allows operators to physically change the mold cavity volume in minutes, ensuring consistent filling without altering complex machine parameters like heating or pressure.

This solution seems simple, maybe too simple. But in my 16 years in the PET blow molding industry, I've learned that the most elegant solutions are often the most effective. They are the ones that solve a complex problem at its root cause. We need to stop chasing symptoms by constantly tweaking machine settings. Instead, we can implement a small mechanical change that offers precise, repeatable control. Let's explore why this small piece of metal is so important for your bottom line and brand reputation.

The High Cost of a Single Milliliter: Why is Volume Control so Critical?

You are losing money with every bottle that leaves your factory. It might be a tiny amount, just a drop. But these drops add up, creating a flood of lost revenue.

Even a 1-2 milliliter overfill per bottle can cost you thousands of dollars daily on a high-speed line. This direct product giveaway silently erodes your profit margins. Conversely, underfilling risks severe regulatory fines and damages the trust consumers have in your brand.

I always tell my clients, "In the beverage packaging world, volume isn't just a technical spec; it's profit and compliance." Precise volume control is the core discipline that ensures every dollar you spend ends up in the product, not given away for free.

The Math of "Free" Giveaways

Let’s do some simple math. Imagine you run a modern production line for a popular soft drink.

- Production Speed: 40,000 bottles per hour (BPH)

- Operating Hours: 20 hours per day

- The Problem: Each bottle is overfilled by just 2 milliliters (ml).

This seems like a tiny, insignificant amount. But let's see the numbers:

- Hourly Giveaway: 40,000 bottles * 2 ml/bottle = 80,000 ml = 80 liters

- Daily Giveaway: 80 liters/hour * 20 hours/day = 1,600 liters

You are giving away 1,600 liters of your finished product for free, every single day. Let's put a price tag on that. If your beverage costs a conservative $0.50 per liter to produce, that's $800 per day straight out of your profit column. Over a year, that's nearly $300,000 in lost revenue from one production line.

Here’s how the cost escalates over time.

| Overfill Amount | Daily Loss (1,600 L) | Weekly Loss (11,200 L) | Monthly Loss (48,000 L) | Annual Loss (584,000 L) |

|---|---|---|---|---|

| Cost @ $0.50/L | $800 | $5,600 | $24,000 | $292,000 |

| Cost @ $0.75/L | $1,200 | $8,400 | $36,000 | $438,000 |

| Cost @ $1.00/L | $1,600 | $11,200 | $48,000 | $584,000 |

The Other Side of the Coin: Underfilling Risks

While overfilling hurts your wallet, underfilling can be even more damaging. Net content regulations are strict across the globe. Government agencies perform random checks, and the penalties for non-compliance are severe.

- Hefty Fines: These can run into tens or hundreds of thousands of dollars per violation.

- Product Recalls: A forced recall is a logistical nightmare and a huge financial blow.

- Brand Damage: This is the most dangerous cost. News of a company short-changing its customers spreads fast. It erodes years of brand loyalty and trust. Once consumers feel cheated, it's incredibly difficult to win them back.

Precise PET bottle volume control is not a luxury. It is a fundamental requirement for a profitable and sustainable beverage business. It protects your finances, your legal standing, and your brand's reputation.

What are the Root Causes of Bottle Volume Fluctuation?

You've invested in a top-tier production line. Yet, you still see frustrating inconsistencies in your bottle volumes. Why does this happen even in the best-run factories?

Volume fluctuation is caused by dynamic variables in the production environment. These include minor differences between PET resin batches, ambient temperature swings, tiny inconsistencies in preform heating, and momentary dips or spikes in compressed air pressure.

A production line is a dynamic system, and variables are everywhere. I've seen many plant managers try to fix this by constantly adjusting the machine's heating or blowing parameters. This approach is highly inefficient. It's like trying to steer a ship in a storm by constantly turning the rudder left and right. It treats the symptom, not the cause, and it can negatively impact other critical bottle properties.

Deeper Dive into the Variables

Let's break down the primary culprits behind this constant battle for consistency. Each one introduces a small element of chaos into a process that demands precision.

1. PET Raw Material Characteristics

Even from the same supplier, PET resin is not perfectly uniform.

- Intrinsic Viscosity (IV) Differences: Different batches of resin will have slightly different IV values. This affects how the material flows and stretches during the blowing process. A higher IV material might stretch less, resulting in a slightly smaller bottle, while a lower IV material might stretch more easily, creating a larger bottle.

- Colorant & Additive Effects: The addition of colorants, UV inhibitors, or other additives can change the thermal properties of the PET. A darker color, for example, will absorb infrared heat in the ovens more quickly than a clear preform. This requires different heating profiles to achieve the same material distribution and final volume. We work with clients on their complete PET bottle mold design guide from concept to production to account for these material factors from the start.

2. Environmental and Machine Temperature Changes

The temperature of your plant and your machinery has a direct impact.

- Ambient Temperature: A factory can be cool in the morning and much warmer in the afternoon. This change in ambient temperature affects the preforms, the mold temperature, and the cooling efficiency of the entire system. A warmer preform entering the oven needs less heat, and if the heating profile isn't adjusted, it can become overheated, leading to volume changes.

- Mold Temperature: Molds heat up during continuous operation. While a chiller system is designed to keep them stable, minor fluctuations are inevitable. A warmer mold allows the PET to stretch further before solidifying, which can increase the bottle's volume.

3. Preform Heating Inconsistencies

The heating oven is the heart of the blow molding process, but it's not perfect.

- Lamp Variation: The infrared lamps that heat the preforms can age differently. One lamp might have a slightly lower output than its neighbor, creating a subtle temperature difference on the surface of the preform.

- Air Flow: Ventilation patterns within the oven can cause some preforms to be cooled slightly more than others as they rotate and travel. This micro-level inconsistency is enough to affect how the material distributes in the mold.

4. Compressed Air Pressure Fluctuations

The high-pressure air that forms the bottle is another key variable.

- System Demand: On a large production floor, multiple machines might draw from the same high-pressure compressor system. When another machine starts a cycle, it can cause a momentary dip in pressure for your machine.

- Valve Response Time: The valves that release the high-pressure air operate thousands of times per hour. Their response time can vary by milliseconds, changing the precise volume and timing of the air entering the preform.

Trying to manually adjust machine settings to counteract all these variables is a losing battle. You might fix the volume for a few minutes, but you could be unknowingly creating other issues, like those detailed in guides to common PET blow molding defects. It’s an unstable and reactive strategy.

What is the Solution: Mechanical Fine-Tuning with Volume Adjustment Spacers?

You are struggling with process variables you can't control. So, instead of fighting a losing battle with computer parameters, what if you could make a simple, physical change?

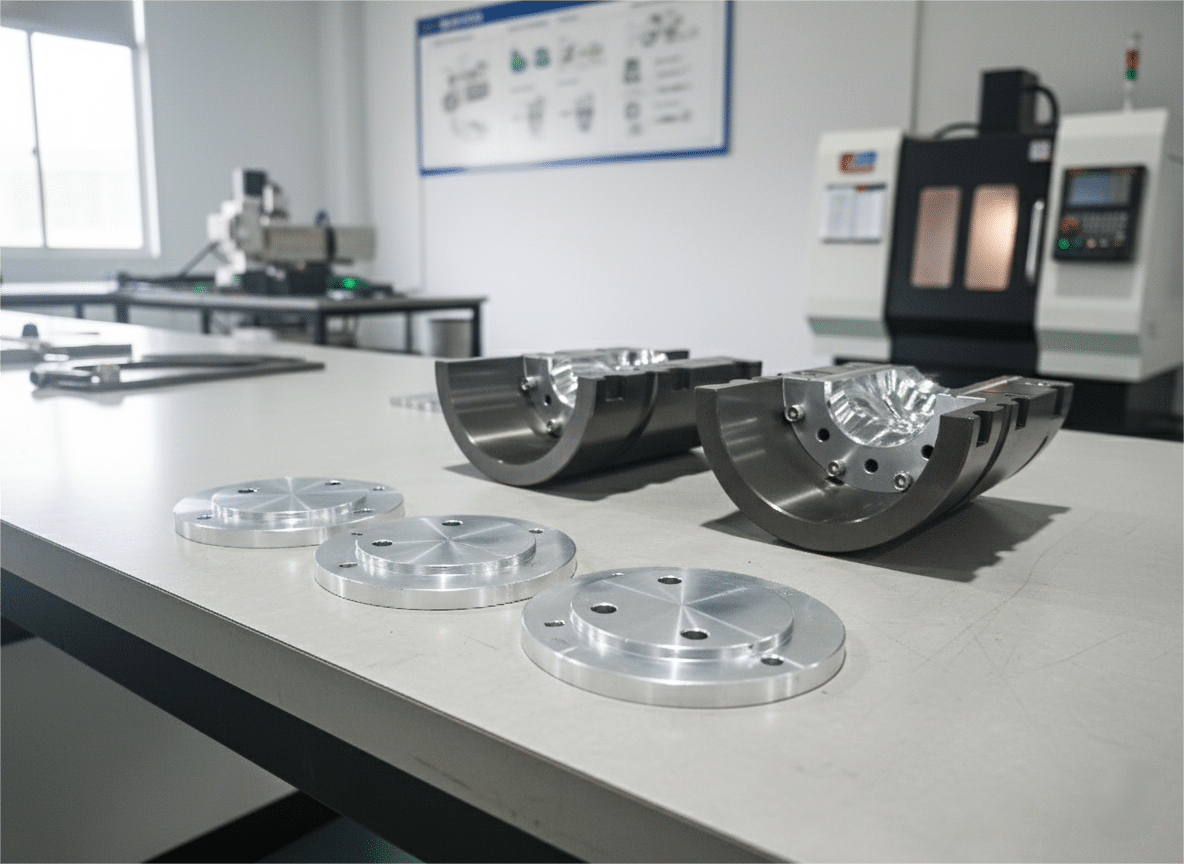

The solution is a set of volume adjustment spacers, also called shims. These are high-precision metal plates of varying thicknesses. They are installed in a specific location in the mold, usually under the bottom insert, to physically change the mold's internal volume.

In my experience, the most advanced solutions are often about mechanical simplicity. We stop asking operators to fight with complex computer screens. Instead, we give them a toolset that works like building blocks. They can add or subtract a physical component to get a precise, predictable, and repeatable result. It brings control back to the physical world.

Understanding the Tool: The Spacer Set

This isn't just one piece of metal; it's a carefully designed system. A standard set of volume adjustment spacers for a blow bottle mold has several key characteristics:

- High-Precision Machining: Each spacer is machined to extremely tight tolerances. Its thickness is not approximate; it is exact. A spacer labeled "5.0 mm" is precisely that, ensuring predictable results.

- Material Durability: They are typically made from hardened stainless steel or a similar durable alloy. They must withstand the immense pressure and temperature cycles of the blow molding process without deforming or wearing down.

- A Range of Thicknesses: A typical set includes multiple spacers of different thicknesses. For example, a kit might contain spacers ranging from 2.0 mm to 9.0 mm, in 0.5 mm or 1.0 mm increments. This allows for fine-tuned adjustments.

How They Fit into the Mold

The design of the mold is critical for this system to work. The mold is engineered to accommodate these spacers in a specific location. Most commonly, this is beneath the "bottom insert" or "push-up" of the mold.

- The Base Mold: The main body of the mold cavity is fixed.

- The Bottom Insert: This is a separate, interchangeable component that forms the base of the bottle.

- The Spacer Pocket: A precise pocket is machined into the mold base, directly under where the bottom insert sits.

- Installation: The operator simply places the selected spacer into this pocket, and then places the bottom insert on top of it. When the mold closes, the spacer physically lifts the bottom insert, slightly reducing the total internal volume of the mold cavity.

The beauty of this system is its directness. You are not indirectly influencing the volume by changing heat or pressure. You are directly changing the physical space that the bottle has to form into. This is a far more stable and reliable method of control.

How does it Work: A 10-Minute Job for a +/- 5ml Adjustment Range?

The theory is simple, but how does it perform on the factory floor? Can your team use this system quickly and effectively without causing major downtime?

The process is fast and straightforward. To increase bottle volume, you install a thinner spacer or remove it. To decrease volume, you install a thicker one. This mechanical swap gives you a reliable adjustment range of roughly +/- 5ml and takes only 10-15 minutes.

The core value of this system is what I call "decoupling." It separates the variable of "volume adjustment" from all the other complex blow molding process parameters. You can now fine-tune the bottle's net content without touching the heating profile, stretch ratios, or wall thickness distribution. You are adjusting one thing, and only one thing: volume.

The Step-by-Step Process

For a skilled operator, changing a spacer during a planned stop is a quick maintenance task. Here is the typical procedure for one mold station on a rotary bottle blowing machine:

- Safety First: The machine is stopped, locked out, and tagged out according to standard safety protocols.

- Access the Mold: The operator opens the mold station to access the bottom section.

- Remove the Bottom Insert: Using simple hand tools, the operator unscrews and removes the bottom insert piece. This exposes the spacer pocket.

- Swap the Spacer: The existing spacer is removed, and the new, selected spacer is placed into the pocket. The selection is based on data from the quality control team. For example, if bottles are consistently 2ml over volume, the operator might install a spacer that is 1mm thicker.

- Re-assemble: The bottom insert is placed back on top of the new spacer and secured.

- Repeat if Necessary: This process is repeated for any other mold cavities that need adjustment.

- Restart Production: Once the changes are made, the machine is safely restarted. The first few bottles are checked by QC to confirm the adjustment was successful.

The entire process for a single mold station is typically completed in 10-15 minutes.

Predictable Results: Spacer Thickness to Volume Change

The relationship between spacer thickness and volume change is fairly linear, making adjustments predictable. While the exact ratio can vary slightly based on the specific PET bottle design, a general rule of thumb can be established for each mold.

Here is an example of what that relationship might look like for a standard 500ml CSD bottle mold:

| Spacer Change | Approximate Volume Change | Example Action |

|---|---|---|

| Install 2.0 mm spacer (from none) | - 2.0 ml | Bottle is 2ml over volume, install 2.0mm spacer. |

| Install 4.0 mm spacer (from none) | - 4.0 ml | Bottle is 4ml over volume, install 4.0mm spacer. |

| Swap 2.0 mm spacer for 3.0 mm spacer | - 1.0 ml | Bottle is still 1ml over, need a finer adjustment. |

| Swap 4.0 mm spacer for 2.0 mm spacer | + 2.0 ml | Bottle is 2ml under volume, need to increase. |

| Remove 2.0 mm spacer | + 2.0 ml | Bottle is 2ml under volume, need to increase. |

This predictability empowers the production team. They are no longer guessing with temperature settings. They are making a calculated, mechanical change with a known outcome. It transforms volume control from a reactive art into a proactive science.

Why is This a Standard Feature for Us, Not an Expensive Option?

When you buy a car, you expect it to come with a steering wheel. You don't pay extra for it. Why? Because it's a fundamental tool needed to operate the car safely and effectively.

We include this volume adjustment system as a standard feature on all our high-end CSD rotary molds. We believe providing tools that solve real-world production problems is a manufacturer's responsibility, not an opportunity for an extra charge.

Our design philosophy is centered on being "operator-friendly." We know the pressures that production teams face every day. Our goal is to provide them with tools that make their jobs easier and their output more consistent. We include the spacer system as standard because we know its immense value in daily operations. It’s a testament to our commitment to our clients' success.

A Philosophy of Partnership

When a molder simply sells a block of steel with a cavity in it, they are selling a commodity. When they provide a tool that anticipates and solves the client's future problems, they are providing a partnership. This is the core of our approach.

- Anticipating Needs: We have spent years on production floors. We have seen the frustration of chasing volume fluctuations. We knew there had to be a better, more stable way. We developed and standardized this system because we anticipated our clients' need for it, even if they hadn't experienced the problem yet.

- Reducing Total Cost of Ownership (TCO): A cheaper mold that doesn't include this feature might save a small amount of money upfront. However, the long-term costs of product giveaway, potential fines, and increased operator intervention are far higher. By including it as standard, we lower the client's TCO over the life of the mold. The mold becomes an asset that actively saves money.

- Empowering Operators: A confident, empowered operator is more efficient and produces higher quality products. Giving them a simple, reliable tool for volume control removes a major source of stress and guesswork. This focus on the human element is crucial. When your team knows they have reliable tools, they can focus on overall line efficiency instead of constantly fighting fires.

The iBottler Standard vs. The Industry Norm

It's true that not all mold makers offer this. Why?

| The iBottler Approach (Standard Feature) | The Common Alternative (Optional or Not Available) |

|---|---|

| Philosophy: Solve the customer's operational problem. | Philosophy: Fulfill the basic technical drawing. |

| Design: Engineered from the ground up for interchangeability and precision. | Design: May not have the required precision for interchangeable parts without extra cost. |

| Cost: Integrated into the base price as a core function of a high-performance mold. | Cost: Often treated as an expensive "add-on" or custom feature. |

| Result: Client gets a proactive tool that saves money and improves quality from day one. | Result: Client is left to manage volume with less effective machine adjustments, leading to inefficiency. |

We made a conscious decision to make this part of our standard offering. It is a feature born from experience, not just from a blueprint. It reflects a deeper understanding of what it truly takes to run a successful bottling operation. It’s one of the key reasons our clients see our blow bottle molds as an investment in production stability, not just a piece of tooling.

How did a Simple Spacer Solve a Major Bottler's Compliance Issue?

Theory and technical specs are important. But the real test of any solution is how it performs in the real world. Let me share a story about one of our clients.

A major beverage company supplying a large international supermarket chain was facing a serious compliance problem. Seasonal temperature swings were causing bottle volume fluctuations, putting them at risk of being delisted by their most important customer.

This client was in a difficult position. They had a high-quality product and a modern production line, but they couldn't guarantee consistent net content. Their QC team was working overtime, constantly adjusting machine parameters, but they were always one step behind the problem. The stress level was high, and the financial risk was enormous.

The Challenge: A Problem of Seasons

The root of their issue was the climate.

- In the summer, the warmer plant temperature and hotter preforms led to bottles that were consistently overfilled. They were giving away product and losing money.

- In the winter, the colder environment meant the preforms and molds were cooler, resulting in bottles that were often on the borderline of being underfilled. This was the bigger danger. Their key retail partner had a zero-tolerance policy for underfilled products. One failed audit could mean losing the contract.

The production manager told me, "We felt like we were flying blind. We'd spend hours in the morning dialing in the process, and by the afternoon, everything had changed, and we were chasing the numbers all over again."

The Solution: Predictable Mechanical Control

They decided to invest in a new set of our molds for their main product line. The key feature that interested them was the standard-issue volume adjustment spacer system. When we installed and commissioned the new tooling, we trained their team on how to use it.

- Establishing a Baseline: They first established a stable baseline process for their bottle blowing machine that produced bottles with excellent material distribution and performance, ignoring the final volume for a moment.

- Implementing the Spacers: They then used the spacers to dial in the final volume. During the summer months, they used thicker spacers to reduce the mold cavity volume and combat the overfilling. In the winter, they switched to thinner spacers or removed them entirely to increase the volume and ensure they were safely above the minimum fill line.

The Result: From 98.5% to 99.9% Compliance

The change was immediate and dramatic. The QC manager reported back to us a few months later with incredible results.

- Capacity合格率 (Compliance Rate): It jumped from an average of 98.5% to a consistent 99.9%.

- Reduced Operator Stress: The operators no longer had to constantly tweak heating and pressure settings. They made a simple, mechanical change once or twice a season.

- Zero Compliance Risk: They passed every random audit from their retail partner with flying colors.

The production manager's feedback was the most powerful. He told me, "This little piece of metal lets us sleep at night. We are no longer worried about getting that dreaded call from our customer. We have control." This story perfectly illustrates our philosophy. We didn't just sell them a mold; we provided them with a solution that eliminated a major business risk and brought peace of mind to their entire team.

Does Your Current Mold Supplier Think This Deeply for You?

You buy tooling to produce bottles. But are you just buying a piece of steel, or are you investing in a production solution? This is a critical question to ask.

A great mold is more than its physical dimensions. It embodies the manufacturer's deep understanding of your daily production challenges. Does your supplier anticipate your problems with volume control, maintenance, and efficiency, or just deliver to a drawing?

The value of a mold isn't in how much it weighs, but in how much thought and experience are embedded within its design. An excellent tooling partner thinks about your problems before you even have them. They design solutions that make your operation smoother, more efficient, and more profitable.

A Checklist to Evaluate Your Tooling Partner

Think about your current mold supplier. Can you confidently say they meet these criteria? This is not just about the quality of the steel, but the quality of the thinking behind it.

| Evaluation Criteria | A Basic Supplier | A True Partner (like iBottler) |

|---|---|---|

| 1. Problem Anticipation | Reacts to problems when you report them. | Proactively designs features (like volume spacers) to prevent common industry problems. |

| 2. Operational Focus | Focuses on delivering a mold that meets the drawing specifications. | Focuses on how the mold will perform in your real-world, dynamic production environment. |

| 3. Operator Experience | The design may require complex adjustments and specialized skills. | The design is "operator-friendly," with simple, mechanical solutions for common tasks. |

| 4. Total Cost of Ownership (TCO) | Emphasizes the low initial purchase price. | Focuses on delivering long-term value by reducing waste, downtime, and operational costs. |

| 5. Integration and Compatibility | Guarantees the mold fits your machine. | Understands the entire process and ensures the mold works in harmony with your upstream and downstream equipment. They can provide mounting dimensions for 80% of blow molding machines worldwide. |

| 6. Support and Expertise | Offers technical support for the mold itself. | Offers process expertise and consultation to help you optimize your entire production line. |

If your current supplier primarily falls into the "Basic Supplier" column, you are leaving money and efficiency on the table. You are buying a tool, but you are missing out on the expertise that makes the tool truly powerful.

A forward-thinking feature like a standard volume adjustment system is a clear indicator of a supplier's mindset. It shows they have been in your shoes. They understand the daily struggle for consistency and have engineered a practical, effective solution. This is the level of deep thinking you should demand.

It's Time to Demand More From Your Tooling: Let's Talk Precision?

Your team is constantly fighting volume fluctuations. You're losing money to product giveaways or risking non-compliance. You might think the problem is your machine or your operators.

Perhaps the problem isn't your process, but your tooling philosophy. If you are still relying solely on machine parameters to control volume, you are using an outdated and inefficient method. Modern mold design can bring a new level of precision and profitability to your line.

If your team is still struggling with bottle volume, it's time to stop and ask if your molds are truly working for you. It's time to demand more than just a cavity. Demand a solution. Demand precision that translates directly to your bottom line.

Moving from a Cost Center to a Profit Center

For too long, many companies have viewed their blow bottle molds as a necessary expense—a cost center. It's time to shift that perspective. The right tooling, engineered with deep process knowledge, is a profit center.

- It SAVES Money: By eliminating tiny overfills, a high-precision mold with a volume control system directly reduces product giveaway, saving hundreds of thousands of dollars per year.

- It PROTECTS Revenue: By ensuring strict net content compliance, it protects you from fines and, more importantly, protects your contracts with major retailers.

- It INCREASES Efficiency: By simplifying adjustments and "decoupling" volume control from other parameters, it reduces downtime and frees up your skilled operators to focus on other areas of line optimization.

Your Next Step Towards Precision

You don't have to continue the daily battle against volume inconsistency. A better, more stable method exists. It’s a solution born from 16 years of hands-on experience in this industry.

I invite you to take the next step. Contact us at iBottler and ask for the technical brief on our "High-Precision Volume Control Mold System." Let us walk you through the engineering, the materials, and the real-world results our clients are achieving. Let's have a conversation about precision. Let's discuss how modern mold design can transform your production line, making it more stable, more efficient, and more profitable.

Conclusion

Stop losing money one milliliter at a time. A simple, mechanical volume adjustment spacer system offers precise control, protects your profits, and ensures compliance without complicating your production process.

Article Summary

| Section | Key Takeaway |

|---|---|

| The Cost of 1ml | A tiny 2ml overfill on a 40k BPH line can cost over $292,000 annually in product giveaway. Underfilling risks fines and severe brand damage. |

| Root Causes of Fluctuation | Volume changes are caused by unavoidable variables like material batches, temperature, heating, and air pressure, not poor operator control. |

| The Spacer Solution | A set of high-precision metal shims physically changes the mold volume, offering direct and repeatable control without altering machine settings. |

| How It Works | A 10-15 minute mechanical swap of a spacer can adjust volume within a +/- 5ml range, "decoupling" it from other critical process parameters. |

| Our Standard | We include this system as standard because we believe in providing proactive solutions that lower the client's Total Cost of Ownership (TCO). |

| Case Study | A client solved a major compliance risk with a key retailer, boosting their volume compliance rate from 98.5% to 99.9% using this system. |

| Evaluating Your Supplier | A true partner anticipates your operational needs and builds solutions into their standard designs, moving beyond just fulfilling a drawing. |

| Demand More | Your tooling should be a profit center, not just a cost. Modern mold design offers a path to greater precision, efficiency, and profitability. |

Frequently Asked Questions (FAQ)

Q: What is the typical volume adjustment range of these spacers?

A: Our standard system provides a total adjustment range of approximately +/- 5 milliliters. This is achieved using a set of spacers with different thicknesses, typically ranging from 2mm to 9mm, allowing for precise control to meet specifications.

Q: How long does it actually take to change a spacer on a rotary machine?

A: For a skilled operator, changing the spacers in one mold station takes about 10-15 minutes during a planned stop. It involves removing the bottom insert, swapping the spacer, and re-assembling.

Q: Is this system also useful for non-carbonated beverage bottles?

A: While it's most critical for CSD and hot-fill bottles (due to pressure and shrinkage), it is also beneficial for high-volume still water production, especially for brands that want to ensure the strictest net content compliance and minimize product giveaway.

Q: Does adding a spacer affect the bottle's overall height?

A: The effect on the bottle's total height is microscopic and typically negligible. Its primary, intended effect is on the internal volume, which is far more sensitive to this small dimensional change.

Q: Why don't all mould makers offer this as a standard feature?

A: It requires a higher level of precision in manufacturing the mould components to ensure interchangeability. More importantly, it requires a deep, first-hand understanding of the daily operational challenges faced by bottlers. It's a feature born from experience, not just from a blueprint.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr