Have you ever wondered about the bottle's strange base? It seems complex. This design is the key to keeping your favorite soda safe, stable, and full of fizz.

The 5-point base, known as a "petaloid base," is an engineering solution to withstand the high internal pressure from carbonated drinks. This design uses arched shapes to distribute stress evenly, preventing the bottle from bulging, tipping over, or bursting, ensuring both strength and product safety.

That bumpy bottom on your soda bottle is not just for looks. It's a marvel of beverage packaging engineering, a silent guardian that battles immense forces every second. It ensures the bottle you pick up from the shelf is as perfect as the day it was filled. This design is born from a deep understanding of physics, materials, and the complex manufacturing process. Let's peel back the layers and discover the science behind this everyday object.

The Simple Answer: It's a Battle Against the Fizz?

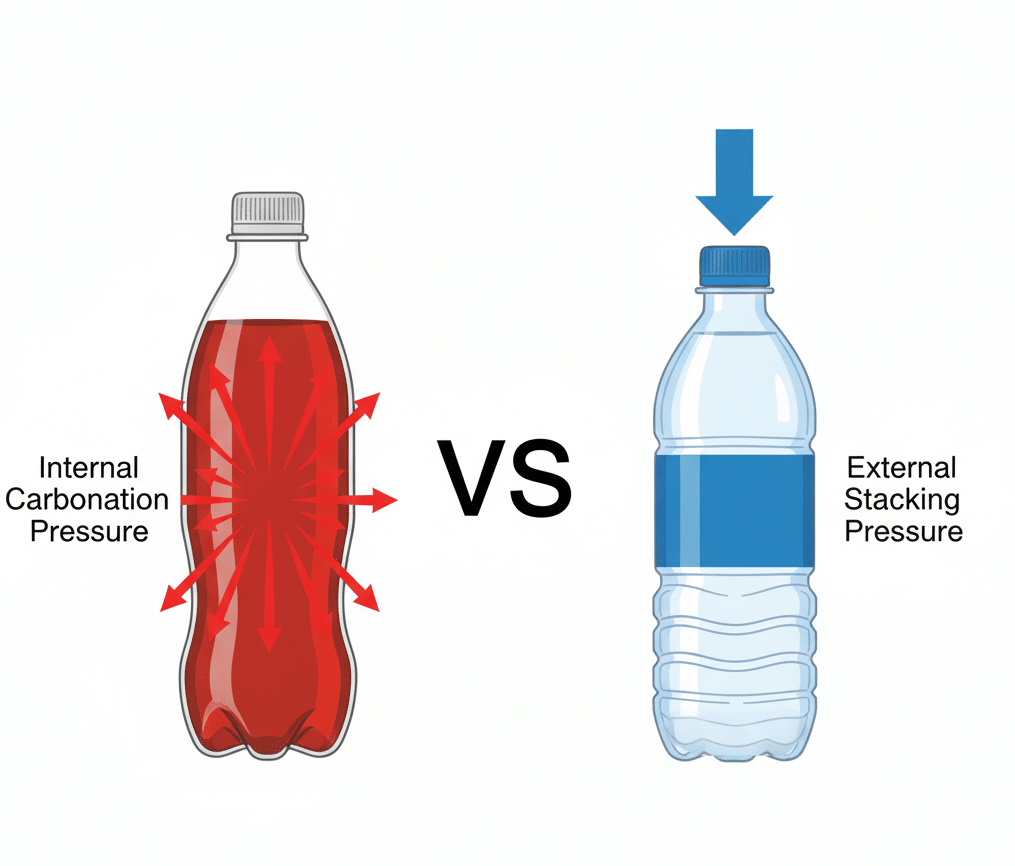

Your soda is packed with dissolved gas. This gas creates constant pressure. A weak bottle design would fail, creating a messy and dangerous situation for everyone involved.

A flat-bottomed bottle simply cannot handle the pressure from carbonated drinks. The force would push the flat surface outwards, creating a rounded, wobbly bottom that makes the bottle unstable and prone to bursting.

The Unseen Enemy Inside the Bottle

When you look at a bottle of soda, you see a calm liquid. But from an engineering perspective, it's a pressure vessel. The carbon dioxide (CO2) that creates the delightful fizz is forced into the liquid under high pressure. This gas constantly tries to escape, pushing outwards on every square inch of the bottle's inner surface. For a standard 500ml soda bottle, this internal pressure can be as high as 60 to 90 psi (pounds per square inch). That's two to three times the pressure in your car's tires. A flat-bottomed bottle, made from relatively thin PET plastic, would stand no chance against this relentless force. The center of the flat base would be its weakest point. The pressure would push it outwards, causing it to deform into a dome shape. Once this happens, the bottle can no longer stand upright. This is a common issue known as "rocking bottom," one of the many common PET blow molding defects that we help clients solve. In the worst-case scenario, the material would stretch beyond its limit and rupture.

The Power of Shape Over Brute Force

Instead of just making the plastic base incredibly thick and heavy, which would be expensive and wasteful, engineers came up with a smarter solution: change the shape. This is where the magic of the petaloid base comes in. In simple terms, these bumps turn a weak 'flat plate' into an incredibly strong 'arched dome' structure. This is one of the most classic and efficient anti-pressure designs in engineering. Each of the five "feet" or "lobes" acts like a small arch, and the entire base structure functions like a complex dome. This geometry doesn't try to block the force; instead, it redirects it. The downward and outward pressure from the carbonation is channeled through the curves of the lobes and into the rigid structure of the bottle's side walls. It's an elegant way to manage immense stress using the least amount of material possible.

| Feature | Flat Base Bottle | Petaloid Base Bottle |

|---|---|---|

| Pressure Resistance | Very Low | Very High |

| Stability Under Pressure | Becomes unstable and wobbly | Remains stable and flat |

| Material Efficiency | Requires very thick plastic | Optimized for strength-to-weight ratio |

| Primary Failure Mode | Center bulging and rupture | Stress cracking (if poorly made) |

| Suitable For | Non-carbonated drinks (water, juice) | Carbonated soft drinks, sparkling water |

This fundamental difference in design philosophy is why you'll never see a major brand of cola or sparkling water in a flat-bottomed plastic bottle. The risk is simply too high, and the petaloid base provides a proven, reliable, and cost-effective solution.

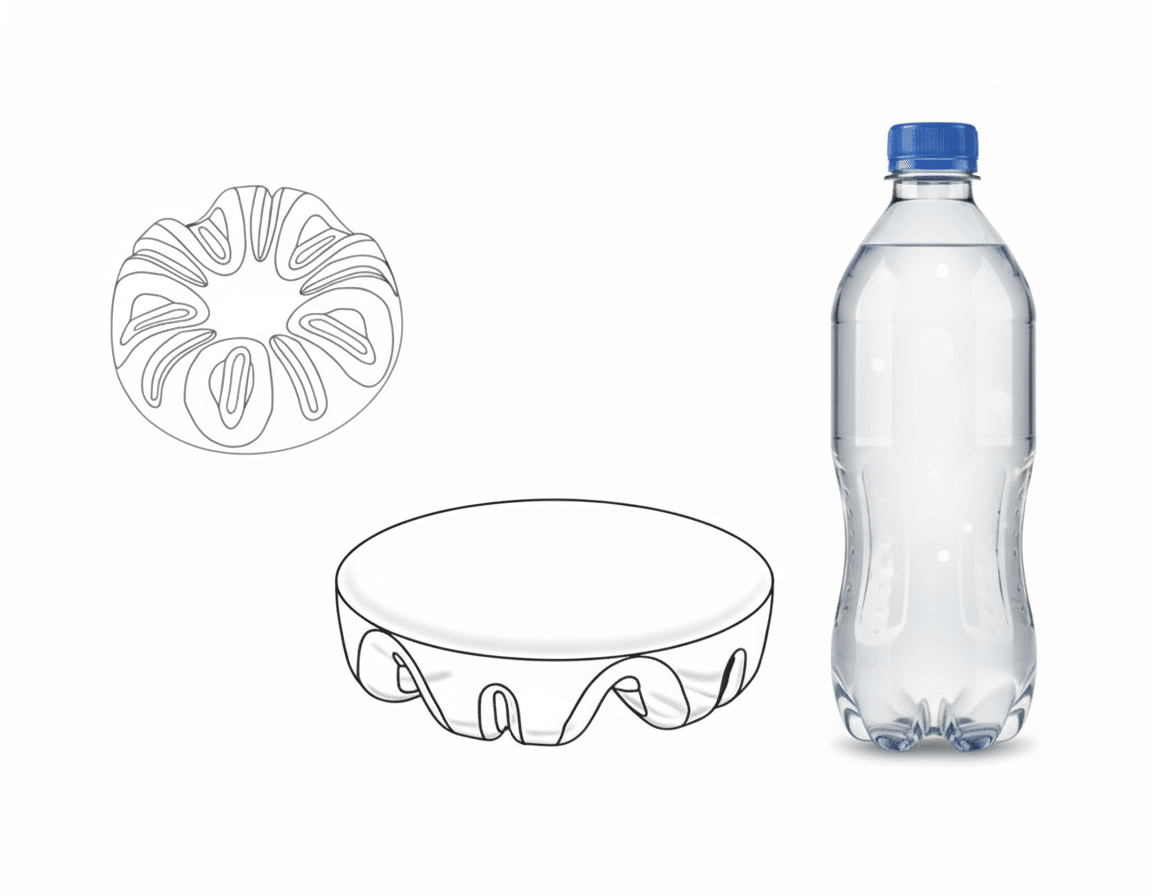

Introducing the "Petaloid Base": The Anatomy of an Engineering Marvel?

The term seems complex, but "petaloid" just means "petal-like." This functional design is not about aesthetics. It's a calculated system where every curve and dimension plays a critical role.

This base is a system of integrated components: the lobes, the gate, and the transition radius. Each part is precisely designed and manufactured to manage pressure, ensure stability, and optimize the use of PET material.

A Closer Look at the Key Components

To truly appreciate the design, we need to break it down into its core parts. Think of it like looking at the blueprints for a building's foundation. Each component has a specific job, and they must all work together perfectly. When we design a blow bottle mold, we spend a significant amount of time optimizing these features, as they are the most critical for bottle performance and safety. Every part's size and curve is precisely calculated. It's not an aesthetic design, but a purely functional one, where every millimeter exists for safety and performance.

The Lobes (or Petals)

These are the five bumps you can see and feel. They are the primary load-bearing structures of the base. When the internal pressure pushes down, the lobes act like arched columns, channeling the force outwards towards the stronger, more rigid sidewall of the bottle. The number five is not arbitrary; it provides the best balance of stability and strength.

The Gate (or Injection Point)

This small, circular mark right in the center of the base is a remnant of the manufacturing process of the bottle's precursor, the test-tube-shaped "preform." It's the spot where molten PET plastic was injected into the preform mold. This area is critical because the material here can have different properties than the rest of the bottle. During the blowing process, it undergoes immense stretching. A poorly designed mold or incorrect machine setup can leave this gate area dangerously thin, making it the bottle's Achilles' heel.

The Knuckle Radius and Standing Ring

The "Knuckle Radius" is the smooth, curved transition from the lobes back up towards the bottle's main body or sidewall. This curve is crucial for preventing sharp angles, which are points of high stress concentration. The "Standing Ring" is the very bottom edge of the lobes, the part that actually makes contact with the surface. The design ensures these five small points create a wide and stable footprint for the bottle.

| Component | Primary Function | Engineering Consideration |

|---|---|---|

| Lobes (Petals) | Distribute downward pressure into radial force. | The curvature and depth must be optimized for the specific pressure level. |

| Gate (Injection Point) | Center point from the preform manufacturing. | Must have sufficient and uniform material thickness after blowing. |

| Knuckle Radius | Provides a smooth transition to the sidewall. | A smooth, generous curve is essential to eliminate stress concentration points. |

| Standing Ring | Creates stable contact points with surfaces. | The diameter and flatness of the ring on all five lobes must be consistent for stability. |

Understanding this anatomy reveals that the petaloid base is not just a single feature but a sophisticated system. The failure of any one of these components to perform its job can lead to the failure of the entire bottle. That's why expertise in mold design and the blow molding process is so vital.

The Physics: How Arches and Domes Make Your Bottle Stronger?

Worried that a simple plastic bottle could burst? The secret to its strength lies in ancient architectural principles. It uses the power of arches and domes to turn weakness into strength.

By transforming downward pressure into compressive forces along its curves, the petaloid base safely manages the immense internal pressure. This geometric trick eliminates weak points and makes the bottle incredibly strong and resilient.

The Timeless Strength of the Arch

The core principle that makes a petaloid base work is the same one that allowed ancient Romans to build massive aqueducts and cathedrals that still stand today: the arch. Imagine pushing down on the top of an archway. The force doesn't travel straight down. Instead, the curved shape of the arch redirects the force outwards and downwards along its legs into the foundation. This process is called converting vertical tension into horizontal compression. Materials, including PET plastic, are incredibly strong under compression. Each lobe on the petaloid base is essentially a miniature arch. The pressure from the carbonation pushes down on these arches, and they expertly redirect that force into the surrounding structure. The entire base, as a collection of these arches, functions as a dome, which is one of the strongest structural shapes known to engineering. It's a perfect example of using geometry to create strength, rather than relying on brute-force thickness.

Defeating the Enemy: Stress Concentration

In engineering, any sharp corner or abrupt change in shape is a potential point of failure. These areas are called "stress risers" or points of "stress concentration." Imagine a river flowing smoothly. If you place a large, sharp-cornered rock in its path, the water will violently churn around the corners. The flow of forces through a material works in a similar way. A flat-bottomed bottle has a very sharp 90-degree angle where the base meets the sidewall. Under pressure, all the stress would concentrate at this sharp internal corner, trying to tear the bottle apart. This is the single biggest reason a flat design fails.

The petaloid base is ingeniously designed to eliminate these weak points. Every transition is a smooth, gentle curve. The knuckle radius, for example, ensures that the forces flowing from the lobes into the sidewall do so without any sharp turns. Our engineers use CAE software for Finite Element Analysis (FEA) when designing bottles. This software allows us to simulate the stress distribution after the bottle is filled with a carbonated beverage. The results are displayed as a color map. In a poor design, you'll see bright red spots, indicating dangerously high levels of stress concentration. A well-designed petaloid base, however, shows a smooth gradient of safe greens and blues. This analysis is a critical part of our comprehensive PET bottle mold design guide, ensuring every bottle we help create is safe and reliable.

| Physical Principle | How it Applies to Petaloid Base | Benefit |

|---|---|---|

| Arch Effect | Each lobe acts as an arch, redirecting vertical pressure. | Massively increases the base's ability to withstand internal forces. |

| Dome Structure | The collective 5-lobe structure forms a dome. | Distributes pressure evenly in all directions, preventing single points of failure. |

| Stress Distribution | Smooth curves and radii eliminate sharp corners. | Prevents the buildup of stress in specific spots, avoiding cracks and ruptures. |

| Material Compression | The redirected forces put the PET material under compression. | Leverages PET's natural strength under compressive loads, making it highly efficient. |

By applying these fundamental physics principles, the petaloid base allows a bottle weighing only 20-30 grams to safely contain pressures that could easily deform a much thicker sheet of flat plastic. It's a testament to brilliant, efficient engineering.

More Than Just Strength: The Stability Bonus?

You might think the base is all about pressure. But it also solves another critical problem: how to make a round bottle stand perfectly still on any surface, every single time.

The five points of contact on the petaloid base create an incredibly stable footprint. This ensures the bottle won't wobble on shelves, conveyor belts, or your kitchen table, a crucial but often overlooked benefit.

The Unshakable Foundation

Think about a three-legged stool. It can never wobble, even on an uneven floor, because three points define a flat plane. A four-legged chair, however, can easily rock back and forth if one leg is slightly shorter or the floor is not perfectly level. A five-point base takes the stability of a three-legged design and enhances it. The five lobes create a wide, stable footprint that resists tipping and eliminates any possibility of wobbling. This is extremely important in the real world. From the high-speed filling lines in a factory to the shelves in a supermarket and finally to your refrigerator door, bottles encounter countless surfaces that are not perfectly flat. The five-point stance ensures the bottle remains upright and stable through its entire journey. It's a brilliant 'integrated' design. It solves the core pressure problem and, as a side benefit, also solves the stability problem. That's the beauty of top-tier industrial design.

A Bottler's Best Friend: Performance in Production

This stability isn't just a consumer convenience; it's a manufacturing necessity. Modern bottling plants are marvels of automation, with bottles moving at incredible speeds.

- Conveyor Systems: Bottles travel single-file on conveyor belts. A wobbly bottle could easily fall, causing a jam that shuts down the entire production line. This can cost a company thousands of dollars in lost productivity.

- Filling and Capping: During the filling and capping stages, the bottle must be perfectly positioned and stable. Any movement could lead to incorrect fill levels, improper sealing, and product waste.

- Labeling and Packing: Labeling machines require the bottle to be stable to apply the label correctly. Similarly, automated packing systems that group bottles into cases rely on their predictable and stable base.

The inherent stability of the petaloid design makes it perfectly suited for this demanding, high-speed environment. It ensures a smooth, efficient process from empty bottle to finished product. Without this stability, the entire economics of mass-market beverage production would be far more challenging.

| Stability Comparison | 3-Point Base | 4-Point Base | 5-Point Petaloid Base |

|---|---|---|---|

| Wobble Potential | Zero. Always stable. | High. Can easily rock. | Zero. Always stable. |

| Footprint Width | Narrower, less resistant to tipping. | Wider, but stability is conditional. | Wide and stable, highly resistant to tipping. |

| Performance on Uneven Surfaces | Excellent | Poor | Excellent |

| Suitability for Automation | Good | Poor | Excellent |

Therefore, the stability provided by the five lobes is not an accidental bonus. It is a co-equal benefit that is just as important as its pressure-resisting capabilities, especially from the perspective of the beverage manufacturer. It's another layer of genius in this seemingly simple design.

The Manufacturing Challenge: Why a Perfect Petaloid Base is Hard to Make?

You have a perfect design on the computer, but turning it into millions of identical, flawless bottles is a huge challenge. The bottle base is where most manufacturing problems hide.

The base is the thickest part of the preform and the hardest to stretch and cool correctly. Achieving perfect material distribution and avoiding thermal defects requires expert process control and a perfectly designed blow bottle mold.

The Journey from Preform to Bottle

The process of making a PET bottle is called Injection Stretch Blow Molding. It starts with a small, test-tube-like object called a preform. This preform is heated to a precise temperature, around 100-120°C, where the PET becomes soft and pliable like rubber. It's then placed inside the mold cavity. A thin steel rod, called the stretch rod, shoots down and stretches the preform vertically, all the way to the bottom of the mold. Almost simultaneously, high-pressure air is blown into the preform, inflating it like a balloon to take the shape of the mold.

The base is the last and most difficult part of the preform to form correctly. It's the thickest area and has to undergo the most extreme stretching and shaping. The tip of the stretch rod must precisely form the central gate area, while the high-pressure air forces the material into the complex negative shape of the five lobes in the mold. The timing and pressure of these two actions must be perfectly synchronized. This entire process, from preform insertion to bottle ejection, happens in just a few seconds on a modern bottle blowing machine. Any tiny error in temperature, timing, or pressure will show up as a defect in the base.

The Hidden Defects That Cause Failure

This is where an experienced mold maker proves their value. We know how to design mold cooling channels to precisely cool specific areas of the base. We know how to shape the stretch rod tip for optimal material distribution. This is the 'know-how' you don't see on a blueprint. Even with a perfect design, several things can go wrong during manufacturing.

- Uneven Material Distribution: If the preform is not heated evenly or the stretch rod is not perfectly centered, the plastic won't be distributed evenly across the five lobes. You might end up with one lobe being too thin and another being too thick. The thin lobe becomes a weak point, ready to fail under pressure.

- Thin Gate: The center gate area is particularly vulnerable. If the stretch rod pushes too hard or the preform is too hot, the gate can become paper-thin, creating a prime location for a leak or rupture.

- Stress Cracking: This is a more insidious problem. It happens when the plastic is not cooled quickly and properly after being blown. The PET molecules can arrange themselves into a crystalline structure, which makes the plastic hazy and brittle. These brittle areas can develop micro-cracks that grow over time, eventually causing the bottle to fail, sometimes days or weeks after it has been filled. This is why having a powerful and properly connected chiller is non-negotiable for quality CSD bottle production.

| Defect | Cause | Consequence |

|---|---|---|

| Thin Lobe | Uneven heating; misaligned stretch rod. | Creates a localized weak spot; risk of bursting. |

| Thin Gate | Preform too hot; excessive stretch rod pressure. | High risk of leaking or catastrophic failure at the center. |

| Pearlescence / Crystallinity | Slow or uneven cooling; excessive stretching. | Base becomes brittle and prone to stress cracking. |

| Rocking Bottom | Insufficient blowing pressure; improper base mold design. | Bottle is unstable and cannot stand upright. |

Mastering the manufacturing of the petaloid base is a blend of science and art. It requires a deep understanding of PET material science, thermodynamics, and the precise mechanics of the blow molding process. It is in this challenging area that true expertise is shown.

Case Study: How We Solved a Client's Base Cracking Problem?

A client was losing money and reputation. Their new soda bottles were failing in transit, creating a huge mess and a bigger business problem. They needed a real solution, fast.

We diagnosed the root cause in their existing mold's cooling system and engineered a new base insert. This completely solved the cracking problem, restored their product's reliability, and saved them from massive losses.

The Challenge: A Costly and Mysterious Failure

A major beverage company in Asia approached us with a critical issue. They had just launched a new line of soda, and the market response was fantastic. However, a disaster was unfolding in their supply chain. They were experiencing a 3% failure rate due to "stress cracking" at the base of the bottles. The bottles weren't bursting immediately; they were failing days later during transportation or while sitting in a warehouse. A 3% failure rate might not sound like much, but when you're producing millions of bottles, it translates into tens of thousands of failed units. This meant huge financial losses from ruined product, costly cleanup operations, and, most importantly, damage to their brand's reputation with distributors and retailers. They were in crisis mode and needed to find the root cause and a permanent solution.

Our Analysis: A Flaw Hidden in the Steel

The client sent us several failed bottles and the blow bottle mold base inserts they were using from another supplier. Our engineering team immediately began a forensic analysis. We examined the cracked bottles under polarized light, which reveals stress patterns in the plastic. The cracks were all originating from the same area: the "knuckle radius," the curve where the lobes transition to the standing ring. This pointed towards a material problem, specifically, brittleness caused by crystallization. We knew this was almost always a cooling issue.

Next, we analyzed their mold insert. On the surface, it looked fine. But when we digitally modeled its internal cooling channels, the problem became obvious. The design was flawed. It used a simple, single-circuit cooling channel that couldn't remove heat quickly or evenly enough from the thick plastic in the base. The outer parts of the base were cooling faster than the inner, thicker parts. This temperature differential was creating the exact crystallization and brittleness that was leading to stress cracking. This is a classic example of a problem that can only be solved by a deep expertise in both mold design and the PET material itself. It’s not just about the shape, but about the thermal management during the fraction of a second the bottle is being formed.

The iBottler Solution: Precision Cooling for Flawless Results

Armed with this diagnosis, we didn't just tweak their old design; we engineered a completely new solution. We designed and manufactured a new set of base inserts for them featuring our proprietary "multi-zone spiral cooling system."

Here’s what that means:

- Multi-Zone: Instead of one cooling circuit, we created several independent circuits, each targeting a specific part of the base (the gate, the lobes, the knuckle radius).

- Spiral Flow: The channels were designed in a spiral or helical pattern, which creates turbulent water flow. Turbulent flow is far more efficient at transferring heat than smooth, laminar flow.

- Optimized Materials: We used a beryllium copper alloy for the inserts, which has much higher thermal conductivity than the standard steel the client's previous supplier had used.

This new design aggressively and uniformly pulled heat out of the molded base, "freezing" the PET in its strong, amorphous state before it had a chance to crystallize. After manufacturing the new inserts, we tested them in our lab, simulating the client's exact production parameters. The results were perfect.

The client installed our new base inserts. Their production line started up, and they held their breath. The results were immediate and dramatic. Their stress cracking failure rate dropped from 3% to less than 0.01%. The problem was completely solved. They were able to restore confidence in their supply chain and continue the successful launch of their new product. This case is a perfect illustration of our philosophy: we don't just sell molds; we provide engineering solutions that solve our clients' most difficult manufacturing challenges. It shows that sometimes, the most critical part of a successful bottle is the invisible engineering hidden deep inside the steel. We also helped them validate the new design quickly using our 3D printed samples service before committing to the final tooling.

The Evolution of Bottle Bases: Beyond the Petaloid?

You might think the petaloid design is the final word in bottle bases. But in the competitive beverage industry, the drive for improvement never stops. Engineers are constantly pushing the limits.

The future is about using less material without sacrificing performance. Advanced computer modeling is leading to new, lighter, and even stronger base designs that push beyond the classic five-lobe shape.

The Relentless Pursuit of Lightweighting

In the world of high-volume bottle production, the single biggest cost factor is the raw material: PET resin. The price of this resin fluctuates with the oil market, but it's always significant. Therefore, the holy grail for beverage companies is "lightweighting"—reducing the amount of plastic in each bottle without compromising its performance. Saving even a fraction of a gram per bottle can translate into millions of dollars in cost savings over a year. The base is one of the heaviest parts of the bottle, so it's a prime target for lightweighting efforts. The challenge is to remove material from the base while ensuring it can still withstand the pressure and remain stable. This is where cutting-edge engineering comes into play.

The Next Generation of Base Designs

While the petaloid base is a classic and remains the workhorse for most carbonated soft drinks, it is not the only design. Our team is constantly researching and developing new options for our clients who want to push the boundaries of performance and cost savings.

- Star Base: Often seen on non-carbonated water bottles, this design uses a star-shaped pattern of ribs. It's very material-efficient but generally not strong enough for highly carbonated beverages. However, hybrid designs that incorporate star-like features are being developed for lightly sparkling drinks.

- Asymmetrical and Ribbed Bases: Using advanced FEA simulation software, engineers can now move beyond simple, symmetrical shapes. They can add tiny ribs, vary the thickness in non-intuitive ways, and create complex geometries that are precisely optimized to place material only where it is structurally needed. These designs might not look as simple or elegant as the classic petaloid, but they can offer superior strength-to-weight performance.

While the petaloid base is a classic, we never stop innovating. Our team is developing next-gen lightweight bases for major brands, aiming to cut another 5% of PET use while maintaining or improving performance. This is how we consistently create value for our clients. This process involves constant refinement of our PET bottle mold design guide and leveraging new technologies to achieve what was previously impossible.

| Base Design | Primary Application | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Petaloid Base | Carbonated Soft Drinks, Sparkling Water | Proven strength and stability | Not the most lightweight option |

| Star Base | Still Water, Juices | Excellent material efficiency | Low pressure resistance |

| Flat Base | Aseptic / Hot-fill products | Simple, easy to label | No pressure resistance (requires nitrogen dosing) |

| Next-Gen Ribbed Base | High-performance CSD, Beer | Highest strength-to-weight ratio | Complex to design and manufacture |

The evolution of the bottle base is a perfect example of how a seemingly solved problem is always open to innovation. As computer modeling gets more powerful and our understanding of materials deepens, we will continue to see even lighter, stronger, and more sustainable packaging solutions emerge.

Is Your Bottle's Foundation Strong Enough? Get a Free Base Design Evaluation

Is your current bottle design wasting money? Are you exposed to the risk of costly failures? An unoptimized base can secretly hurt your bottom line and your brand's reputation.

Let our experts analyze your bottle's base design. We will provide a confidential report identifying opportunities for lightweighting, strengthening, and cost reduction—absolutely free of charge.

The Hidden Costs of a Sub-Optimal Design

The base is the foundation of your bottle. If the foundation is weak or inefficient, the entire product is at risk. Many companies use "good enough" bottle designs for years, not realizing the hidden costs they are incurring every single day.

- Material Waste: An unoptimized base can easily carry an extra 0.5 to 1 gram of PET. If you produce 100 million bottles a year, that's 50 to 100 metric tons of wasted resin, potentially costing you hundreds of thousands of dollars.

- Production Inefficiency: A poorly designed base can lead to higher defect rates on the production line. This means more downtime, more operator intervention, and lower overall equipment effectiveness (OEE).

- Catastrophic Failure: As our case study showed, a design flaw can lead to widespread product failures in the field. The cost of recalls, damaged goods, and lost brand trust can be astronomical.

- Missed Opportunities: Your competitors are constantly working to lightweight their packaging. If your bottle is heavier, you are at a cost disadvantage, which can erode your profit margins or make your product less competitive on the shelf.

The base is the foundation of your product's safety and performance. Is your current design optimized for cost and strength? Let us give your design a free 'health check' before you invest in your next million-unit order.

What Our Free Evaluation Includes

When you send us your bottle sample or technical drawing, our team of experienced PET packaging engineers will conduct a thorough analysis. This is not a superficial glance; it's a deep dive into the critical performance aspects of your bottle's base. Our confidential report will provide you with:

- Material Distribution Analysis: We'll assess how well the plastic is distributed across the base, identifying any areas that are dangerously thin or unnecessarily thick.

- Stress Concentration Assessment: Using our experience and analysis tools, we'll pinpoint any high-stress areas that could be potential failure points.

- Lightweighting Opportunities: We will identify specific ways you can remove material from the base without compromising its structural integrity.

- Manufacturability Review: We'll look at the design from a production perspective, pointing out any features that might make it difficult to manufacture consistently at high speeds.

A Simple, Risk-Free Process

We've made the process as simple as possible.

- Contact Us: Reach out to our team and tell us you're interested in the free base design evaluation.

- Send Your Sample/Drawing: Ship us a few samples of your current bottle or email us the 3D file or technical drawing.

- Receive Your Report: Our engineers will perform the analysis and prepare a concise, easy-to-understand report with actionable recommendations.

There is no cost and no obligation. This is our way of demonstrating our expertise and the value we can bring to your business. Let our engineers provide you with a free, confidential base design evaluation and point out potential improvements or risks.

Conclusion

The 5-point petaloid base is a perfect blend of physics, engineering, and manufacturing necessity. It masterfully solves the challenges of pressure and stability for carbonated beverages.

| Aspect | Summary |

|---|---|

| Core Problem | High internal pressure from carbonation (CO2). |

| The Solution | The 5-point "Petaloid Base" design. |

| Key Principle | Uses arches and domes to redirect force and eliminate stress concentration. |

| Primary Benefits | High strength to resist bursting; excellent stability to prevent wobbling. |

| Manufacturing | Challenging process requiring precise control of heating, stretching, and cooling. |

| Key Takeaway | An ingenious, functional design that ensures product safety and efficiency. |

Frequently Asked Questions

Q: Why are there always five bumps, not four or six?

A: Five points provide the optimal balance of strength, stability, and material usage. A four-point base can create a rocking motion (like a wobbly table), as it doesn't guarantee all points will touch a flat surface simultaneously. Six or more points adds unnecessary complexity and weight during manufacturing without providing a significant increase in strength or stability. The five-point design is the engineering sweet spot.

Q: Do glass bottles for sparkling drinks also need this kind of base?

A: Yes, they need a pressure-resistant base, but they use a different design. Glass bottles for champagne or sparkling wine typically have a deep concave dome called a "punt" or "kick-up." The principle is exactly the same—to create a strong dome shape that resists pressure. However, the execution is different because glass is a much more rigid and brittle material than PET plastic, and it is formed using a different manufacturing process.

Q: Is it possible to make a flat-bottomed bottle for a carbonated drink?

A: While it's technically challenging and generally not recommended for highly carbonated drinks like cola, it is possible for beverages with light carbonation. This requires several special measures: a much thicker base to resist deformation, using specific grades of PET with higher strength, and often employing nitrogen dosing technology. Nitrogen dosing involves adding a droplet of liquid nitrogen into the bottle just before capping. The nitrogen evaporates and creates a baseline internal pressure, which helps to counteract deformation and rigidify the bottle. However, this significantly increases both the cost and complexity of production.

Q: How much does the base design affect the total weight of the bottle?

A: The base has a huge impact on the total weight. It is typically one of the heaviest parts of the bottle, along with the neck finish. A poorly optimized base on a 500ml bottle can easily waste up to 1 gram of PET. An optimized design, like the ones we develop through advanced analysis, can save 10-15% of the material in the base area alone. When a company is producing hundreds of millions of bottles per year, these small savings per bottle add up to massive cost reductions in raw material purchasing.

Q: What is the most common problem you see with petaloid base designs from other mould makers?

A: The single most common issue we encounter is uneven material distribution, which very often leads to a thin and weak gate area (the center point) that is highly prone to stress cracking. This is almost always caused by a combination of two things: a poorly designed mold cooling system that doesn't extract heat uniformly, and a lack of deep understanding of the preform stretching dynamics. Many mold makers can copy a shape, but very few can truly engineer a mold and process that guarantees optimal material distribution every single cycle.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr