Confused by bottle neck numbers like PCO1881 or 29/25? You're not alone. These codes dictate cost, performance, and sustainability. Choosing the wrong one can be a costly mistake.

These numbers are standards for PET bottle openings. PCO1881 and PCO1810 are ISBT codes for shorter and taller carbonated drink necks. 29/25 and 30/25 are dimensional names (thread/inner diameter in mm), typically used for water bottles, representing a similar short vs. tall evolution.

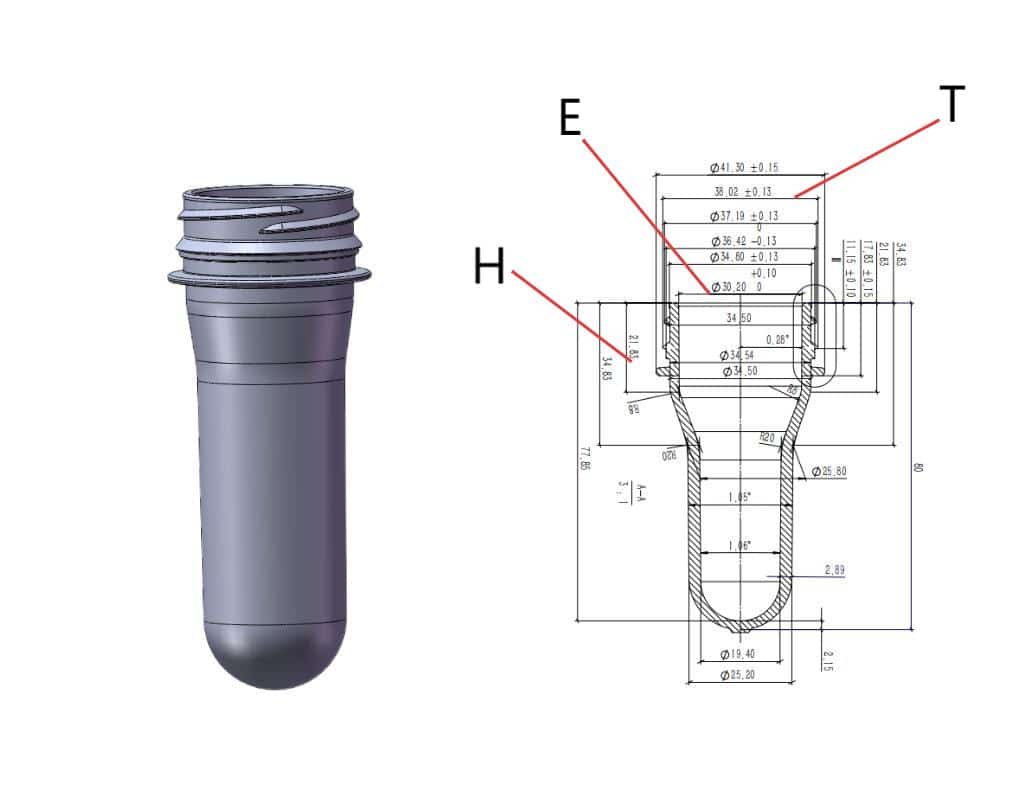

.png)

Choosing a bottle's neck finish feels like a small detail, but it has huge consequences. It affects everything from the raw material cost of your preform to the type of cap you can use. It even impacts how your final product feels in the consumer's hand. In my years in this industry, I've seen how this single decision can define a product's success or failure. It's not just about a few millimeters of plastic; it's about your entire business strategy. Let's break down these cryptic numbers so you can make the right choice with confidence.

What Do These Numbers Actually Mean? A Quick Primer?

Struggling to understand the jargon behind PET neck finishes? The codes seem random, making it hard to compare options. This confusion can lead to poor choices for your product line.

These numbers define the bottle's opening. "PCO" stands for Plastic Closures Only, an industry standard. "1881" and "1810" are standard codes. "29/25" and "30/25" refer directly to the neck's dimensions in millimeters, making them easier to understand at a glance.

The naming conventions for these neck finishes tell a story about their origins. From my experience, you can see how they were developed. The PCO series comes from an industry association's push for standardization. It was about creating a universal language for bottlers, especially for carbonated soft drinks (CSDs). On the other hand, necks like 29/25 and 30/25 grew more organically from the market's needs. They were driven by the fierce competition in the bottled water industry, where every fraction of a gram of plastic saved translates into massive cost reductions. When you understand this "standardization vs. market-driven" background, you start to see why each neck finish has its specific place in the market. It's not just random numbers; it's a reflection of the industry's history and economic pressures.

The "PCO" Designation: A Mark of Standardization

The term "PCO" is one you will see often. It stands for "Plastic Closures Only." This was an important designation created by the International Society of Beverage Technologists, or ISBT. Their goal was to create clear standards that everyone in the beverage world could follow. Before these standards, there was a lot of variation, which caused problems with cap compatibility and sealing performance.

The PCO standard defines everything about the neck finish. This includes the thread profile, the height, the diameter, and the design of the tamper-evident band. When you choose a PCO neck finish, you are choosing a well-documented, globally recognized standard. This makes it much easier to find compatible caps from a wide range of suppliers. It takes the guesswork out of a critical part of your packaging. For businesses that need reliability and a robust supply chain, the PCO standard is the foundation.

The "1810" and "1881" Codes: The Legacy System

Within the PCO family, 1810 and 1881 are the most famous, especially for carbonated drinks. These are not measurements. They are simply code names assigned by the ISBT.

- PCO 1810: This is the older, "tall neck" standard. For many years, it was the go-to finish for sodas and sparkling water. Its taller neck provided a strong seal, which was necessary to hold carbonation under pressure. You can spot it by the significant height of the neck section above the support ring.

- PCO 1881: This is the newer, "short neck" or "low profile" standard. It was developed as a direct response to the industry's demand for lightweighting. By reducing the neck height and optimizing the thread design, the 1881 standard uses significantly less plastic than the 1810. It achieves the same excellent sealing performance for CSDs but at a lower cost and with a smaller environmental footprint. This shift from 1810 to 1881 was a true revolution in beverage packaging.

The "29/25" and "30/25" Dimensions: A Practical Approach

Unlike the PCO codes, the names "29/25" and "30/25" are much more direct. They are based on physical dimensions, which I find makes them more intuitive for people new to the industry. Here is what the numbers mean:

- First Number (e.g., 29 or 30): This is the approximate outer diameter of the threads, measured in millimeters. So, a 30/25 neck is slightly wider than a 29/25 neck.

- Second Number (e.g., 25): This is the approximate inner diameter of the bottle opening, also in millimeters. In both these cases, the inner opening is about 25mm.

This naming system is common for non-pressurized beverages, especially still water. It clearly communicates the key dimensions. Just like the PCO family, this group also has its own "tall" and "short" versions: 30/25 is the older, taller, and heavier version, while 29/25 is its lightweight, short-neck successor. The logic is exactly the same: use less material to achieve the same function and save costs.

Here is a simple table to summarize the naming systems:

| Neck Finish | Naming System | Primary Meaning | Common Use Case |

|---|---|---|---|

| PCO 1810 | ISBT Code | The original "tall neck" standard for CSDs. | Old CSD lines |

| PCO 1881 | ISBT Code | The modern "short neck" lightweight standard for CSDs. | CSDs, Teas, Water |

| 30/25 | Dimensional | A "tall neck" water bottle finish (30mm thread / 25mm bore). | Older water bottle lines |

| 29/25 | Dimensional | A "short neck" water bottle finish (29mm thread / 25mm bore). | Modern water bottles |

Understanding these basic definitions is the first step. It allows you to speak the language of the industry and begin to evaluate which option makes the most sense for your specific product.

The Applications: Matching the Neck to the Product?

Worried about choosing a neck finish that doesn't fit your product? The wrong choice can lead to sealing issues, higher costs, or supply chain problems. You need a clear guide.

Match the neck to the beverage type. PCO1881 is the all-rounder for carbonated drinks, teas, and water. 29/25 is the modern specialist for still water. The older 1810 and 30/25 standards are now mostly used only for legacy production lines.

This matching list reveals the business strategy behind each choice. When a client tells me they've selected PCO1881, I know they are prioritizing flexibility and future-proofing their production. They can launch a carbonated drink today and a bottled tea tomorrow using the same preform stock. It’s a versatile choice. But when a client chooses 29/25, it signals a different strategy: a laser focus on cost leadership. They are planning to produce a single product, like still water, at a massive scale where saving a fraction of a cent per bottle adds up to millions. So, before you pick a neck finish, you should ask yourself: what is my core business goal? Am I building a flexible brand platform or a highly efficient, single-product factory? Your answer will point you to the right piece of plastic.

PCO1881: The "All-Around Champion"

If there is one neck finish that can do almost everything, it is the PCO1881. Its rise to dominance has been incredible to watch. Its main advantage is its versatility.

- Carbonated Soft Drinks (CSDs): This is what PCO1881 was originally designed for. It provides an excellent gas seal to keep drinks fizzy, even under pressure. Major brands like Coca-Cola and PepsiCo have largely transitioned to this standard.

- Bottled Water (Still & Sparkling): While 29/25 is the specialist for still water, PCO1881 is also an excellent choice. For sparkling or carbonated water, it is the preferred option due to its pressure-holding capabilities.

- Ready-to-Drink Teas & Juices: For many teas, sports drinks, and juices that do not require a hot-fill process, the PCO1881 is a perfect fit. It offers a secure seal and has a vast supply chain of compatible caps.

Choosing PCO1881 is often the safest bet. It gives you the widest range of options for future product development and ensures you can source components easily. The decision to use it is a strategic one that balances cost, performance, and supply chain security.

29/25: The "New Generation Water Specialist"

The 29/25 neck finish was born from the need to squeeze every possible cost saving out of bottled water production. It is the result of relentless optimization. As the successor to the 30/25, its primary application is for non-carbonated, or still, beverages.

Its main advantage is its weight. It is one of the lightest neck finishes available that still provides a great consumer experience. For a high-volume water bottler, switching from 30/25 to 29/25 can result in saving hundreds of tons of PET resin per year. This has a direct and massive impact on the bottom line. This focus makes it less versatile than the PCO1881. It is not generally recommended for carbonated beverages. However, for still water, it has become the new king, rapidly replacing its taller predecessor on new production lines around the world.

The Legacy Necks: PCO1810 and 30/25

While new projects almost always use the shorter neck finishes, the older, taller standards haven't disappeared completely.

- PCO1810: You will mostly find this neck finish on older CSD production lines that have not yet been updated. Some companies continue to use it because the cost of converting an entire bottling line—from the blower to the capper—can be very high. However, no one is installing a new line with a PCO1810 standard today. It is a legacy product.

- 30/25: Similar to the 1810, the 30/25 is the legacy "tall neck" for water bottles. It was once the standard, especially for premium water brands that wanted a more substantial feel. Today, its market share is shrinking fast. Existing lines still use it, but nearly all new investment goes into the lighter 29/25 format.

A Note on Other Products: Juices, Dairy, and Hot-Fill

It is important to note that the four neck finishes we are discussing do not cover the entire beverage market. For products like pulpy juices, dairy drinks, or beverages that need to be hot-filled, a wider mouth is necessary. In these cases, a 38mm neck finish is the industry standard. This larger opening makes it easier to fill viscous liquids and allows for a smooth pouring experience for the consumer. It's a different category of neck finish for a different set of challenges. When a customer comes to me with a juice project, for instance, we immediately shift the conversation to the 38mm family of options.

Here is a table that maps these applications clearly:

| Neck Finish | Primary Application | Secondary Applications | Not Recommended For | Strategic Focus |

|---|---|---|---|---|

| PCO 1881 | Carbonated Soft Drinks (CSDs) | Still Water, Sparkling Water, Teas | Hot-fill, Pulpy Juices | Flexibility |

| 29/25 | Still Water | Low-carbonation drinks | High-pressure CSDs, Hot-fill | Cost Leadership |

| PCO 1810 | Legacy CSD Lines | - | New Projects of any kind | Maintaining Old Lines |

| 30/25 | Legacy Water Bottle Lines | - | New Projects of any kind | Maintaining Old Lines |

Head-to-Head (Part 1): PCO1881 vs. PCO1810 - The CSD Lightweighting Revolution?

Sticking with the old PCO1810 standard? You are likely wasting money on every single bottle you produce. The weight difference is significant, and it adds up to a huge expense.

PCO1881 is the clear winner. It uses less plastic, weighs less, and costs less to produce than the older PCO1810 standard. It provides the same high-performance seal for carbonated drinks, making the switch a financially smart decision for any beverage company.

I saw the power of this transition firsthand. We worked with a large Canadian mineral water brand. They had a historic production line for their flagship sparkling water that still used the old PCO1810 standard. They were hesitant to change. I put together a detailed analysis for them. We showed them exactly how much PET resin they were wasting per bottle. Then, we designed a new, modern bottle for them and manufactured a full set of new blow bottle molds with the PCO1881 neck finish. After the conversion, they reduced their preform weight by over 15%. Based on their production volume, they calculated this would save them nearly half a million dollars every year. That one project showed them that updating a neck finish isn't just a technical change; it's a massive business opportunity.

The Physical Differences: More Than Just Height

At first glance, the main difference between PCO1810 and PCO1881 is the height of the neck. The 1810 is visibly taller above the neck support ring. But the design changes are much more sophisticated than that. The entire geometry was re-engineered for efficiency and performance.

- Neck Height: This is the most obvious difference. The shorter neck on the 1881 is the primary source of material savings.

- Thread Profile: The 1881 features a modified thread design. It requires fewer turns to seal the cap, which can lead to slightly faster capping speeds on the bottling line.

- Weight: This is the critical factor. A typical PCO1810 preform for a 500ml CSD bottle might weigh around 21-23 grams. A PCO1881 preform for the exact same bottle can weigh as little as 18-20 grams. A saving of 2-3 grams per bottle is enormous at scale.

- Cap Design: The PCO1881 also allows for a lighter cap design, adding another layer of material and cost savings to the total package.

Let's look at the numbers in a direct comparison:

| Feature | PCO 1810 (Tall Neck) | PCO 1881 (Short Neck) | Advantage of 1881 |

|---|---|---|---|

| Typical Neck Height | ~21 mm | ~17 mm | Reduced material usage |

| Typical Preform Weight | 21-23 g | 18-20 g | Significant cost savings (~15% less PET) |

| Thread Turns for Seal | ~2.5 turns | ~1.75 turns | Potentially faster capping speeds |

| Cap Weight | Heavier | Lighter | Additional material and cost savings |

| Market Standard | Legacy | Current Global Standard | Wider supply chain, better future compatibility |

The Driving Force: A Revolution in Cost and Carbon Footprint

The shift from 1810 to 1881 wasn't just for fun. It was driven by powerful economic and environmental forces. The price of PET resin can be volatile. Reducing the amount of plastic in each bottle directly protects a company's profit margins from this volatility. When you produce hundreds of millions of bottles a year, a 3-gram saving per bottle translates into thousands of tons of PET resin saved. This is a multi-million dollar impact.

Furthermore, sustainability became a major focus for consumers and corporations. Reducing plastic usage is a key goal for every major beverage company. The PCO1881 was a huge step forward. Less plastic means less oil consumed, lower energy use in manufacturing, and a smaller carbon footprint for transportation because the preforms are lighter. The transition was a classic win-win: it was good for the planet and great for the company's finances.

Performance Under Pressure: Why 1881 Still Works

A common question I get is: "If you remove so much plastic, how can the PCO1881 possibly hold the pressure of a carbonated drink as well as the old 1810?" This is a valid concern, and the answer lies in smart engineering.

The designers of the 1881 standard didn't just chop the top off the 1810 neck. They used advanced modeling tools to optimize the remaining structure. The thread design engages the cap more effectively, creating a tight seal with less material. The area under the neck support ring was also analyzed to ensure it had enough strength to withstand the top-load pressure on a filling line without deforming. The result is a neck finish that is a marvel of efficiency. It delivers the same, if not better, sealing integrity and structural performance, all while using significantly less raw material. It proves that better design can achieve more with less. Our work in PET bottle mold design ensures that the bottle body perfectly complements this efficient neck, creating a package that is both light and strong.

Head-to-Head (Part 2): 29/25 vs. 30/25 - The Evolution of Water Bottle Necks?

Using the older 30/25 neck for your water bottle? You are missing out on significant cost savings. Every bottle is heavier and more expensive than it needs to be in today's market.

The 29/25 neck is the modern, lightweight successor to the 30/25. It offers nearly identical performance for still water bottles while using less plastic. This directly translates to lower preform costs and a reduced environmental impact for bottlers.

This trend of switching to shorter necks is happening everywhere. We recently partnered with a major beverage company in Thailand. They wanted to modernize their entire bottled water line, which was still using the old 30/25 neck finish. We presented a complete conversion plan to the 29/25 standard. The project involved designing a new, sleeker bottle and manufacturing all the new preform molds and blow molds. The results were fantastic. Each preform was about 0.8 grams lighter, which is a huge saving at their scale. Plus, the new bottle design had a much more modern look on the shelf. The project was so successful that they are now planning to do the same lightweighting conversion for their iced tea product line.

A Familiar Story: The Water Bottle's Lightweighting Journey

The battle between 29/25 and 30/25 is almost a perfect replay of the PCO1881 vs. 1810 story, but this time in the world of still beverages. The motivation is exactly the same: reduce weight, cut costs, and improve sustainability.

- 30/25 (The Original): This was the long-standing choice for premium water bottles. Its taller neck and slightly heavier weight gave it a feeling of quality and substance. It was a reliable, well-understood standard for many years.

- 29/25 (The Successor): As the bottled water market became more competitive, the pressure to reduce costs intensified. The 29/25 was developed as a "drop-in" lightweighting solution. It shortens the neck and slightly reduces the thread diameter, all while maintaining the same inner opening and providing a secure seal for non-pressurized drinks.

The transition is a logical step in the evolution of packaging. As engineering and material science improve, we find ways to deliver the same functionality with less material. The 29/25 is the current peak of that evolution for still water.

By the Grams: Quantifying the Savings

In the high-volume world of bottled water, savings are measured in fractions of a gram. But these tiny fractions add up incredibly quickly. Let's break down the real-world impact.

Consider a standard 500ml bottle of water:

| Feature | 30/25 (Tall Neck) Preform | 29/25 (Short Neck) Preform | The Difference (per bottle) |

|---|---|---|---|

| Typical Preform Weight | 13.5 - 14.5 grams | 12.7 - 13.7 grams | ~0.8 - 1.0 grams saved |

An average saving of 0.8 grams may not sound like much. But let's see what it means for a medium-sized production line producing 50 million bottles per year:

- Total PET Saved: 50,000,000 bottles * 0.8 grams/bottle = 40,000,000 grams = 40,000 kilograms = 40 metric tons.

- Cost Savings: The price of PET resin fluctuates, but let's use a conservative estimate of $1,500 per ton. 40 tons * $1,500/ton = $60,000 per year.

These are direct, tangible savings that go straight to the bottom line, all from changing a few millimeters of plastic at the top of the bottle. And this calculation doesn't even include the secondary savings from lower shipping costs for the lighter preforms.

My Experience: The Thai Beverage Company Upgrade

When we started working with the Thai company, their team had some reservations. They were worried that the new, lighter 29/25 neck would feel "cheap" to their customers who were used to the 30/25. This is a common concern.

To address this, our approach was holistic. We didn't just change the neck finish. We used this opportunity to redesign the entire bottle. We added subtle ribbing and a modern base design that increased the bottle's rigidity and top-load strength. This meant that even though the bottle was lighter, it felt just as strong, if not stronger, in the consumer's hand.

A key part of our process was using rapid prototyping. We created 3D printed samples of the new bottle design. This allowed their marketing and management teams to physically hold the new bottle, feel its strength, and see its modern aesthetics long before we cut any steel for the molds. This step was crucial in getting everyone to enthusiastically support the change. The final product was a huge success, proving that lightweighting, when done correctly, can also be an opportunity to refresh a brand's image.

Market Share & Future Trends: The Unstoppable Shift to "Short Necks"?

Confused about which neck finish to choose for a new project? Betting on an old standard like PCO1810 or 30/25 could leave you with higher costs and a limited supply chain.

The future is short. The market has decisively shifted towards lightweight, "short neck" standards like PCO1881 and 29/25. These options offer lower costs, better sustainability, and the widest variety of compatible components, making them the smart choice for all new projects.

My advice to any new brand or entrepreneur entering the beverage market is simple and direct. Unless you have a very specific, technical reason tied to existing machinery, you should choose a short neck solution. Go with PCO1881 for versatility or 29/25 for ultimate cost efficiency in water. This choice immediately puts your product on a competitive cost footing from day one. More importantly, it aligns you with the future of the industry. You will have access to the widest selection of cap suppliers, the latest innovations in closure technology, and the most efficient preforms. Choosing a short neck isn't just a technical decision; it's a strategic move to ensure the long-term health and competitiveness of your business. It is, without a doubt, choosing the future.

The Data Doesn't Lie: Short Necks are Dominating

While exact market share numbers can be proprietary, the trend on the ground is crystal clear to anyone in the industry. I spend my days talking to bottlers, preform manufacturers, and equipment suppliers. The conversation is always about lightweighting and efficiency.

- New Production Lines: Virtually 100% of new bottling lines being installed for CSDs and water are designed for short neck finishes (PCO1881 and 29/25). Investing in a new line based on an old, heavy standard simply makes no financial sense.

- Component Supply: Cap and preform manufacturers are focusing their R&D and production capacity on short neck products. While they still supply the older standards for existing customers, all the innovation and most competitive pricing are found in the short neck market.

- Retailer and Brand Owner Mandates: Many large retailers and brand owners are setting aggressive sustainability goals. They are actively pushing their suppliers and co-packers to adopt lightweight packaging like the PCO1881 and 29/25 to help meet these targets.

The tall neck standards of PCO1810 and 30/25 have been relegated to the status of "legacy parts." They are needed to service existing equipment, but their share of the overall market is shrinking every year as old lines are retired and replaced.

Why are Short Necks the Future? The Triple Advantage

The dominance of short necks is not a temporary trend. It is a permanent shift based on a powerful combination of three key benefits:

- Economic Advantage (Cost): This is the primary driver. Less plastic means lower raw material costs. As we've shown, this can add up to millions of dollars in savings for large-scale producers. In a competitive market, lower cost of goods is a powerful weapon.

- Environmental Advantage (Sustainability): Using less plastic directly translates to a lower environmental footprint. This is a crucial selling point for modern consumers and a core part of corporate responsibility for major brands. Less raw material extraction, less energy consumption in production, and lower carbon emissions from transport all contribute to a greener product.

- Logistical Advantage (Efficiency): Lighter preforms are cheaper to transport. You can also fit more short neck preforms into a standard shipping container or pallet box compared to their taller counterparts. This optimizes the entire supply chain, from the preform plant to the bottling facility, adding another layer of cost savings.

My Advice for New Beverage Brands

If you are launching a new beverage product, the choice is clear. Start with a short neck finish. It might be tempting to use an older standard if you find some cheap, used equipment, but this is a classic example of being "penny wise and pound foolish." The short-term savings on equipment will be quickly wiped out by the long-term, higher costs of your preforms and caps.

I highly recommend you consult a guide on how to choose the right preform neck size before making a final decision. By starting with a modern standard like PCO1881 or 29/25, you are building your business on a solid, efficient, and future-proof foundation. You ensure access to the best technology and the most competitive component pricing for years to come.

Beyond the Numbers: The Mold is What Brings It to Life?

You've chosen the perfect neck finish standard. But how do you connect that standard to your unique, custom bottle design? This is where many projects get stuck.

A high-precision blow mold is the critical tool that unites them. The mold's neck-finish insert perfectly forms the standardized opening, while the mold cavity shapes your unique bottle body. It is the bridge between a global standard and your specific brand identity.

I always tell my clients this: the numbers like 1881 or 29/25 define the "interface" of your bottle. That's the part that needs to connect perfectly with a standard cap. It's all about technical precision. But the body of the bottle—its curves, its texture, its shape—that is the "soul" of your brand. That's what the customer sees and holds. My company's entire purpose is to ensure that the soul you've designed can be perfectly and reliably attached to the interface you've chosen. The blow bottle mold is the instrument that makes this connection possible, turning a technical specification into a physical product on the shelf.

The Neck is the Standard, The Body is the Brand

This is a core concept in bottle manufacturing. The neck finish must adhere strictly to the chosen standard (e.g., PCO1881). There is no room for creativity here. The dimensions must be perfect down to fractions of a millimeter to ensure a proper seal and prevent leaks. This is the non-negotiable, technical part of the bottle.

But from the neck support ring down, you have almost complete creative freedom. This is where your brand comes to life. Do you want a classic, elegant shape for your premium water? A sleek, aggressive design for an energy drink? A ribbed, easy-to-grip body for a sports drink? All of this is defined by the main body of the blow mold. The mold is the custom tool that imparts your unique branding onto a standardized platform. It allows for mass customization, where every bottle has a unique soul but speaks the same universal language at the cap.

How a Blow Mold Bridges the Gap

A blow mold is a highly precise piece of engineering, typically made from aircraft-grade aluminum or steel. It is composed of several key parts that work together:

- Mold Cavities: These are the two halves of the mold that define the main outer shape of your bottle. When they close, they form a cavity in the shape of your final product.

- Bottom Mold: This piece forms the base of the bottle, including the critical "feet" that allow it to stand stably.

- Neck Finish Inserts: These are arguably the most critical parts. They are separate, ultra-high-precision inserts at the top of the mold. These inserts form the threads, the tamper-evident ring, and all the other critical features of the neck finish. They are made to exacting tolerances to perfectly match the ISBT or dimensional standard you've chosen.

During the blowing process, a heated preform is placed inside the closed mold. A stretch rod extends the preform downwards, and then high-pressure air inflates it, forcing the soft plastic to take the shape of the mold cavity and the neck finish inserts. It is in this instant that the standard and the brand are fused together.

The Critical Role of Precision

I cannot overstate the importance of precision in mold making. A tiny mistake in the mold can lead to huge problems down the line. If the neck finish insert is off by a tiny fraction, you could face issues like:

- Leaking Caps: The seal will not be secure, causing product to leak during shipping and on the shelf.

- Stripped Threads: The cap will not screw on properly.

- Tamper-Band Failure: The tamper-evident ring may not engage or break correctly.

- Bottle Defects: An imperfect mold can cause a range of common PET blow molding defects that can ruin your product quality.

This is why choosing an experienced mold maker is so important. We use advanced CNC machines and meticulous quality control to ensure that every mold we produce is a perfect translation of the design, especially in the critical neck finish area. We also have a massive library of specifications to ensure that the mold we build for you will fit your specific bottle blowing machine, which is a crucial step often overlooked.

A Quick Guide to Visually Identifying the Four Necks?

On a busy production floor, you need to identify preforms quickly. Mistaking a PCO1810 for an 1881 can cause line stoppages and waste. How can you tell them apart instantly?

Focus on the neck height above the prominent support ring. Tall necks (1810 and 30/25) have a visibly longer, skinnier section there. Short necks (1881 and 29/25) look much more compact and squat in that same area.

This simple visual trick is one of the first things I teach new technicians. In the workshop, being able to grab the right box of preforms without having to read the label is a basic but essential skill. It makes you faster and more efficient. When you can walk up to a pallet and confidently identify the product just by looking at it, it also makes you look more professional when communicating with suppliers or clients on-site. It's a small detail that shows you really know your craft.

The Telltale Sign: Neck Height Above the Support Ring

Every PET preform has a flange, or a small plastic ring, partway down the neck. This is called the Neck Support Ring. Its job is to support the preform as it travels through the heating oven in the blow molding machine. The area above this ring is the key to visual identification.

- Tall Necks (PCO1810 and 30/25): In these older standards, the section of the neck finish that extends above the support ring is noticeably tall. It creates a longer, more slender appearance.

- Short Necks (PCO1881 and 29/25): In the modern, lightweight standards, this section is much shorter and more compressed. The threads start much closer to the support ring, giving the entire neck finish a low-profile, squat look.

Once you train your eye to look specifically at this one feature, the difference becomes obvious.

A Quick Comparison Table for Identification

Let's break down the comparisons with a simple guide.

| Comparison | How to Tell Them Apart | The Winner in a Lineup |

|---|---|---|

| 1810 vs. 1881 | Look at the neck above the support ring. The 1810 is visibly taller and skinnier. The 1881 is short and compact. | 1810 is taller. |

| 30/25 vs. 29/25 | It's the same principle. The 30/25 has the taller neck. The 29/25 has the shorter, lightweight neck. | 30/25 is taller. |

| 1881 vs. 29/25 | Both are short necks. Look at the opening diameter. The PCO1881 is noticeably smaller in diameter. | 29/25 is wider. |

| 1810 vs. 30/25 | Both are tall necks. The 30/25 has a wider opening and thread diameter. The PCO1810 is narrower. | 30/25 is wider. |

Practice Makes Perfect: A Workshop Story

I remember when a new quality control intern started at one of our facilities. He was bright, but he kept getting confused by the pallets of preforms coming in. He would spend a lot of time double-checking box labels, which slowed down the receiving process.

I took him aside and grabbed one PCO1810 preform and one PCO1881 preform. I didn't tell him which was which. I just said, "Look at the space between the top of the preform and the support ring. Which one looks taller?" He pointed to the 1810 immediately. "That's it," I said. "Tall neck, old standard. Short neck, new standard. That's 90% of what you need to know."

We did the same with the 29/25 and 30/25. Within five minutes, he had it. He could walk down an aisle and correctly identify every pallet at a glance. It's a simple, practical skill that just requires seeing them side-by-side once or twice. It's about knowing what specific feature to focus on and ignoring the rest.

Get an Expert Recommendation for Your Next Project?

Reading charts is helpful, but are you sure you're making the absolute best choice for your specific product? A small mistake in neck finish selection can lock you into higher costs for years.

Don't leave this critical decision to chance. A personalized recommendation from an expert can analyze your unique needs—from product type to market strategy—and help you choose the most profitable and efficient neck finish for your project, saving you money and preventing future problems.

The information in this article is a great start, but it's no substitute for experience. Every project is different. Your product might have unique requirements for pressure resistance, your target market might have specific aesthetic preferences, or your filling line might have certain limitations. This is where we can help. Tell us about your project. We will provide you, completely free of charge, with a detailed "Neck Finish Selection Proposal." This isn't a generic sales pitch. It's a technical and market-based recommendation from our engineering team to help you make the smartest possible decision for your business.

Why a Standard Chart Isn't Enough

A comparison chart can tell you that PCO1881 is good for CSDs and 29/25 is good for water. But it can't answer the more complex questions specific to your business:

- What if you are launching a new, lightly carbonated juice? Should you use the PCO1881 for better pressure handling, or is a lighter neck sufficient?

- You've found a great deal on surplus caps with a 30/25 neck finish. Is the low cap price enough to justify using an older, heavier preform standard? (The answer is almost always no, but it requires a cost analysis to prove it.)

- How does the choice of neck finish impact the required performance of your other equipment, like the chiller and air compressor?

- Your bottle design is very tall and slender. Does this create any top-load issues that might make one neck finish a better structural choice than another?

These are the kinds of nuanced questions that require deep industry experience to answer correctly. Making the wrong assumption can be a costly mistake.

Our Process: The Neck Finish Selection Proposal

When you ask us for a recommendation, we don't just give you a one-line answer. We engage in a detailed process to give you a truly valuable and actionable report. Here’s what our free proposal includes:

- Project Analysis: We start by listening to you. We want to understand your product, your target market, your production volume, and your business goals.

- Technical Evaluation: We assess the technical requirements. Does your product need to hold pressure? Is it a hot-fill application? What are the shelf-life requirements?

- Cost-Benefit Breakdown: We model the costs for you. We will compare the preform costs, estimated cap costs, and potential shipping savings for the top 2-3 most suitable neck finish options.

- Supply Chain Considerations: We provide insights into the availability and variety of stock caps for each recommended option, helping you de-risk your supply chain.

- Final Recommendation: We conclude with a clear recommendation, explaining exactly why we believe a specific neck finish is the optimal choice for your project, balancing cost, performance, and market factors.

Let's Talk About Your Project

The goal is to empower you to make the best decision with all the facts at your disposal. We believe that an informed customer is our best partner. The first step is a simple conversation.

Reach out to our team today. Tell us about your new beverage idea, your existing production challenges, or your plans for modernization. We will put our 16 years of experience to work for you and provide you with a clear, honest, and data-driven recommendation. Don't guess when it comes to a decision this important. Let us help you get it right from the very start. We can even discuss how to ensure the mold and blowing machine are a perfect match, a critical step for a smooth production launch.

Conclusion

Choosing the right PET neck finish is a key decision. The industry has clearly moved towards shorter, lighter standards like PCO1881 and 29/25 to save costs and plastic.

Final Summary Table

| Feature | PCO 1810 | PCO 1881 | 30/25 | 29/25 |

|---|---|---|---|---|

| Profile | Tall Neck | Short Neck | Tall Neck | Short Neck |

| Primary Use | Legacy Carbonated Drinks (CSDs) | Modern CSDs, Water, Teas | Legacy Still Water | Modern Still Water |

| Key Advantage | Compatibility with old lines | Versatility, Lightweight, Low Cost | Substantial feel | Extreme Lightweighting, Lowest Cost |

| Market Trend | Declining / Phasing Out | Growing / Global Standard | Declining / Phasing Out | Growing / New Standard for Water |

| Recommendation | Avoid for New Projects | Recommended for Most New Projects | Avoid for New Projects | Recommended for New Water Projects |

Frequently Asked Questions (FAQ)

Q: Can I use a PCO1881 cap on a PCO1810 bottle?

A: No, absolutely not. Although they are from the same PCO family, the thread profiles and heights are completely different. A PCO1881 cap will not seal properly on a PCO1810 neck, and it will lead to leaks, especially with carbonated products. You must always use the cap designed specifically for your bottle's neck finish.

Q: What do the numbers "29/25" and "30/25" actually mean?

A: The numbers are a direct reference to the neck's physical dimensions in millimeters. The first number (29 or 30) is the approximate outer diameter of the thread. The second number (25) is the approximate inner diameter of the opening, or bore. This dimensional naming makes it very easy to understand the basic size of the neck finish at a glance.

Q: As a startup, which neck finish has the widest variety of available stock caps?

A: PCO1881, without a doubt. Because it is the global standard for the massive carbonated soft drink industry as well as many other beverage categories, the variety of available stock caps is enormous. You can find PCO1881 caps in every color, with different liner types (or linerless), and from countless suppliers around the world. This gives you maximum flexibility and competitive pricing for your components.

Q: How much heavier is a 30/25 preform compared to a 29/25 for the same bottle?

A: For a typical 500ml water bottle, a 30/25 preform is approximately 0.8 to 1.2 grams heavier than a 29/25 preform. While this sounds like a tiny amount, when you multiply it by a production run of millions of bottles, the savings in PET resin are significant, often translating into tens or even hundreds of thousands of dollars per year.

Q: Does choosing a lighter neck finish like 29/25 put my bottle at a higher risk of damage?

A: Not if the bottle and secondary packaging are designed correctly. While the neck itself has less plastic, modern bottle designs compensate for this by adding structural features like ribs and optimized bases to improve top-load strength and rigidity. Furthermore, the way bottles are packed in cases and stacked on pallets is a critical factor. A well-designed total packaging system ensures that a lightweight bottle can perform just as well as a heavier one throughout the distribution cycle.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr