Stuck choosing between European quality and Chinese prices? This decision feels complex, but the old stereotypes are misleading and hurting your bottom line.

The best choice depends on Total Cost of Ownership (TCO), not just the initial price. Top-tier Chinese molds often provide a lower TCO due to faster lead times, greater agility, and comparable quality, giving businesses a significant competitive edge in today's fast-paced market.

Deciding on a blow mold supplier is a huge commitment. For years, the industry operated on a simple, almost lazy, assumption. "European made" was the code for high quality, precision engineering, and a hefty price tag. "Made in China" suggested a bargain, but it came with a cloud of doubt about quality and longevity. As we move forward, I want to show you why this black-and-white thinking is not just outdated, it's dangerous for your business. The game has completely changed. I believe we need a smarter, more complete way to measure value. We need to look at the Total Cost of Ownership, or TCO. This framework forces us to look beyond the price on the invoice and consider every single cost, both obvious and hidden, over the entire life of the mold. It is the only way to make a truly informed decision that will benefit your company in the long run.

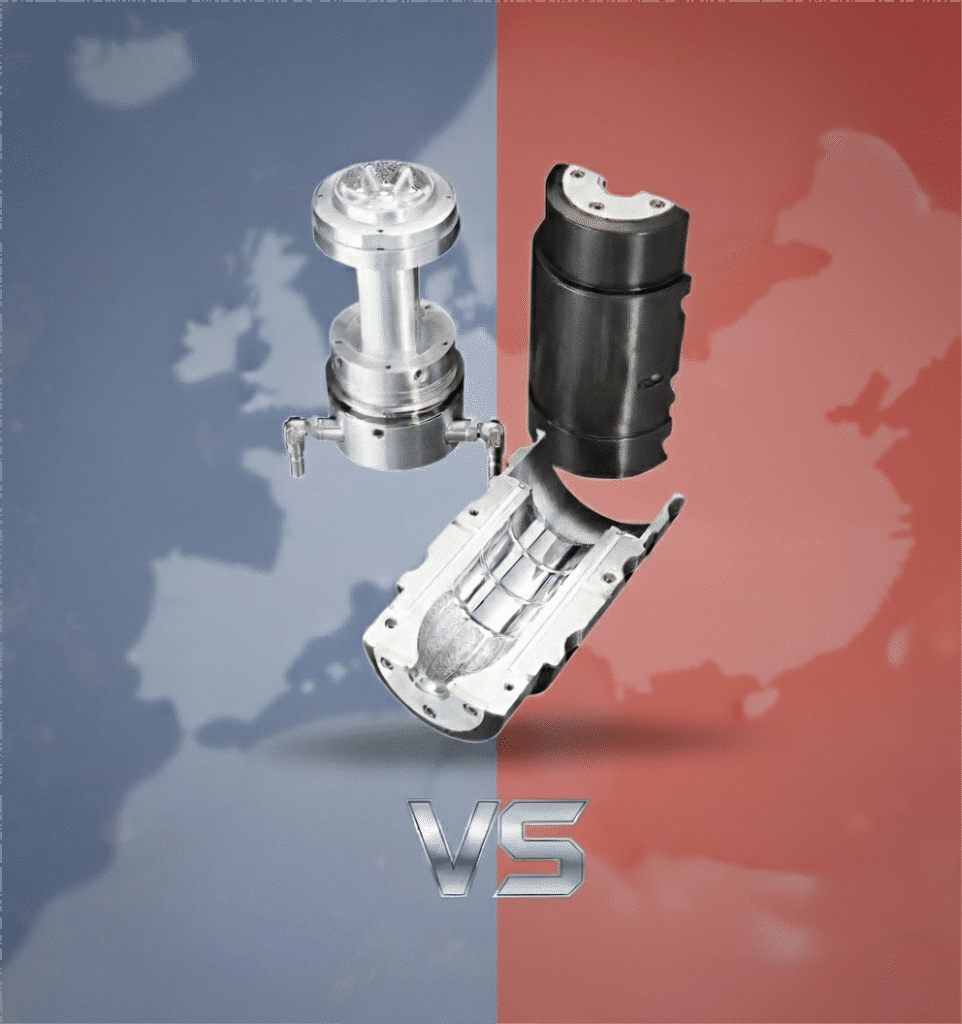

Introduction: Moving Beyond Outdated Stereotypes?

Are you still thinking of mold purchasing as a simple choice between two labels? "Europe" for high quality at a high price, and "China" for a low price with questionable quality.

In 2025, this simple view is completely outdated. To truly understand the value, you must use the "Total Cost of Ownership" (TCO) model. This looks at the entire picture, not just the initial price tag, to reveal the smarter investment for your business.

For too long, the decision-making process for sourcing critical manufacturing equipment like blow bottle molds has been clouded by stereotypes. The narrative was straightforward: If you wanted guaranteed quality and had a big budget, you went to established European manufacturers. If you were trying to save money, you took a risk on a Chinese supplier. I am here to tell you that this entire framework is broken. In my 16 years in this industry, I have had a front-row seat to a massive transformation. I've watched my European colleagues work hard to maintain their legacy of quality. I have also witnessed firsthand how the best Chinese manufacturers, including my own company, have systematically closed the quality gap. We did not do this by cutting corners. We did it by investing heavily in the very same technology and processes that made Europe the benchmark for quality. We brought in state-of-the-art 5-axis CNC machines from Germany. We adopted lean management principles from Japan. And we combined it all with the incredible speed and work ethic that China is known for.

This journey has completely rewritten the definition of "high quality" in the blow molding world. Today, the discussion is no longer about one country versus another. It is about different business philosophies. It is about understanding the total, real-world cost of getting your product to market. This article is my attempt to share a more truthful, more complete picture with you. I want to guide you beyond the outdated labels and give you the tools to analyze your choices through the powerful lens of TCO. We will look at every factor, from the initial quote to the hidden costs of waiting, to help you see the full economic impact of your decision.

The Old Logic vs. The New Reality

Let's break down the shift in thinking.

The Old Logic: Focused almost exclusively on two metrics: initial purchase price and perceived engineering quality. The fear of production downtime from a "cheap" mold often pushed buyers toward the much higher-priced European option, even if it strained their budget. The thinking was, "pay more now to avoid problems later." This logic assumed that a higher price was a perfect guarantee of quality and that all Chinese suppliers were a gamble.

The New Reality: Acknowledges that globalization and technology have leveled the playing field. The new reality is centered on TCO, a much more holistic and accurate measure of value. This model understands that cost is more than just the number on an invoice. It includes:

- Opportunity Cost: How much revenue do you lose if your product launch is delayed by three months because of a long mold lead time?

- Agility Cost: What is the cost of being unable to quickly test a new design or respond to a competitor's move because your mold supplier is too rigid?

- Service & Support Costs: What is the true cost of downtime when you are waiting for a service technician to fly in?

Here is a table to illustrate the shift in mindset:

| Decision Factor | Old Logic (Stereotype-Based) | New Reality (TCO-Based) |

|---|---|---|

| Primary Metric | Initial Purchase Price | Total Cost of Ownership (TCO) |

| Quality Perception | "European" = Good, "Chinese" = Risky | Top-tier Chinese manufacturers use the same equipment and materials as European counterparts. |

| Speed | Not a primary cost factor | A critical competitive advantage. Speed-to-market has a direct monetary value. |

| Flexibility | Considered a "nice-to-have" | Essential for innovation and market responsiveness. Inflexibility is a major hidden cost. |

| Supplier Role | A simple vendor providing a piece of hardware. | A strategic partner contributing to your overall business success. |

In my experience, the companies that thrive are the ones that have embraced this new reality. They understand that choosing a supplier is not just a procurement task; it is a strategic business decision. They are looking for partners who can deliver not just a high-quality mold, but also speed, agility, and a clear return on investment. The goal of this article is to equip you with this modern mindset.

The First Line on the Invoice: Initial Purchase Price?

Is the price tag on a Chinese mold just too good to be true? Many buyers worry that a lower price must mean a hidden compromise on quality or materials.

A top-tier Chinese mold is typically 30-50% less expensive than a comparable European one. This is not due to lower quality, but to a more efficient supply chain, optimized operational costs, and a highly competitive domestic market that drives value.

The initial purchase price is the most visible number and the first point of comparison for any procurement manager. It is also where the difference between top-tier Chinese and European suppliers is most dramatic. Let's be direct about it. When you compare quotes for a mold of the same specifications, materials, and cavitation, the price from a leading Chinese manufacturer like us will often be 30% to 50% lower than the price from a major European OEM. This significant difference naturally raises questions. How is this possible? Where are the savings coming from? The outdated stereotype would suggest the savings come from cutting corners: using inferior steel, less precise machinery, or inexperienced labor. This is a fundamental misunderstanding of the modern, high-end Chinese manufacturing landscape.

I always tell my clients that our price advantage is our "invitation to a conversation," but our quality and service are why they become long-term partners. The price is just the tip of the iceberg. A wise purchasing decision requires looking below the surface at the massive, hidden parts of the cost structure that ultimately determine the success of your project. The savings we offer are not the result of compromise. They are the result of a fundamentally different and more efficient economic structure. This structure includes a deeply integrated domestic supply chain for raw materials, a lower cost of skilled labor and engineering talent, and government policies that support advanced manufacturing. We pass these structural efficiencies on to our clients. So, when you see that lower number on our quote, you should not see it as a red flag. You should see it as the first piece of evidence that you are dealing with a more efficient business model.

Deconstructing the Price Difference

To truly understand the cost advantage, we need to break it down. It is not one single thing, but a combination of several structural factors that work together.

Supply Chain Efficiency: China is the world's manufacturing hub. This means we have immediate, local access to a vast network of suppliers for everything from raw aluminum and steel to specialized components like heating elements and pneumatic cylinders. This proximity dramatically reduces logistics costs, shipping times, and import duties that our European counterparts have to bear when sourcing parts. We can get high-quality materials faster and cheaper.

Operational Cost Structure: The overall cost of running a large, modern factory is simply lower in China. This includes land costs, utility expenses, and administrative overhead. These are not compromises on quality; they are economic realities. A German factory and a Chinese factory might both run the same DMG MORI machine, but the cost per hour to operate that machine is fundamentally different because of the surrounding economic environment.

Labor and Engineering Talent: China produces millions of highly skilled engineers and technicians every year. This creates a large, competitive talent pool. While we pay our top engineers and machinists very well, the overall market rates are more competitive than in Western Europe. This allows us to build world-class technical teams without the massive salary overhead faced by European companies.

Market Hyper-Competition: The domestic market in China is incredibly competitive. There are many manufacturers, and this forces everyone to be extremely efficient and price-conscious. This environment has weeded out inefficiency. To survive and succeed as an exporter, we have had to become masters of cost control and process optimization, all while pushing our quality to world-class levels.

Here is a simplified table showing how these factors contribute to the final price:

| Cost Component | European Manufacturer | Top-Tier Chinese Manufacturer | Impact on Final Price |

|---|---|---|---|

| Raw Materials (e.g., Steel) | Often imported, adding logistics and tariff costs. | Sourced from top domestic mills or imported efficiently. | Lower material acquisition cost. |

| Skilled Labor (Machinist) | High hourly wages due to local economic standards. | Competitive wages for a large pool of skilled talent. | Significant reduction in labor-related overhead. |

| Factory Overhead (Utilities/Rent) | High costs associated with European industrial zones. | Lower operational costs in Chinese industrial parks. | Reduced fixed costs per mold produced. |

| Supply Chain Logistics | Complex international sourcing for some components. | Highly integrated, localized, and efficient supply chain. | Faster turnaround and lower costs for components. |

It is critical to understand that these are structural advantages, not a result of skimping on quality. We are playing the same game but on a more efficient field. This is why I can confidently say that the initial price is just the beginning of the TCO story. It is a powerful beginning, but the plot gets even more interesting when we start to factor in time.

The Unseen Cost of Waiting: Lead Time & Speed-to-Market?

How much is your time really worth? Waiting for a mold can feel like a passive delay, but every week of waiting is a week you are not selling your product.

The delivery time for a blow mold is a huge hidden cost. European OEMs often quote 20-24 weeks, while a top-tier Chinese factory can deliver in 8-12 weeks. Getting your product to market 3-4 months earlier can be worth more than the entire cost of the mold itself.

This is where the TCO calculation starts to dramatically favor the agile Chinese manufacturing model. For any company in the Fast-Moving Consumer Goods (FMCG) sector, speed is everything. Market trends change in the blink of an eye. Competitors are always ready to launch a new product. Being first to market, or even just on time for a seasonal launch, can be the difference between a huge success and a complete failure. The "opportunity cost" of waiting is a real, calculable number that is often completely ignored in traditional procurement.

I have a perfect real-world example. We worked with a beverage company that was planning to launch a new line of fruit juices for the summer season. Their marketing campaign was set, their bottling line was ready, but their European mold supplier was quoting them a 24-week lead time. A 24-week wait meant they would completely miss the peak summer sales window. The potential revenue lost from that single season was several times the cost of the mold itself. They came to us, and we committed to an 11-week delivery. We delivered on that promise. They were able to launch their product in early June and had a blockbuster summer. That is not just a story about a faster mold; it is a story about how manufacturing speed directly translates into market success. The money they made by being on the shelves all summer was a massive credit on the TCO worksheet for our mold.

How can we be so much faster? It is not magic. It is a result of our entire operational philosophy. Our management structure is very flat, which means decisions are made in hours, not weeks. We run multiple shifts, often keeping our critical CNC machines running 24/7 to maximize output. Our production scheduling is incredibly dynamic and flexible. We are built for speed because we know that in our customers' world, time is the most valuable currency.

Quantifying the Cost of Delay

Let's make this less abstract. How can you put a dollar value on lead time? It is simpler than you think. You need to calculate your projected revenue and profit for the product that will use the new mold.

Opportunity Cost Formula:

(Projected Weekly Profit) x (Difference in Lead Time in Weeks) = Opportunity Cost

Let’s use a conservative example:

- Product: A new sports drink.

- Projected Profit: $10,000 per week.

- European Mold Lead Time: 22 weeks.

- Our Lead Time: 10 weeks.

- Difference in Lead Time: 12 weeks.

Now, let's calculate the opportunity cost:

$10,000 (Weekly Profit) x 12 (Weeks) = $120,000

In this scenario, the "hidden cost" of choosing the slower supplier is a staggering $120,000 in lost profit. This cost will never appear on any invoice or quote, but it is as real as the steel in the mold. Suddenly, a 30% difference in the initial purchase price seems much smaller, doesn't it? The faster lead time does not just save you money; it makes you money.

This speed is crucial for several business scenarios:

- Seasonal Products: Like the juice example, any product tied to a holiday, season, or specific event cannot afford delays.

- Responding to Competitors: If a rival launches a new bottle shape that is gaining market share, you need to be able to react quickly with your own innovative design. A 6-month wait is not a response; it is a surrender. This is where rapid 3D printed samples and production can be a game-changer.

- Entering New Markets: When you are expanding into a new region, being the first brand on the shelf is a massive advantage. Speed allows you to capture that critical early market share.

This is why I believe lead time should be one of the top three criteria in any mold purchasing decision, right alongside quality and price. It is a direct lever for your profitability. In the modern market, fast is not just better; fast is everything.

The Agility Advantage: Customization & Flexibility?

Does your product development process involve testing, learning, and changing? Many large suppliers see design changes as a problem, a disruption to their rigid workflow.

Top-tier Chinese manufacturers are built for agility. We welcome design modifications and small-batch trials. This flexibility allows you to innovate faster and bring a better, more market-tested product to launch, reducing risk and increasing your chance of success.

The modern product development cycle is not a straight line. It is a loop of designing, testing, and refining. You might have a brilliant idea for a new bottle, but until you hold it in your hand and get feedback from consumers, you cannot be 100% sure it is perfect. This is where flexibility becomes incredibly valuable. The ability to quickly make small changes, test different variations, and get real-world feedback is a huge competitive advantage. Unfortunately, many traditional European manufacturers, with their long-established and rigid processes, are not built for this kind of agility. They often discourage changes once a project has started, or they charge very high fees for any deviation from the original plan. Their system is optimized for large, unchanging production runs, not for the iterative process of innovation.

This is another area where our approach is fundamentally different. We see ourselves as partners in our clients' innovation process. We have built our systems to be flexible from the ground up. I have a great story that illustrates this point perfectly. We were working with a startup beverage company in Eastern Europe. They were launching their first product and had a new bottle design, but they were torn between three different designs for the grip area. They wanted to test which one felt best in the consumer's hand. They told us that when they approached a major European supplier with this request, they were essentially told to pick one design and stick with it. Requesting three variations for testing was seen as a major problem that would disrupt the production schedule and incur huge costs.

When they came to us, our response was completely different. We said, "Great idea. Let's do it." We saw this not as a problem, but as a smart way to reduce their market risk. Within a week, we had produced sample bottles for all three grip designs and shipped them to the client. They were able to conduct consumer testing and choose the winning design with confidence. This is what we mean by agility. It is about saying "yes" to our clients' needs. It is about being a flexible partner who helps them innovate. This kind of "let's figure it out together" service is built into our company's DNA. This is why having a clear PET bottle mold design guide from concept to production is so important for our clients.

The Value of Iterative Design

The ability to make changes and test variations is not just a convenience; it has a direct impact on the success of your product.

- Reduced Market Risk: Launching a new product is always a risk. By testing multiple variations of a design—whether it is the grip, the cap, or the overall shape—you can gather real data and make an informed decision. This dramatically increases the chances that your final design will be a hit with consumers.

- Faster Innovation Cycles: If you can test three ideas in the time it takes a competitor to produce just one, you can learn and improve much faster. This allows you to out-innovate your competition and stay ahead of market trends. The ability to quickly test different preform neck sizes can also be a critical part of this process.

- Improved Product Quality: The first idea is rarely the best idea. The iterative process of testing and refining almost always leads to a better final product. A flexible manufacturing partner enables this process of continuous improvement.

Let's compare the two approaches in a table:

| Process Step | Rigid (Traditional) Approach | Agile (Modern) Approach | Business Impact |

|---|---|---|---|

| Initial Design Submission | Design must be final and "locked in." | Initial design is a starting point for collaboration. | Lower stress, more room for creativity. |

| Request for a Design Change | Discouraged. Results in significant delays and high fees. | Encouraged. Seen as part of the process to improve the product. | Faster innovation, lower cost of experimentation. |

| Prototyping/Sampling | A slow, formal process for producing a single prototype. | A fast, flexible process to produce multiple variations for testing. | Ability to gather real-world feedback before committing to production. |

| Final Product | The product that was designed months ago. | The product that has been tested, refined, and proven. | Higher chance of market success. |

This agility extends beyond just the initial design phase. It also applies to the size of production runs. Many large suppliers are not interested in small, custom orders. They want massive orders for thousands of identical items. We, on the other hand, are happy to work with clients of all sizes, from startups testing their first product to multinational corporations needing a short run for a promotional item. This flexibility makes us a much more accessible and valuable partner for a wider range of businesses. In a world where market demands change quickly, your supplier's agility is your agility.

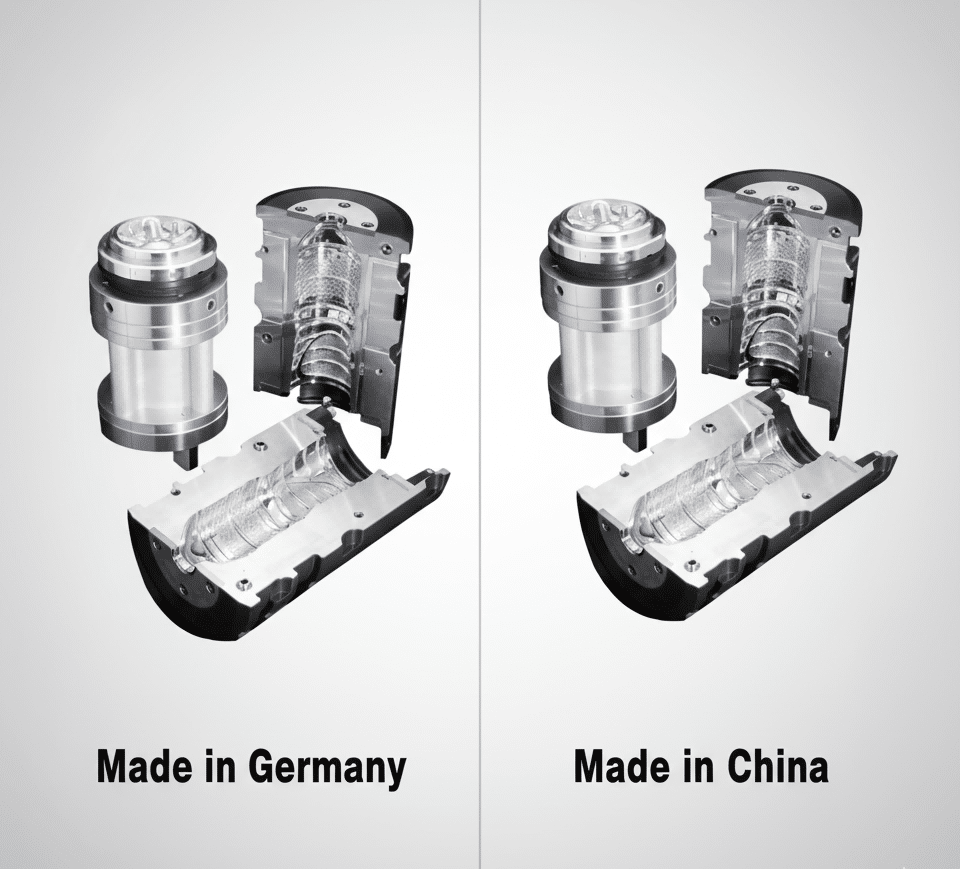

The Quality Question: How Top-Tier Chinese Molds Closed the Gap?

This is the biggest question, the one that causes the most concern: Can a Chinese mold truly match the quality and precision of one made in Europe?

Yes, absolutely. Top-tier Chinese manufacturers now use the exact same high-end equipment, premium imported materials, and strict international quality standards as their European competitors. The difference in quality has disappeared, but the difference in price has not.

Let's confront this issue head-on. For years, the single biggest point of hesitation for buyers considering a Chinese supplier was the fear of inconsistent or inferior quality. It is a valid concern, born from an era when the Chinese manufacturing landscape was very different. I will be the first to admit that the Chinese market is vast and not all suppliers are created equal. There are still small, low-cost factories that do cut corners. But to judge the entire industry, especially the top-tier, export-focused manufacturers, by that old reputation is a huge mistake. The leading companies have invested massively to compete on a global stage, and that meant meeting and exceeding the European quality benchmark.

I often make a bold statement to potential clients who visit our facility. I tell them, "If I take one of our finished blow bottle molds and place it next to a brand new mold from a top German or Italian maker, and I cover up the logos, you will not be able to tell the difference." I can say this with total confidence because I know we are using the same inputs to get the same world-class output. The precision of the machining, the finish of the surfaces, the tolerances of the moving parts—they are identical. The only time you will notice a difference is when you see the price on the invoice. Our philosophy has been simple: provide "European Quality at a Chinese Price." This is not just a marketing slogan; it is a description of our daily reality, and it is made possible by a deliberate strategy of investing in the best "hard assets" the world has to offer.

The Pillars of Modern Mold Quality

World-class quality is not an accident. It is the result of a systematic approach built on three core pillars: equipment, materials, and standards.

1. World-Class Equipment:

The heart of any modern mold-making facility is its CNC (Computer Numerical Control) machining center. This is where the precision is born. We recognized early on that to achieve the tightest tolerances, we needed the best machines. That is why our workshop is filled with equipment from industry-leading German and Japanese brands, most notably DMG MORI 5-axis CNC machines. A 5-axis machine can move a part or a cutting tool along five different axes simultaneously. This allows us to machine incredibly complex shapes, undercuts, and cooling channels in a single setup. This not only increases precision but also efficiency, reducing the chance of human error that comes from moving a part from machine to machine.

2. Premium Imported Materials:

A mold is only as good as the metal it is made from. While China produces a lot of steel, for our highest performance molds, we insist on using the best materials from trusted global sources.

- For the Mold Body: We often use high-grade 7075 aircraft-grade aluminum imported from Europe. This alloy offers an excellent combination of strength, light weight (which is great for cycle times), and superb thermal conductivity, which is critical for efficient cooling.

- For the Mold Core and Cavity: For applications requiring extreme durability and a perfect finish, we use S136 mold steel imported from Sweden. This is a stainless, corrosion-resistant steel that can be polished to a mirror finish, making it perfect for crystal-clear PET bottles. It also offers excellent wear resistance, ensuring a very long mold life even with high production volumes.

3. Strict International Standards:

Great machines and materials are not enough without a rigorous process to ensure quality at every step. Our entire operation is certified under the ISO 9001 quality management system. This is not just a piece of paper for us; it is the framework for our daily work.

- Design Review: Every design is checked and validated by our engineering team to ensure it is optimized for manufacturing and performance.

- In-Process Inspection: We use advanced CMM (Coordinate Measuring Machine) equipment to check the dimensions of mold components at critical stages of the machining process.

- Final Assembly and Testing: Before any mold ships, it is fully assembled, and we conduct rigorous tests to check for things like cooling channel leaks and proper alignment. We also help clients avoid common PET blow molding defects by ensuring our molds are designed and built to the highest standards.

Here is a direct comparison of the key quality factors:

| Quality Factor | Top European Manufacturer | Top-Tier Chinese Manufacturer (iBottler) | The Verdict |

|---|---|---|---|

| CNC Machinery | Primarily high-end German or Swiss brands (e.g., DMG MORI) | Primarily high-end German or Japanese brands (e.g., DMG MORI) | Identical Capability |

| Primary Material | European-sourced 7075 Aluminum, German/Swedish tool steels | European-sourced 7075 Aluminum, Swedish S136 tool steel | Identical Quality |

| Quality System | ISO 9001 Certified | ISO 9001 Certified | Identical Standard |

| Engineering Expertise | Highly experienced, often specialized engineers | Highly experienced, agile, and globally-trained engineers | Comparable Expertise |

The evidence is clear. When you partner with a top-tier Chinese supplier, you are no longer making a compromise on quality. You are making a smart business decision to get the same level of engineering and performance at a much better value.

The Service Equation: Proximity vs. 24/7 Responsiveness?

What does "good service" really mean? Is it having a technician who is geographically close, or one who answers your call in the middle of the night?

The nature of service has been transformed by technology. While European suppliers offer the advantage of proximity, top-tier Chinese suppliers offer unmatched responsiveness, using 24/7 remote support to solve most issues in minutes, not days.

The question of after-sales service is a critical part of the TCO calculation. A mold that is sitting idle because of a technical problem is a mold that is losing you money every single minute. The traditional argument in favor of European suppliers has always been proximity. If your factory is in Germany and your mold supplier is a few hundred kilometers away, it is comforting to know that a service technician can be on-site relatively quickly. This is a valid advantage, and for some companies, it might be the deciding factor. However, this model of service is becoming increasingly outdated in a connected world. Technology has fundamentally changed what it means to be "close" to your customers.

Let me ask you a question. Which supplier is "closer" to you? The one who is 200 kilometers away but tells you their next available service appointment is in one week? Or the supplier who is 8,000 kilometers away but has an engineer on a video call with your machine operator 20 minutes after you send an email at 2 AM? In my experience, the speed of response is far more important than the physical distance between two factories. The vast majority of issues that arise with a mold are not catastrophic failures requiring a complete overhaul. They are often small problems with setup, processing parameters, or a minor component. These are problems that can be diagnosed and solved remotely by an experienced engineer.

This is the service model we have perfected. We offer our clients a feeling of "always-on" security. We operate across all time zones. We have dedicated technical support staff who are available around the clock. When a customer in North America has a problem in their afternoon, it is our morning. We are fresh and ready to help. We use high-definition video calls to see exactly what the operator is seeing. We can guide them through diagnostic steps, help them adjust settings on their bottle blowing machine, and identify the root cause of the problem in real-time. More than 80% of all customer support inquiries are resolved this way, within an hour of the first contact.

A Modern, Multi-Layered Service Approach

Our service philosophy is not just about being responsive; it is about being proactive and comprehensive. We have a multi-layered approach to ensure our customers experience maximum uptime.

- 24/7 Remote Diagnostics: This is our first line of defense. Instant access to expert engineers via video call, email, and instant messaging. This solves the majority of issues immediately, saving our clients invaluable time and money.

- Comprehensive Spare Parts Package: We know that certain small components, like seals, O-rings, or heating elements, can wear out over time. That is why every mold we ship includes a carefully selected package of critical spare parts. This allows our clients to make immediate repairs without having to wait for a shipment.

- Detailed Documentation and Training: We provide extensive maintenance manuals, schematics, and video tutorials that empower our clients' own maintenance teams to handle routine service and troubleshooting. We believe in making our clients self-sufficient. One of the biggest worries for clients is whether a new mold will fit their existing machines. We have solved this problem by building a massive library, so we already have the mounting dimensions for 80% of blow molding machines worldwide. This proactive step eliminates a huge source of stress and delay.

- Network of Regional Partners: For the rare, complex issues that do require on-site assistance, we have a growing network of trusted technical partners in key regions like Europe, North America, and South America. This gives us the ability to provide hands-on support when it is truly needed, providing the best of both worlds.

Let's compare the service models:

| Service Aspect | Traditional Proximity Model (Europe) | Modern Responsiveness Model (China) | Customer Benefit |

|---|---|---|---|

| Initial Response Time | Can take hours or days to get a call back and schedule a visit. | Typically under 20 minutes, 24/7. | Problems are addressed immediately, minimizing downtime. |

| Problem Resolution | Often requires an expensive and time-consuming on-site visit. | Over 80% of issues are resolved instantly via remote diagnostics. | Faster and much more cost-effective problem solving. |

| Proactive Support | Limited. Service is usually reactive to a problem. | Comprehensive spare parts, detailed manuals, and proactive compatibility checks are standard. | Empowers the customer's own team and prevents problems before they start. |

| Cost of Service | High cost for travel time, labor, and parts. | Remote support is often included, and spare parts are provided upfront. | Significantly lower lifetime service costs, improving the TCO. |

In today's global economy, the definition of "good service" is changing. It is less about physical location and more about the speed and effectiveness of communication. The peace of mind that comes from knowing an expert is always just a video call away is, for many modern businesses, more valuable than having a supplier in the same country.

A TCO Worksheet: Calculate Your True Cost?

How can you move from theory to a real financial calculation? You need a simple tool to compare suppliers and see the complete economic picture for yourself.

Use a Total Cost of Ownership (TCO) worksheet. By assigning a monetary value to factors like lead time and maintenance, you can clearly see how a lower initial price combined with faster delivery often results in a vastly superior overall investment.

Theory is great, but making a major capital investment requires concrete numbers. The Total Cost of Ownership model is powerful because it forces you to quantify the "hidden" costs and add them to the "visible" costs to get a true, apples-to-apples comparison. It moves the conversation from "which mold is cheaper?" to "which mold is the better investment for my business?" I encourage all of our clients to go through this exercise. Often, the results are eye-opening. The initial price difference, which might have seemed like the most important factor, becomes just one piece of a much larger financial puzzle.

I want to give you a simple, practical worksheet that you can use to evaluate your next mold purchasing project. Do not worry about getting the numbers perfect down to the last dollar. The goal is to use realistic estimates to understand the relative difference between your options. You will be amazed at how quickly the TCO of a seemingly "more expensive" mold can be overshadowed by the immense opportunity cost of a long lead time from a "cheaper" supplier. I invite you to copy this framework and use it. When you monetize time and opportunity, the value proposition of a high-quality, fast, and agile Chinese supplier becomes crystal clear.

Your TCO Calculation Framework

Here is a step-by-step guide and a worksheet to calculate the TCO for two potential suppliers: Supplier A (a traditional European option) and Supplier B (a top-tier Chinese option like us).

The TCO Formula:

The basic formula is straightforward:

TCO = [A] Initial Purchase Cost + [B] Shipping & Import Costs + [C] Opportunity Cost of Lead Time + [D] Estimated Lifetime Maintenance Costs

Let's define each component:

- [A] Initial Purchase Cost: This is the quoted price for the mold.

- [B] Shipping & Import Costs: The cost of freight, insurance, and any import duties or tariffs. A good supplier will help you calculate this accurately.

- [C] Opportunity Cost of Lead Time: This is the hidden cost we discussed earlier. Use the formula:

(Projected Weekly Profit) x (Lead Time in Weeks). - [D] Estimated Lifetime Maintenance Costs: This can be estimated as a percentage of the initial purchase price over a set period (e.g., 5 years). For high-quality molds from any good supplier, this should be a relatively low number.

TCO Worksheet Example:

Let's fill in the worksheet with a realistic scenario.

| Cost Component | Supplier A (European) | Supplier B (Top-Tier Chinese) | Notes |

|---|---|---|---|

| Projected Weekly Profit from New Product | $10,000 | $10,000 | This is the baseline profit your new product will generate. |

| [A] Initial Purchase Cost | $150,000 | $90,000 | Based on a typical 40% price advantage for the Chinese supplier. |

| [B] Shipping & Import Costs | $5,000 | $12,000 | Higher shipping and tariff costs for the Chinese mold. |

| Total Upfront Cost (A + B) | $155,000 | $102,000 | The initial cash outlay required. |

| Lead Time (in Weeks) | 22 Weeks | 10 Weeks | A typical 12-week advantage for the Chinese supplier. |

| [C] Opportunity Cost (Profit x Lead Time) | $10,000 x 22 = $220,000 | $10,000 x 10 = $100,000 | The total profit you forgo while waiting for the mold. This is a crucial number. |

| [D] Estimated 5-Year Maintenance | $15,000 (10% of Purchase Price) | $13,500 (15% of Purchase Price) | We can be conservative and assign a slightly higher percentage to the Chinese mold, although quality is comparable. |

| TOTAL COST OF OWNERSHIP (A+B+C+D) | $155,000 + $220,000 + $15,000 = $390,000 | $102,000 + $100,000 + $13,500 = $215,500 | This is the true cost to your business. |

| TCO Difference | Supplier B is $174,500 less expensive in TCO. |

The result is not even close. The company that chooses Supplier B is not just saving money on the initial purchase; they are getting their product to market 12 weeks earlier, capturing an additional $120,000 in profit that the other company simply misses. The TCO advantage is massive. It is also important to consider the cost of auxiliary equipment, like ensuring you have the right chiller connected to your PET blow molds for optimal performance. These are all part of the total picture of running an efficient production line.

This worksheet is a powerful tool. It changes the conversation from an emotional one based on old stereotypes to a rational, data-driven business decision.

The Verdict: Which Choice is Smarter for Your Business?

So, after analyzing price, speed, agility, quality, and service, what is the final conclusion? Which path should you choose for your next project?

The best choice is not about country of origin; it is about aligning your supplier with your business model. For businesses that value speed, agility, and a high return on investment, a top-tier Chinese partner is overwhelmingly the smarter choice in today's market.

We have moved beyond the simple, outdated stereotypes. The question is no longer "which country is better?" but rather, "which manufacturing model is the right fit for my business strategy?" The decision to source a critical piece of equipment like a blow mold should be a reflection of your company's goals and its position in the market. The world of manufacturing has evolved, and your procurement strategy must evolve with it. Choosing a supplier is choosing a partner, and that partner's capabilities will either accelerate your growth or hold you back.

I believe the choice has become very clear. It is no longer a debate about nationality but a decision about your business philosophy. Do you operate on a traditional, slow-moving, and budget-insensitive model? Or are you part of the new generation of agile, fast-moving, and cost-conscious companies? Your answer to that question will tell you exactly which type of mold supplier you need. If your business values speed, flexibility, and getting the absolute most out of every dollar you invest, then we should talk. We have built our company to serve businesses like yours, helping you turn our advantages in manufacturing into your advantages in the marketplace.

A Decision Framework

To make the final verdict as clear as possible, let's frame it based on your company's profile.

You should choose a traditional European supplier if:

- Your budget is extremely large and not a primary concern. You are willing to pay a 30-50% premium for the legacy brand name and the comfort of a local supplier.

- Your project timeline is very long and not sensitive to delays. A 20-24 week lead time does not negatively impact your business plan or revenue projections.

- Your product design is 100% fixed and will not change. You have no need for iterative prototyping or flexibility during the development process.

- Your factory is located within a very short distance of the supplier, and you place a very high value on the ability to have their technicians on-site, even if it takes time to schedule.

You should choose a top-tier Chinese partner, like us, if:

- You are focused on maximizing your Return on Investment (ROI). You want world-class quality at the most competitive price point to improve your bottom line.

- Your product needs to get to market quickly. You understand that speed-to-market is a critical competitive advantage and that opportunity cost is real.

- You need an agile partner who can adapt to your needs. Your design process may involve testing, changes, and customization, and you need a supplier who supports that.

- You value immediate, 24/7 responsiveness. You believe that solving a problem in 20 minutes over a video call is better than waiting a week for an on-site visit.

In essence, the choice is between two different eras of manufacturing. The European model represents the traditional, legacy approach: solid, dependable, but also slow and expensive. The top-tier Chinese model represents the modern, agile approach: fast, flexible, cost-effective, and built for the speed of today's global market. For the vast majority of businesses competing in the 21st century, the second choice is not just better—it is the only one that makes strategic sense.

Conclusion

Choosing between "Made in China" and "Made in Europe" is no longer about price versus quality. It is about selecting a business model. A Total Cost of Ownership analysis proves it.

Final Comparison Summary

| Feature | Traditional European Supplier | Top-Tier Chinese Partner (e.g., iBottler) | The Smart Business Choice Is... |

|---|---|---|---|

| Initial Price | High | 30-50% Lower | A partner who improves your project ROI. |

| Lead Time | Slow (20-24 weeks) | Fast (8-12 weeks) | A partner who gets your product to market faster. |

| Flexibility | Rigid, Discourages Changes | Agile, Welcomes Customization | A partner who supports your innovation. |

| Quality & Technology | Excellent | Excellent (Same Equipment/Materials) | A partner who delivers proven quality. |

| Service Model | Proximity-Based | Responsiveness-Based (24/7) | A partner who minimizes your downtime. |

| Total Cost (TCO) | Very High | Significantly Lower | The partner with the lowest Total Cost of Ownership. |

FAQs

Q: How do import duties and tariffs affect the TCO of a Chinese mold?

A: They are a mandatory and important part of the TCO calculation. A professional supplier will provide you with all the necessary documentation (like the correct HS codes) to ensure a smooth and predictable customs process. However, even after adding tariffs, which can vary by country, the significant initial price advantage of Chinese molds almost always means they maintain a lower overall TCO.

Q: Is my intellectual property (IP) for my unique bottle design safe with a top-tier Chinese supplier?

A: Absolutely, yes. This is a common concern, but reputable, export-oriented manufacturers like us operate under strict international business standards. We treat client IP with the utmost seriousness. The first step in any technical discussion is always to sign a Non-Disclosure Agreement (NDA) to legally protect your designs and concepts. Our reputation is built on trust.

Q: What about the language and communication barrier?

A: For top-tier suppliers focused on the global market, this barrier no longer exists. Our project managers, sales teams, and engineers are fluent in English. More importantly, they are trained to communicate clearly, concisely, and efficiently across different cultures and time zones. We prioritize clear and constant communication throughout the project.

Q: How is after-sales support handled from thousands of miles away?

A: We use a multi-layered approach that is often faster than waiting for a local technician. It includes: 1) 24/7 remote video diagnostics to solve most issues instantly. 2) A comprehensive spare parts package that is shipped with every mold. 3) Detailed maintenance manuals and video tutorials to empower your own team. 4) A network of regional partners for the rare cases where on-site support is necessary.

Q: Does "Made in China" mean all components are from China?

A: Not necessarily, especially for top-tier manufacturers. We operate on a principle of using the best component for the job, regardless of its origin. We often integrate high-quality imported components based on client requirements, such as German heating elements or specific valve brands from Japan. We provide a fully transparent bill of materials (BOM), so you know exactly what you are getting, giving you the best of both worlds.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr