Struggling with high entry costs for your bottling business? The price of fully automatic lines feels overwhelming and risky. Many smart entrepreneurs, especially in Southeast Asia, find a better way by starting with semi-automatic machines.

Yes, semi-automatic blow molding machines are often the most intelligent choice in Southeast Asia. This is not because they are "low-tech," but because they offer the best return on investment. They provide low initial capital cost, excellent flexibility for varied products, and simpler maintenance.

This choice might surprise some people. The global push is always towards more automation. We see headlines about "Industry 4.0" and fully robotic factories. But I spend my days talking to the people who actually run these businesses. My experience on the ground, especially in dynamic markets, shows a different story. Choosing a semi-automatic machine is often a brilliant, calculated business decision. Let's dive into the real reasons why this choice makes so much sense.

Why challenge the myth that "fully automatic is always better"?

See the sleek, fast videos of fully automatic lines? It's easy to believe they are the only serious option. But this ignores the reality many businesses face, especially in fast-growing markets.

I talk with entrepreneurs and factory managers across Southeast Asia every week. I speak to people in Vietnam, Indonesia, the Philippines, and Thailand. While the appeal of a high-speed, fully automatic line is strong, I am always impressed by their smart cost-benefit calculations. Many of them conclude that for their current scale and market, a high-quality semi-automatic bottle blowing machine is the right investment. This is not a compromise. It is a strategic move to get the best possible return. They are choosing profit and sustainability over just having the newest technology.

To understand this, we need to change our thinking. "Best" does not always mean "fastest" or "most automated." "Best" means the most appropriate, profitable, and manageable solution for your specific business context.

The Global Automation Trend vs. On-the-Ground Reality

The global narrative, often driven by equipment manufacturers in highly developed economies, focuses on reducing labor costs and achieving massive scale. This makes sense in Germany, Japan, or the United States, where labor is very expensive and markets are stable and massive. They design machines for running millions of the same bottle, 24/7, for years.

But this is not the reality in many parts of the world. In Southeast Asia, the market is incredibly dynamic. Consumer tastes change. New drink categories pop up. A business might need to launch a new product quickly to see if it works. I had a client in Vietnam who wanted to test a new herbal tea. A fully automatic line would have cost him over $200,000 and taken 6 months to order and install. He would have missed the market trend. Instead, we got him set up with a semi-automatic system in weeks for a fraction of the cost. He was selling his tea before his competitor's new line was even built. This is the on-the-ground reality. Agility often beats raw speed.

Redefining "Smart" Investment

A "smart" investment is one that solves your biggest problem with the least amount of risk.

For many businesses I work with, the biggest problem is not "how do I make 10,000 bottles an hour?" The biggest problem is "how do I start producing my product with $30,000 in capital?" or "how do I add a new bottle shape for a new customer without stopping my main line?"

A semi-automatic machine directly answers these questions.

- It minimizes financial risk.

- It allows for market testing.

- It keeps cash flow healthy.

- It fits into existing, smaller factory spaces.

- It can be run by staff who are trained quickly.

When I see a customer in the Philippines carefully calculate their payback period, and they see they can pay off a semi-automatic machine in 6 months versus 5 years for an automatic one, the choice is clear. That, to me, is a very smart investment. They are prioritizing business health and rapid profitability. They are building a strong foundation from which they can grow, and perhaps one day, that growth will justify a fully automatic line. But they will do it when it's the right time, funded by the profits they're already making.

Key Questions to Ask Yourself

Instead of just asking "what is the fastest machine?", I encourage my clients to ask these questions:

- What is my real production target for the next 12-24 months? (Be realistic!)

- What is my total available budget, including for molds and auxiliary equipment?

- How many different bottle types will I need to produce?

- How often will I need to change molds?

- What is the skill level of my local maintenance team?

- What is the stability of my power supply and factory space?

The answers to these questions often point directly to a semi-automatic solution as the most logical and intelligent choice.

Reason 1: How sensitive is your capital to initial investment and risk?

Facing a huge upfront cost for a new production line? This cash barrier stops many great ideas. It's a risk that many startups or expanding businesses simply cannot afford to take.

This is the number one driver. A semi-automatic blow molding machine is the perfect solution. It lowers the entry barrier. You can start your business or test a new product without risking huge amounts of capital.

For a startup company in the Philippines launching a new juice brand, investing over $150,000 in a fully automatic line is a massive gamble. What if the product doesn't sell? They are left with huge debt and an expensive machine. I've seen this happen. A smarter path, and one I recommend, is to start with a reliable semi-automatic machine. A good one might cost around $20,000. This lets them enter the market, generate revenue, and prove their business model with much, much lower financial risk. It's simply smart business.

The Stark Reality of the 10x Cost Barrier

Let's be very clear about the numbers. A brand new, entry-level fully automatic linear blow molding machine often starts at $100,000 and can easily go up to $300,000 or more, especially for well-known brands. A high-speed rotary machine? That's often $500,000 to over $1 million.

Now, compare that to a high-quality, 2-cavity semi-automatic machine. You are looking at a price range of $15,000 to $25,000. This is not a small difference. It's a 5x to 10x (or more) difference in cost.

For a business in an emerging market, this is the difference between "possible" and "impossible." This capital can be used for other critical things: marketing, ingredients, distribution, or developing more products. It frees up cash, which is the lifeblood of any new business.

The "Test and Validate" Model

I am a big believer in the "test and validate" approach. A semi-automatic machine is the ultimate tool for this. I worked with a small company in Malaysia that wanted to launch a line of bottled sauces. They had three different recipes and two different bottle-shape ideas.

Instead of spending a fortune on a high-speed line dedicated to just one bottle, they bought one semi-automatic machine and three different sets of blow bottle molds. The total cost was manageable. They were able to produce small batches of all their different products. They ran market tests in local stores. They found out that two of their sauces sold very well, but one was not popular. They also learned that customers preferred one bottle shape over the other.

This was an invaluable lesson. They learned it fast and they learned it cheap. Now, they are focusing their production on the winning products. They are making money. If they had bought a fully automatic line, they would have been locked into one bottle shape, and they might have failed completely by choosing the wrong product.

Cash Flow and Financing in Southeast Asia

In many Western countries, getting a large business loan for equipment is a standard process. In many Southeast Asian economies, the financing environment can be different. Banks may be more conservative. They may demand high collateral for large loans, especially for a startup without a long history.

This means many entrepreneurs are building their businesses with their own capital or money from family and friends. They don't have $150,000 to spare. But they do have $20,000. A semi-automatic machine allows them to buy their equipment outright. They start with zero debt. This makes their business much more resilient. They are not beholden to a bank, and every dollar they earn (after costs) is profit they can reinvest.

Table: Simplified Capital Investment Comparison

Let's look at a simple, hypothetical comparison for a new startup.

| Feature | Semi-Automatic Machine | Fully Automatic Line |

|---|---|---|

| Initial Machine Cost | ~$20,000 | ~$150,000 |

| Installation & Setup | Simple, (1-2 days) | Complex, (1-2 weeks) |

| Financing | Often paid with cash | Usually requires a large loan |

| Initial Risk | Low. Can pivot or stop with minimal loss. | Very High. Locked into the investment. |

| Time to Market | Fast. (e.g., 1-2 months) | Slow. (e.g., 6-9 months) |

| Business Strategy | Validate market, build cash flow. | Commit to large-scale production. |

When you see it laid out like this, you understand why my clients in the Philippines feel so smart. They are not "buying cheap"; they are investing in a low-risk strategy to build a profitable business from day one.

Reason 2: Do you need operational flexibility for varied products and small batches?

Is your market demanding many different products? Are you tired of long, costly downtime just to switch from one bottle to another? This is a huge problem for modern bottlers.

You need to be agile. A semi-automatic machine gives you this agility. It is much faster and easier to change molds on a semi-automatic machine compared to a complex, large rotary machine. This agility is critical for co-packers or brands with a wide product portfolio.

I had a client in Thailand who runs a co-packing facility. They produce specialty sauces for five different small brands. On Monday, they might need to run 5,000 bottles of a 250ml chili sauce. On Tuesday, it's 8,000 bottles of a 500ml soy sauce. A fully automatic line would be a nightmare for them. The mold changeover could take half a day or more! Their production time would be less than their setup time. We provided them with a semi-automatic solution with a quick-change mold design. They can now switch between bottle sizes in under an hour. This flexibility is the core of their business model.

The Diverse ASEAN Consumer and SKU Proliferation

The Southeast Asian market is not one single entity. It's a vibrant collection of cultures, tastes, and income levels. A drink that is popular in Manila might not sell in Jakarta. This creates a huge demand for product diversity.

Big companies and startups alike are constantly launching new flavors, seasonal items, and different-sized packages to capture niche markets. This is called SKU proliferation (Stock Keeping Units). You might have:

- 350ml fruit juice

- 500ml fruit juice

- 1000ml fruit juice

- A special 200ml size for a promotional event

A fully automatic machine is built for efficiency in one thing. A semi-automatic machine is built for flexibility in many things. When your business success depends on launching new products quickly, flexibility is more valuable than raw speed. This is where we help clients a lot, not just with the machine, but with the whole concept. We can help them with a PET bottle mold design guide to create shapes that are efficient to produce.

The High Cost of Downtime: Mold Changeovers

Let's talk about the technical reality of a mold change.

On a semi-automatic machine:

- The machine is small and accessible.

- You stop the machine.

- You disconnect the cooling water lines (usually 2-4 lines).

- You unbolt the mold halves (a few bolts).

- You lift the mold out (it's heavy, but manageable with a small hoist).

- You put the new mold in, bolt it, and connect the water.

- You adjust the heating settings for the new preform/bottle.

An experienced operator can do this in 30-60 minutes.

On a fully automatic rotary machine:

- This is a massive, complex piece of equipment.

- You have to stop the entire line.

- You need to access the blowing station, which might be one of 10 or 16 stations.

- Each station has complex connections: high-pressure air, low-pressure air, and multiple cooling circuits.

- The molds are part of a complex mechanical system.

- Changing all 10 or 16 molds is a precise, time-consuming job.

- You then have to synchronize the new setup with the preform infeed and bottle outfeed.

This process can take 4 hours at a minimum, and often a full 8-hour shift. That is a full day of lost production. For my Thai co-packer client, that would be disastrous.

Table: Mold Changeover Comparison

| Aspect | Semi-Automatic Machine (2-Cavity) | Fully Automatic Rotary (10-Cavity) |

|---|---|---|

| Typical Time | 30 - 60 minutes | 4 - 8 hours |

| Complexity | Low. Basic mechanical skill. | High. Requires specialized technicians. |

| Lost Production | ~500-800 bottles | ~40,000 - 80,000 bottles |

| Ideal For | High-mix, low-volume (HMLV) | Low-mix, high-volume (LMHV) |

| Business Model | Co-packers, startups, diverse brands | Mass-market commodity products |

Managing Your Product Portfolio with Smart Design

We love helping clients who have diverse portfolios. We can help them design their blow bottle molds to be as efficient as possible. Sometimes, we can design different bottles that can all use the same preform neck size, which simplifies things.

We can also help them prototype new designs very quickly. Instead of committing to an expensive steel mold, we can use our 3D printed sample service. This lets them hold a physical model of their new bottle in their hands in just a few days. They can test the feel, the look, and the label. This level of agility is exactly what dynamic markets demand.

Reason 3: How do labor dynamics influence your machinery choice?

Worried about finding and paying for highly skilled technicians? In many areas, reliable general labor is available, but specialized automation experts are very hard to find.

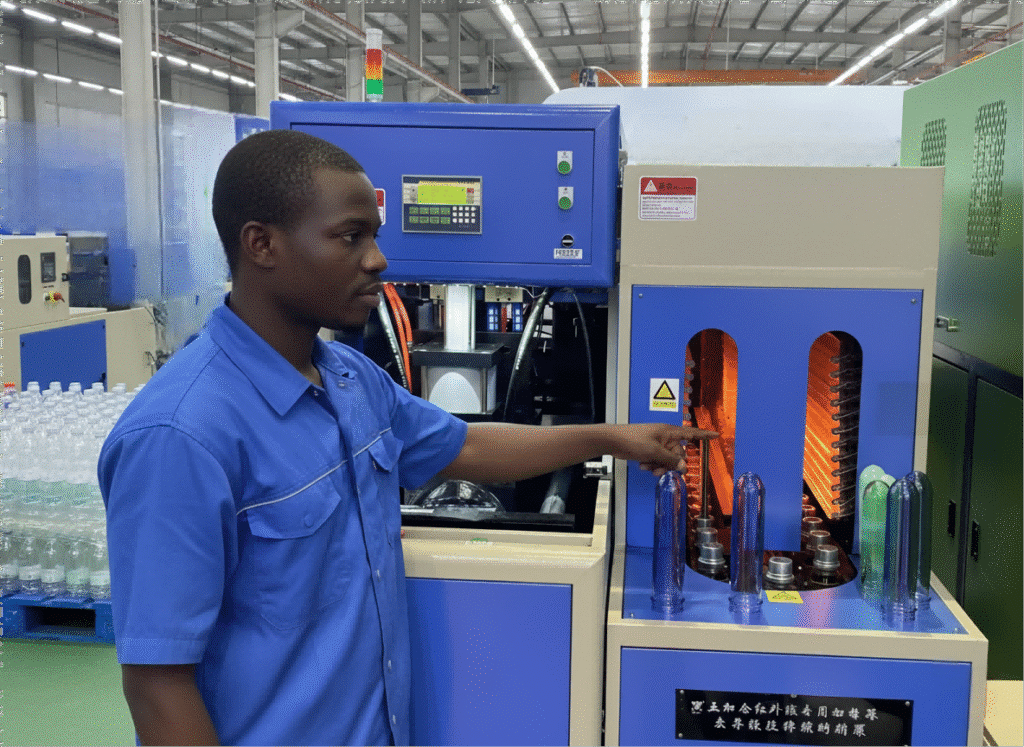

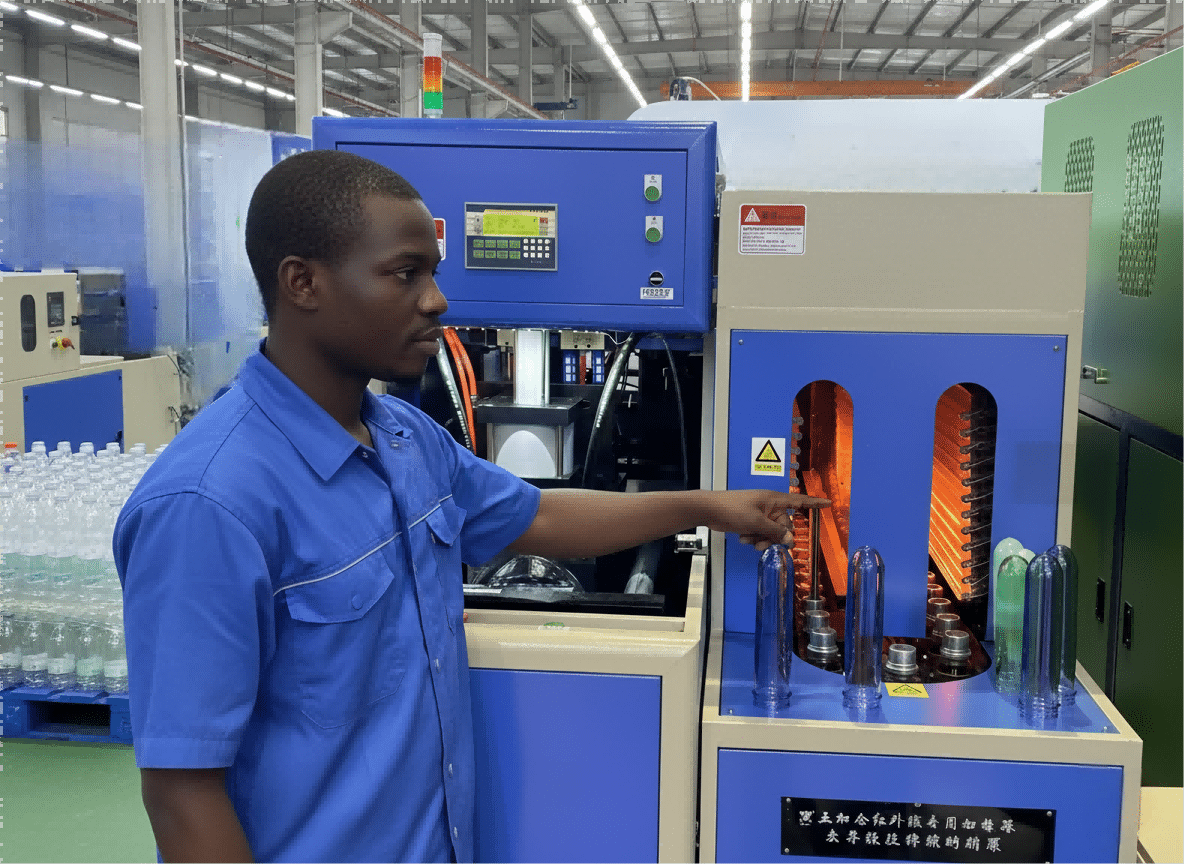

This is a smart way to use your available workforce. A semi-automatic machine balances machine precision with human input. It uses the machine for the critical blowing step and people for the simple loading and unloading.

This is not just about labor cost. It is also about skill matching and maintenance. I have seen factories in remote areas struggle. A highly complex automatic line goes down. They have to find a specialized PLC programmer or electronics technician. It can take days, or even weeks, to get someone to their factory. The line stands idle. In contrast, a semi-automatic machine is mechanically simpler. A good local mechanic with a set of tools can usually diagnose and fix the problem. They can replace a standard pneumatic valve or cylinder. This keeps the factory running. For many of my clients, uptime is more important than high speed.

The "Hybrid" Model: Optimizing Man and Machine

The semi-automatic process is a perfect hybrid model. Let's break down the roles:

The Machine's Job (The "Skilled" Part):

- Precise Heating: The infrared oven heats the PET preforms to the exact, uniform temperature needed. This is critical for bottle quality.

- High-Pressure Blowing: The machine handles the two-stage blowing (pre-blow and high-pressure blow) with exact timing.

- Clamping: The machine clamps the blow mold shut with tons of force to create a perfectly formed bottle.

The Operator's Job (The "Simple" Part):

- Loading: The operator takes the heated preforms from the oven and places them into the blowing station.

- Unloading: The operator takes the finished bottles out of the blowing station.

The machine does the complex, sensitive work that requires precision. The human does the simple, flexible work of material handling. This is a very efficient use of resources. You get high-quality, consistent bottles (thanks to the machine) without needing a highly paid technician to stand there all day.

Training and Skill Matching

Training an operator for a semi-automatic machine is fast and straightforward.

- Safety: The first and most important step.

- Process: How to load the preforms, press the buttons, and unload the bottles.

- Quality Check: How to spot a bad bottle (which I'll discuss later).

We can usually train a new team of operators in one or two days. They become very fast and efficient quickly.

Training a technician for a fully automatic rotary machine is completely different. They need to understand:

- Programmable Logic Controllers (PLCs)

- Advanced sensor systems

- Complex pneumatics and hydraulics

- Servo motor controls

- Network communication protocols

Finding a person with these skills is difficult and expensive in many regions. And if that one person gets sick or quits, the factory is in serious trouble. A semi-automatic machine is more "democratic." Several people on your staff, including a general mechanic, can understand and maintain it. This reduces your operational risk.

It's Not Just Cost, It's Reliability

My client with the remote factory put it perfectly. He said, "I cannot afford downtime. I am 8 hours from the nearest major city. If my machine breaks, I need my local mechanic, Mr. Budi, to be able to fix it. Mr. Budi is a great mechanic, but he is not a PLC programmer."

This client chose a robust, mechanically simple semi-automatic machine from us. One time, a pneumatic valve failed after two years of operation. They called us. We identified the part. It was a standard, high-quality valve. They were able to buy a replacement from a local industrial supplier in the nearest town and Mr. Budi installed it the same day. They were back in production in 24 hours.

If this had been a proprietary electronic board on a complex automatic machine, they would have had to wait for me to ship it from overseas. The machine would have been down for a week or more. This is why "simplicity" and "reliability" are such powerful and economic advantages.

Reason 4: What about infrastructure and simple operation?

Is your factory space limited? Worried about your power grid or compressed air supply? Complex machines need complex and expensive support systems. This can break your budget.

Semi-automatic machines are the answer. They are smaller. They use less power. Their compressed air needs are simpler. This makes them much easier to install in existing buildings without needing major, expensive upgrades.

We often see this with customers who are not starting from scratch. They might have an older factory building or a space in a shared industrial park. The power supply might be unstable. They simply cannot support the massive infrastructure needed for a high-speed automatic line. I had a client in a rural area whose factory had power fluctuations. A complex, sensitive automatic machine would have constant errors. Our semi-automatic machines are more "robust." They are easier to integrate, need less auxiliary support, and are tougher in challenging operating environments.

The Hidden Costs of Automation: Infrastructure

When you get a quote for a fully automatic machine, the price of the machine itself is only the beginning. The hidden costs are in the infrastructure.

A high-speed line requires:

- A Huge Footprint: These lines are long. They include the main machine, preform feeders, air conveyors, and outfeed conveyors. You often need to build a new, dedicated space.

- Massive Power: You may need a new, dedicated high-voltage transformer and cabling. This is a major civil works project.

- A Massive Air System: High-speed machines are air-hungry. You need a large, high-pressure air compressor system, plus large air dryers, filters, and tanks. This system alone can cost as much as a semi-automatic machine.

- High-Capacity Chilling: To cool all those molds at high speed, you need a very powerful industrial chiller.

These infrastructure costs can easily add 50-100% to the total project cost. My client with the older factory was quoted $200,000 for an automatic line, but the total project cost with infrastructure upgrades was almost $350,000. It was simply not feasible.

The "Easy Integration" Advantage

A semi-automatic system is much simpler.

- Footprint: The machine (heater and blower) is very compact. You can often fit two or three semi-auto machines in the space of one small automatic line.

- Power: It runs on standard industrial power. The main draw is the heating oven. It does not require a special transformer.

- Air: It still needs high-pressure air, but the volume is much lower. A smaller, more affordable compressor is sufficient. We often consult with clients on how to build a cost-efficient air system that can grow with them.

- Chilling: A smaller, standard chiller is all that is needed to keep the blow molds at the correct temperature.

This "easy integration" means the client with the older factory could install two of our semi-automatic machines and all the auxiliary equipment for under $60,000. They were in production within a month of receiving the equipment.

Table: Infrastructure Requirement Comparison

| Infrastructure | Semi-Automatic System (2-Cavity) | Fully Automatic Line (6-Cavity) |

|---|---|---|

| Footprint (approx.) | 15-20 sq. meters | 60-100+ sq. meters |

| Power Requirement | ~15-25 kW | ~80-150+ kW |

| High-Pressure Air | ~1.5-2.0 m³/min @ 3.0 Mpa | ~6.0-9.0 m³/min @ 3.0 Mpa |

| Chiller Capacity | ~5-7 HP | ~20-30+ HP |

| Installation | Simple. Can fit in existing spaces. | Complex. Often needs building modification. |

Operational Simplicity and Robustness

"Robust" is a word I use a lot. It means the machine is not "fragile." In environments with dust, humidity, and unstable power (common in many industrial areas), a simpler machine with fewer sensitive electronics is a huge advantage.

Our semi-automatic machines are built with this in mind. They have:

- Strong, heavy-duty steel frames.

- High-quality pneumatic components from trusted brands.

- Simple, reliable control relays and timers (or a very basic, rugged PLC).

- Heating systems with good insulation and durable lamps.

This robustness means less downtime, easier troubleshooting, and a longer machine life, even when the operating conditions are not perfect. It's a practical choice for real-world factory environments.

What makes a "reliable" semi-automatic machine truly worth it?

Thinking "semi-automatic" means "low quality"? This is a huge mistake. The benefits of low cost and flexibility disappear completely if the machine is poorly made and always breaking down.

You must choose a reliable machine. The core blowing function must be precise and repeatable. A cheap, low-quality machine will cause constant problems and waste, costing you more in the long run.

The biggest mistake I see is when a customer equates "low cost" with "any cheap machine will do." This is wrong. I had a client in Vietnam who learned this the hard way. He bought an ultra-cheap local machine. It failed constantly. He bought another. It also failed. In two years, he went through three different machines. He was losing money from downtime and material waste. He was stressed and his customers were angry. Then he came to us. He bought one of our iBottler semi-automatic machines. It has been running reliably for him ever since. The price of our machine was higher than the cheap ones, but the cost was much, much lower.

The "Cheap Machine" Trap

A machine that is built to be "cheap" above all else will cut corners on the most important parts. This is what happens:

- Inconsistent Heating: The oven uses cheap lamps or has poor reflectors. The preforms are not heated evenly. This is the #1 cause of common PET blow molding defects. You get

bottles that are too thin in one spot and too thick in another. - Failing Pneumatics: The machine uses low-grade valves and seals. They start to leak air. The high-pressure blowing becomes weak and inconsistent. The machine fails to operate.

- Weak Clamping: The frame is built with thin steel. Over time, the clamping mechanism can flex or crack. The mold won't seal properly, creating ugly parting lines or flash on the bottles.

- No Support: When the machine breaks, the supplier is gone. There is no manual, no spare parts list, and no one to call.

This "cheap machine" is not a tool; it's a trap. It will destroy your business.

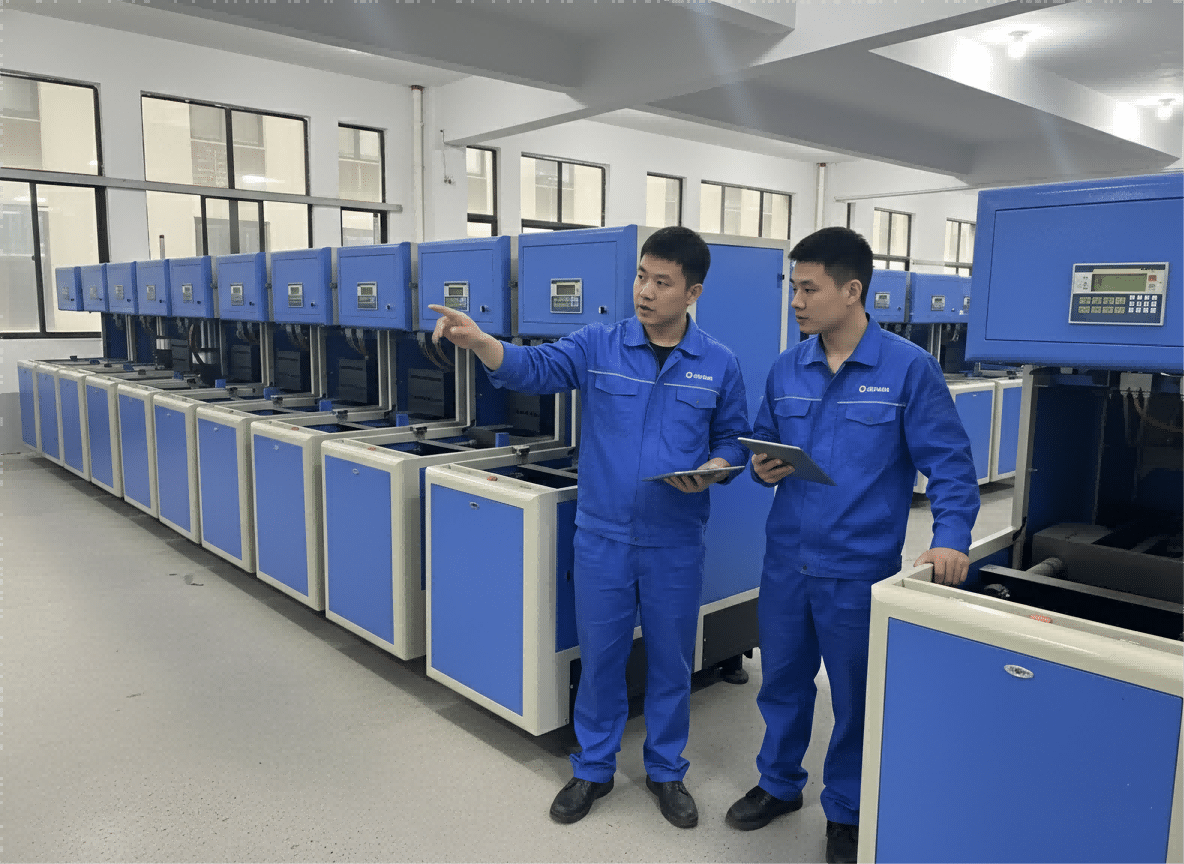

What Defines a High-Quality Semi-Automatic Machine?

When I show a customer one of our iBottler bottle blowing machines, I point out the details that matter. These are the features that define a reliable machine:

- A Robust, Heavy Frame: The machine should be heavy. This means it's made of thick, strong steel that will not flex under pressure.

- Quality Components: We use pneumatic valves, cylinders, and filters from world-class brands (like Festo, SMC, or Airtac). These parts are reliable and, if they ever do wear out, they are easy to find replacements for.

- Precise Heating Control: Our ovens have multiple zones of heating. You can adjust the temperature of different parts of the preform. This gives you the control you need to make perfect bottles.

- A Powerful, Stable Clamping System: We use a toggle-joint or hydro-pneumatic system that provides consistent, high clamping force. This ensures your mold seals perfectly, every time.

- Good Mold Compatibility: The machine should be designed to easily accept standard molds. We know all about mold mounting. We have data on blow mold fit for 80% of machines worldwide, so we design our machines to be flexible.

The Mold is Your Partner in Quality

You cannot make a good bottle with a bad mold, even with the best machine. A quality blow bottle mold is just as important.

What makes a good mold?

- Good Material: Using high-quality aircraft-grade aluminum or steel.

- Precise Machining: Made with high-precision CNC machines so the two halves fit perfectly.

- Optimized Cooling: Designed with water channels in the right places to cool the bottle quickly and evenly. This is critical for high-quality, clear bottles and faster cycle times.

- Excellent Polishing: The inside surface must be polished like a mirror.

We also supply high-quality preform molds for clients who want to make their own preforms. The entire system—preform, machine, and mold—must work together. Investing in a reliable semi-automatic machine and quality molds is the key to making the semi-automatic strategy successful.

How does iBottler understand and serve these dynamic market needs?

Are you tired of salespeople just pushing the most expensive model? Do you feel like they don't understand your specific budget, market, or operational reality?

We are different. We listen first. We respect our clients' smart business reasons for choosing a semi-automatic solution. Our goal is to provide high-quality, durable, and easy-to-use machines that are perfectly suited for the challenges and opportunities of markets like Southeast Asia.

We never push the most expensive machine. My job is to find the right machine for the client. I have honest conversations. I ask, "What is your budget? What is your market? What are your real production goals?" We are proud to offer powerful semi-automatic solutions. We know these machines help businesses in Southeast Asia and other emerging markets compete effectively and grow sustainably. Our success comes from our clients' success.

Our Philosophy: The Right Tool for the Job

Our business philosophy is simple: we provide the right tool for the job. We are engineers and manufacturing experts, not just salespeople.

- If you need to make 10,000 bottles an hour of one single product, we will tell you that you need a fully automatic rotary machine. We can help you with that.

- But if you tell us you are a startup with a $30,000 budget, or a co-packer who needs to change molds three times a day, we will not try to sell you that $500,000 machine.

- We will proudly and confidently recommend one of our iBottler semi-automatic machines.

We know that for your business, this machine is the superior choice. It is the tool that will make you profitable. It is the tool that will give you the flexibility you need. We have designed our machines to be the best semi-automatic machines on the market. They are reliable, easy to use, and built to last. We are proud of them because they are the right solution for so many of our customers.

Beyond the Sale: Support in Your Region

We have been working with clients in Southeast Asia for years. We understand the region. We know the logistics. We understand the operational challenges.

Our support does not end when the machine is shipped. We provide:

- Comprehensive Manuals and Videos: Our machines come with clear, easy-to-understand documentation and video guides for operation and maintenance.

- Remote Diagnosis: If you have a problem, you can send us a video. My team of engineers and I can often diagnose the issue remotely in minutes.

- Fast Spare Parts: We stock all critical spare parts. We can ship them to you quickly by air freight (like DHL or FedEx) so you can get back into production.

- Expert Advice: We are always here to help. If you are struggling with a new bottle shape or seeing a defect, you can call us. We will help you troubleshoot. Maybe you need to adjust your heating, or maybe we can suggest a solution to a common molding defect.

This long-term partnership is why clients trust us. They know we are not just a supplier; we are a partner in their production.

Ensuring a Perfect Fit: Molds and Machines

A common worry for customers is, "If I buy a mold from you, will it fit my existing machine?" or "If I buy your machine, can I use my old molds?"

This is a valid concern. We have solved it. We have spent years collecting data. As I mentioned, we have the mounting dimensions for 80% of blow molding machines worldwide.

This means:

- If you buy a mold from us: You can tell us what machine you have. We will design the blow mold to be a perfect, drop-in replacement.

- If you buy a machine from us: We can design the mold holder to be compatible with the molds you already own, if possible.

This level of technical expertise and flexibility saves our customers time, money, and stress. It is part of our commitment to providing a complete solution, not just a product.

Could a semi-automatic machine be the smart choice for your business too?

Are you a startup, a small business, or a large company launching a niche product? Do you see yourself in the challenges of capital, flexibility, and labor we've discussed?

Then this logic applies to you, no matter where you are. A semi-automatic solution might be the smartest move you can make. It is a proven, low-risk, high-flexibility path to success.

The business logic that drives a bottler in Southeast Asia is often the same for an entrepreneur in Africa, Latin America, or even a small town in North America. If you are capital-sensitive, need to be flexible, or are working in a challenging environment, these machines are worth a serious look. I invite you to contact us for a free consultation. Let's analyze your specific needs. Let's see if one of our reliable semi-automatic machines is the right choice to start or grow your bottling business.

Are You a "Southeast Asian" Bottler (Even if You're Not)?

This article focuses on Southeast Asia because it's a perfect example of these market dynamics. But the principles are universal. Ask yourself these questions:

- Is my initial capital limited? Do I want to prove my product before I take on huge debt?

- Is my market uncertain or diverse? Do I need to produce multiple bottle types or change designs often?

- Am I a co-packer? Is my entire business built on flexibility for my clients?

- Is my available labor good at general tasks, but lacking in specialized PLC/robotics skills?

- Is my factory space small or my power supply limited?

- Do I value reliability and low maintenance over raw, top-end speed?

If you answered "yes" to two or more of these questions, you should be seriously considering a semi-automatic solution. You are facing the same business logic.

A Personal Invitation for a Free Consultation

As an expert in this field, I've seen too many people make the wrong choice. They either over-spend on a machine that is too big and complex, or they under-spend on a cheap, unreliable machine that breaks down. Both are paths to failure.

I want to help you find the right path.

I personally invite you to contact our team. We offer a free, no-obligation consultation.

This is not a sales call. This is a problem-solving session.

Here is what we will do:

- We Will Listen: You tell us about your project. What product? What bottle sizes? What are your production goals (bottles per day)? What is your budget?

- We Will Analyze: We will use our experience to analyze your needs. We'll consider your capital, your market, and your operational reality.

- We Will Recommend: We will give you an honest recommendation. We will tell you if a semi-automatic machine is a good fit. We will also be honest if we think you do need a fully automatic line.

- We Will Provide a Full Picture: If a semi-automatic machine is the right fit, we can give you a clear idea of the total system. This includes the bottle blowing machine, the blow molds, and the necessary auxiliary equipment like an air compressor and chiller.

This is the smart way to start. Don't gamble with your capital. Make an informed decision based on expert advice that is aligned with your goals.

Conclusion

Choosing a semi-automatic machine is not a compromise. For many businesses in Southeast Asia and beyond, it is the smartest, most profitable, and lowest-risk decision for building a successful bottling operation.

Summary of Key Reasons

| Reason (H2 Title) | Key Business Driver | Why It Leads to Semi-Automatic |

|---|---|---|

| Challenging the Myth | Realistic ROI | A "smart" investment is profitable and manageable, not just fast. |

| Capital Sensitivity | Low Initial Cost & Risk | 5x-10x cheaper than full auto. Protects cash flow. |

| Operational Flexibility | Diverse Products & Small Batches | Fast, easy mold changes (under 1 hour) are vital for agility. |

| Labor Dynamics | Skill & Maintenance Reality | Uses available general labor; avoids need for rare, costly PLC techs. |

| Infrastructure | Existing Factory Limits | Smaller footprint, lower power, and simpler air needs. Easy to install. |

| Reliability | Total Cost of Ownership | A quality semi-auto machine avoids the downtime of cheap, bad ones. |

| iBottler's Approach | Partnership & Trust | We listen and provide the right solution, not the most expensive one. |

| Your Business? | Universal Logic | If you are capital-sensitive and need flexibility, this model works anywhere. |

Frequently Asked Questions (FAQ)

Q: Do semi-automatic machines only produce low-quality bottles?

A: Absolutely not. A well-made semi-automatic machine paired with a high-quality mold (like the ones we provide!) can produce bottles with excellent quality, clarity, and consistency. These bottles are suitable for most beverage applications. The bottle's quality is determined by the machine's core blowing mechanism and the mold, not by the loading method.

Q: What is the typical production speed difference between semi-auto and fully-auto?

A: A semi-automatic machine's output is typically between 300 to 1,000 bottles per hour (BPH), depending on the bottle size and operator, per machine. An entry-level fully automatic linear machine starts around 2,000 BPH, and rotary machines go much higher (10,000+ BPH). The difference is significant, which is why the choice depends entirely on your required volume.

Q: How difficult is it to train an operator for a semi-automatic machine?

A: It is relatively easy. The process involves manual loading and unloading, but the machine handles the critical blowing steps. Basic safety and operation training can usually be completed in 1-2 days.

Q: Can I upgrade from a semi-automatic to a fully automatic line later?

A: Yes, many businesses do this as they grow. While the semi-automatic machine itself is not "upgraded," the experience and market you build with it provide a strong foundation. When your volume is high enough, you can invest in a fully automatic line. Some auxiliary equipment, like your air compressor or chiller, may even be usable with the new line.

Q: Does iBottler provide support and spare parts for its semi-automatic machines in the Southeast Asia region?

A: Yes, we provide comprehensive support. This includes remote diagnostics, easily accessible spare parts, and detailed manuals and videos. We have extensive experience supporting clients in Southeast Asia and understand the importance of a fast service response.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr