You are designing a product and see this code: 28/410. You might ignore it. But this small code can cause big, expensive leaks and project delays. Understanding it is the key to a successful product launch.

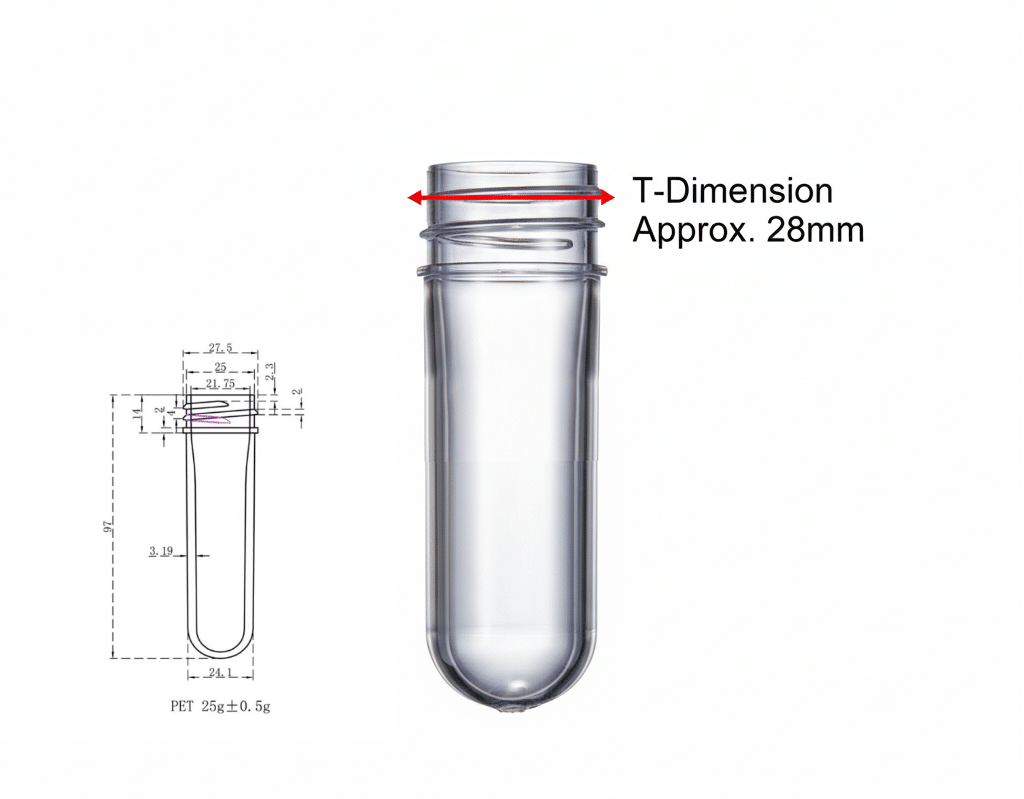

A 28/410 neck finish is a standard size for bottle openings. The "28" means the outer diameter of the threads is approximately 28 millimeters. The "410" is a code from the GPI/SPI that defines the thread style, indicating it has about one and a half thread turns.

You see this code, but what does it really mean for your bottle, your cap, and your business? This code is not just a technical detail. It is a business decision. It affects your costs, your suppliers, and your customer's experience.

Let's dive deep and break down every part of this "universal language" of packaging. I will share my experiences to help you avoid common mistakes.

Key Points: Understanding the 28/410 Standard

| Feature | Description | Why It Matters |

|---|---|---|

| The "28" | 28mm outer thread diameter (T-Dimension) | This number determines the "size" or diameter of the cap you must use. |

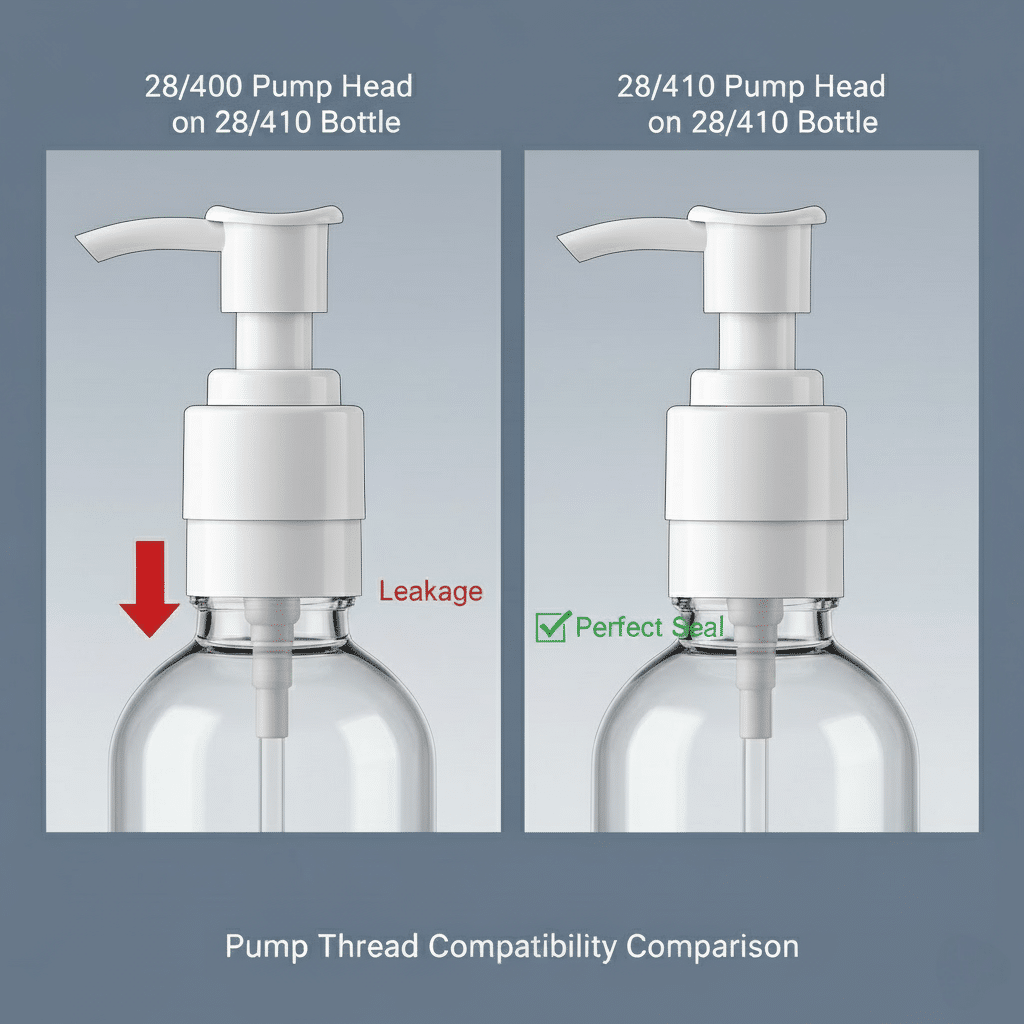

| The "410" | GPI / SPI thread standard | Defines the thread height and turns (approx. 1.5 turns). It is not interchangeable with 28/400. |

| Compatibility | Only a 28/410 cap will fit a 28/410 bottle | Mismatching these numbers will cause leaks, cap stripping, or function failure. |

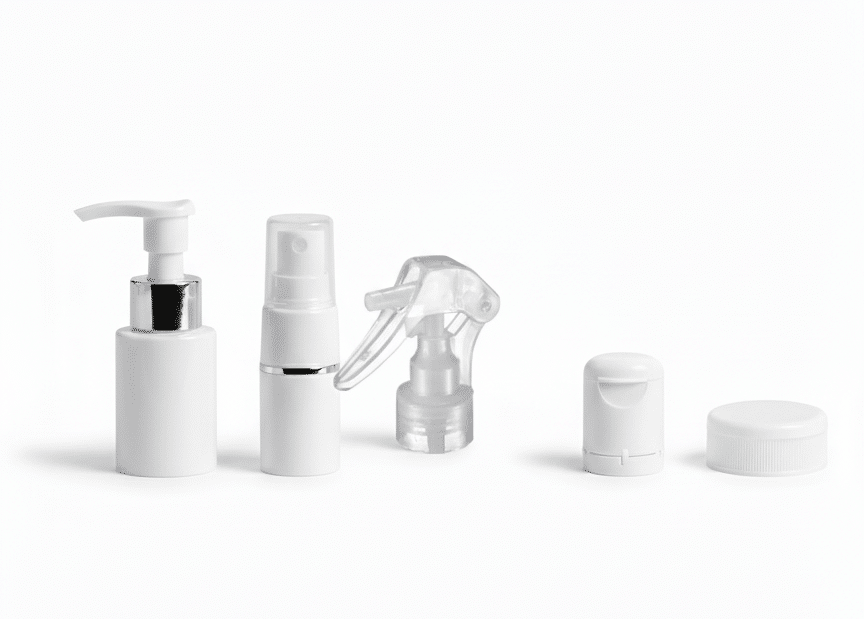

| Common Use | Pumps, sprayers, lotions, soaps, cleaners | This neck is ideal for dispensing products, not for high-pressure (like soda). |

| Supply Chain | Extremely common "ecosystem" | This is a "safe" choice. It gives you many options for caps and bottles at a good cost. |

Why is 28/410 more than just numbers?

You are designing new packaging or buying bottles. You see "28/410" on a spec sheet. It looks like a random number. But ignoring it can stop your entire project. This code is the "universal language" that stops costly mistakes.

It's the "universal language" for packaging. This code ensures a bottle from one factory in China perfectly matches a cap from another factory in Europe. Understanding it is the first step to avoiding project delays, product leaks, and unhappy customers.

I have seen too many projects fail because of this small detail. I remember a client, a new skincare brand. They spent thousands on a beautiful custom bottle. They bought the bottles first. Then they tried to find a lotion pump. They just searched for "28mm pumps." They bought 10,000 units. When the pumps arrived, they did not fit. They leaked. The project was delayed by two months. The problem? Their bottle was 28/410. The pump was 28/400. This tiny difference cost them a lot of money and time. This is why I say these numbers are not just details. They are the foundation of your package.

This "universal language" comes from standards bodies. The two most common are the GPI (Glass Packaging Institute) and SPI (Society of the Plastics Industry). These groups created a "dictionary" for bottle necks. This dictionary allows everyone in the supply chain to speak the same language.

Imagine a world without these standards.

- A bottle maker in one country would have their own "28mm" neck.

- A cap maker in another country would have their "28mm" cap.

- They would never fit together.

- Every brand would have to buy their bottles and caps from the exact same supplier. This is risky. If that supplier has problems, your entire production stops.

Standards like 28/410 create a modular system. It is just like a USB-C cable. You can buy a charger from Apple and a cable from Anker. They work together. 28/410 is the "USB-C" for many shampoo, lotion, and soap bottles.

This is a business decision, not just a technical one. When you choose a 28/410 neck, you are not just choosing a size. You are choosing:

- Supply Chain Security: You can buy compatible caps from hundreds of different suppliers.

- Cost Control: High competition and high volume make 28/410 caps and preforms very affordable.

- Speed to Market: You can often find "stock" caps and bottles in this size. You can launch your product faster.

- Flexibility: You can start with a simple screw cap. Later, you can use the exact same bottle and just swap to a lotion pump. The bottle does not need to change.

So, when you see "28/410," do not just nod. Ask questions. "Is my cap also 28/410?" "Have we tested the fit?" This small number is the difference between a product that leaks all over a shipping box and one that works perfectly for your customer. It is the first link in a long chain of quality. And in my experience, a chain is only as strong as its weakest link. Do not let this number be your weak link.

What does the "28" in 28/410 really mean?

You need to buy a cap for your bottle. You guess the size. It looks like it fits, but it feels loose. Knowing that "28" means 28 millimeters is the first key to finding the right fit.

The "28" is the "diameter password." It refers to the approximate outer diameter of the bottle's threads, measured in millimeters. This is the primary measurement for matching the cap "size." This is often called the "T" dimension.

You can think of this like your home water pipes. You cannot connect a 1-inch pipe to a 3/4-inch fitting. It just will not work. The "28" is the "diameter" of the pipe. 28mm is a very common, medium-small size. It is perfect for bottles that you hold in your hand, like a 250ml (8 oz) soap bottle or a 500ml (16 oz) shampoo bottle.

How do you measure this? The most accurate way is with a digital caliper. You measure across the very top of the threads, from the outside edge of one thread to the outside edge of the opposite thread.

Now, why do I say "approximate"? In manufacturing, nothing is exact. There is always a "tolerance." A 28mm neck finish is not 28.0000mm. It is usually made to a tolerance of something like 27.70mm to 28.10mm. The cap is also made with a matching tolerance. Its inner diameter is designed to fit perfectly over a neck within this tolerance range.

This "28" is the first filter in your search. If you are looking for a cap, the first thing you must check is this number. A 24mm cap will not fit on a 28mm bottle. A 38mm cap will be huge. This sounds simple, but it is the most common mistake.

Let's compare 28mm to other common sizes. This helps you understand why it is so popular.

- 18mm, 20mm: These are small. You see them on perfume bottles, eye droppers, and small "treatment pump" bottles.

- 24mm: This is also very common. It is a bit smaller than 28mm. You see it on many lotions and face washes.

- 28mm: This is the "Goldilocks" size. It is big enough for thick liquids like shampoo or conditioner to flow easily. It is also the standard size for most trigger sprayers and lotion pumps.

- 38mm: This is much larger. You see this on milk jugs, large juice bottles, or gallon containers.

The popularity of 28mm is directly linked to its use. It is the perfect balance. It is small enough to look good on a 250ml bottle, but large enough to be functional on a 1-liter bottle. This versatility is why it became a standard.

When we talk about PET bottles, this 28mm neck is already formed on the PET preform. The preform mold creates this neck. Then, our bottle blowing machine heats and stretches the preform body to make the final bottle. The neck itself does not change. So, the precision of that "28" is locked in from the very first step. If this "28" is wrong, every single bottle will be wrong.

What is the "410" thread standard?

You found a 28mm cap for your 28mm bottle. You screw it on. But it keeps spinning. Or it tightens, but you can pull it right off. The "410" (the thread) was the problem.

The "410" is the "thread password." It is a GPI/SPI standard that defines the thread's height and style. A "410" finish typically has one and a half thread turns. This is a common, shallower thread.

If "28" is the diameter of the pipe, "410" is the number of "teeth" on the screw and how "deep" they are. You need both the diameter and the thread to match perfectly.

The "400 series" (400, 410, 415, etc.) is the most common for plastic bottles. The main difference is the height of the neck and the number of thread turns.

- 400: Has about 1 full thread turn. It is very shallow.

- 410: Has about 1.5 thread turns. This is the "middle" ground.

- 415: Has about 2 full thread turns. It is deeper and can provide a tighter seal.

Let's look at this in a table.

Common 28mm Thread Comparisons

| Neck Finish | Approx. Thread Turns | Thread Height | Common Use Cases |

|---|---|---|---|

| 28/400 | 1 | Shallow | Simple screw caps, dry goods (powders), some pills. |

| 28/410 | 1.5 | Medium-Shallow | Most pumps, sprayers, flip-tops, lotions, soaps. |

| 28/415 | 2 | Deeper | Some chemicals, sauces. Better seal for some liquids. |

Why does 1.5 turns (the 410) matter so much?

It is all about "thread engagement." This means how much of the cap thread is touching the bottle thread.

A 28/400 has very little engagement. It is fine for a simple screw cap on a jar of pills. You open it once a day.

But imagine a lotion pump. You push down on that pump hundreds of times. This action puts upward and twisting force on the cap. A 28/400 cap would "strip" or pop off after just a few uses.

The 28/410's extra half-turn provides just enough extra grip. It holds the pump or sprayer firmly in place. It stops the cap from unscrewing itself during use. It also provides a good seal for non-pressurized liquids like shampoo or soap.

Why not use 28/415 (2 turns) for everything?

- Cost: A 28/415 cap is "taller." It uses more plastic. This adds cost.

- User Experience: It takes longer to unscrew a 2-turn cap.

- Compatibility: Pumps and sprayers are designed for the 410 standard.

The 28/410 is the perfect balance of cost, performance, and user experience for dispensing products. It is the workhorse of the industry.

When you are designing a new PET bottle, you are really designing it around this 28/410 neck. The neck is the "anchor." The rest of the bottle design flows from there. This is why getting the neck standard right is the most important part of the entire blow bottle mold design.

What products use a 28/410 neck?

You are developing a new shampoo. You are lost in thousands of bottle options. The 28/410 is the standard, proven choice for this exact product.

You see 28/410 everywhere, every single day. It is the top choice for personal care (shampoo, soap, lotion) and cleaning products (sprays, disinfectants). This is because it works perfectly with pumps, sprayers, and flip-tops.

I tell my clients to look at the function. You will notice 28/410 is rarely used on carbonated drinks like Coca-Cola. Why? Those drinks are under high pressure. They use special necks (like PCO1881) designed to hold that pressure. The 28/410 is not designed for pressure. It is designed for dispensing.

Let's break down the most common applications.

1. Personal Care & Cosmetics

This is the biggest category. Go into your bathroom. I bet you will find at least five 28/410 necks.

- Liquid Hand Soap: Almost always 28/410. It needs a lotion pump.

- Shampoo & Conditioner: Very common. Uses a 28/410 with either a lotion pump, a disc-top cap (the one you press on one side), or a flip-top cap.

- Body Lotion & Moisturizer: Almost always 28/410 with a lotion pump.

- Shower Gel: 28/410 with a flip-top or disc-top.

- Micellar Water / Toners: Often use 28/410 with a simple screw cap or a disc-top.

- Hair Gels & Serums: 28/410 with a "treatment pump" (which has a smaller output).

2. Household & Cleaning

This is the second-biggest category.

- Trigger Sprayers: This is the key one. Most standard trigger sprayers (for window cleaner, all-purpose cleaner, etc.) are made to fit a 28/410 neck.

- Fine Mist Sprayers: Room sprays, disinfectant sprays, or plant misters often use a 28/410 neck with a sprayer attachment.

- Dish Soap: Many brands use a 28/410 with a push-pull cap or a flip-top.

3. Food & Beverage (Less Common)

You see it, but less often.

- Sauces & Syrups: Some condiment bottles (like BBQ sauce) or coffee syrups use a 28/410. This allows them to be used with a food-grade pump.

- Oils & Vinegars: Some may use a 28/410 with a special non-drip cap.

- But again, never for carbonated or hot-fill beverages. These require different neck types.

Why this link between product and neck?

It is simple. The 28/410 neck is the platform. The functional caps (pumps, sprayers) are the tools. The 28/410 became the standard platform because it works with the widest variety of tools.

This is critical for your product. If you choose a 28/410 neck:

- You can offer your customer a "pump" version and a "flip-top" version of the same bottle.

- You can source these pumps and caps from many different suppliers.

- You are not locked into a custom, proprietary neck that only one company makes.

This choice is a core part of your PET bottle design. The application (shampoo) defines the required cap (pump), which in turn defines the required neck (28/410).

How do I find the right cap for a 28/410 neck?

You bought 28mm bottles. You bought 28mm caps. You are ready for production. But they don't fit! You missed the "410."

Finding the "soulmate" cap is critical. You must match "28/410" on the bottle with "28/410" on the cap. A "28/400" cap will leak. A "24/410" cap will not fit. The entire code must match.

This is the exact story I told earlier about the startup brand. They bought 28mm bottles (which were 28/410) and 28mm pumps (which were 28/400). They looked almost the same. A 28/400 cap will start to screw onto a 28/410 bottle. It will catch that first thread. The brand owner thought it was "good enough."

They filled 10,000 bottles. They put them in boxes. The shipping process and temperature changes caused pressure. The caps, with their weak 1-thread grip, started to pop off. Liquid soap was everywhere. It was a disaster. All because of the "410" vs "400."

So, how do you find the right one?

First, you must confirm your bottle's neck finish. Ask your supplier for the "technical drawing" or "spec sheet." It will clearly state "28/410."

Second, when you search for caps, you only search for "28/410" caps.

Here is a list of the cap "soulmates" you can find for your 28/410 bottle.

Types of 28/410 Closures

- Lotion Pumps: The most common. They come in different "outputs" (e.g., 2cc, 4cc per pump) and styles (locking up, locking down, different head shapes).

- Fine Mist Sprayers: For spraying thin liquids like water or alcohol.

- Trigger Sprayers: For cleaning products. These have different spray patterns (stream, spray) and chemical resistance.

- Flip-Top Caps: Very common for shampoo and shower gel.

- Disc-Top Caps: Also common for shampoo and lotions.

- Simple Screw Caps: These can be "lined" or "unlined."

- Lined: Has a small foam or plastic liner inside for a better seal.

- Induction Seal: Has a foil liner that you "weld" to the bottle rim with a special machine. This provides a perfect, tamper-evident seal.

- Push-Pull Caps: Like on a water bottle or dish soap.

The Other Compatibility: Dip Tube Length

This is the "gotcha" for pumps and sprayers. You found a 28/410 pump. It fits the neck perfectly. But the plastic tube (the dip tube) is 12 inches long, and your bottle is only 6 inches tall.

The dip tube always needs to be cut to size. You must measure the exact height of your bottle. The dip tube should be cut so it just touches the bottom corner of the bottle. If it's too short, it wastes product. If it's too long, it will bend and block the flow.

My advice: ALWAYS test. Before you order 50,000 caps, order 50 samples. Get your 3D printed bottle sample. We can provide 3D printed samples from your mold design for this exact purpose.

Then, you manually screw on the sample caps. Fill the bottle with water. Turn it upside down. Shake it. Let it sit for 24 hours. If there are no leaks, you have a match. This simple test can save you a fortune.

What is the difference between 28/410 and 28/400?

They look almost identical. You think they are interchangeable. But using a 28/400 cap on a 28/410 bottle is a ticking time bomb. It will lead to leaks.

The difference is small but critical: the thread height. A "400" has about one thread turn. A "410" has about one and a half thread turns. They are not interchangeable. A 400 cap on a 410 bottle will be loose.

I use this analogy:

- 28/400 is like a "single thread" screw. It is fast to put on, but it does not have a lot of "grip."

- 28/410 is like a "one-and-a-half thread" screw. It has more "grip."

Why does this "grip" (or "thread engagement") matter so much?

- Sealing Power: The 410 has more thread surface area touching the cap. This creates a more secure, longer path for liquid to travel, making leaks less likely.

- Stripping: A 400 cap can be "stripped" easily. This means you tighten it, and it just "pops" over the threads and is loose again. This is very rare with a 410.

- Functional Caps (The Big One): This is the most important reason. As I said before, a lotion pump or trigger sprayer puts force on the cap. When you push the pump down, the cap wants to "pop" up. The extra grip of the 410 prevents this. A 28/400 cap would likely fail after 10-20 pumps. This is why almost all pumps and sprayers are 28/410.

Let's go back to that startup client with the leaky soap. Their 28/400 pump only caught that top thread on the 28/410 bottle. It felt tight. But when a customer pushed the pump, the force would "strip" that single thread, and the pump would pop off. Or, it would create a small gap, and soap would leak from the base of the cap.

This is a classic bottle defect, but it is not a molding defect. It is a sourcing defect.

Can I ever use them together?

I will be very direct: No. Do not do it.

I have heard people say, "Oh, a 410 cap on a 400 bottle sometimes works." Yes, it might screw on. But the cap is "taller" than the neck. You will have a gap at the bottom. It looks ugly and unprofessional.

And a 400 cap on a 410 bottle (the startup's problem) will never work reliably. It will always leak. It is a product recall waiting to happen.

This is not a place to save a few pennies. The standard exists for a reason. Respect the standard, and your product will be safe.

When we create a blow bottle mold, we are not just cutting metal. We are precisely recreating the 28/410 standard. We use special gauges to test the necks. We check our mold dimensions against machine specs to ensure a perfect fit. Precision is everything. There is no "close enough" in neck finishes.

What does picking 28/410 mean for my product?

You have to pick a bottle neck for your new product. It feels like a small, random choice. But choosing 28/410 is a major strategic business decision.

Choosing 28/410 means you are choosing an "ecosystem." You get the widest possible selection of pumps, sprayers, and caps. You also get a mature supply chain and controlled costs. It is a smart, safe, and flexible choice.

When I consult with a new brand, this is one of the first things we discuss. I often say, "Choosing a bottle neck is like choosing what kind of power outlet to install in your house."

- You could invent your own new, custom plug. It might look cool. But then only you can make appliances that fit it. It is expensive and very risky.

- Or, you can use the standard plug for your country. Now, you can buy any standard appliance from any store, and it just works.

The 28/410 is the "standard plug" for the personal care and cleaning world.

The Strategic Advantages of the 28/410 Ecosystem

Massive Cap Selection (The Ecosystem)

This is the number one benefit. Because it is the standard, everyone makes caps for it.- Want a pump that outputs 4cc of thick conditioner? You can find it in 28/410.

- Want a special "foaming" pump? It exists in 28/410.

- Want a gold metal-shelled sprayer? Easy to find in 28/410.

- This gives you incredible design freedom. You are not locked into one cap supplier's limited catalog.

Mature Supply Chain & Availability

Billions of 28/410 closures are made every year. This means:- Preforms are in stock: PET preforms with 28/410 necks are a commodity. They are easy to buy.

- Caps are in stock: You can often buy "stock" 28/410 caps (in black, white, or natural) for immediate delivery. This is great for a fast launch.

- Multiple Suppliers: You can get quotes from 10 different cap suppliers. This keeps your suppliers honest and your prices low.

Controlled Cost

High volume means high efficiency. High competition means low prices.- The preform molds and cap molds for 28/410 have been perfected over decades. They run fast and produce low-cost parts.

- This helps you keep your final "Cost of Goods Sold" (COGS) low, which improves your profit margin.

Proven User Experience

- Consumers are familiar with it. They know how to use these pumps and caps.

- The 28mm opening is wide enough for users to see the product. For some products, it is even wide enough for refilling.

When would you NOT choose 28/410?

It is not perfect for everything. You would choose a different neck if:

- Your product is carbonated: You need a PCO (Plastic Closure Only) neck, like PCO1881.

- Your product is hot-filled: You need a special neck and bottle material that can handle the heat.

- Your product is very small: A 15ml (0.5 oz) bottle would look silly with a giant 28mm cap. You would use an 18/410 or 20/410.

- Your product is very large: A 1-gallon (4L) jug needs a 38mm or 45mm neck.

- You need extreme chemical resistance: Some harsh chemicals might require a specific material or a "buttress" thread style (like 28/430).

But for 80% of the products I see in the personal care, cosmetic, and cleaning space, the 28/410 is the smartest, safest, and most flexible choice. It is the definition of a standard.

How do I make sure my 28/410 bottle is made perfectly?

You have made the smart choice. You picked 28/410. You assume any mold maker can do it. But a tiny, 0.1mm error in the mold tool can make every single bottle you produce completely useless.

Understanding the spec is step one. Manufacturing it perfectly is step two. The blow mold's neck area must be perfect. A tiny error in the steel means thousands of leaky bottles. Precision is everything.

At iBottler, this is what we obsess over. We are a blow bottle mold manufacturer. We know that a perfect bottle starts with a perfect neck.

There is a critical distinction here that most people miss. How the neck is made depends on the plastic type.

1. For PET Bottles (The clear, hard plastic):

The neck finish is not made in the blow mold. It is already finished on the preform. The preform looks like a small test tube. Our bottle blowing machine heats the body of the preform, but it protects the neck. The neck threads are never heated. The blow mold then closes around the preform and blows the body into the final bottle shape.

- Your responsibility: You must buy high-quality preforms that already have a perfect 28/410 neck.

- Our responsibility: Our mold design must fit your blowing machine and be designed to protect that neck during the blowing and stretching process.

2. For HDPE/PP Bottles (The softer, often opaque plastic):

This is different. For Extrusion Blow Molding (EBM) or Injection Blow Molding (IBM), the neck is formed inside the blow mold. The mold closes on a "tube" of hot plastic (parison) and forms the neck and body at the same time.

- Our responsibility: The "neck insert" part of our blow bottle mold must be machined to exact GPI 28/410 tolerances. This is where our expertise is critical.

Our Process for a Perfect 28/410 Mold

When a client asks us for a 28/410 mold (for HDPE, for example), here is what we do:

- Design: We do not guess. We pull the official GPI/SPI 28/410 standard drawing. Our PET bottle mold design is based 100% on this international standard.

- Machining: We use high-precision CNC machines to cut the steel. The neck area is often made from a separate, harder steel (like S136) and is machined with extreme accuracy.

- Cooling: We design cooling channels all around the neck area. This is critical. If the neck does not cool properly, it can warp. A warped neck will leak. This is why a mold chiller is so important.

- Validation: Before we ship the mold, we test it. We also recommend the client use a 3D printed sample of the bottle to test with their chosen cap. This confirms the fit before we even cut the final steel.

- Support: We also look at the whole system. Do you have the right high-pressure air compressor? Is your machine compatible? We solve the whole problem, not just one part.

A perfect bottle neck is the result of perfect design, perfect machining, and a perfect process. If you are starting a new project with a 28/410 neck, talk to us. We can ensure that the foundation of your product—the mold—is precise from day one.

Conclusion

The 28/410 is not just a number. It is a powerful standard. It is the "universal language" that connects your bottle to a huge ecosystem of caps, pumps, and sprayers.

Summary of 28/410

| Aspect | Key Takeaway |

|---|---|

| What is it? | A standard neck finish: 28mm diameter, 410 thread style (1.5 turns). |

| Why use it? | Compatibility. It gives you endless options for caps, pumps, and sprayers. |

| Key industries? | Personal Care (soap, lotion, shampoo) and Cleaning (sprayers). |

| Biggest mistake? | Confusing it with 28/400. They are not interchangeable and will leak. |

| How to succeed? | Match 28/410 on the bottle with 28/410 on the cap. Always test the fit. |

Frequently Asked Questions (FAQ)

Q: How do I measure a bottle neck to see if it is 28/410?

A: You need a caliper. First, measure the outer diameter of the threads. It should be very close to 28mm (e.g., 27.8mm). Second, look at the threads. You should see the thread go around the neck one full time, plus about another half turn. If you have both (28mm diameter and 1.5 turns), it is almost certainly a 28/410. The best way is to test it with a known 28/410 cap.

Q: What materials are 28/410 bottles usually made from?

A: The bottles themselves are most commonly PET (clear, rigid), HDPE (opaque, semi-rigid), or PP (semi-translucent, rigid). The choice depends on your product's chemical compatibility. The caps are almost always made from PP (Polypropylene).

Q: Are all lotion pumps and sprayers 28/410?

A: No. This is a common mistake. 28/410 is the most common size, but pumps and sprayers also come in 20/410, 24/410, 24/400, and many other sizes. You must always match the pump's spec to the bottle's spec.

Q: Should I use 28/410 for my carbonated drink?

A: Absolutely not. The 28/410 thread is not designed to hold pressure. It will fail. Carbonated beverages require specialized high-pressure necks, such as the PCO1881.

Q: Where can I buy 28/410 bottles and caps?

A: This is a very common standard, so almost all plastic packaging suppliers will offer them. You can find many options on sites like Alibaba or by searching for "packaging suppliers" in your region. If you need a custom-shaped bottle with a 28/410 neck, you need a mold manufacturer like us, iBottler, to create the blow bottle mold for you.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr