You dream of your own water brand. It feels pure and simple. But the first step is a hard question: how much money do I need?

The cost to start a water bottle brand varies wildly, from $30,000 for a micro-operation to over $200,000 or $500,000 for a competitive, automated small factory. The final price depends on your scale, market, and chosen production method (in-house vs. co-packing).

| Key Cost Factor | Low-End Estimate (Micro) | High-End Estimate (Small Auto) | Notes |

|---|---|---|---|

| Primary Choice | Co-Packing (Low initial) | In-House Production (High initial) | In-house gives control and long-term profit. |

| Foundation Costs | $2,000 - $10,000 | $10,000 - $50,000+ | Includes water sourcing, legal permits, basic branding. |

| Production Line | $30,000 - $80,000 | $200,000 - $500,000+ | This is the biggest variable. Includes water treatment, blowing, filling, packing. |

| Operational Costs | Variable | Variable | Raw materials (bottles, caps, labels), labor, utilities. |

| Sales & Marketing | $1,000 - $5,000 | $20,000+ | Warehousing, logistics, and actually selling the product. |

This article will break down all these costs. I will help you build a real budget. We will focus on the most important part: the production line. Let's get started.

From dream H₂O to reality: the must-take path to a budget?

Having your own water brand sounds like a pure, beautiful dream. But turning this dream into reality means facing a very real problem: how much money do I need?

The answer is not one simple number. It depends on your size, your market position, and your production model. This article breaks down the main costs, especially the core production parts. I will help you make a realistic budget.

In my 16 years, I have talked to hundreds of entrepreneurs. They all want to enter the bottled water industry. The biggest mistake I see is a huge underestimation of the startup costs. They especially underestimate the cost of production equipment. A clear and realistic budget is the first anchor stone for your business. It ensures your dream ship can sail. It stops it from getting stuck on the beach.

The appeal of the water market is strong. Water seems simple. In many places, water is almost free. People see a bottle on the shelf for $1. They think, "The water is free. The plastic is cheap. This is a high-profit business." This is the "dream" phase.

The "reality" phase is different. Bottled water is a heavy manufacturing business. It is a high-volume, low-margin game. You make money by making millions of bottles very efficiently. It is also a logistics business. Water is heavy and expensive to ship. And it is a branding business. You are competing with giant companies for a tiny bit of shelf space.

A bad budget means you fail before you start. You run out of cash. I remember a client around 2010. He had a great brand concept. He found a beautiful water source in the mountains. He spent $50,000 on amazing branding, website design, and fancy labels. He came to me for the production equipment. He only had $20,000 left in his budget. He thought he could buy a complete, automatic production line for that price.

I had to tell him the hard truth. A single good mold can cost $5,000. A basic semi-auto bottle blowing machine costs more than that. A full line was impossible. He was shocked. His project stalled for two years. He had to go back and find new investors. All his initial excitement was gone. A clear budget from day one would have saved him.

So, why is there no simple number? The final cost depends on your answers to three questions:

1. What is your scale?

Are you planning to sell water to your local village from a small shop? Or are you trying to get into supermarkets across an entire state? A production line that makes 1,000 bottles per hour (BPH) has a very different cost from a line that makes 10,000 BPH.

2. What is your market position?

Are you a discount brand, competing only on price? This means you must have the lowest production cost. You need extreme efficiency. Or, are you a premium mineral water in a custom glass bottle? A premium product needs more complex and expensive equipment. It might need special mineral dosing systems. It will need gentler, more expensive filling machines. It needs high-end packaging machines.

3. What is your production model?

This is the biggest factor. We will discuss it in detail later. But it is the simple choice: do you build your own factory? Or do you pay someone else (a co-packer) to make your product? This one choice can change your startup cost from $20,000 to $500,000.

People see a simple bottle. They do not see the complex factory behind it. They do not see the water treatment system. This is not just a filter from a hardware store. It is an industrial system of tanks, pumps, filters, and sterilizers. They do not see the high-pressure air compressor system, which can be the size of a small car. They do not see the bottle blowing machine, a piece of precision engineering that heats and stretches plastic perfectly in seconds. They do not see the filler, the labeler, the wrapper, and all the conveyors that connect them.

All these parts must work together. The integration is a hidden cost. I often ask new clients: "What is your total project budget?" Then I ask, "What percentage did you allocate for production machinery?" If they plan to build their own factory, and their answer is less than 40-50% of the total, I know they have a problem. They are still in the "dream" phase.

This article is your bridge from that dream to reality. It is a guide to thinking about your budget. It helps you make the right choices. A clear, realistic budget is your map. My goal is to help you draw that map correctly.

The foundation: water, legal, and brand "entry tickets"?

You focus on the factory. But you forget the "invisible" costs. These are the entry tickets. You cannot start without them. They are your foundation.

These are foundational costs. You must pay for water source access or testing. You need government permits and certifications. You also need to create your brand identity, like logos and labels. These costs can range from a few thousand to tens of thousands of dollars.

These are the "invisible" costs. But every single one is essential. I see people try to save money here. It is a huge mistake. In my 16 years, I have seen rules get stricter every year. Your compliance with these rules is your "protective charm." It is what lets your brand survive long-term. Do not try to save money here.

Let's break down these foundational "entry tickets."

1. Water Source and Testing

This is the heart of your product. Your brand is only as good as its water.

- Source Access: Where does the water come from?

- Municipal (City) Water: This is the easiest. You use city water and then filter it heavily, usually with Reverse Osmosis (RO). You still have to pay for the water.

- Drilling a Well: You might drill your own borehole to access an aquifer. This costs money. Drilling can be $5,000 to $25,000 or more, with no guarantee of quality or volume.

- Spring Rights: You might buy or lease land with a natural spring. This can be very expensive.

- Water Testing: This is non-negotiable. Before you buy any land or equipment, you must get a detailed laboratory water test. This test can cost $500 to $5,000. It will tell you the mineral content, the pH, and if there are any contaminants (bacteria, heavy metals, etc.).

- I had a client in Southeast Asia. He bought land with a "pure spring" on it. He skipped the detailed lab test to save $1,000. He just did a simple bacteria test, which passed. He then spent $50,000 on equipment. When he applied for his government license, they did their own detailed test. The water had high levels of naturally-occurring arsenic. It was unusable. His entire project died. That $1,000 he "saved" cost him his whole business.

- The water test also tells you what kind of water treatment system you must buy. Clean water needs simple filtration. Bad water needs a very expensive, complex system.

2. Legal, Regulations, and Permits

This is your "protective charm."

- Business Registration: This is the basic cost to start any company in your country.

- Factory Permits: You need a food production license. You may need building permits, zoning permits, and wastewater discharge permits. These all cost money in fees and take a lot of time.

- Water Rights: You need a legal permit to extract a certain amount of water (e.g., 10,000 liters per day) from your well or spring.

- Certifications: You will likely need certifications like HACCP or ISO 22000. These are international standards for food safety. Getting the certification involves audits and fees. You may have to change your factory layout to meet these standards. If you want to export to the USA, you need to meet FDA rules.

- My advice is simple: Pay the fees. Do the paperwork. Be 100% legal. A government shutdown for non-compliance costs 100 times more than the permit. A product recall can destroy your brand forever.

3. Brand Image Construction

This is your "face" to the world.

- Brand Identity: Your company name, logo, and colors. You can get a cheap logo online for $50. Or you can hire a professional branding agency for $50,000. Your brand must look professional.

- Bottle Design: This is critical.

- Stock Bottle: You can use a standard, "stock" bottle shape that many companies use. This is the cheapest option.

- Custom Bottle: You can design a unique bottle shape. This makes your brand stand out. But it means you must pay for a custom blow bottle mold. A high-quality custom mold is a significant investment ($3,000 - $15,000). A good PET bottle mold design guide can help you understand this process.

- Label Design: Your label must be attractive. It must also be legal. It must show all the required information: volume, source, ingredients (if any), nutritional facts, expiry date, etc.

- Packaging Design: This is the 12-pack or 24-pack shrink wrap or cardboard box. This also needs to be designed.

- Basic Website: A simple website that shows your product and tells your story.

This table summarizes these foundation costs.

| Foundation Cost | Low-Budget Action | High-Budget Action | Why it Matters |

|---|---|---|---|

| Water Source | Use municipal water | Buy/lease a private spring | Defines product quality and treatment costs. |

| Water Testing | Basic local lab test | Full-panel international lab test | Non-negotiable. Dictates equipment needs. |

| Permits | Local business/food license | Full ISO/HACCP certification | The "license to operate." Do not skip. |

| Branding | Stock bottle, freelance logo | Custom blow bottle mold, agency branding | Your identity. A custom mold is a real asset. |

These foundation costs are your "entry tickets." You cannot play the game without them. They happen before you make a single bottle. You must put them in your budget first. Only then can you look at the factory.

Core choice: in-house production vs. co-packing?

You face a big choice. Do you build your own factory? Or do you pay another factory to make your water? This choice changes your budget completely.

This is your first major strategic decision. Co-packing (using another factory) has a very low startup cost. But you have low-profit margins and no control. In-house production (building your own factory) has a huge initial cost but gives you high-profit margins and full control.

I am asked this question every week. "Should I co-pack or build my own factory?" My answer is always another question: "What is your long-term goal?" Your risk preference also matters. If you just want to test a brand idea quickly, co-packing can be a good choice. But if you are serious about building a real, lasting 'brand,' you must own your production. It is the only way to control your destiny.

Let's look at the two paths.

Path 1: Co-Packing (Contract Packing)

This is the "outsource" path.

- What it is: You find an existing, certified water bottling plant (a "co-packer"). You design your brand. You buy your printed labels and maybe your custom caps. You ship them to the co-packer. They use their factory, their water, their bottles, and their labor to fill your bottles. They charge you a final price per bottle.

- The Advantages (Pros):

- Very Low Startup Cost: This is the biggest advantage. You skip the entire $200,000 - $500,000+ cost of a factory and machines. You just need money for your brand design, your labels, and your first minimum order (e.g., one truckload of water). You could potentially start for $10,000 - $30,000.

- Speed to Market: You can have a product on the shelf in a few months, not one or two years.

- No Factory Headache: You do not have to manage workers. You do not have to learn how to maintain a bottle blowing machine. You do not have to worry about quality control audits.

- The Disadvantages (Cons):

- Low Profit Margin: This is the big problem. The co-packer takes a large profit. Your cost per bottle is high. It is very, very hard to compete on price. You can only compete as a premium, high-price brand.

- No Control: This is the business-killer. You do not control the quality. You do not control the production schedule. If your co-packer has a big client (like a supermarket chain), their orders come first. Your small order gets delayed for weeks.

- Brand Risk: What if the co-packer has a quality problem? What if their water gets contaminated? It is your brand name on the bottle. Your brand is destroyed, and it was not your fault.

- Scalability Issues: What if your brand is a big success? You get a huge order from a national retailer. Your co-packer might not have the extra capacity. Or, they might see your success and raise your price. You are trapped.

Path 2: In-House Production

This is the "build your own" path.

- What it is: You build your own factory. You lease or buy a building. You buy the water treatment, the blower, the filler, and the packing machines. You hire your own staff. You are in 100% control.

- The Advantages (Pros):

- High Profit Margin: This is the long-term prize. Once your factory is running, your cost per bottle is extremely low. It is just the cost of water, a few cents of plastic, a label, and electricity.

- Full Control: You control the quality of every bottle. You control the production schedule. You control your recipe (you can add minerals, change pH, etc.). You control your destiny.

- Asset Building: The factory and the machinery are real assets. They have value.

- Flexibility: Do you want to launch a new bottle size? You just buy a new blow bottle mold and run it. Do you want to try flavored water? You can add a small dosing system.

- The Disadvantages (Cons):

- Huge Startup Cost: This is the barrier. As we will see, you need hundreds of thousands of dollars.

- Complexity: You are not just a brand owner. You are now a factory manager. You must learn about machine maintenance. You must manage a supply chain for preforms, caps, and labels. You must handle labor laws and quality control.

- Time to Market: It can take one to two years to go from a business plan to your first bottle. You have to find a site, get permits, order machines (this can take 6 months), install them, and get certified.

I have a customer in Texas. He started with a co-packer. His brand was very successful and grew fast. The co-packer saw his success. In the second year, the co-packer raised his price by 30%. In the third year, the co-packer launched their own brand. It looked almost identical to my customer's brand. He was trapped. The co-packer was using his own money to build a competitor.

He came to me, and he was furious. He said, "I am building my own line. I will never let someone else control my destiny again." We helped him plan and build a full factory. It was a huge investment. But his cost-per-bottle dropped by 60%. He is now in 10 states. He started with co-packing, but he survived and grew by building his own line.

This table summarizes the choice:

| Feature | Co-Packing (Outsource) | In-House Production (DIY) |

|---|---|---|

| Initial Cost | Very Low ($10k - $30k) | Very High ($200k - $500k+) |

| Cost per Bottle | High | Very Low (after payback) |

| Control (Quality/Schedule) | Very Low | Total Control |

| Speed to Market | Fast (Months) | Slow (1-2 Years) |

| Complexity / Headache | Low | Very High |

| Long-Term Profit | Low | High |

The rest of this article will focus on the in-house production path. Why? Because that is where the real, complex costs are. That is where my 16 years of experience can help you. If you choose co-packing, your budget is simple. If you choose in-house, you need a detailed map. Let's make that map now.

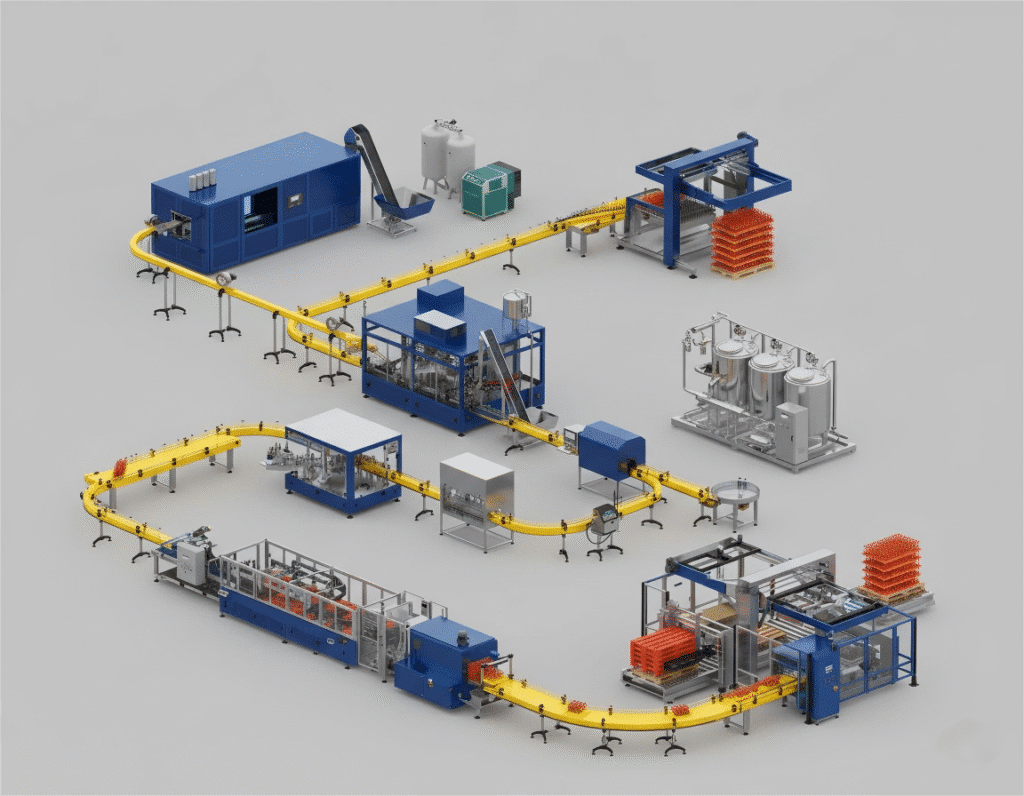

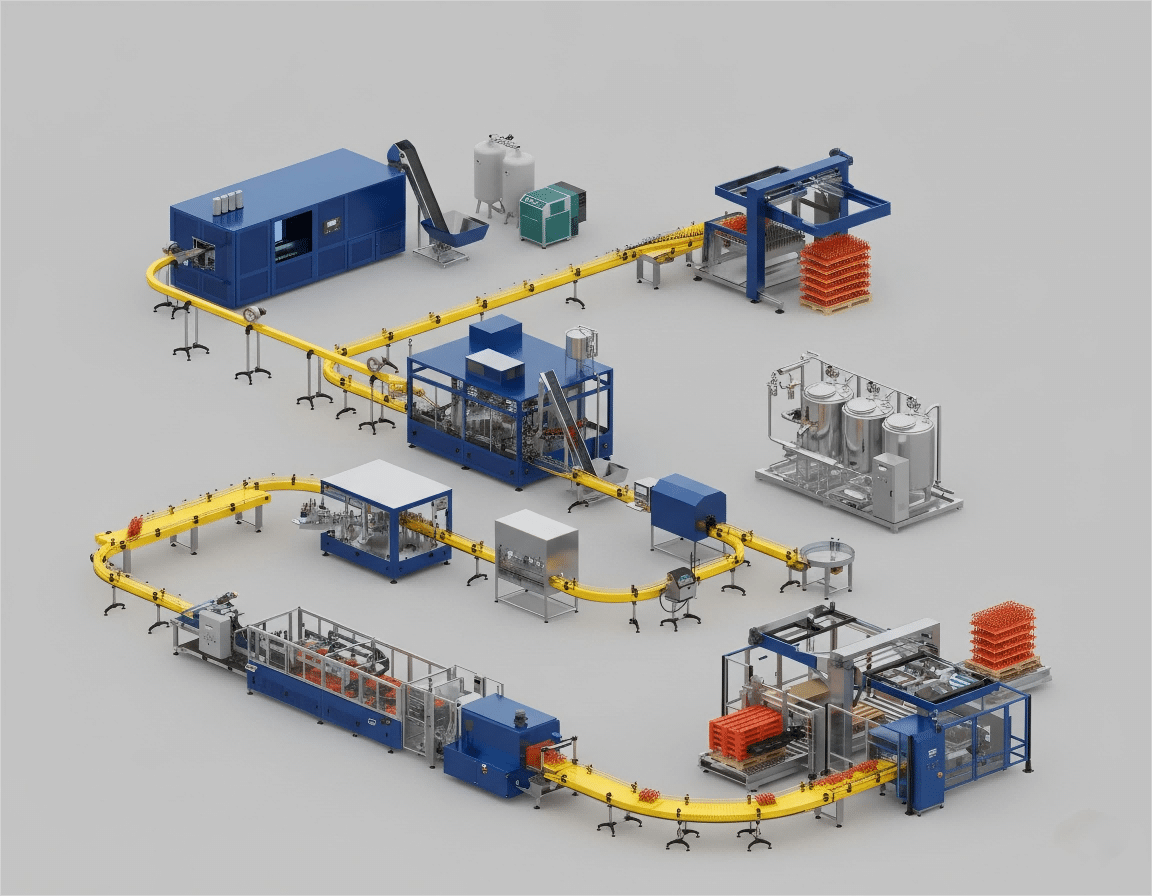

The core: decoding "bottled water production line" costs?

You decide to build. Now, the big question. What machines do I need? And how much do they really cost? This is the heart of your budget.

The production line is your biggest cost. It includes water treatment ($5k-$50k+), a blowing system ($10k-$50k+), a filling system ($30k-$100k+), and packing ($15k-$90k+). A tiny, basic line might start at $30k. A competitive, automated line starts at $200k.

The production line is the biggest capital expense in your project. Your choice here defines your future. It sets your efficiency, your quality, and your running costs for years to come.

I must be honest here. I helped an entrepreneur in Africa build a complete production "point." His total equipment budget was around $30,000 USD. We got him a basic water treatment system, a semi-automatic bottle blowing machine, a simple 4-head filler, and manual tools for packing. It worked. It got him started. It allowed him to survive in his local market.

But this is not the same as building a brand to compete in a developed market like America or Europe. The $30k setup is a "survival" line. The $200,0L+ setup is a "competitive" line. The goals are completely different.

Let's break down the production line, piece by piece, for a competitive small factory.

1. Water Treatment System

- Job: To take your source water (from the well or city) and make it 100% pure, safe, and stable.

- Components: This depends 100% on your source water test.

- Basic System: For clean spring water. This includes Quartz Sand Filters (for particles), Carbon Filters (for taste/smell), Micron Filters (for fine polish), and a sterilizer (either UV light or Ozone).

- Advanced System: For city water or high-mineral water. This includes all the basic steps plus a Reverse Osmosis (RO) system. RO uses high pressure to push water through a very fine membrane. It strips everything out, leaving pure H₂O. You can then add a "mineral dosing" system to add back a specific blend of minerals (like calcium, magnesium) for a consistent, premium taste.

- Cost: A basic system might be $5,000 - $20,000. An advanced RO system for a small factory will be $20,000 - $50,000+.

- My Advice: Do not save money here. Your water is your product. A failure here means a product recall that will kill your brand.

2. Bottle Blowing System

- Job: To turn small PET "preforms" (they look like plastic test tubes) into your full-size bottles.

- Components:

- Bottle Blower Machine: For a small, competitive factory, you need a full-automatic linear blower. A 2-cavity or 4-cavity machine is a common start. This machine automatically feeds, heats, and blows the preforms.

- Blow Molds: You need one set of molds for each bottle size and shape. A high-quality, durable blow bottle mold is critical for quality. You might also need preform molds if you plan to make your own preforms, but most startups buy preforms.

- Air System: This is a major hidden cost. To blow bottles, you need very clean, very high-pressure air (around 30-40 bar). This requires a special high-pressure air compressor, air dryers, filters, and a storage tank.

- Cost:

- Small Auto Blower (2-4 cavity): $20,000 - $50,000+

- Molds (per set): $3,000 - $10,000+

- Complete Air System: $10,000 - $30,000+

- Total Blowing Cost: $33,000 - $90,000+. This is a professional entry-level system. It's very different from the $7,000 semi-auto machine in the "survival" line. A semi-auto machine has high labor costs and inconsistent quality. You can see many common PET blow molding defects from bad machines or untrained operators.

3. Filling System (The "Monobloc")

- Job: To rinse the new bottles, fill them with water, and put the cap on.

- Components: In a modern factory, this is one single machine called a "3-in-1 Monobloc." It combines the Rinser, Filler, and Capper. This is vital for hygiene. The bottle is never open to the air.

- Cost:

- Simple Linear Filler (Survival Line): Fills 4 or 6 bottles at a time. Slow. High risk of contamination. Cost: $5,000 - $15,000.

- Automatic Linear Filler (Small Factory): A common starting point. Speed of 2,000 - 4,000 BPH. Cost: $30,000 - $80,000.

- Automatic Rotary Filler (Medium Factory): This is the real standard for efficiency. A large rotating machine. An 8,000 BPH rotary filler alone can cost $100,000 or more.

4. Downstream Packaging System

- Job: To label the bottle, print the date, and bundle them for shipping.

- Components:

- Labeling Machine: Puts the label on. A "sleeve labeler" ($15k-$40k) shrinks a plastic sleeve. An "OPP/roll-fed labeler" ($15k-$35k) is very fast and uses cheaper labels, common for water.

- Date Coder: An inkjet or laser printer to put the expiry date on the bottle. Cost: $1,000 - $10,000.

- Packing Machine: A "shrink wrapper" ($10k-$50k+) is most common. It bundles bottles into a 12-pack or 24-pack and wraps them in plastic film.

- Total Packaging Cost: $30,000 - $90,000+

5. Conveyors and Integration

- Job: To connect all these machines so they work as one line.

- Components: Air conveyors (to move light, empty bottles) and chain conveyors (to move heavy, full bottles).

- Cost: This is the most forgotten cost. A good conveyor system for a small factory can be $5,000 - $30,000+.

This table summarizes the equipment costs.

| Machine Component | "Survival" Line (Micro) | "Small Auto" Line (~3-4k BPH) | Notes |

|---|---|---|---|

| 1. Water Treatment | Basic Filters + UV | RO System or Advanced Filters | Cost depends 100% on water source. |

| $5,000 - $15,000 | $20,000 - $50,000+ | ||

| 2. Blowing System | Semi-Auto Blower | 2/4-Cavity Auto Blower | Includes air system. Auto is key for scale. |

| $10,000 - $20,000 | $35,000 - $90,000+ | ||

| 3. Filling System | Simple Linear Filler | Auto Linear/Rotary Monobloc | Hygiene and speed are critical here. |

| $5,000 - $15,000 | $30,000 - $80,000+ | ||

| 4. Packaging System | Manual Label + Hand Wrap | Auto Labeler + Shrink Wrapper | Labor vs. Automation. Auto wins on cost/bottle. |

| $1,000 (Hand tools) | $30,000 - $80,000+ | ||

| 5. Conveyors | (Minimal) | Full Integration | Connects everything. Don't forget it. |

| $1,000 - $3,000 | $5,000 - $30,000+ | ||

| TOTAL (Equipment) | ~$22,000 - $53,000 | ~$120,000 - $330,000+ | This is the reality. The $30k case and the $200k+ factory are two different worlds. |

As you see, the costs add up fast. The $200,000+ starting point for a competitive small line is very realistic. You must decide which business you are in. Are you in the "survival" business or the "competitive" brand business?

Budget tiers: equipment thresholds for different water plants?

So, how much for my plan? The cost depends on your size. A tiny village plant is not a regional brand. Let's look at the price levels.

We can group equipment budgets into tiers. A micro, manual plant needs $30k-$80k. A small, automated regional brand (3k-8k BPH) needs $200k-$500k+. A large, high-speed factory (10k+ BPH) needs $500k to many millions. Find your starting level.

This tier table gives you a real-world concept. It helps you find your bracket based on your market goal and your capital. My most important advice is this: even at Tier 1, choose reliable suppliers. This builds a foundation for your future upgrades. Buying the cheapest machine possible from an unknown source is a classic, and fatal, mistake.

Let's detail the three Tiers of equipment investment.

Tier 1: The Micro / "Survival" Plant

- Speed: Less than 1,000 BPH.

- Who is this for? A local entrepreneur in a small town or a developing market. Or, a "garage" startup testing a concept, willing to use high manual labor.

- Philosophy: "Just get it done." The goal is the lowest possible capital cost. This means you accept high variable costs (like labor).

- Equipment Mix:

- Water Treatment: Basic ($5,000 - $15,000).

- Blowing: 1-cavity or 2-cavity semi-automatic blower. A worker loads preforms by hand. ($7,000) + 1 mold ($1,500) + small air system ($3,500). Total: ~$12,000.

- Filling: Simple 4-head linear filler ($3,000). Manual capping ($500).

- Packaging: Manual labeling with a simple tabletop jig ($500). A hand-held heat gun for shrink film ($100). A manual date stamp ($50).

- Total Equipment Budget: $30,000 - $80,000 USD.

- My Story: This is my African client I mentioned. He started this way. He had 5 people standing at the line: two loading the blower, one at the filler, one capping, one packing. It worked. He made money. But two years later, he came back to me. He bought a full automatic (Tier 2) line. He told me, "I could not sleep. I always worried about hygiene with the manual filling. I worried about my workers. The semi-auto line got me started. The automatic line lets me build a real business." This is the right way to think.

Tier 2: The Small Regional Brand (The "Competitive" Start)

- Speed: 3,000 - 8,000 BPH.

- Who is this for? A serious entrepreneur. You are aiming for a whole city or a regional market. This is the true starting point for a competitive brand.

- Philosophy: "Efficiency and reliability." You must automate the core processes. This reduces labor. It ensures consistent quality.

- Equipment Mix:

- Water Treatment: Standard RO or advanced multi-stage filtration ($25,000+).

- Blowing: 4-cavity or 6-cavity full-automatic linear blower ($40,000 - $70,000). A full, professional air system with dryers and filters ($25,000). Several high-quality molds ($15,000). We help clients ensure their molds and machines match, which is a common failure point. Total: $80,000 - $110,000.

- Filling: A 3-in-1 Automatic Rotary Monobloc (Rinser-Filler-Capper). This is the key. A 6,000 BPH machine is a great start. Cost: $70,000 - $120,000.

- Packaging: Automatic OPP labeler ($25,000). Inkjet date coder ($4,000). Automatic shrink wrapper ($20,000).

- Conveyors: Full air and chain conveyor system ($15,000).

- Total Equipment Budget: $200,000 - $500,000+ USD.

- My Advice: This is the "sweet spot" for most new brands. At this level, you must focus on Total Cost of Ownership (TCO). Do not just buy the cheapest machine. Buy the one with good spare parts, good service, and high efficiency. A machine that stops 1 day a week is more expensive than a machine that costs 20% more but runs 24/7.

Tier 3: The Mid-to-Large Scale Factory

- Speed: 10,000 BPH or much, much more.

- Who is this for? Established companies, national brands, or startups with major investor funding.

- Philosophy: "Maximum speed, minimum cost-per-bottle." This is about high-speed, 24/7 operation and squeezing every tenth of a cent from the cost.

- Equipment Mix:

- Water Treatment: Advanced, high-capacity, redundant systems ($50,000 - $150,000+).

- Blowing/Filling: At this level, you buy a "Combi" block. The blower, filler, and capper are one giant, integrated machine. This is from a major European or Chinese supplier. Speed: 10,000 - 40,000+ BPH. Cost: $300,000 - $2,000,000+.

- Packaging: High-speed everything. Robotic palletizers, automatic case erectors. Cost: $100,000 - $500,000+.

- Total Equipment Budget: $500,000 - $5,000,000+ USD.

- My Advice: At this level, you are not just "buying machines." You are buying a complete, integrated "solution." The planning and engineering are just as complex as the machines. We often help clients at this stage with very specific, high-tech parts, like developing and validating custom bottle designs using 3D printed samples before they commit $100,000 to a high-speed rotary mold set.

You must be honest with yourself. Which tier are you really in? Do not budget for Tier 1 but dream of Tier 2 results. The $200,000 minimum for a competitive small brand (Tier 2) is the most important number in this article. It grounds your dream in reality.

Flowing costs: raw materials, packaging, and labor?

You bought the machines. But machines need food. These are the "flowing" costs. They happen every day. You must budget for them, or you will run out of cash.

These are your ongoing operational costs. You must buy PET preforms (bottle material), caps, and labels every day. You also pay for electricity, water, and your workers' salaries. These costs determine your final price per bottle and your profitability.

Equipment is a one-time cost (or a loan payment). But these items are "flowing" costs. I call them "bleeding" costs. They are a daily expense. When you plan your factory, you must think about these. A good equipment choice can reduce these flowing costs.

For example, a machine that is more energy-efficient saves you money on electricity every single day. A modern, high-precision blow bottle mold that can blow a lighter-weight bottle is a perfect example. If you can use a 12-gram preform instead of a 14-gram preform, you save 2 grams of plastic on every bottle. At 6,000 bottles per hour, that is a huge cost saving over a year.

Let's break down these flowing costs.

1. Raw Materials (The Bottle Itself)

- PET Preforms: This is your main material cost. It is the plastic. You buy them by weight. A 12-gram preform makes a 500ml bottle. The price of PET resin (the raw plastic) changes with the global price of oil. It is a commodity.

- Saving money: As I said, the best way to save is to use a lighter preform. But, your bottle design and mold must be very good. A bad design for a 12-gram preform will be too weak and collapse. This is why a good PET bottle mold design guide is so important.

- Neck Finish: The preform neck size also matters. A lighter-weight neck (like a 29/25mm) saves plastic compared to an old, heavy PCO 1881 (28mm) neck. But you must be sure you can find suppliers for the 29/25 caps. This preform neck size guide is a discussion I have with all my new clients.

- Caps: (HDPE plastic). You buy them by the thousand.

- Labels: (OPP film, PVC sleeves, or paper). The cost varies by material, size, and number of colors in your design.

2. Utilities (The Factory "Fuel")

- Electricity: This is a huge operational cost. The two biggest power users are:

- The ovens in the blow molder (to heat the preforms).

- The high-pressure air compressor.

- When you buy a machine, ask for its kW (kilowatt) rating. A cheap, inefficient machine can cost you more in electricity over 2 years than a more expensive, efficient machine.

- Water: You pay for the source water (if from the city). You also pay to treat your wastewater.

- Compressed Air: Leaks in your air pipes are like throwing money away. A well-designed air system is critical.

- Chilled Water: The blow molds must be kept cold. This requires an industrial water chiller. This chiller also runs on electricity.

3. Labor (The People)

- Tier 1 (Micro): High labor cost per bottle. You may need 5-10 people. Workers to load the blower, move bottles, fill, cap, label, and pack.

- Tier 2 (Small Auto): Low labor cost per bottle. You may only need 3-5 people per shift. A skilled line operator, a quality control inspector, a forklift driver, and a helper for the packaging end.

- My Advice: Do not just budget for salaries. You must include taxes, insurance, training, and uniforms. A skilled machine operator is very valuable. You must pay to keep them. An untrained operator can crash a $50,000 mold or stop production for a whole day.

4. Working Capital

This is the most overlooked cost. It kills new businesses.

- You must buy your first 1-2 months' worth of preforms, caps, and labels before you sell your first bottle. This is cash you must have. If your monthly material cost is $50,000, you need $50,000 - $100,000 in cash just for this inventory.

- The Cash Gap: You sell your water to a supermarket. They will not pay you for 30, 60, or even 90 days. But you must pay your plastic supplier in 15 or 30 days. You must pay your workers every week. This "gap" between paying your bills and getting paid by customers is the "cash gap." You must have enough extra money in the bank to survive this gap.

This table shows an example of how automation (Tier 2) saves on flowing costs.

(These are example numbers, not real prices)

| Cost Item | Tier 1 (Micro / Manual) | Tier 2 (Small Auto) | Notes |

|---|---|---|---|

| Preform (14g) | $0.030 | $0.030 | Same material cost. |

| Cap | $0.005 | $0.005 | Same material cost. |

| Label | $0.010 (sticker) | $0.008 (OPP roll) | Auto line can use cheaper (OPP) labels. |

| Electricity | $0.010 (inefficient) | $0.006 (efficient) | Efficient, fast machines use less power per bottle. |

| Labor | $0.025 (5 workers, 800 BPH) | $0.005 (3 workers, 6000 BPH) | This is the biggest difference. |

| Est. Flowing Cost / Bottle | $0.080 | $0.054 | The automated line is 32% cheaper per bottle. |

The math is clear. Automation (Tier 2) costs more today. But it saves you money on every single bottle you make, forever. My insight is true: when you buy your equipment, you are also buying your future 'flowing costs.' Choose wisely.

Getting the water out: warehouse, logistics, and marketing?

You made a perfect bottle. The factory is running. But the bottle is still in your factory. Now you must sell it. This costs real money.

Your product is not finished until a customer buys it. You must budget for warehousing (storing bottles), logistics (trucks to deliver them), and marketing (convincing people to buy). These "go-to-market" costs are a major, ongoing expense.

I have seen beautiful, high-tech factories fail. Why? They spent 100% of their budget on the machines. They had zero dollars left for marketing and sales. A good product needs a good channel. Production and sales are the two wheels of your car. You need both to move.

Let's break down these "post-production" costs.

1. Warehousing (Storage)

Water is bulky. It is mostly air and water. It takes up a lot of space for its value.

- You need a warehouse for two things:

- Raw Materials: You need space to store pallets of preforms, stacks of caps, and rolls of labels.

- Finished Goods: Your factory is running. A 6,000 BPH line (Tier 2) produces 48,000 bottles in one 8-hour shift. That is 2,000 cases (of 24 bottles). That is about 40 pallets of water. Every single day.

- You need a lot of space. You need forklifts to move the pallets. You need pallet racking to store them vertically.

- Cost: This is the cost of renting a large warehouse. Or, it is the extra cost of building a much larger factory building.

- My Advice: I always tell clients: calculate the total floor space for your production line. Then double that number, at a minimum. You need that extra space for materials coming in and finished products going out.

2. Logistics (Movement)

Water is heavy. This makes it expensive to ship.

- This is the number one rule of the water business: water is a local game.

- It is almost impossible to make money by shipping water 1,000 miles away. The cost of the truck and fuel will be more than the value of the water inside it. You cannot compete with a local factory in that distant city.

- This means your factory location is critical. It must be close to your main market (a big city). It must have good access to major highways. A cheap factory in a remote location will be killed by high logistics costs.

- Your Costs:

- Own Trucks: Buying or leasing delivery trucks. Paying for drivers, fuel, and maintenance.

- 3PL (Third-Party Logistics): Paying an outside company to store and deliver your water. They charge you per pallet.

3. Marketing and Sales (Demand)

You have a warehouse full of 40 pallets of water. Now what? How do you make people buy it?

- This is not the "build it and they will come" business. The water aisle is the most competitive aisle in the supermarket. You are competing directly with Coca-Cola (Dasani), PepsiCo (Aquafina), and Nestlé (Poland Spring, etc.). They have billions of dollars.

- Your startup budget must have a large amount of money for sales and marketing.

- Your Costs:

- Sales Team: You need to pay people (a salary + commission) to physically go to stores, distributors, and restaurants and beg them to take your product.

- Slotting Fees: This is a hard secret of the grocery business. Many big supermarkets will charge you money just to put your product on their shelf. This "slotting fee" can be thousands or tens of thousands of dollars.

- Promotions: You will have to give away free products. You will have to pay for "Buy one, get one free" sales. You will have to pay for special displays at the end of the aisle.

- Advertising: Local radio ads, social media marketing, sponsoring a local 5k run, etc.

I had a client in Florida. He budgeted $300,000 for his Tier 2 production line. I asked him, "What is your sales and marketing budget for your first year?" He said, "$10,000." I told him to stop the project. I told him he was building a beautiful factory with zero customers. He was angry with me. But he paused the project. He went back to his investors and raised another $150,000 just for sales, marketing, and slotting fees. A year later, he called me. He said it was the hardest advice to take, but it was the best advice he got. His factory is running, and his water is now in 200 convenience stores. He burned through that $150,000 in 8 months to get there.

This table shows the two sides of your business:

| "The Factory" (Production) | "The Market" (Sales) |

|---|---|

| Goal: Make a high-quality bottle for the lowest cost. | Goal: Get a customer to pay the highest price for that bottle. |

| Costs: Machines, Raw Materials, Labor, Electricity | Costs: Warehouse, Trucks, Sales Team, Slotting Fees, Ads |

| Insight: Focus on efficiency and Total Cost of Ownership. | Insight: Focus on distribution, brand, and channels. |

| My Take: "A perfect factory with no sales is a museum. A great brand with no factory (co-packing) has no profit and no control. You must plan and budget for both." |

In your total startup budget, do not let the 'machine' cost blind you. You must hold back a large amount of cash. You need it for warehousing, for trucks, and for the hard, expensive work of selling. Production gets you to the starting line. Sales lets you run the race.

Conclusion: starting a water brand = a major investment, plan first?

So, what is the final number? It is not small. Starting a water brand is a major, serious investment. The dream is free, but the factory is not.

The total cost to start a water brand is significant. It ranges from $30k-$80k for a micro-survival setup to $200k-$500k+ for a competitive, automated factory. The key is planning. Find your real budget and your target market first.

So, how much does it cost? After 16 years, I can tell you the total investment can be $50,000 for a tiny manual setup in a village. It can be $500,000 for a small, automated, competitive factory for a big city. It can be $5,000,000 for a high-speed national plant.

The key is to find the right "input-output ratio" for your specific goal and your stage. You must have a plan.

We started with a dream of a pure brand. We faced the reality of the budget.

We listed the "invisible" foundation costs: water, legal, and brand design.

We made the first big choice: low-cost co-packing (no control) vs. high-cost in-house (full control).

We dived deep into the core cost: the production line. We saw the $30,000 "survival" line is a world away from the $200,000+ "competitive" line.

We defined the three Tiers of investment, from Micro to Large-Scale.

We understood the "flowing" costs (plastic, labor, power) and how automation saves you money on every bottle.

Finally, we learned that making the bottle is only half the job. Selling it (logistics and marketing) is the other, expensive half.

So, if you ask me, "How much to start?" I have to ask you questions back:

- "What is your market?"

- "What is your production goal in bottles per hour?"

- "Are you competing with big brands, or just selling locally?"

But I will give you a hard number. If you want to start a serious, competitive, automated brand (Tier 2), you should not even start the conversation without a total project budget of $300,000 to $500,000 USD.

Where does that money go?

- $200,000 - $350,000 for the Tier 2 equipment line.

- $20,000 - $50,000 for foundation costs (legal, permits, brand, water tests).

- $30,000 - $50,000 for factory setup (rent deposit, basic construction, office).

- $50,000 - $100,000+ for Working Capital (your first 2 months of preforms, caps, labels) and Marketing (to get your first sales).

This is a real number. It is a major investment. This is not a 'get rich quick' business. It is a serious manufacturing business.

My final advice is this: Plan first. A good plan is more valuable than a cheap machine. A good plan saves you from buying the wrong machine. It saves you from running out of cash in six months.

Over my 16 years, my company (iBottler) has changed. We don't just sell machines. We sell planning. We sell successful factory layouts. We help you match your budget to your goal. We help you pick the right, efficient air system so you don't waste electricity. We help you design a lightweight bottle that saves you plastic. We help you choose a machine that you can upgrade later, not just throw away.

If you are serious, and you have a realistic budget, you need a detailed plan. If you want a 'production line and budget plan' for your specific scale, contact an expert. Contact us. We provide the equipment. But more importantly, we provide the 16 years of experience to help you succeed.

Conclusion

Starting a water brand is a major financial step. A micro-plant may start at $30k, but a competitive brand needs $200k-$500k+. Success depends on realistic, detailed planning first.

Summary of Startup Costs

| Cost Category | Key Components | Budget Range (Example) | My Final Advice |

|---|---|---|---|

| 1. Foundation | Water Source, Legal Permits, Brand Design | $5,000 - $50,000+ | Do not save money here. Compliance is your "protective charm." |

| 2. Production Model | Co-Packing vs. In-House | $10k (Co-Pack) vs. $200k+ (In-House) | In-house is the only way to build a real, long-term brand. |

| 3. Core Equipment | Water Treatment, Blowing, Filling, Packing | $30k (Micro) - $500k+ (Small Auto) | This is your biggest cost. A $200k+ line is the real starting point. |

| 4. Flowing Costs | Preforms, Caps, Labels, Labor, Electricity | Varies (e.g., $0.05 - $0.08 / bottle) | Smart equipment choices (automation) will lower this cost. |

| 5. Go-to-Market | Warehouse, Logistics, Marketing, Sales Team | $50,000 - $150,000+ (Year 1) | Production and Sales are the two wheels of your car. Budget for both. |

| TOTAL (Serious Brand) | All of the above | $300,000 - $500,000+ | Plan first. A good plan is your most valuable asset. |

Frequently Asked Questions (FAQs)

Q: For a new brand, is in-house or co-packing less risky?

A: In the short term, co-packing has less financial risk because the startup cost is low. But in the long term, in-house production is less risky for your brand. You control your quality, your production schedule, and your profit margins. You build a real asset and are safe from your co-packer becoming a competitor.

Q: What is the absolute minimum cost to start a basic water production point?

A: As our budget tiers show, a "micro" or "survival" plant (Tier 1) could start with an equipment budget of $30,000 to $80,000 USD. This includes basic water treatment, semi-automatic blowing, and manual packing. But this is a high-labor, low-efficiency model. A competitive small automated factory (Tier 2) starts at $200,000+ for the equipment alone.

Q: In the equipment, which part is the most expensive: blowing, filling, or water treatment?

A: In a typical automated line (Tier 2), the high-speed bottle blowing system (including the high-pressure air compressors) and the high-speed 3-in-1 filling monobloc are usually the two biggest costs. The cost of water treatment varies the most; it can be cheap ($5,000) for very clean source water or very expensive ($50,000+) for water that needs Reverse Osmosis (RO).

Q: Is it hard or expensive to get water permits and certifications?

A: This depends 100% on your country and local region. Yes, it can be difficult and can take a lot of time. It requires passing strict water quality tests and following food-grade hygiene rules. I strongly advise you to hire a local consultant before you buy any land or machines. You must add these legal and consulting fees to your initial budget.

Q: What is the profit margin for bottled water? How long to get my investment back?

A: The profit margin varies wildly. It depends on your brand (premium vs. discount), your "flowing costs" (an automated line is cheaper per bottle), and your scale. The investment payback period can be from 2 years to 7 years. A solid business plan, based on a reliable and efficient production line, is the only way to predict your return on investment (ROI).

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr