Your beverage startup needs bottles. But big machines seem complex and expensive. You worry about making the wrong choice and wasting capital.

Two-step blow molding is the answer. You buy ready-made "preforms" (like test tubes) and your machine just blows them into bottles. It's flexible, cost-effective, and perfect for startups. This guide explains how it works, step by step.

This process might sound simple, but understanding the details is key to saving money and avoiding common mistakes. I've seen many startups succeed, and many fail, based on these first decisions. As someone who has been a factory founder in this industry for 20 years, I want to walk you through this process. Let's break down exactly what this means for your factory.

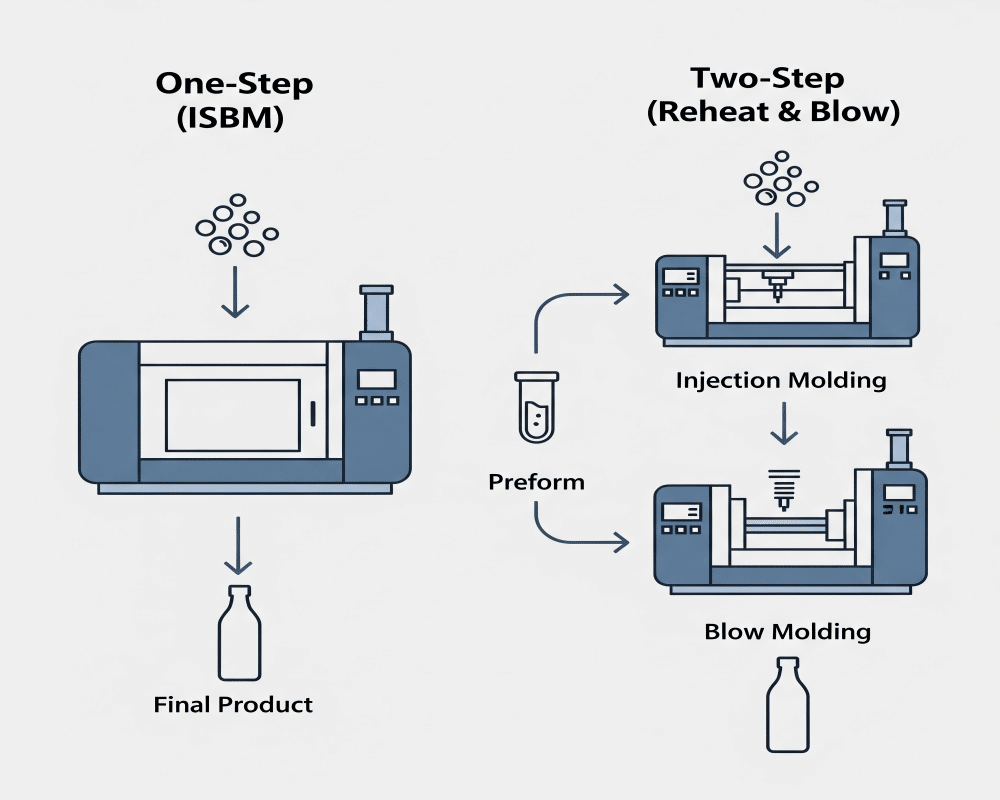

What is "Two-Step" Blow Molding? (A Simple Definition)?

You hear "blow molding" and picture a complex factory. You are not an engineer. You just want to know the simplest way to make bottles.

"Two-step" means the process is split. Step 1: A factory makes a "preform" (a small, test-tube-like part). Step 2: Your machine heats and blows that preform into your final bottle. They are two separate, independent steps.

As someone in this industry for 20 years, I like to call this "modular" production. This is the most important concept you need to understand.

- Step 1 is "standardized." A big factory makes millions of "preforms." These look like small, thick-walled test tubes. The "neck" part of the bottle (with the threads for the cap) is already perfectly formed.

- Step 2 is "personalized." This is what you do. You buy these standard preforms, and your bottle blowing machine heats them and blows them into your unique bottle shape.

This separation is the foundation for a low-cost start and flexible production. Your job is to create the "personality" (the bottle shape). The preform is the "standard part" (the raw material).

Let's dig deeper into why this separation is such a big deal. The material we are talking about is PET (Polyethylene Terephthalate). It's the clear, lightweight, and strong plastic used for water, juice, and soda bottles.

The "two-step" logic was born from one simple idea: logistics.

Think about it. A finished 500ml water bottle is 99% air. It is bulky and takes up a lot of space. I can fit maybe 50,000 empty bottles in a large shipping container.

Now, think about the preform for that same bottle. It's small, solid, and stackable. I can fit over 1,000,000 (one million!) preforms in the exact same shipping container.

It is 20 times cheaper to ship preforms than to ship empty bottles.

This is why the entire beverage industry runs on this model. Big companies like Coca-Cola do not ship empty bottles around the world. They ship tiny preforms to local bottling plants. Those plants blow the bottle (Step 2) right on the filling line.

As a startup, you are using the same powerful logic. You are buying the cheap-to-ship, standard preforms from a supplier. Then, in your own factory, you are "manufacturing" the bulky, final bottle at the last possible moment. This saves you a huge amount of money in shipping and warehousing.

This modular concept changes your entire business plan:

- Your factory can be smaller. You do not need the giant, complex, and expensive "injection molding" machines that make preforms. You only need the "blowing" machine, an air compressor, and a chiller.

- Your startup cost is much lower. You are focusing your capital on Step 2 only.

- Your time-to-market is faster. You can order standard preforms from a supplier today. They can arrive in a few weeks. You don't have to wait 6 months for a complex preform mold to be built.

Let's define the two parts again, very clearly, so you know what you are buying.

Part 1: The PET Preform (Your "Raw Material")

- This is what you buy.

- It looks like a test tube.

- Its neck and threads are already finished. This part is critical. It must match the cap you plan to use. This is why a guide on choosing the right preform neck size is so important.

- It has a specific weight, measured in grams. A 12-gram preform can make a lightweight 500ml water bottle. A 25-gram preform makes a heavier, stronger 500ml juice bottle. The weight of the preform is the weight of your final bottle. This is your main cost.

- It can be clear, or it can be colored (blue, green, amber).

Part 2: The Blowing Process (Your "Manufacturing")

- This is what your bottle blowing machine does.

- Your machine takes the preform.

- It heats the body of the preform until it is soft (like cooked pasta).

- It places the hot preform into a blow mold (which is shaped like your bottle).

- It stretches and inflates the preform with high-pressure air.

- The soft plastic slams against the cold mold walls and freezes instantly into your bottle shape.

This shift in mindset is key. You are not running a complex plastics factory. You are running an efficient blowing line. You are an "inflater," not a "creator." This makes the entire project much less scary and much more achievable.

Step 1: Injection Molding (Creating the "Preform")?

You know you need "preforms," but where do they come from? You worry about quality control. What if the preforms you buy are bad?

Preforms are made in a separate factory using an "injection molding machine." This machine melts PET plastic pellets and injects them into a "preform mold." This mold shapes the preform, including the critical neck threads.

As a startup founder, here is my most important piece of advice from 20 years of experience: I do not recommend you do this step.

You will be a buyer of preforms, not a maker of preforms. This is a very good thing.

Why do I say this?

- Massive Cost: A good injection molding machine is very expensive. But the real cost is the PET preform mold. These are incredibly complex tools. They are made of hardened steel and must be perfect. A single mold with 48 cavities (making 48 preforms at once) can cost $100,000, $200,000, or even more. Your startup capital should not go here.

- High Skill Required: This is a separate field of engineering. You need to be an expert in polymer science. You have to manage massive PET resin dryers (if PET is wet, it's useless). You have to manage hot runner systems and complex cooling. It's a full-time, high-skill business all on its own.

- Massive Volume: These systems are designed to run 24 hours a day, 7 days a week, pumping out millions and millions of the exact same preform. As a startup, you probably don't need 50 million preforms of one type in your first year. You need flexibility.

So, you will buy your preforms from a supplier. This is great. It lets you focus your money and energy on your blowing line.

But... you must be an educated buyer. As I said in my insight, your success in Step 2 depends 100% on the quality of the preform you buy in Step 1.

Here is what you must know when you talk to a preform supplier. This is your checklist.

- Neck Finish: This is #1. It is the thread for your cap. It is not-negotiable. You must first decide on your cap. Is it a 28mm PCO 1881? Is it a 30/25? You must order the preform with that exact neck. I have written a detailed guide on choosing preform neck sizes because one small mistake here means your bottles will leak.

- Weight (Grammage): This is #2. This is your main cost and quality lever. The supplier will ask, "What gram-weight do you want?" You must have an answer.

- Example: For a 500ml round water bottle:

- 12g preform = very lightweight, "crinkly" bottle. Very cheap.

- 14g preform = standard, firm bottle. Good quality.

- 18g preform = very strong, premium-feeling bottle.

- A good machine supplier can help you with this. They can analyze your bottle design and recommend a weight.

- Example: For a 500ml round water bottle:

- Quality: When you get samples, look at them closely.

- Clarity: Are they crystal clear? Or are they hazy?

- Defects: Look for black specks (burned plastic), bubbles, or "sink marks."

- Gate: Look at the bottom "dot" where the plastic was injected. It should be clean. If it's white or hazy (crystallized), that preform will not blow. It will break.

I tell my clients, "Do not just buy the cheapest preform." A 0.1-cent saving on a bad preform is not worth a 10% failure rate on your blowing line. That is a quick way to go bankrupt. Find a good, reliable preform supplier and build a relationship. They are your first partner.

Just so you understand the process, here is how a preform is made (in your supplier's factory):

- Drying: PET pellets (which look like rice) absorb water from the air. They must be dried in a special, hot-air dryer for 4-6 hours. If you mold wet PET, it becomes brittle and shatters.

- Melting: The dry pellets are fed into the injection machine. A heated "screw" melts them into a liquid, like honey.

- Injecting: The machine "shoots" (injects) this molten plastic at very high pressure into the preform mold.

- Cooling: The mold is filled with cold water channels (from a chiller). The plastic "freezes" into the solid preform shape in about 5-10 seconds.

- Ejecting: The mold opens, and the finished preforms are pushed out by a robot.

This cycle repeats every 15-20 seconds. A 48-cavity mold makes 48 preforms every 15 seconds. That is the kind of scale you are (smartly) avoiding by starting with Step 2.

Your job is simple: Be a good shopper. Find a supplier who obsesses over this process so you don't have to.

Step 2: Re-heating, Stretching, and Blowing (The Blowing Process)?

This is the core. You need to turn a small preform into a big bottle. You worry it is complex. What if the bottles break or look bad?

This is what your machine does. It has two parts. 1) A "heater" or "oven" warms the preform body. 2) A "blowing station" stretches it with a rod and inflates it with high-pressure air inside a mold.

This is where you, as the factory owner, must focus your attention. You are buying a bottle blowing machine, and its stability is the only thing that matters.

As my insight says: "The machine's stability is shown in 'heating' and 'blowing'."

Let's walk through the life of a preform in your factory.

Step 2A: The Infeed (Loading)

You will dump a large box of preforms into a "hopper." This is just a big funnel. A machine called a "preform unscrambler" or "loader" will automatically pick up the preforms one by one. It will orient them so they are all standing up, neck-up, in a perfect line. This is the start of your automation.

Step 2B: The Re-heating (The Most Critical Part)

This is the heart of the machine. The preforms march in a line through a "heating oven." This oven is not like your oven at home. It is filled with special, high-intensity infrared (IR) lamps.

This is where the magic (or the disaster) happens.

- The Goal: Heat the body of the preform until it is soft and flexible, around 90-110°C.

- The Trick: You must not heat the neck. The neck (with the threads) must stay cool, hard, and rigid. A good machine has "neck shields" that protect it.

- My Insight: "Many cheap machines fail right here. Their heating ovens are poorly designed."

- What happens with bad heating?

- The oven heats the preform unevenly. One side is 110°C, but the other side is only 90°C.

- The preform then goes to the blower.

- The "hot" side stretches too much and becomes paper-thin.

- The "cold" side stretches too little and stays thick.

- Your Result: A lopsided bottle. It's thick on one side and dangerously thin on the other. If you fill this with a carbonated (fizzy) drink, the thin wall will explode. Even with water, it will fail a drop test.

- This is what I mean by yield rate. A bad machine gives you a 80% yield rate. That means 2 out of every 10 bottles you make go straight into the garbage. You are throwing away 20% of your money.

- A good bottle blowing machine has a well-designed oven. It has multiple "zones" of lamps. It rotates the preforms as they pass through. This gives you perfect, even heat. Your yield rate will be 99.5%+.

Step 2C: The Transfer

The hot, soft preform is quickly and gently moved from the heater to the blowing station. This must be fast. If it cools down, it will not blow correctly.

Step 2D: The Stretch-Blow (The Action)

This all happens in about one second, inside your blow mold.

- Mold Close: The mold (shaped like your bottle) closes around the hot preform.

- Stretch: A long, thin "stretch rod" shoots down from the top. It pushes the soft preform, stretching it vertically (like pulling a Toffee) all the way to the bottom of the mold. This stretching is what gives the PET its strength and clarity.

- Pre-Blow: A small puff of low-pressure air (around 10 bar) is released. This starts to inflate the bottle, pushing it out towards the mold walls.

- High-Pressure Blow: A fraction of a second later, a blast of high-pressure air (30-40 bar) is shot in. This slams the plastic against the cold, hard walls of the mold.

- Cooling: The mold itself is cold. It has chiller water running through it. The moment the hot plastic hits the cold mold, it "freezes" instantly, locking in its final shape.

- Exhaust & Eject: The high-pressure air is released (a "psssht" sound). The mold opens. Your finished bottle is ejected onto a conveyor belt.

This cycle repeats. If you have a 2-cavity machine, it does this for two bottles at once. A 2-cavity machine making 2,000 bottles per hour (BPH) means this whole cycle takes about 3.6 seconds.

To do this, your blowing machine needs two critical partners:

- A High-Pressure Air Compressor: This is not a normal compressor. It must supply a large volume of very clean air at 40 bar (about 580 PSI).

- A Chiller: This machine supplies cold water to your blow mold. If your mold is not cold, your bottles will come out soft, hazy, and deformed.

Your investment is for the yield rate. My advice is to pay for a machine with a good, stable heating oven. It is the heart of the entire process. If you have problems, it often shows up as common bottle defects, and the solution is almost always in the heating.

Key Advantages: Why Water & Beverage Plants Prefer the Two-Step Process?

You want a proven system. You cannot afford to risk your startup on a new, unproven technology. You need what the big players use.

Two-step is the industry standard. It offers huge flexibility (one machine, many bottle shapes), high speed for mass production, and massive shipping savings by transporting small preforms, not bulky bottles.

Let's list the reasons why this is the only system I recommend for a beverage startup.

1. Flexibility (This is the #1 reason for you)

This is the most powerful benefit. Because the preform (Step 1) and the blowing (Step 2) are separate, you have incredible flexibility.

You can have one bottle blowing machine and make many different bottles.

Let me give you a real-life example from my insight.

- Case Study: My Client in Kenya

- He started his business with one of my 2-cavity automatic blowing machines.

- Month 1: He wants to sell 500ml water.

- He buys: 20g preforms (with a 28mm neck).

- He buys: One 2-cavity blow mold for his 500ml bottle design.

- He runs his machine and makes 500ml water bottles.

- Month 6: His business is good. He wants to add a new product: 350ml juice.

- Juice needs a stronger, heavier bottle to handle hot-filling or just to feel premium.

- What does he do? He does not buy a new machine.

- He calls me and buys: One 2-cavity blow mold for his new 350ml juice bottle design.

- He calls his preform supplier and buys: 25g preforms (with the same 28mm neck).

- His Process: He stops the machine. His operator spends 30 minutes swapping the 500ml mold for the 350ml mold. He loads the new 25g preforms. He adjusts the heating settings (more heat for the heavier preform). He presses "Start."

- His exact same machine is now producing 350ml juice bottles.

This is low-cost expansion. His cost to launch a new product line was just the price of a new blow mold, not the price of a whole new factory line. This is the power of the two-step process.

2. Efficiency & Speed (Scalability)

Modern automatic two-step machines are fast.

- A startup 2-cavity machine makes 2,000 - 3,000 bottles per hour (BPH).

- A 4-cavity machine makes 4,000 - 6,000 BPH.

- Large rotary machines (for big companies) can make 80,000 BPH.

This gives you a clear growth path. You can start with a 2-cavity. When you get a big contract, you can add a 4-cavity. The process is identical. The skill is transferable.

Also, the processes are "decoupled." The preform factory can run 24/7 making preforms, building up inventory. Your blowing line can run 8 hours a day, pulling from that inventory. This makes production scheduling much, much easier.

3. Logistics & Cost (The Preform Advantage)

I said this before, but it is worth repeating because it is a huge part of your business model.

- Storage Cost: You can store 1,000,000 preforms in the space it takes to store 50,000 bottles. You save a fortune on warehouse space.

- Shipping Cost: You can import preforms from the best supplier in the world, and the shipping cost per bottle will be tiny. If you tried to import empty bottles, the shipping cost would be more than the bottle itself.

This "preform advantage" is a permanent cost saving baked into your business.

4. Quality & Aesthetics

The stretch-blow process (biaxial orientation) does something special to the PET. It aligns the polymer chains in two directions. This is what makes the bottle both very strong and crystal clear. This process is perfect for showing off your pure water or colorful juice. The bottles come out with a beautiful, high-gloss finish that customers love.

| Advantage | Why It Matters for a Startup | My 20-Year Experience |

|---|---|---|

| Flexibility | Launch new bottle sizes/shapes cheaply. Just buy a new blow mold. | This is the #1 reason I recommend it. My Kenyan client is a perfect example of low-cost expansion. |

| Low Startup Cost | You only buy the "Step 2" machine. You don't buy the expensive "Step 1" machine. | Focuses your limited capital on the part you control (the bottle shape). |

| Logistics | Buying/shipping preforms is 20x cheaper than buying/shipping empty bottles. | This saving drops right to your bottom line. It's a massive, permanent cost advantage. |

| High Speed | You can scale from 2,000 BPH to 10,000 BPH as your sales grow. | Start with a machine that fits your current need, knowing you can easily add capacity later. |

| Quality | Produces strong, clear, glossy bottles perfect for beverages. | The "stretch-blow" process is what gives PET its strength. It's ideal for holding pressure. |

When you add all this up, the choice is clear for 99% of beverage startups. You are not reinventing the wheel. You are using a globally proven, optimized, and flexible system.

Two-Step vs. One-Step: Which is Right for a Startup?

You see "one-step" machines advertised. It sounds simpler. "One machine does it all." You are confused. Maybe "one-step" is better?

One-step machines do injection and blowing in one box. They are for low-volume, high-value, or special bottles (like cosmetics). For a beverage startup, two-step is better. It is faster, cheaper, and more flexible.

This is a very common question, and it's a good one. "One-step" sounds more efficient. Let's look at it.

A "one-step" (or "injection-stretch blow molding") machine is one single, large piece of equipment.

- You put plastic pellets in one end.

- A finished bottle comes out the other end.

- Inside the machine: It has an injection station (to make the preform) and a blowing station (to blow the bottle). It makes the preform, then immediately (while still hot) moves it to the blowing station.

So, when is "One-Step" a good idea?

- High-End Cosmetics: For a $50 face cream jar. You cannot have any scratches. In two-step, preforms are shipped in a bag and can get tiny scuffs. One-step has no handling, so the quality is perfect.

- Special Materials: For materials like PC (Polycarbonate) or Tritan, which are hard to re-heat.

- Non-Standard Shapes: When you need a special neck, a wide mouth, or a shape that is very difficult to blow from a standard preform.

- Low-Volume, High-Value: When you only need 1,000,000 bottles per year, not per month.

Why is "One-Step" a bad idea for your beverage startup?

Here is my direct insight: If you are making water or juice, do not even think about one-step. I give this advice to all my startup clients. One-step machines solve "special process" problems. You have a "scale and cost" problem. Two-step is designed to solve for scale and cost.

Here are the three big reasons why two-step wins for you:

Speed (Cycle Time): This is the biggest killer.

- Think about it. In a one-step machine, the injection part (Step 1) takes maybe 15 seconds. The blowing part (Step 2) takes 3 seconds.

- The whole machine is a chain. The chain is only as fast as its slowest link.

- The blowing station must sit idle for 12 seconds, waiting for the injection station to finish. It's a massive bottleneck.

- In two-step, my two machines are separate. My injection machine (in another factory) runs its 15-second cycle. My blowing machine runs its 3-second cycle. They both run at their maximum possible speed. The total output is much, much higher.

Flexibility: This is the second killer.

- In a one-step machine, you are locked in. The machine is the preform maker.

- What if you want to change your 500ml bottle from 15g to 18g?

- In two-step: You just call your supplier and order 18g preforms. Done.

- In one-step: You must stop the machine. You must bring in a crane. You must change the entire injection mold inside the machine. This is a $50,000 part and a 2-day job. It is a disaster. You have zero flexibility.

Cost:

- A one-step machine is two machines (injection + blowing) fused together. It is very complex and very expensive.

- The molds are even worse. A "combo" mold that does both injection and blowing is a piece of high-tech art, and it costs a fortune.

- Your startup cost for a one-step line is dramatically higher than for a simple, two-step bottle blowing machine.

Here is a simple table to help you decide.

| Feature | One-Step Machine | Two-Step Machine | My Recommendation for You |

|---|---|---|---|

| Main Use | Cosmetics, special shapes, non-PET | Water, CSD, Juice, Oil (PET) | Two-Step |

| Speed (BPH) | Lower (limited by injection) | Much Higher | Two-Step |

| Flexibility | Very Low (locked to one preform) | Very High (use any preform) | Two-Step |

| Initial Cost | Very High | Low to Medium | Two-Step |

| Mold Cost | Extremely High (combo mold) | Low (just a blow mold) | Two-Step |

| My Advice | For "special process" problems. | For "scale and cost" problems. | Two-Step is your answer. |

Do not be tempted by the "simplicity" of one machine. The "separation" of the two-step process is its greatest strength. It gives you freedom. It gives you flexibility. It lets you use a global supply chain of preforms. As a startup, you need that freedom to adapt.

What Core Molds Do You Need? (Preform Molds vs. Blow Molds)?

You hear "molds" and get confused. "Preform mold?" "Blow mold?" You are worried you will buy the wrong one. It's a very expensive mistake.

It's simple. As a two-step startup, you only buy the "Blow Mold." This mold defines your bottle's outside shape. The "Preform Mold" is used in Step 1, which you are not doing. You are buying preforms, not making them.

This is the single most common point of confusion for new clients. Let's make this crystal clear. There are two molds in the universe of this process. You are only involved with one of them.

Mold 1: The Preform Mold

- What it does: It makes the "test tube" preform.

- What it controls: The preform's weight (grammage) and its neck finish (the threads).

- Who uses it: The Step 1 factory. The preform supplier.

- Who buys it: NOT YOU.

- Why? This is the super expensive one. It's made of hardened steel, has 32, 48, or 96 cavities, and has complex "hot runner" systems. It costs hundreds of thousands of dollars. You are avoiding this cost.

- Your relationship to it: You are a customer of this mold. You order "15-gram, 28mm-neck preforms," which come from this mold.

Mold 2: The Blow Mold (This is your mold)

- What it does: It defines the final shape of your bottle.

- What it controls: The bottle's external design. Is it round? Square? Ribbed? Does it have your logo embossed on it? It also controls the final volume.

- Who uses it: YOU. It gets installed inside your bottle blowing machine.

- Who buys it: YOU. This is your primary "tooling" cost.

- Why it's affordable: This mold is usually made of aircraft-grade aluminum. Aluminum is easy to cut (machine), so it's cheaper to make. It also transfers heat very well, which is perfect for the "fast cooling" that you need.

- Cost: A 2-cavity aluminum blow mold for a 500ml bottle costs thousands of dollars, not hundreds of thousands. This is a manageable and expected startup cost.

My Insight: The Critical Link (This is what I do)

This is where my 20 years of experience comes in. A customer cannot just send me a drawing of a bottle and say, "Make me this mold."

My first question is always: "What preform are you using?"

Why? Because the preform and the blow mold are a matched set. This is a key engineering concept called the "stretch ratio."

- Imagine a 15g preform. It has a set amount of plastic. I can easily blow it into a 500ml round bottle.

- Now, what if the client wants to blow that same 15g preform into a 500ml square bottle?

- This is much harder. The corners of the square mold are "far away" from the round preform. The plastic has to stretch much more to reach those corners.

- If we try, the corners will be paper-thin and weak.

- My professional advice: "You cannot use the 15g preform. For this square design, you must use a 22g preform. It has more plastic 'meat' for us to stretch into those corners."

A good, professional supplier (like my company) does this before you spend any money.

- You send us your bottle design idea.

- We analyze it. We calculate the stretch ratios.

- We recommend the correct preform weight and neck.

- Then, we design the blow mold to be a perfect match for that preform and your bottle.

- We often 3D print a sample of the bottle for you to hold in your hand before we cut any metal.

A bad supplier just says "yes," takes your money, and makes the mold. When it doesn't work, they blame your preform. A good supplier (a partner) helps you design the entire system (preform + mold) to guarantee success.

One last point: the blow mold must fit your machine. We have the mounting dimensions for over 80% of the world's machines, so we can guarantee our mold will fit your machine.

| Question | Preform Mold | Blow Mold |

|---|---|---|

| What does it make? | The "test tube" preform. | The final bottle. |

| Who buys it? | Step 1 Factory (Not you). | Step 2 Factory (You). |

| What does it control? | Preform weight & neck. | Bottle shape, volume, logo. |

| Material | Hardened Steel | Aluminum (usually) |

| Cost | $$$$$ (Very High) | $$ (Manageable) |

| My Advice | Find a good supplier of these. | Find a good designer of these. |

Semi-Auto vs. Fully-Automatic: A Startup's First Machine?

You need a machine. You see "semi-auto" for $5,000 and "fully-auto" for $50,000. The cheap one is tempting. But will it ruin your business?

A semi-auto machine requires a worker to load preforms and remove bottles by hand. It's cheap but slow (800 BPH). A fully-auto machine does everything (2,000+ BPH). It costs more but saves labor and has better, more consistent quality.

This is your biggest investment decision. Both are "two-step" machines. They both use preforms and blow molds. The difference is labor.

What is "Semi-Automatic"?

It's typically two separate machines: a heater and a blower.

- Heater: A worker stands here. They manually pick up a preform and place it on a holder. The holder moves through an oven.

- Blower: The worker manually takes the hot preform from the heater. They manually place it inside the blow mold. They press two buttons (a safety feature, so their hands are clear).

- The machine blows.

- The worker manually takes the finished bottle out and throws it in a box.

- Repeat.

- Output: A good worker can make 800, maybe 1,000, bottles per hour (BPH).

What is "Fully-Automatic"?

This is one integrated bottle blowing machine.

- A worker dumps a whole 50-pound box of preforms into a "hopper" (a big funnel).

- The worker presses "Start."

- The worker walks away.

- The machine does everything else:

- An "unscrambler" automatically sorts the preforms and lines them up.

- They are automatically fed through the heater.

- A robotic arm transfers the hot preform to the blow mold.

- It blows.

- It ejects the finished bottle onto a conveyor belt.

- Output: Starts at 2,000 BPH (for a 2-cavity) and goes up from there. A single worker can supervise three of these machines.

My Insight (The Uzbekistan Case Study):

I had a client in Uzbekistan. He had almost no money, but his local labor cost was extremely cheap. He insisted on a semi-auto machine.

I sold it to him. And for him, it worked. He "survived" his first year. He got his water into the local market. The bottles were not perfect (some were good, some were "meh"), but they were good enough for his market.

The second year, he called me. He said, "Vivian, I am ready. Send me the fully-automatic line." He used the profit from the "bad" semi-auto machine to buy the "good" fully-auto machine.

So, here is my honest advice:

Do not despise the semi-auto machine. It has a place. If you are in a market with (1) extremely low labor cost and (2) extremely low startup capital, it can get you in the game. It helps you "live to fight another day."

BUT... for 99% of startups, this is the wrong choice.

My Uzbek client is the exception, not the rule.

The Case for Fully-Automatic:

- Labor Cost: In most countries, labor is expensive. A semi-auto machine needs one dedicated worker (at least). A fully-auto line needs one worker to supervise 3-4 lines. The labor savings alone will pay for the more expensive machine, often within one year.

- Quality & Consistency (This is the real reason):

- Humans are not robots.

- The worker on the semi-auto machine gets tired.

- He leaves a preform in the heater for 1 second too long. It's now overheated. The bottle comes out hazy and white. (Scrap)

- He is slow moving from the heater to the blower. The preform cools down. The bottle doesn't form correctly. (Scrap)

- He fumbles a bottle. It drops on the floor. (Contamination)

- His "human" scrap rate might be 5%, 10%, or even 15%.

- A fully-automatic machine does the exact same thing every 3.6 seconds. The heating is perfect. The transfer is perfect. The timing is perfect.

- Your scrap rate is less than 1%. Your quality is 100% consistent.

My Final Insight on This:

If your goal is to sell your water to a supermarket, a distributor, or a brand... you must choose fully-automatic.

Why? Because they demand consistency. If they get one batch of your bottles and they are "soft" or "lopsided," they will reject the entire truckload. You will be ruined.

The "human error" from a semi-auto machine will eat all your profit. The money you "saved" on the machine, you will throw in the garbage every single day as scrap bottles.

Please, listen to me on this: Start with the smallest fully-automatic machine you can afford. A 2-cavity, 2,000 BPH fully-automatic machine is the workhorse of the startup world. It is the perfect balance of cost, speed, and quality.

| Factor | Semi-Automatic Machine | Fully-Automatic Machine | My Recommendation |

|---|---|---|---|

| Initial Cost | Very Low | Medium to High | Semi-Auto (if budget is zero) |

| Labor Cost | High (1+ person per machine) | Very Low (1 person/3 machines) | Fully-Auto |

| Output (BPH) | Low (800 - 1,000) | High (2,000 - 10,000+) | Fully-Auto |

| Quality | Poor (Inconsistent, operator-dependent) | Excellent (Very consistent) | Fully-Auto |

| Scrap Rate | High (5-15% is common) | Very Low (<1%) | Fully-Auto |

| Best For... | Very low budget, very low labor cost. | Professional startups, supermarkets. | Fully-Auto (if possible) |

Conclusion: Choosing the Right First Machine for Your Production Line?

You now understand the process. But the final choice is scary. You have one shot to spend your startup capital wisely. What is the final decision?

The two-step process is the clear standard for beverage startups. Your choice is not "if" but "which." Start with a fully-automatic, 2-cavity PET blow molding machine. It offers the best balance of cost, quality, and speed.

We have covered a lot of ground. We've confirmed that "two-step" is your path. It's flexible, it's scalable, and it's cost-effective. It separates the complex "Step 1" (making preforms) from your core business, "Step 2" (blowing bottles).

We've established that you will be a buyer of preforms and a buyer of a blow mold.

Your final decision is the machine itself. And this brings me to my final, and most important, professional insight.

"Buying a PET blow molding machine is not like buying a car. You are not buying a 'metal box.' You are buying a 'capability.' You are buying the 'capability to produce millions of qualified bottles at a low cost.'"

This mindset changes how you shop.

When you contact a supplier (like me), do not just ask: "What is your price?"

You must ask these questions instead. These questions will tell you if the supplier is an expert partner or just a "box seller."

Question 1: "Do you understand my bottle?"

- Show them your bottle design. Ask them: "What gram-weight preform do I need? What neck finish should I use? Can you guarantee this design will blow correctly?"

- A bad supplier: "We just sell machines."

- A good supplier (a partner): "That square bottle is difficult. The stretch ratio to the corner is high. We recommend a 22g preform, not 18g. We should do a 3D sample first to confirm the design."

Question 2: "What about the molds?"

- Ask them: "Can you design and make the blow mold for me? Is it aluminum? Does it have good cooling channels? Can you guarantee it will fit?"

- A bad supplier: "You can buy a mold from someone else."

- A good supplier (a partner): "Yes, we design the mold and machine as a system. Our molds have optimized cooling to match the machine's cycle time."

Question 3: "What about the auxiliary machines?"

- Ask them: "What exact air compressor and chiller do I need? What flow rate? What pressure?"

- A bad supplier: "Just buy a 40-bar compressor."

- A good supplier (a partner): "For this 2-cavity machine, you need a 1.2 m³/min compressor at 40 bar, and a 5HP chiller. We can supply the full package so you know it all works together."

Question 4: "What about service?"

- Ask them: "What happens when my bottles have defects? Can you help me fix it over a video call? Do you have service technicians?"

- A bad supplier: "Read the manual."

- A good supplier (a partner): "Yes, we offer 24/7 support. 90% of problems are simple settings. We will train your operator."

You see the difference? You are not buying a machine. You are buying a partner. You are buying a system.

This path removes the guesswork. It de-risks your project. It lets you focus on what you do best: building your brand, marketing your water, and selling your product.

Your factory should run smoothly in the background. Choosing the right two-step system, from the right partner, is the most important step to making that happen.

Conclusion

The two-step PET blow molding process is the flexible, cost-effective, and scalable standard for beverage startups. Choose a good machine supplier as a partner.

Final Summary: My Recommendation for a Startup

| Aspect | My Recommendation for a Startup | Why? (The "Vivian's Insight") |

|---|---|---|

| Process | Two-Step Process | It's "modular." It separates Step 1 (preform) from Step 2 (blowing), giving you flexibility. |

| Machine | Fully-Automatic (2-Cavity) | Consistency is king. Auto machines remove human error, lower scrap, and save labor. |

| Molds | Buy the "Blow Mold" only | You buy preforms (Step 1). You buy the blow mold (Step 2) to create your unique shape. |

| Sourcing | Partner with Preform Supplier | Your machine is only as good as the preform. Get the weight and neck size right. |

| Supplier | Choose a "System Partner" | Don't buy a "box." Buy a full solution (machine + mold + compressor + chiller) from one expert. |

Frequently Asked Questions (FAQs)

1. How much does a startup blow molding line cost?

This depends. A "semi-auto" machine can be under $10,000. But as we discussed, this is often a bad idea. A complete, fully-automatic line (including the bottle blowing machine, blow mold, high-pressure air compressor, and chiller) is a more realistic investment. A good startup line (like a 2-cavity, 2000 BPH) might range from $40,000 to $80,000. I advise focusing on the total cost of ownership, including the savings from a low scrap rate.

2. Can I use one machine for 500ml and 1.5L bottles?

Yes! This is the key advantage of the two-step process. You buy one machine. To make 500ml bottles, you use your 500ml blow mold and a light preform (e.g., 15g). To make 1.5L bottles, you stop the machine, change to your 1.5L blow mold, and use a heavier preform (e.g., 28g). The same machine does both jobs. You just need the correct mold and preform.

3. What is the difference between a PCO 1881 and PCO 1810 neck?

This is a very important detail. Both are 28mm necks, but PCO 1881 is a "short neck" design. It uses less plastic (is lighter) than the older, taller PCO 1810 neck. PCO 1881 is now the standard for most carbonated soft drinks and water. You must make sure your preform neck, your cap, and your neck size choice all match perfectly.

4. How much space do I need for a blow molding line?

It's smaller than you think. A 2-cavity fully-auto machine itself is only a few meters long. The entire line, including the machine, compressor, chiller, and space for a worker, plus storage for preforms and finished bottles, can fit comfortably in a 100-200 square meter (1,000-2,000 sq. ft.) area. The compressor and chiller can often be placed in a separate room or even outside.

5. My bottles are hazy and white at the bottom. What's wrong?

This is the most common of all bottle defects. It's called "crystallization." 99% of the time, it means your preform was too hot when you blew it. The PET plastic "burned." You need to turn down the temperature on your heating lamps in that zone. The other cause is a blow mold that is too warm because your chiller is not working well, so the plastic isn't "freezing" fast enough.

🔗 Related Pages on Our Website

PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr