You need a new beverage bottle. You search for "unique bottle designs" to stand out on a crowded shelf. But this first creative step is also a major technical decision.

Both "Pure Innovation" and "Strategic Benchmarking" are valid paths. Pure innovation risks high R&D costs for a unique identity. Strategic benchmarking uses proven engineering data from big brands, allowing you to focus on aesthetics for a much faster, safer market launch.

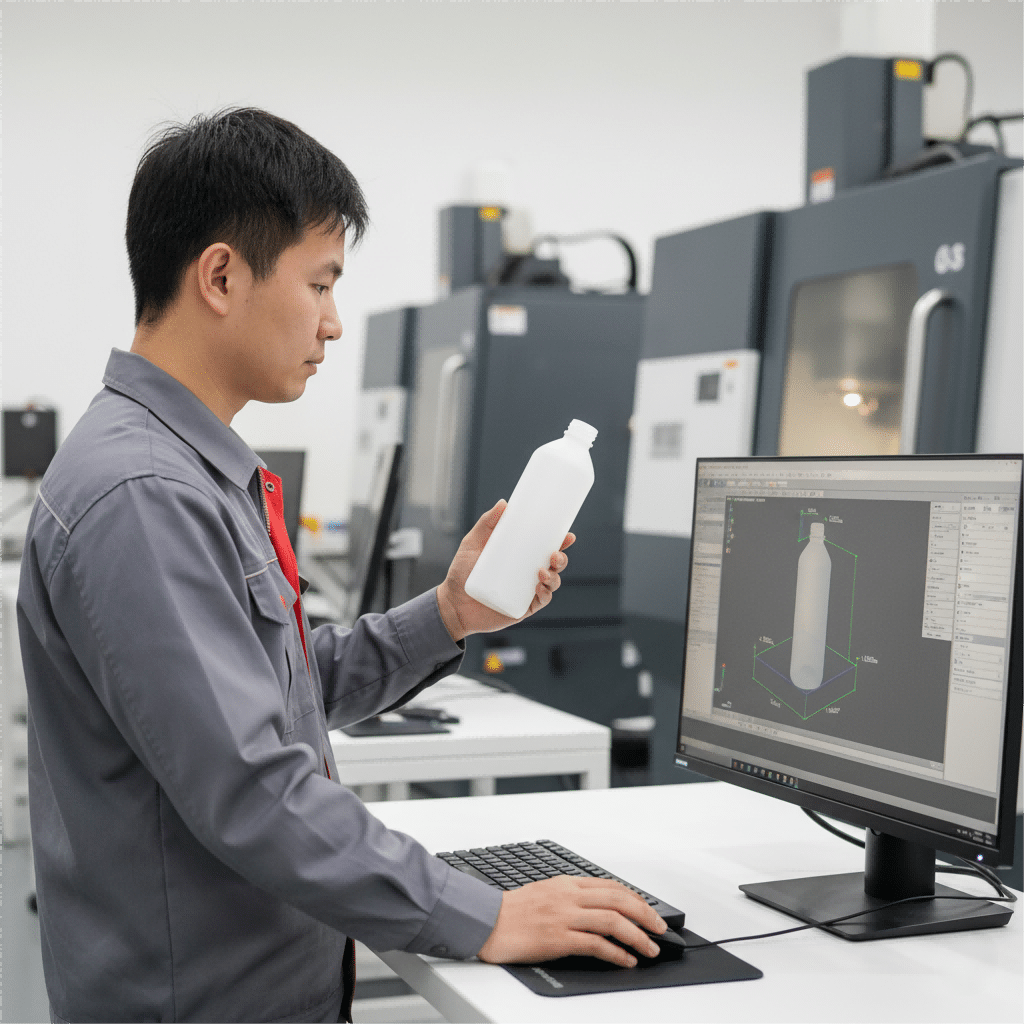

I am Vivian, and I have been in the PET packaging industry for 16 years with iBottler. I love supporting a client's "unique idea". But my job is to be objective. There is a huge technical gap between a "unique" 3D drawing and a bottle that can be mass-produced efficiently and cheaply. This article will objectively analyze these two common paths. We will look at their challenges and their opportunities. Let's explore which path is right for you.

The Startup's Desire vs. The Expert's Strategy: Two Paths to "Differentiation"?

In the beverage market, "differentiation" is everything. A startup's first idea is often 100% original. An expert's first thought is proven data. Both seek to stand out, but in different ways.

Startups often choose 'Pure Innovation' for a 100% original look. This path has high R&D risks. Experts prefer 'Strategic Benchmarking' by adapting proven designs. This 'smart' path is faster and safer, focusing on aesthetics while using verified engineering.

"Differentiation" is the key to survival. As a 16-year veteran, I see clients approach this challenge in two very different ways. The first is the passionate startup. The second is the experienced brand manager. Their goals are the same: to win on the shelf. Their methods are completely different.

Path 1: The "Pure Innovation" Journey

This is the path most entrepreneurs dream of. They want a bottle that is 100% original. They want to create an icon. They believe a unique shape will communicate their brand's value. For example, they want a "leaf" shape for an organic tea, or sharp "lightning bolt" angles for an energy drink.

The Advantage: A True Icon

If this path is successful, the reward is huge. You create a brand-new, powerful brand identity. Think of the original Coca-Cola contour bottle, the Perrier bottle, or the Method soap bottle. The container becomes the brand. This gives you a powerful marketing tool. It also gives you strong legal protection. You can get a design patent or trade dress that makes it very difficult for competitors to copy you. This is the dream.

The Challenge: High-Risk R&D

This is where I, as your technical partner, must provide a dose of reality. The risks of this path are enormous. A 3D drawing is just pixels. A real bottle is a piece of structural engineering that must perform in the real world.

- Risk 1: Consumer Acceptance. You have to test everything. Does it feel good in the hand (ergonomics)? Does it fit in a car cup holder? Does it fit in a refrigerator door? Does it pour without spilling? Big brands spend millions of dollars on consumer panels to answer these questions. You will have to do this research yourself.

- Risk 2: Technical Feasibility. This is the biggest hurdle. Your bottle must survive a complex supply chain.

- Top-Load: Can your bottle be stacked on a pallet, 10 feet high, in a warm warehouse without crushing?

- Logistics: Can it survive being dropped, shaken, and thrown during shipping?

- Production: Will it stand up straight on a high-speed filling line? Or will it fall over, stopping your entire production?

- Physics: Most importantly, can it even be made? We will discuss this in our "Square Bottle" example later.

- Risk 3: Cost and Time. All of this testing costs money. It also, and more importantly, costs time. You will need prototypes. You might start with a 3D-printed sample to check the look. This costs a little. But then you must make a pilot mold to create a real, functional bottle for testing. This costs more. This entire R&D loop can add weeks, or even months, to your launch schedule. A complex design might also require a heavier, more expensive preform, which increases your unit cost forever.

I remember a client who wanted a bottle shaped like a beautiful, twisting spiral. On the computer, it looked amazing. But when we ran the first simulation, the PET material would flow unevenly. The 'valleys' of the spiral were paper-thin, and the 'peaks' were too thick. It would have failed any drop test. We had to spend six weeks modifying the design, softening the curves, and testing different preforms. The client loved the final product, but their launch was delayed by two months. This is the reality of pure innovation.

Path 2: The "Strategic Benchmarking" Strategy

This is the path favored by experienced brand managers. They are launching a new flavor, or a new product line in a mature category. Their primary goal is not to "reinvent the wheel." Their primary goal is "speed to market" and "profitability."

The Advantage: Speed, Safety, and Focus

This is the number one reason to choose this path. You are intentionally skipping the most painful, expensive, and time-consuming R&D.

- Proven Success: You are "drafting" behind a market leader. They already proved this bottle shape works. Consumers like the hand-feel. It ships without breaking. It runs on existing filling lines.

- Cost Savings: You leverage their multi-million dollar R&D budget for free. We will discuss this in the next section.

- Focus: This is a key benefit. You can put 100% of your creative energy and budget into the things that really drive a purchase decision: your label design, your branding, and your marketing message.

The Challenge: The Legal Line

This path has one main challenge: you must find the perfect balance between "benchmark" and "infringement." You cannot copy a competitor's bottle. You can be sued for trade dress infringement if your bottle creates "consumer confusion."

This is where a good technical partner is essential. We understand the legal boundaries. We can take the engineering data (like the wall thickness, the base design, the preform weight) and apply it to a new, visually distinct shape. We can change the shoulder line, add a new grip pattern, or emboss your logo. It will feel familiar to the consumer, but it will look like your own original brand.

A brand manager at a large beverage company once told me, "Vivian, my bonus is tied to launching this new juice by Q2. I cannot afford a 3-month delay because a bottle keeps falling over on the filling line." This is the expert mindset. They manage risk. They know the bottle is a container. The product inside and the brand on the label are what they are selling. They use a PET bottle mold design guide to understand the fundamentals, then they ask us, "How can we make this standard bottle look premium without adding risk?" This is the "smart" path.

Comparing the Two Paths: A Quick Guide

| Feature | Path 1: Pure Innovation | Path 2: Strategic Benchmarking |

|---|---|---|

| Primary Goal | Create a unique brand icon. | Fast and safe market entry. |

| R&D Time | High (Months) | Low (Weeks) |

| Financial Risk | Very High | Low |

| Key Challenge | Engineering feasibility, cost, consumer testing. | Legal boundaries (avoiding infringement). |

| Best For... | Well-funded startups, new categories, brand-focused products. | Startups needing speed, new flavors, mature markets. |

Why "Strategic Benchmarking" is the Fastest Path to Market?

You need to get your drink on shelves now. But engineering tests for a new bottle take months. Strategic benchmarking lets you skip this line by using data that is already proven.

It is fastest because you use millions of dollars of R&D from big brands for free. Their bottles have perfect engineering for weight, strength, and logistics. You skip these tests and focus only on aesthetic changes, like your logo or label.

Time is the most valuable resource for a new product. "Strategic Benchmarking" is, without question, the fastest path from an idea to a filled bottle on a store shelf. The reason is simple: you are building on a foundation that has already been tested and paid for by the market leaders.

When I say big brands "paid millions for your tuition," I am not exaggerating. A single new bottle line for a global brand goes through an incredible amount of R&D. When you "benchmark" their bottle, you get all that knowledge for free.

You Are Adopting Proven Engineering Data

This is the core of the strategy. You are not copying the look; you are adopting the engineering specifications. Here is what that includes:

1. Market Acceptance & Ergonomics

The market leader has already proven that:

- Consumers like the "hand-feel" and grip.

- The diameter fits in standard car cup holders and refrigerator doors.

- The capacity is accurate. A "500ml" bottle holds 500ml plus the correct "headspace" needed for high-speed filling without spilling.

This research is tedious and expensive. You get to skip it.

2. Structural Integrity & Engineering Mechanics

This is the most valuable data. A PET bottle is a lightweight structural vessel.

- Top-Load Strength: The market leader's bottle is designed to be stacked 5 pallets high in a warehouse. This performance comes from a perfectly designed shoulder angle and base structure.

- Base Design: The "feet" or "petals" on the bottom of a bottle are not random. On a carbonated drink bottle, they are specifically designed to manage high internal pressure. On a still water bottle, the base is designed for maximum stability and minimum weight.

- Logistics Performance: The bottle has already survived real-world shipping. It has been tested for vibration, drop impacts, and handling.

When you benchmark, you are not guessing. You are starting with an engineering specification that is proven to work.

3. Cost Optimization (Lightweighting)

This is a huge factor. Global brands fight to remove tenths of a gram of PET from a bottle. Removing just 0.5 grams, multiplied by 100 million bottles, saves a fortune in material costs.

The "benchmark" bottle is the result of many generations of optimization. It is designed to be "lightweighted" to the absolute minimum amount of material required to guarantee structural performance.

If you start from scratch with "Pure Innovation," you will almost certainly over-engineer your bottle. You will make it heavier "just to be safe." This means you are paying extra for wasted plastic on every single bottle you produce, forever. By benchmarking, you start with the most cost-effective, optimized design from day one.

How This Shortens Your R&D Cycle

Let's compare the product development timelines. The R&D phase is not a straight line; it is a loop. You design, you test, you fail, you re-design. Benchmarking eliminates most of these loops.

| R&D Step | Path 1: Pure Innovation | Path 2: Strategic Benchmarking |

|---|---|---|

| 1. Concept Design | 1-2 Weeks | 1-2 Weeks |

| 2. Engineering Simulation (FEA) | 1-3 Weeks (Multiple revisions) | 1-2 Days (Verification only) |

| 3. Prototyping (Pilot Mold) | 2-4 Weeks (High risk of failure) | 1-2 Weeks (Low risk, just for aesthetics) |

| 4. Physical Testing (Top-load, Drop) | 1-2 Weeks (May fail, return to Step 2) | 1-2 Days (Verification only) |

| 5. Production Blow Bottle Mold Tooling | 4-6 Weeks | 4-6 Weeks |

| Total Estimated Time | 9 - 17 Weeks (High variability) | 6 - 10 Weeks (Low variability) |

As this table shows, you can save 1-2 months of R&D time. The "fail and repeat" loops are gone.

Your Focus Shifts from "Engineering" to "Aesthetics"

This is the key business benefit. You are now free from the physics problem. You can put all your energy into the art problem. Your conversations with me (Vivian) change.

- Instead of asking: "Will this shape explode under pressure?"

- You ask: "Can we emboss my logo on the shoulder?"

- Instead of asking: "Will this bottle stand up on the filling line?"

- You ask: "Can we add these subtle 'grip' lines to the side?"

This is a much faster and more creative process. We can use our expertise to make your custom PET bottle design yours visually, while it stands on the shoulders of giants from an engineering perspective.

Many clients, especially those using co-packers, have their bottle blowing machine and filling lines set up for specific bottle diameters and heights. If you bring them a "unique" bottle that is too tall or too wide, they may have to re-tool their entire line. This is a massive cost and delay. By benchmarking a standard bottle, you are creating a container that you know will run on 90% of the filling lines out there. You have a "drop-in" solution. This makes your product much more attractive to co-packers and distributors. This is not "cheating." It is a smart, professional business strategy.

Unique Design Challenge #1: The "Square" or "Diamond-Cut" Bottle?

Square and diamond-cut bottles look stunning in 3D renders. They feel modern and high-end. But these sharp edges and flat panels create major manufacturing challenges in the real world.

The challenge is physics. PET gas is round. It fills flat panels first and sharp corners last. This creates weak, thin corners that can break easily. The flat panels also tend to be too thick, which wastes material and cost.

I get requests for "square" or "diamond-faceted" bottles every single week. And I understand why. They look modern, architectural, and premium. Clients see high-end water brands like Fiji or Voss and they want that same look.

The Dream: A Modern, Geometric Masterpiece

The client's 3D rendering is always beautiful. The flat, clear panels look like glass. They are a perfect canvas for a minimalist label. The sharp, 90-degree corners look crisp and high-end. In a digital world, this design is a 10/10.

The Reality: Fighting Blow Molding Physics

My job is to be the "bad guy" who brings physics into the room. A blow bottle mold is not a 3D printer. It uses heat and air pressure. Here is a simple explanation of the process:

- A preform (which is a small, thick-walled test tube) is heated until it is soft.

- It is placed inside the cold, metal blow mold.

- A stretch rod pushes the preform down to the bottom.

- High-pressure air (the "blow") inflates the soft preform like a balloon.

Here is where the problem starts. The preform inflates from the center, outwards. The plastic "balloon" hits the closest part of the mold wall first.

Technical Trap 1: Material Distribution

In a square bottle mold, what is the closest point to the center? The flat center of the panel.

What is the farthest point? The sharp corner.

This means the plastic has to stretch the least to hit the panel, and the most to hit the corner.

- Result: The center of the flat panel gets too much material. It becomes thick, heavy, rigid, and wastes plastic.

- Result: The sharp corner gets almost no material. It is stretched paper-thin.

I have personally cut open bottles where the panel is 0.8mm thick, but the corner is only 0.1mm thick. This is an 8x difference in thickness! That bottle is incredibly fragile. If you drop it, the corner will shatter. It will fail 100% of the time. This also causes other common PET blow molding defects. For example, the thick panel may not cool fast enough, leading to "haze" or a cloudy appearance.

Technical Trap 2: The "Paneling" Problem (Vacuum)

There is another major problem with large, flat panels. It is called "paneling."

- If you fill the bottle with a hot product (like hot-fill juice), the liquid cools and shrinks. This creates a vacuum inside the bottle.

- On a round bottle, this vacuum pressure is distributed evenly.

- On a square bottle, the weakest point is the center of the flat panel. The vacuum will suck the panel inward.

- Your beautiful, premium, flat bottle now looks dented, concave, and cheap.

- This can also happen with cold-fill products (like water) just from altitude changes during shipping.

The Solution: How We Make It Work

A professional mold factory does not say "No." We say, "Here is how we solve this." We have solutions.

Solution 1: Smart Design Changes (The 2mm Fix)

The best solution is a small design compromise.

- Change sharp corners to "micro-round" corners. We ask the client, "Can we change your 90-degree 'sharp' corner to a corner with a 2mm or 3mm radius?"

- To the consumer, the bottle still looks perfectly square.

- To the plastic, this tiny radius dramatically helps material flow. It reduces the "stretch distance" to the corner. This simple change can be the difference between a 100% failure rate and a 100% success rate.

- Add "vacuum panels." For hot-fill, we can design subtle, recessed panels (often on the sides or back) that are meant to flex inward. This controls the vacuum, so your main "hero" panel stays perfectly flat.

Solution 2: Specialized Preforms and Processes

If the design must be sharp, we have other tools.

- We can use a special preform that is thicker or made of a different material. This gives us more plastic to push to the corners. This will, however, increase your unit cost.

- We can use "preferential heating" on the bottle blowing machine. This means we heat some parts of the preform more than others to control exactly how it stretches.

My job is to present these options. I will say, "We can make your square bottle. To do it right, we recommend adding a 2mm radius to the corners and using this specific 24-gram preform. This will give you a strong, beautiful bottle. Here is the cost difference." This way, you are making an informed business decision, not just chasing a 3D dream.

Unique Design Challenge #2: "Character" or "Animal" Shaped Bottles?

A bottle shaped like a character or animal is a powerful marketing idea. It can create a viral buzz. But these complex 3D shapes are the absolute hardest to produce.

The main challenges are 'undercuts' and 'material flow'. Undercuts, like an arm, will trap the bottle in the mold. Thin areas, like ears, are hard to fill. The bottle may also be unstable and unable to stand on a filling line.

This is the "Pure Innovation" path taken to its extreme. A client comes to me with a design for a "teddy bear" bottle for a kids' drink, or a "muscle-bound torso" for a protein shake.

The Dream: A Viral, Collectible Package

The marketing logic is perfect. The client is not just selling a drink; they are selling a toy, a collectible, an experience. They imagine kids collecting all the different animal bottles. They see gym-goers posting the "muscle" bottle on Instagram. The bottle is the advertisement. The potential for a viral hit is huge.

The Reality: A 3D Geometry Nightmare

As an engineer, I am excited by this challenge. But my brain immediately scans the 3D model for three critical, project-killing traps.

Technical Trap 1: Undercuts (The "Stuck in the Mold" Problem)

This is the number one killer of character designs.

- A blow bottle mold is almost always two simple halves (a "clamshell") that open and close horizontally.

- An undercut is any part of the design that hooks behind this opening path.

- Example 1: The "teddy bear's" chin. If his head is tilted down, his chin juts out over his chest. This is a classic undercut. The mold cannot open.

- Example 2: The "muscle man's" bent arm. The inside of his elbow creates a "hook." When the mold tries to separate, the bottle is trapped.

This is not a "difficulty." It is a physical impossibility. The bottle will be torn apart, or the mold will be damaged.

Technical Trap 2: Material Flow (The "Ears and Fingers" Problem)

This is the same problem as the "square bottle" corner, but 100 times worse.

- The preform expands from the center (the torso).

- The hot PET material has to travel a very long way to fill the tiny, complex details, like the "bear's ears" or the "muscle man's fingers."

- By the time the material gets there, it is too cold. It has been stretched too thin.

- Result: You get "short shots" or "non-fills." The ears are not fully formed. The fingers are just weak, thin nubs. The bottle is a reject, and it is unusable.

Technical Trap 3: Stability (The "Falling Over" Problem)

This is the "Day 2" problem. Let's say we solve the undercuts and material flow. We have a beautiful "teddy bear" bottle.

- Now, we try to stand it on a table.

- The "bear's feet" are tiny and rounded. The bottle tips over.

- If it cannot stand on a table, it will definitely fall over on a high-speed conveyor belt.

- This makes the bottle impossible to fill, impossible to cap, and impossible to label. The entire project is a complete failure. Production feasibility is just as important as the design itself.

How We Make the "Impossible" Possible

This is the fun part. This is where real engineering comes in. We do not just say "no." We say, "We can get you 95% of this design, and make it 100% manufacturable."

- Solution 1: Smart Design Modification.

- Fixing Undercuts: We use 3D simulation software. We show the client a cross-section. "See this arm angle? It is 5 degrees, which is an undercut. If we change it to 1 degree, it is no longer an undercut. It will still look like a bent arm, but it will release from the mold."

- Fixing Stability: We look at the "bear's feet." We add a tiny, subtle, flat "ring" that connects the two feet. It is invisible from the front. But this "tripod" gives the bottle a stable base. Now it can run on the filling line.

- Solution 2: Advanced (and Expensive) Mold Technology.

- If the client insists on a true undercut (like a bottle with a handle), we can do it.

- This requires a much more complex and expensive blow bottle mold. The mold will need "cams" or "sliders." These are moving parts inside the main mold.

- For example, a slider might move in to form the inside of the handle, and then retract before the main mold opens.

- This technology is brilliant, but it is expensive. A simple 2-part mold might cost $X. A mold with sliders might cost $3X or $4X.

- It also slows down production. The bottle blowing machine has to run slower to allow for these extra moving parts.

My job is to present this choice. "We can keep 95% of your design with a standard, fast, affordable mold. Or, we can keep 100% of your design with a complex, slow, expensive mold. Which is better for your business?" 99% of the time, the client happily chooses the 95% design modification.

[Case Study #1] A "Pure Innovation" Win: The Birth of the Thai "Pineapple" Bottle?

A Thai juice company wanted a 100% unique pineapple bottle. Their concept was beautiful, but the sharp spikes and curves were impossible to mold. They needed a technical partner.

This 'Pure Innovation' path succeeded because of collaboration. We did not reject the idea. Our engineers worked for 3 weeks to re-design the spikes into 'round, strong bumps' and optimized the preform to ensure even material flow.

This case study is one of my favorites. It is a perfect example of "Pure Innovation" done right. It shows that a "crazy" idea is possible, but only with a deep, collaborative technical partnership.

The Client's Vision: "A Bottle That Is a Pineapple"

A startup from Thailand contacted us at iBottler. They were launching a new line of premium, 100% pure pineapple juice. Their entire brand identity was built around this single fruit.

They did not want a round bottle with a paper label of a pineapple. They wanted the bottle to be a pineapple.

They sent us a 3D rendering. It was a piece of art. It had sharp, angular "bracts" (the spiky skin of a pineapple). It had a complex, curved, "bulging" body. It was beautiful.

The Initial Challenges: A "Red Flag" Design

As an engineer, my mind immediately saw two "red flags" that made this design completely unmanufacturable.

Challenge 1: The Sharp Spikes. The design had hundreds of sharp, angular points.

- Mold Release: These spikes would act like hundreds of tiny undercuts. The bottle would be "stuck" in the blow bottle mold, and would be torn apart when the mold opened.

- Material Flow: Just like the "diamond-cut" bottle, these sharp points were the farthest point for the plastic to stretch. They would be paper-thin, fragile, and would likely have "short shots" (not fully formed).

- Safety: A bottle with hundreds of sharp plastic spikes could even be a consumer safety hazard.

Challenge 2: The Complex Curve & Base.

- Uneven Wall Thickness: The bottle had a wide "bulge" in the middle, just like a real pineapple. This non-uniform shape was a nightmare for material distribution. The "bulge" (the widest part) would be stretched very thin, while the narrow "neck" and "base" would be too thick.

- Stability: The base of their design was rounded, just like the bottom of a real pineapple. It would not stand up on its own. It was 100% guaranteed to fall over on a filling line.

A "cheap" or "lazy" mold factory would have done one of two things:

- Replied "No, this is impossible. Please send a new design."

- Said "Yes, no problem," made a terrible mold, and delivered a non-functional bottle that failed in production (after taking the client's money).

We chose the third path: partnership.

The Solution: 3 Weeks of Collaborative Engineering

We sent a reply: "We love this idea. It is brilliant. However, the current design is not manufacturable. Our engineers have identified the problems, and we already have solutions. Can we work with your designers to make it a reality?"

The client was thrilled. They did not want to give up on their idea.

For the next 3 weeks, our engineering team and their design team had several video calls. We shared 3D files back and forth.

- Solving the Spikes: Our engineer took their 3D file. He did not delete the spikes. Instead, he replaced every "sharp, angular spike" with a "smooth, rounded, but powerful bump."

- The new bumps were smooth, so they would release from the mold perfectly.

- A rounded "dome" shape is extremely strong. The material would flow evenly.

- Visually, the effect was the same. It still "read" as a pineapple, but the manufacturing risk was 100% gone.

- Solving the Curve & Stability:

- We ran blow-molding simulations on the body. We sent the client a color-map showing the wall thickness. "See this red area? It's too thin. If we reduce the 'bulge' by 10%, it turns green." The client agreed.

- We carefully selected a specific preform with the perfect weight and length to provide enough material for the wide body.

- For the base, we added a subtle, flat "ring" base, similar to what we described for the "character" bottle. It was hidden in the design, but it gave the bottle perfect stability.

The Result: A "Unique" and "Manufacturable" Bottle

After 3 weeks, we had a new, approved 3D model. It kept 95% of the client's original "spirit" but was 100% manufacturable.

We then made a 3D-printed sample. The client held it in their hands and loved it. They gave us the "go" for the production mold.

The final product was a massive success in their market. It was totally unique. It stood out on the shelf. It was strong. And it ran perfectly on their filling line. This case study is my favorite example of "Pure Innovation" done right. It is possible, but it requires a deep technical partnership.

[Case Study #2] A "Strategic Benchmark" Win: How a "Familiar" Bottle Captured the Market?

A mature sports drink client wanted to launch a new flavor. They needed to compete with the leader, fast. Reinventing the bottle was too slow and risky.

They used 'Strategic Benchmarking'. We adopted the market leader's engineering data (weight, base, dimensions) for speed. Our job was to design a new, non-infringing shoulder and grip pattern. The 'familiar' bottle was a fast, successful launch.

This is the other kind of success story. It is less "artistic," but it is more "business-savvy." It shows the power of "Strategic Benchmarking" (Path 2).

The Client's Goal: "Speed and Compatibility"

This client was not a startup. They were an established beverage company with a strong brand.

Their goal was to launch a new line of sports drinks to challenge the #1 market leader in their region.

They came to us with a very clear, professional brief:

- "We are launching in 6 months."

- "We have a co-packer already lined up."

- "The co-packer's entire filling line is set up for the market leader's bottle."

- "We need a bottle that uses the exact same preform, has the exact same weight, and the exact same diameter and height."

This is the definition of "Strategic Benchmarking." Their primary concerns were speed and compatibility.

The "Copy" vs. "Benchmark" Trap

The client's first, casual request was, "Just make us that bottle, but put our logo on it."

My first and most important job was to be their legal guardrail. I explained, "We cannot do a 1:1 copy. That is trade dress infringement. You will be sued, and so will we. But, we can benchmark the engineering data and create a new, original design."

The client understood immediately. Their real request was not "copy the look." Their real request was "copy the performance and compatibility."

The Engineering Task: Adopt the "Data Core"

We call this the "Data Core." We identified the market leader's bottle specifications:

- Weight: 28g

- Preform Neck: A standard PCO 1881 neck.

- Base Design: A specific 5-petal base, perfect for high-pressure (carbonated) filling.

- Diameter: 73mm (to fit the co-packer's "pucks" and rails).

- Height: 220mm (to fit their labeler and capper).

This "Data Core" was our starting point. It was non-negotiable. This guaranteed that the bottle would run on the co-packer's line. It guaranteed the low material cost. It guaranteed the top-load strength.

The Creative Task: "Familiar but Different"

Now, our designers had a "box" to work in. Their job was to create a new bottle that fit inside these fixed dimensions.

- The client's brand was about "power," "energy," and "speed."

- The market leader's bottle had a well-known "swirl" grip.

- Our designer created a new bottle with:

- A "stronger," more angular shoulder, instead of the leader's sloped shoulder.

- A new "muscle line" grip. We used vertical, recessed lines that looked "athletic" and also improved grip.

- A large, smooth, perfectly flat panel for their shrink-sleeve label.

- A deep, crisp embossing of their brand logo on the shoulder.

The Result: A Seamless, Successful Launch

The final design was 100% legally safe. It was visually distinct. If you held the two bottles side-by-side, they were clearly different.

But for the consumer, it felt familiar. When a customer grabbed it from the cooler, the weight and diameter felt "right." It felt like a "proper" sports drink bottle.

The Launch:

- We delivered the production blow bottle mold in 5 weeks.

- The client shipped it to their co-packer.

- The mold was installed. It fit the machine perfectly.

- They ran the first bottles. They passed all QC tests on day one. No delays.

- The product launched ahead of schedule.

This client was thrilled. They did not win an art award. They won market share. They achieved their business goal with maximum speed and zero technical risk. This is the power of "Strategic Benchmarking."

Summary: Two Types of Success

| Metric | Case 1: "Pineapple" (Innovation) | Case 2: "Sports Drink" (Benchmark) |

|---|---|---|

| Client Goal | Unique brand identity. | Speed to market, compatibility. |

| Our Main Role | Solve physics problems. | Optimize aesthetics, avoid legal issues. |

| R&D Time | 3 weeks (design) + 2 weeks (prototype) | 1 week (design) |

| Biggest Risk | Manufacturing failure. | Legal infringement (which we avoided). |

| Outcome | A 100% unique, iconic bottle. | A fast, safe, and profitable launch. |

Conclusion: So, Which Approach is "Fastest to Market"?

You must choose a path. 'Unique' is tempting, but 'proven' is safe. The best choice depends on your primary business goal: speed or originality?

'Strategic Benchmarking' is always the fastest path. It skips 90% of the engineering and market testing risks. 'Pure Innovation' is 100% possible (like our pineapple bottle), but it requires a longer R&D cycle to solve unknown manufacturing challenges.

Let me be very direct in answering the question.

The fastest path is "Strategic Benchmarking." It is not even close.

As we saw in the Sports Drink case study, you are removing 90% of the risk from your project. And in manufacturing, risk equals time.

By benchmarking, you are eliminating:

- Time for multiple engineering simulations (FEA).

- Time for building and testing multiple prototypes.

- Time for physical drop-testing and top-load testing.

- Time for consumer hand-feel and ergonomic testing.

- Time for "line-compatibility" testing with your filler.

You are skipping all of these time-consuming loops. You are jumping straight to the "Aesthetics" phase. This can save you 2-3 months of R&D.

When "Pure Innovation" Is the Right (But Slower) Path

"Pure Innovation" (the Pineapple case) is the right path only if your brand identity is 100% tied to the container itself.

You must go into this path with your eyes open.

- It is not fast. You must accept this. You must build this extra R&D time into your business plan.

- It is not cheap. You must have a budget for R&D, for pilot molds, and for potential failures.

- It requires a true technical partner. If you take a complex "pineapple" design to a cheap factory, you will lose your entire investment. You need a partner who will collaborate, simulate, and solve problems with you.

"Pure Innovation" is viable, respectable, and can lead to a huge win. But it is a longer, more expensive journey. You must plan for it.

The Hidden Cost: Cycle Time

"Fast to market" (R&D) is one thing. "Fast in production" (cycle time) is another.

A "benchmark" bottle is, by its nature, optimized for high-speed production. It is a simple, proven shape.

A complex "Pure Innovation" bottle (like our "character" bottle) might require a slower production cycle.

- A standard bottle might run at 1,000 bottles/hour/cavity.

- Your complex "character" bottle might have to run at 800 bottles/hour/cavity because it has complex mold sliders or needs extra cooling time.

This is a 20% reduction in output. This is a permanent increase in your manufacturing cost (cost-per-bottle) for the life of the product.

A good partner like iBottler will tell you this before you cut the mold. We will give you a "Cycle Time" estimate for your design.

So, "fastest to market" (Benchmarking) is also, very often, the "cheapest to produce."

Your Choice Determines Our Role

As your technical partner, my role at iBottler changes based on your choice.

- If you choose "Speed" (Benchmarking): My role is to be your Creative Optimizer and Legal Guardrail. You give me the "engineering data core." I help you design the most beautiful, unique-looking bottle that fits within that safe data.

- If you choose "Unique" (Innovation): My role is to be your Physics Problem-Solver. You give me your "dream" design. I find the failure points (thin corners, undercuts, instability). I come back to you with solutions.

Both paths lead to a successful bottle. But they are different roads, with different speeds, different costs, and different risks.

How Your "Creative Idea" Becomes Reality: The iBottler Role?

You have a great idea for a bottle. But you are worried about manufacturing risks and costs. An expert partner helps you balance creativity with reality for a successful launch.

My final advice: Be an 'expert' on engineering and a 'creative artist' on aesthetics. Benchmark the proven data (weight, base) to control cost. Use your 'unique' idea on the parts consumers see (logo, texture, label). We help you find this perfect balance.

After 16 years of launching new bottles, I believe the most successful products follow a "Hybrid Path."

This path combines the intelligence of "Strategic Benchmarking" with the creativity of "Pure Innovation."

Here is the practical, step-by-step process I recommend to all my new clients.

Step 1: Be an "Expert" on Engineering (The Benchmark Part)

This is your foundation. This is where you control 90% of your cost and risk before you even start designing.

You will make a few key decisions.

- Benchmark the Preform: Do not reinvent the preform. Choose a standard, widely available preform (like a 21g PCO 1881). This is your single biggest cost-saver. It sets your material cost.

- Benchmark the Neck Finish: By choosing a standard preform, you are also choosing a standard neck size. This means you can buy standard, low-cost caps from any supplier.

- Benchmark the Base Design: Adopt a proven base design for your application. If you have a carbonated drink, use a standard "petaloid" base. If you have still water, use a standard "stability" base.

- Benchmark the "Envelope": Decide on the basic shape. A simple "round" or "cylinder" bottle is always the easiest, fastest, and cheapest to produce.

By making these 4 "expert" decisions, you have just eliminated almost all of the technical defects and R&D delays. You have built a safe, low-cost, high-performance "chassis" for your product.

Step 2: Be an "Artist" on Aesthetics (The Innovation Part)

Now that your "chassis" is secure, you can be 100% creative. You can put your "uniqueness" budget on the parts of the bottle that consumers actually see and touch.

This is where you make the bottle yours.

- Logo Embossing: This is the best value in packaging. We can add a deep, crisp embossing of your logo onto the shoulder or body. It adds a premium "glass-like" feel for almost no extra cost.

- Texture and Grip: Instead of a plain, smooth bottle, we can add a new texture. We can add a "swirl," a "diamond" pattern, a "stipple" texture, or "grip" lines. This changes the hand-feel and how the bottle reflects light.

- Shoulder and Waist: We can change the profile. Even on a standard round bottle, we can design a "strong, angular" shoulder or a "slim, pinched" waist. This creates a new silhouette.

- Label Design: Never, ever underestimate the power of the label. A brilliant, beautiful label on a "hybrid" bottle will beat a terrible label on a "pure innovation" bottle every single time.

The iBottler Role: Your Balance Point

Our role at iBottler.com is to be the pivot point between your "expert" and "artist" sides.

You come to us with your "Data Core" (Step 1) and your "Creative Ideas" (Step 2).

We merge them into a PET bottle mold design that is:

- Cost-effective: Uses a standard preform.

- Fast to market: Based on proven engineering.

- Visually Unique: Includes your custom logo, textures, and shape.

This "Hybrid" path is the fastest way to a successful, unique, and profitable product.

It avoids the high risk and R&D hell of "Pure Innovation."

It avoids the "boring" and "me-too" look of simple copying.

This is the strategy I have seen work for hundreds of clients, from small startups to major brands.

Summary Table: Your Path to a New Bottle

| Path | Pure Innovation ("Pineapple") | Strategic Benchmark ("Sports Drink") | The Hybrid Path (Our Recommendation) |

|---|---|---|---|

| Philosophy | "My bottle must be 100% unique." | "My bottle must be fast and safe." | "My bottle must be smart AND unique." |

| Focus | Art & Design | Speed & Cost | Aesthetics & Engineering |

| Key Action | Design from scratch. | Adopt a proven "data core." | Adopt "data core," innovate on "aesthetics." |

| Main Risk | Manufacturing failure, high cost, long delay. | Legal infringement, "boring" design. | Minimal (Best of both worlds). |

| iBottler's Role | Physics Problem-Solver | Creative Optimizer | Strategic Partner |

5 FAQs About "Unique Bottle Design"

1. What is the line between "Strategic Benchmarking" and "plagiarism/infringement"?

This is a critical question. "Plagiarism" or "infringement" is 1:1 copying or creating a design so similar that it "confuses the consumer." "Strategic Benchmarking" is borrowing the engineering principles, not the visual identity.

- You CAN benchmark: Gram weight (e.g., 18g), neck finish (e.g., PCO 1881), diameter (e.g., 68mm for a filling line), and core principles (e.g., a "petaloid base" for a carbonated drink).

- You CANNOT copy: A unique, trademarked shoulder design, a specific grip pattern, or a logo.

Our engineers will help you navigate this line. We ensure your bottle is 100% legally safe and visually distinct.

2. If I insist on a "unique" design (like the pineapple), can iBottler make it?

Yes. Absolutely. This is the fun part of our job. We have world-class CNC machines and engineers. We can (and do) make "crazy ideas" a reality, just like the "Pineapple" case.

But, as your "technical consultant," my job is to be honest before we start. I will objectively show you all the manufacturing challenges, the long-term costs, and the risks. We will then work with you to solve them. We will not just "take the order" and let you fail. We will partner with you to make your unique vision successful.

3. How can I see a physical sample before I spend $10,000 on a production mold?

This is a very smart step. We strongly recommend this. You have two main options, which have different costs and purposes.

| Prototype Method | Cost (Approx.) | Purpose |

|---|---|---|

| 1. 3D Printed Prototype | $50 - $80 USD | To check "Look and Feel." This is a 1:1 solid resin model. You can hold it, check the size, see the grip, and show it to your team. It is not a real bottle. |

| 2. Pilot Mold (1-Cavity) | $300 - $350 USD | To get a "Real Bottle." This is a low-cost aluminum mold. It produces a real, functional PET bottle. You can fill it, test the capacity, test the cap, and even do drop tests. |

We always recommend starting with a 3D print. If you need to test the function, a pilot mold is the most professional, lowest-risk way to verify your design before committing to the expensive, multi-cavity production mold.

4. Will a "unique design" affect my "preform" choice?

This is a common worry, but the answer is usually no. There are thousands of standard, "off-the-shelf" preforms available in every possible gram weight, length, and neck size.

A huge part of our job as your factory partner is to "match" your unique design to an existing, standard preform. For example, for a "short, wide" juice bottle, we will find a "short, wide" standard preform.

You almost never need to pay for a "custom preform mold." That is a "high-level" investment for massive brands (100 million+ bottles) trying to save 0.1 grams. Startups should not worry about this.

5. Where should I "spend my money" to get the most value on a unique design?

My honest advice: Your best investment is in a high-quality, professional mold factory.

- A "cheap" factory will tell you your unique design is "impossible."

- Or, they will say "yes" and deliver a low-quality mold that produces

defective bottles, costing you far more in the long run. - A true "technical partner" (like iBottler) will act like your own R&D department. As we did in the "Pineapple" case, we will collaborate with you. We will balance your creative idea with real-world physics. We will find and fix every manufacturing trap before the mold is ever made.

This partnership is the investment that guarantees your unique design will be a success.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr