Are you looking to invest in PET bottles in Nigeria but worried about choosing the wrong direction? You might be debating between water bottles and oil bottles. Choosing the wrong market can waste your startup capital.

The high-profit opportunities in 2025 include: bottled water, local drinks (like Zobo), large-format edible oil bottles, cosmetic bottles, and becoming a preform supplier. Each option has different investment levels, technical needs, and profit margins.

I work with investors in Nigeria every day. I've found that successful investors don't just "catch a golden moment." Instead, they find the right entry point for them, based on market demand. The Nigerian market is vast, but the business model and profit drivers are completely different for each type of PET bottle.

In this guide, as a machine manufacturer with 20 years of experience, I will break down the 5 most worthwhile PET bottle business ideas to invest in for 2025.

Idea 1: Bottled Water – The Eternal Necessity & Upgrade Opportunity?

Want to start a stable business? Bottled water seems like the obvious choice. But you might worry that the market is already crowded.

Bottled water is the safest and most stable bet. The demand is already here. You are not creating a new market. You are just capturing the massive, existing shift from sachet water to bottles.

Dive Deeper: Why Water is Your Best "First" Business

When I talk to new investors in Nigeria, I often call the water bottle business the "Fast, Stable, Accurate" choice.

- Fast: The market demand is immediate. You do not need to spend money educating consumers. They already want bottled water. You can start generating cash flow very quickly.

- Stable: Water is a human necessity. It is not a luxury. People need to drink it every day, in good economic times and bad. This makes your business very stable and recession-proof.

- Accurate: Your target market is clear: it is everyone.

The key is to not over-invest at the start. Many people think they need a giant, fully automatic factory. This is a mistake. For a startup, the best strategy is to use a semi-automatic machine.

The Semi-Automatic Advantage for Startups

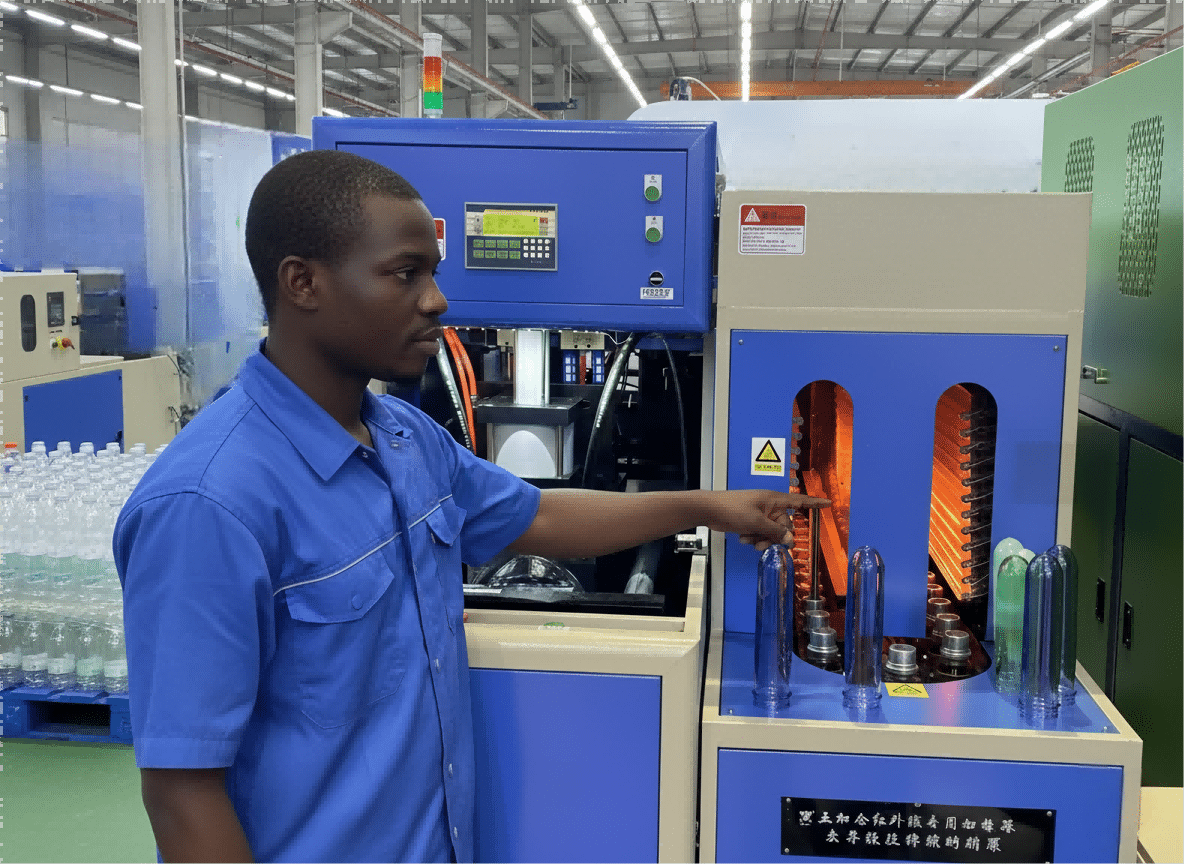

A semi-automatic bottle blowing machine is the smartest choice for a new business in Nigeria. This is a machine where you manually load the preforms (the small test-tube-like plastic) and the machine does the blowing automatically.

Why is this my top recommendation?

- Low Investment: The cost is a fraction of a fully automatic machine. This keeps your startup costs low and reduces your risk.

- Flexibility: You can change your blow bottle mold in 30 minutes. This means you can make 500ml bottles in the morning and 1.5L bottles in the afternoon. This flexibility is critical for testing your market.

- Faster ROI: Because the cost is low, you get your money back much faster. This cash flow is the lifeblood of a new business.

My Customer Story: The Port Harcourt Strategy

Let me tell you about a client of mine in Port Harcourt. He is a very smart businessman. He started small. He bought a 2-cavity semi-automatic bottle blowing machine from us.

He did not try to compete with the big national brands in supermarkets. Instead, his strategy was B2B (Business-to-Business). He focused on supplying bottled water to local schools, offices, hotels, and event centers. His costs were low. His demand was stable and predictable. He told me he recovered his entire investment in the first year.

This is the model I recommend to many new investors. Start focused. Control your costs. Use a practical machine. Then, once you are profitable, you can use that cash flow to expand. There is also a growing market for high-end, beautifully designed bottles for hotels and restaurants. This requires a better PET bottle mold design, but the profit margins are much higher.

Idea 2: PET Packaging for Local Drinks (Zobo) and Juices?

You see popular local drinks everywhere. Drinks like Zobo, palm wine, and fresh juices. They are often sold in old, returned glass bottles or simple pouches. This seems like a clear opportunity.

This is a huge growth market. But it has one key technical challenge: hot-filling. Many local drinks like Zobo need heat to have a long shelf life. Normal PET bottles will melt. You must solve this technical problem first.

Dive Deeper: The Hot-Fill vs. Cold-Fill Decision

This is one of my specialty areas. The opportunity is massive. Consumers love these local drinks, but they hate the inconvenient packaging. A lightweight, unbreakable, and branded PET bottle is the perfect solution.

But, when a client tells me they want to bottle Zobo, I ask one question: "Will you use a hot-fill process or a cold-fill process?"

This is the most important decision.

- Cold-Fill: This is simple. You can use standard PET bottles. However, your drink will need preservatives, or it will have a very short shelf life (only a few days). This is not ideal for wide distribution.

- Hot-Fill: This is the traditional method for juices and teas. You heat the product to 85-92°C to pasteurize it, killing bacteria. This gives it a long shelf life (6-12 months) with no preservatives.

Here is my warning: Do not use standard PET bottles for hot-fill. I have seen clients make this expensive mistake. The 90°C liquid will cause a normal bottle to shrink, twist, and deform instantly. You will lose your entire production.

The Solution: Heat-Resistant (HR) Bottles

To win in this market, you need "Heat-Resistant" or "Heat-Set" PET bottles.

These are not standard bottles. They are made through a special process.

- Special Mold: The blow bottle mold is heated to a high temperature (120-140°C) during blowing.

- Special Process: This heat "crystallizes" the neck and body of the bottle, making it rigid and stable.

- Special Design: Hot-fill bottles also have special designs, like panels on the side. When the hot liquid cools, it creates a vacuum. These panels "suck in" to absorb the vacuum, so the bottle does not collapse.

The technology is more advanced. But if you are the first person in your market to offer Zobo and local juices in a professional, long-shelf-life PET bottle, you will dominate the market. You will take all the customers who are tired of heavy, breakable glass. This is a real, high-profit opportunity.

Idea 3: Large-Format Bottles for Edible Oil (Palm Oil) & Condiments?

Water bottles seem too small. You want a product with higher profit margins. You see palm oil and groundnut oil everywhere in Nigeria.

Large oil bottles (1L to 5L) are a very profitable business. This is a big B2B or B2C opportunity. But you must know that these large bottles are harder to blow. Your machine and mold quality are critical.

Dive Deeper: The High-Margin Edible Oil Market

Nigeria is one of the world's largest consumers of palm oil, groundnut oil, and other edible oils. Traditionally, this is sold in large, unbranded jerry cans or tins. This packaging is inefficient. It is hard to pour, it can be unhygienic, and it is not good for branding.

This is where PET comes in. A 1L, 3L, or 5L PET bottle is a massive upgrade.

- It is transparent, so customers can see the quality of the oil.

- It is sealed, ensuring hygiene and preventing tampering.

- It is easy to pour and has a handle.

- It provides a large, flat surface for a beautiful brand label.

The profit margin on a 5L oil bottle is often much higher than on a 500ml water bottle. You can run this as a B2B business (selling empty bottles to oil factories) or a B2C business (filling the bottles yourself).

The Technical Challenge of Large Bottles

I must be clear: blowing a good 5-liter bottle is technically more difficult than blowing a 500ml water bottle. When my clients want to make oil bottles, I tell them to focus on two things.

- Stretching Performance: The preform must be heated and stretched evenly over a much larger and taller area. This requires a bottle blowing machine with a powerful, stable, and precise stretching system. If the stretching is uneven, you will get weak spots in the bottle.

- Mold Quality: The mold for a 5L bottle is very large. It must be perfectly sealed. Any small air leak in a large mold becomes a big problem. The handle area is also very complex to get right.

My Customer Story: The Onitsha Oil Trader

I have a great customer in Onitsha. He is a major trader in the Onitsha Main Market. He saw this opportunity years ago. He bought a 1-cavity large-format semi-automatic blowing machine from us. He does not make water bottles. He only makes 3L and 5L edible oil bottles.

His business model is pure B2B. He supplies these empty bottles to all the local oil filling factories and traders in the market. His profits are excellent. Why? Because the technical barrier is higher. Not many of his competitors could figure out how to make a good 5L bottle. He invested in a good machine and good molds, and now he has less competition and very loyal customers. This is a very smart way to build a business.

Idea 4: Household Chemicals & Cosmetics (The High-Value Market)?

You want the highest possible profits. You see a growing demand for premium, locally-made goods. But you are afraid of the technical details and high standards.

This is the high-value, high-profit market. In this segment, customers are buying the "packaging experience," not just the product. The key is precision. The bottle neck and thread must be perfect, or the pump will leak and ruin your brand.

Dive Deeper: Selling the "Packaging Experience"

This is a market I personally love. We are not talking about a commodity like water. We are talking about high-value products:

- Hand Soaps

- Shampoos and Conditioners

- Body Lotions

- Hand Sanitizers

- Liquid Detergents

- Pharmaceutical syrups

In this market, the bottle is the brand. It sits in a person's bathroom or kitchen for weeks. It must look and feel like a quality product. This means you need unique shapes, beautiful colors, and a design that stands out.

The "Tyranny of the Neck": Why Precision is Everything

This is my core advice for anyone entering this market: Focus on the neck.

Almost all of these products use a pump, a sprayer, or a special flip-top cap. If the thread on the bottle's neck is even 0.1mm off, the cap will not seal. It will leak.

Imagine a customer buys your expensive lotion. They put it in their handbag, and it leaks everywhere. You have not just lost that customer. You have lost all their friends, too. Your brand is damaged.

This is the ultimate test of your supplier's blow bottle mold making ability. The precision of the neck and thread is everything. When you discuss this with a supplier, you need to talk about specific neck sizes, like 28/410 or 24/410. I recommend reading a guide on how to choose the right preform neck size, because this is a critical detail.

Design, Prototyping, and My Lagos Customer

To stand out, you need a custom design. A stock bottle will not work. This is where a good partner is important. We have a complete PET bottle mold design guide that walks you through this process.

A service my high-value clients love is 3D printed sampling. Before we cut any expensive steel for the mold, we 3D print a perfect model of the bottle. We mail it to you. You can hold it, feel it, and test your exact pump or cap on it. This step saves thousands of dollars and weeks of time.

I have a client in Lagos who is a leader in this space. She targets the high-end cosmetics market. She ordered several custom shampoo and lotion molds from us. We spent weeks working with her and her pump supplier just to perfect the neck thread. Today, her products sell for a huge premium. Her success comes from her smart marketing and her investment in that perfect, high-precision packaging.

Idea 5 (Expert Tip): Become a PET Preform Supplier?

Blowing bottles seems like a lot of work. You have to manage many different customers and bottle types. What if there is a simpler, more focused, B2B business model?

This is the "sell the shovels" business. Instead of blowing bottles, you make and sell the PET preforms. The initial investment is much higher, but so are the barriers to entry. This means less competition.

Dive Deeper: The "Sell the Shovels" Strategy

During the gold rush, the people who made the most money were not the miners. They were the people who sold the shovels, picks, and jeans. This is that business.

What is a preform? It is the small, test-tube-shaped piece of plastic that is the starting material for every PET bottle. Preforms are not made in a blow molding machine. They are made in an injection molding machine.

Your customers are all the other people I just described: the water bottlers, the juice makers, and the oil fillers. Right now, most of these small and medium-sized factories in Nigeria must import their preforms. This is expensive, slow, and requires a lot of cash to be tied up in shipping.

If you become a local, reliable, high-quality preform supplier, you will be a hero. You save your customers time, money, and headaches. They will be incredibly loyal.

The Investment: Why This is a "High-Barrier" Business

This is not a cheap business to start. This is its biggest advantage. The high cost creates a "barrier to entry" that keeps out casual competition.

You need three main things:

- A PET Injection Molding Machine: This is a large, expensive machine.

- A High-Quality Preform Mold: This is the heart of the business. You do not buy a 2 or 4-cavity mold. You buy a preform mold with 16, 32, or even 48 cavities. These are complex, high-precision tools that cost a lot but produce preforms for a very low cost.

- Auxiliary Equipment: You must have a large PET resin dryer and dehumidifier. You cannot make good preforms without them.

The initial investment is high. But your cost per preform is very low. You make money on volume.

Why This is a Great Long-Term Business

I have helped set up a few of these plants. It is a very stable, B2B business. Your customer list is smaller, but they buy from you every single week. They depend on you. They cannot easily switch suppliers because you are local, and your quality is consistent.

This "customer stickiness" is extremely valuable. While your competitors are fighting over 1-Naira differences in bottle prices, you are the one supplying the raw material to everyone. It is a powerful, protected, and profitable position in the market. If you have the capital, this is one of the smartest long-term plays.

How to Choose the Right Machine for Your Nigerian Business? (Investment Estimates)?

You are convinced. You have an idea. Now you need to buy the equipment. You see "semi-auto" and "fully-auto." The choices are confusing, and you are afraid of making an expensive mistake.

My advice for 90% of Nigerian startups is to be practical. Start with a semi-automatic machine. The investment is much lower. You are more flexible. You can test your market and start making cash flow faster.

Dive Deeper: The Big Decision (Semi-Auto vs. Fully-Auto)

This is the first question every investor asks me. Let's break it down with real numbers.

1. Semi-Automatic Machines

This is a 2-step machine. An operator places the preforms into the heater (oven) by hand. Then they move the hot preforms into the blowing machine, which blows the bottle automatically.

- Pros:

- Low Cost: A good 2-cavity or 4-cavity semi-auto line (including molds) can be $10,000 - $30,000.

- Flexibility: You can change the blow bottle mold in 30-60 minutes. This is perfect for making many different bottle types.

- Simple Maintenance: The systems are simpler and easier for local technicians to repair.

- Cons:

- Labor: You need 1 or 2 operators.

- Speed: Lower output, typically 800-2000 bottles per hour (BPH).

2. Fully-Automatic Machines

This is a 1-step machine. You dump a large box of preforms into a hopper. The machine does everything else automatically: feeding, heating, blowing, and exiting the bottles.

- Pros:

- High Speed: Very fast, from 4,000 to 10,000+ BPH.

- Lower Labor (per bottle): Requires at least one operator/supervisor to monitor the process and add preforms, but the labor cost per bottle is much lower than semi-auto.

- Cons:

- High Cost: A high-speed line can cost $80,000 to $300,000+.

- Inflexible: A mold changeover can take 4-8 hours and requires a highly-skilled engineer.

- Complex: Much more complex to maintain.

| Feature | Semi-Automatic Machine | Fully-Automatic Machine |

|---|---|---|

| Initial Cost | Low ($10k - $30k) | High ($80k - $300k+) |

| Speed (BPH) | 800 - 2,000 | 4,000 - 10,000+ |

| Labor Needed | 1-2 Operators | At least 1 Operator/Supervisor |

| Flexibility | Very High (Fast mold changes) | Very Low (Slow changeovers) |

| My Advice for Nigeria | Best for 90% of Startups | Only for high-volume, single-product lines |

The "Total Solution" (What People Forget to Buy)

Warning: The bottle blowing machine is only one part of your factory. A cheap machine is useless if you forget the "auxiliary" equipment. This is what we provide as a "Turnkey Solution."

You must also buy:

- A High-Pressure Air Compressor: This is the "lungs" of your factory. It creates the 30-bar air to blow the bottle. Do not get a cheap one. We can help you configure a cost-efficient air system.

- A Water Chiller: This is the "kidneys." It pumps cold water through your mold. This is not optional. A chiller is required to cool the plastic instantly. Without it, your bottles will be soft and melt.

- Air Filters: To clean the air before it enters the bottle.

My practical advice for startups is this: Be pragmatic. Do not spend all your capital on a fancy full-auto machine. You will have no money left for preforms, bottle caps, or a good generator. Start with a high-quality 4-cavity semi-auto. Learn the business. Build your customer base. Make money. Then, use your profits to upgrade. This is the path to real success.

Your Reliable Partner: How iBottler Can Power Your Nigerian Business?

You need to buy a machine. But you are buying it from a factory in China. You are worried. Will I get bad quality? Will there be no support? What about customs problems and SONCAP?

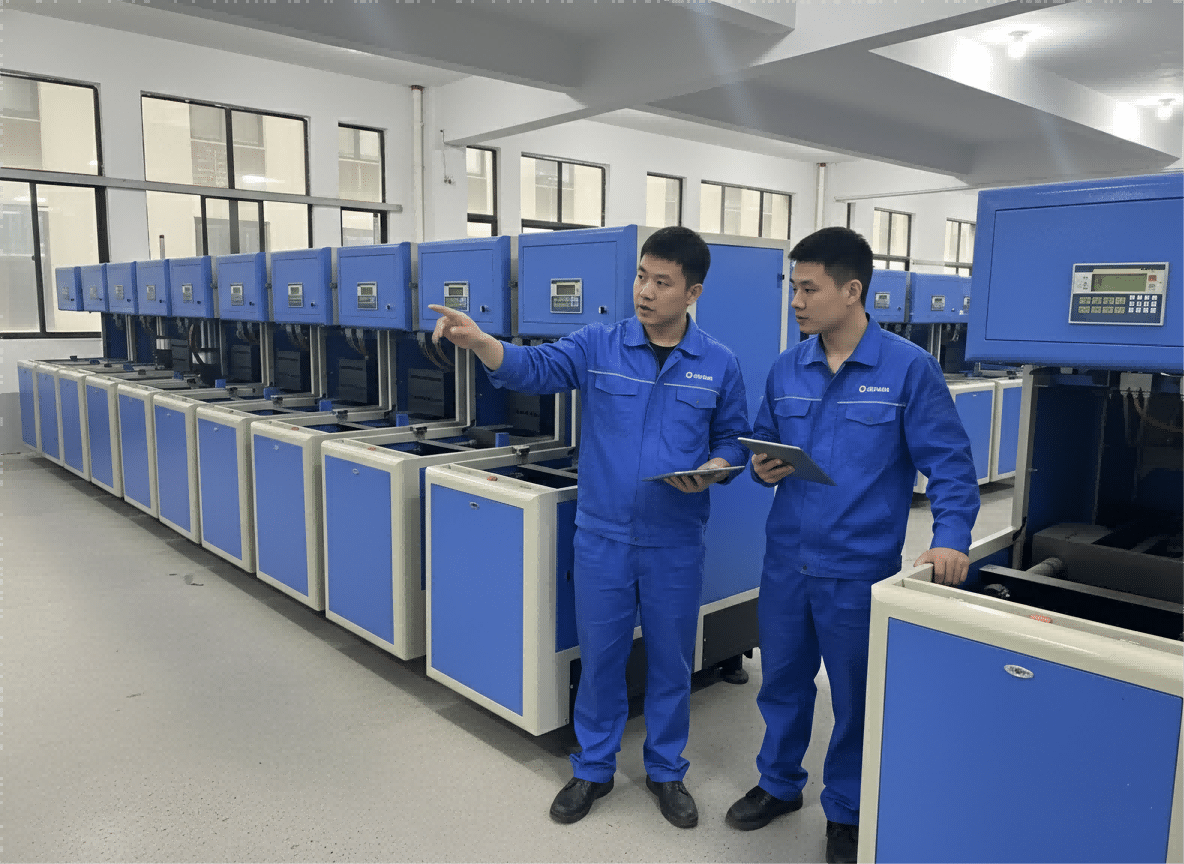

Choosing a partner is more important than choosing a machine. As a 20-year manufacturing factory (www.ibottler.com), we know the Nigerian market. We provide specific solutions for unstable power, full support with SONCAP, and lifetime remote service.

Dive Deeper: We Are a 20-Year Factory, Not a Trading Company

This is the most important thing I can tell you. I am Vivian. My company is iBottler (www.ibottler.com). We are not a "trading company" that finds a cheap machine and sells it to you. We are a 20-year-old engineering factory. We design and build these machines. We have been working with Nigerian clients for decades.

This experience is your biggest advantage. We know the real problems you will face in Nigeria, not just the "textbook" problems. And we have already built the solutions.

Our "Nigeria-Specific" Solutions

When you buy a machine from us, it is different from a standard machine. We have "Nigeria-Specific" upgrades.

1. The Unstable Power Solution:

We know that industrial electricity in Nigeria is often unstable. The voltage spikes and drops. This can burn out the electronics (like the PLC and heater) on a standard machine.

- Our Solution: Every machine we ship to Nigeria is equipped with a high-standard voltage stabilizer. We use more robust, durable electrical components that are designed to handle this stress. Our machines are built to survive in your exact environment.

2. The SONCAP & Customs Solution:

We are experts in Nigeria's SONCAP certification process. We know it can be confusing.

- Our Solution: We provide the full set of documents you need. We work with your clearing agent. We know exactly what forms and numbers are required. We guarantee your machine will clear customs smoothly. You will not have extra troubles or delays.

3. The "No Local Engineer" Solution:

We know it is hard and expensive to find a local technician who is an expert in PET blow molding.

- Our Solution: We provide world-class remote service.

- Clear Labels: Every wire, pipe, and part on our machine is clearly labeled in English.

- Detailed Videos: We send you detailed videos for installation, operation, and maintenance.

- Live Video Support: If you have a problem, you video-call me or my engineers. We will look at the machine with you and tell you exactly what to do. We can help you fix common PET blowing defects over a simple WhatsApp call.

A Partner, Not Just a Seller

When you buy from us, you are not just buying a machine. You are buying a complete, "turnkey" solution.

- We help you plan your factory layout.

- We help you design your bottle.

- We make sure your mold and machine fit perfectly.

- We are your partner for the entire life of the machine.

We provide a complete solution, from your first idea to stable, profitable production. Welcome to contact us. Let's get your exclusive investment analysis for Nigeria.

Conclusion

Nigeria's 2025 PET packaging market is full of opportunities. The demand is clear and growing. Success depends on picking the right idea, starting with a practical machine, and choosing a partner who truly understands Nigeria.

Summary of Nigerian PET Business Opportunities

| Business Idea | Key Challenge | Recommended Machine | Profit Potential |

|---|---|---|---|

| 1. Bottled Water | High competition | Semi-Auto (2/4 Cavity) | Stable / High Volume |

| 2. Zobo / Juices | Hot-Fill Technology | Semi-Auto (Heat-Set Molds) | High |

| 3. Edible Oil (5L) | Large bottle quality | Semi-Auto (1-Cavity Large) | High |

| 4. Cosmetics | Neck thread precision | Semi-Auto (High-Precision Mold) | Very High |

| 5. Preform Supplier | High initial capital | Injection Molding Machine | Very High (B2B) |

Frequently Asked Questions (FAQs)

1. What is the minimum cost to start a small water bottling business in Nigeria?

To be practical, you should budget for a complete system. A good startup "turnkey" package from us, including a 2-cavity semi-automatic machine, a blow bottle mold, a high-pressure compressor, and a water chiller, starts around $15,000 to $20,000. This does not include your factory building, generator, or water filtration system.

2. Do I really need a full-auto machine, or is semi-auto better for Nigeria?

For 90% of startups in Nigeria, I strongly recommend starting with a semi-automatic machine. The investment is much lower, the flexibility is higher, and you will get a return on your investment much faster. Only consider a fully-automatic machine if you have a guaranteed high-volume contract for a single bottle type.

3. What is SONCAP, and do you help with it?

SONCAP is a mandatory certification from the Standards Organisation of Nigeria (SON) required for most products imported into Nigeria, including our machines. Yes, we are experts in this. We provide all the necessary test reports and documentation to ensure your machine is fully compliant and clears customs without any problems.

4. How do I handle the unstable electricity for my machine in Nigeria?

This is a critical problem we have solved. We specifically equip all machines going to Nigeria with high-quality voltage stabilizers and robust electrical components that are designed to withstand the power fluctuations common in the industrial grid.

5. Can I make both 500ml water bottles and 5L oil bottles with the same machine?

No. These two bottles are very different. A machine designed for small bottles (like 500ml, using a 2 or 4-cavity semi-auto) cannot stretch and blow the large preform and body required for a 5L bottle. You need a dedicated machine for small bottles and a dedicated machine for large bottles (like a 1-cavity or 2-cavity large-format machine). We can help you choose the correct equipment.

PET bottle business ideas Nigeria, how to start bottling plant in Nigeria, PET packaging market in Nigeria, high-profit business in Nigeria 2025, blow molding machine price in Nigeria, plastic bottle manufacturing business Nigeria, PET preform mold supplier, water bottling plant cost Nigeria, business opportunities in Nigeria, iBottler Nigeria

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr