Starting your PET bottle line? You need the right mould, but the options are confusing. A 2 cavity mould is a common starting point, but which one is right for you?

A 2 cavity PET bottle mould is a tool that produces two identical PET bottles every time the bottle blowing machine completes one cycle. The "2 cavity" name is determined by the blowing machine it is designed for, not just the mould itself.

Understanding this basic definition is the first step. Now, we must look deeper at how these moulds are built, what they are made of, and how much they cost. This guide will walk you through every detail you need to know before you buy.

What Exactly Is a 2 Cavity PET Bottle Mould?

You know you need a 2 cavity mould, but why? The definition seems simple, but it directly impacts your production numbers. Understanding this helps you plan your output.

A 2 cavity PET bottle mould is a mould set designed specifically for a 2-cavity bottle blowing machine. This means every time the machine opens and closes (one cycle), it produces two finished bottles. This setup is ideal for small to medium-scale production.

This definition is important because the mould is always secondary to the machine. In my experience, clients already have their blowing machine, or they are buying it at the same time. The machine's specification dictates the mould's specification. If you buy a 2-cavity machine, you must buy a 2-cavity mould.

Why the Machine Dictates the Mould

This is a common point of confusion for new clients. I often get asked, "Can I buy a 4-cavity mould for my 2-cavity machine to make more bottles?" The answer is always no.

A 2-cavity bottle blowing machine is built with hardware for two bottles. This means:

- It has two stretch rods (to stretch the preforms).

- It has two blow pins (to inject high-pressure air).

- Its heating zone continuously heats preforms, but the heating channel and lamp layout are optimized for the production rhythm of 2 cavities.

- The clamping unit is designed for the size and weight of a 2-cavity mould.

Most importantly, a 2-cavity machine has a fixed "cavity pitch." This is the exact distance between the center of the first cavity and the center of the second cavity. The blow bottle mold must be machined to this exact distance. You cannot fit a 4-cavity mould onto a 2-cavity machine.

Calculating Your Real-World Production

The "2 cavity" definition is not just technical. It is the core of your business plan. It tells you your maximum potential output. Let's use a real-world example.

I worked with a startup client in Kenya. They bought a 2-cavity semi-automatic blowing machine to produce 500ml water bottles. We needed to calculate their real output.

A semi-automatic machine relies on a worker. The cycle includes:

- The worker manually loads two heated preforms into the mould.

- The worker presses the buttons to close the mould, stretch, and blow.

- The mould stays closed for the "cooling time" (e.g., 3-4 seconds) to set the plastic.

- The mould opens, and the worker manually removes the two finished bottles.

A skilled, motivated worker can get this entire cycle down to 7 or 8 seconds. Let's do the math:

- Time per cycle: 8 seconds

- Cycles per minute: 60 seconds / 8 seconds = 7.5 cycles

- Bottles per cycle: 2

- Total bottles per minute: 7.5 cycles * 2 bottles = 15 bottles

- Total bottles per hour: 15 bottles/minute * 60 minutes = 900 bottles

So, I could tell my client that with one 2-cavity semi-auto machine and one good worker, he could realistically produce 900 to 1,000 bottles per hour. This number is a direct result of the "2 cavity" definition.

Semi-Auto vs. Full-Auto Output

This calculation changes for a 2-cavity fully-automatic linear machine. This machine does not rely on a worker. Preforms are automatically sorted and loaded by a preform unscrambler, and finished bottles are removed by a gripper.

The cycle time is faster and more consistent. It might be 3-3.5 seconds.

- Time per cycle: 3 to 3.5 seconds

- Hourly Output (at 3.5 sec): (3600 sec / 3.5 sec) * 2 bottles ≈ 2057 bottles

- Hourly Output (at 3.0 sec): (3600 sec / 3.0 sec) * 2 bottles = 2400 bottles

- Total bottles per hour: Therefore, a 2-cavity fully-auto machine typically has an actual output of 2,000 to 2,400 bottles per hour.

Even though both are "2 cavity," the machine type changes the output from 900 to 2,000-2,400 bottles per hour. This also means the mould structure is completely different, which we will cover next.

The main takeaway is this: "2 cavity" is your production multiplier. It is fixed by your machine. Your main goal is to make the cycle time as short as possible. This depends on the worker (for semi-auto) and the mould's cooling efficiency (which we control with material and design).

Mould Types: Semi-Automatic vs. Fully-Automatic (Structure is Key)?

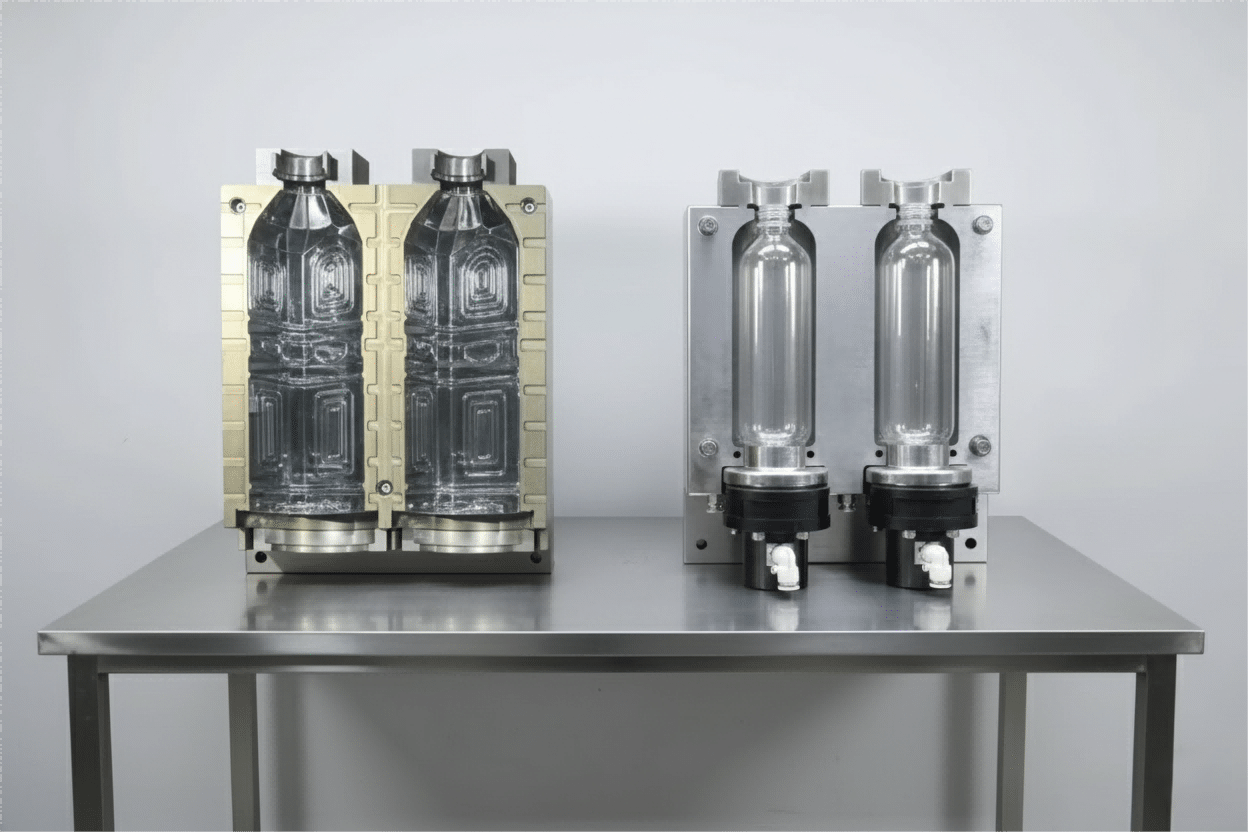

You see two moulds, both "2 cavity." One costs much more. Why? The structures are completely different. Choosing the wrong one means it will not fit your machine at all.

Semi-automatic moulds are simple, light, and rely on the machine's clamps. Fully-automatic linear moulds are heavy and complex. They have a thick "back plate" with precise mounting holes or slots designed to lock into a specific machine brand (like Ribo, etc.).

This is the most critical technical difference a buyer must understand. I have seen clients waste thousands of dollars by ordering the wrong type.

The Semi-Automatic Mould Structure

A 2-cavity semi-automatic blow bottle mold is the simpler and cheaper of the two.

- Structure: It consists of the main mould body (the "A" and "B" sides, which hold the cavity shape) and often a separate bottom mould piece.

- Mounting: It is designed to be mounted directly onto the machine's clamping platens, usually with simple bolts or small clamps.

- Weight: It is built to be as light as possible. While still heavy, the design avoids extra, unnecessary metal.

- Locking: The machine's clamping unit provides all the locking force to keep the mould closed during blowing. The mould itself has no complex locking mechanism.

- Best For: This mould is perfect for startups, small-scale production, or when you need to produce many different bottle shapes with low volume for each.

The Fully-Automatic Linear Mould Structure

This is a much more complex and expensive piece of engineering. It is designed for high-speed, 24/7 production.

- Key Feature: The Back Plate. The most obvious difference is a thick, heavy, precision-machined plate on the back of each mould half.

- Purpose of the Back Plate: This plate is the interface between the mould and the blowing machine's clamping unit. It is not optional.

- Brand-Specific Mounting: This is the crucial part. Different machine brands (like Ribo, Sidel, Krones, etc.) have different mounting systems.

- Some use a "quick-change" system with T-slots. The mould's back plate must be perfectly machined to slide and lock into these slots.

- Others use a specific pattern of large bolt holes. The mould's back plate must have these holes drilled in the exact locations (within 0.01mm) to match the machine.

- Complexity: This complexity is why the price is 1.2x to 1.4x higher. It requires much more raw material (the big plate) and many hours of high-precision CNC machining.

My Warning: They Are 100% Not Interchangeable

I must be very clear here. A client once bought a 2-cavity semi-auto machine to start. Two years later, his business grew, and he bought a new, expensive 2-cavity fully-automatic linear machine.

He called me and asked, "Can I adapt my old semi-auto moulds to fit my new linear machine?"

The answer is absolutely not.

- Mounting: There is no way to safely and accurately mount a simple semi-auto mould (which has no back plate) onto the complex T-slot or bolt-hole system of a linear machine.

- Alignment: The alignment systems are totally different.

- Safety: Trying to "make it fit" is extremely dangerous. A linear machine runs at high speed and high pressure. A poorly-mounted mould could shift or even fly off, destroying the machine and injuring operators.

When you buy a mould, you MUST tell the supplier the exact brand and model of your machine. At iBottler, we have a large library of mounting dimensions for 80% of the machines worldwide. If we don't have it, we require the client to send us the machine's official mould-mounting drawings. This is non-negotiable for a successful project.

Here is a simple table to summarize the differences.

| Feature | 2-Cavity Semi-Automatic Mould | 2-Cavity Fully-Automatic Linear Mould |

|---|---|---|

| Structure | Simple, lighter weight, no back plate. | Complex, very heavy, with a thick back plate. |

| Mounting | Clamped/bolted directly to machine platens. | Mounts via precision holes or slots in the back plate. |

| Machine Fit | More generic fit for "semi-auto" machines. | Brand-specific. Must match Ribo, Sidel, etc. |

| Compatibility | NOT compatible with fully-auto machines. | NOT compatible with semi-auto machines. |

| Cost | Base price (e.g., $600 for 500ml). | 1.2x to 1.4x base price (e.g., $720 - $840 for 500ml). |

| Best For | Startups, lower volume, flexible production. | High-speed, high-volume, continuous 24/7 production. |

Mould Material Guide: 7075 Aluminum vs. S136 Stainless Steel?

Your mould's material seems like a small detail. But it controls your production speed and bottle quality. Choosing the wrong one means slow cycles or rusty moulds.

7075 Aluminum is the standard for high-speed production (like water bottles) because it cools very fast. S136 Stainless Steel is a premium, harder material used for mirror-polish bottles (cosmetics) or for its extreme lifespan and rust-proof qualities.

This is a key decision that impacts price, lifespan, and performance. As a professional mould maker, we have stopped using older, cheaper materials like P20 or S45C steel. They rust easily and have very poor cooling. The choice today is almost always between 7075 and S136.

The Case for 7075 Aviation Aluminum

This is now the most common, mainstream material for high-quality PET blow moulds.

- Key Advantage: Heat Dissipation. 7075 Aluminum transfers heat extremely well. It is much better than any steel.

- Why This Matters: In blow molding, the longest part of the cycle is "cooling time." This is the time the mould must stay closed to cool and "set" the hot plastic bottle.

- Benefit: Because 7075 aluminum pulls heat away from the bottle faster, you can shorten the cooling time. This shortens the total cycle time.

My Case Study (The Water Plant):

I had a large water bottling client in the Middle East. They run their machines 24/7 and efficiency is everything. They were using old P20 steel moulds. We built them new 2-cavity moulds made from 7075 Aluminum.

We optimized the cooling channels for the new material. They successfully cut their average cycle time by 0.5 seconds.

This sounds small. But for them:

- 0.5 seconds saved per cycle on a 6-second cycle is a huge 8% production increase.

- This meant they could produce hundreds more bottles every hour, 24 hours a day.

- The extra profit from the new production paid for the new moulds in just a few months.

7075 Aluminum is also easier and faster to machine, which means we can deliver the mould to the client faster.

The Case for S136 Stainless Steel

S136 is a different type of high-end material. It is a stainless steel that must be hardened with a special heat-treatment process. Its advantages are different.

- 1. Mirror Polish: S136 can be polished to a true, flawless mirror finish. 7075 can be polished to be shiny, but not to this level. This is essential for high-end cosmetic or luxury spirit bottles, where the bottle plastic needs to be crystal clear and glossy.

- 2. Extreme Lifespan: After heat treatment, S136 is extremely hard and durable. It resists wear and tear. It can last for 10 million cycles or more.

- 3. 100% Rust-Proof: This is a major factor for many factories.

- Environment: Many workshops are in high-humidity (tropical) climates.

- Water Quality: The cooling water from the chiller might be hard or have impurities.

My Case Study (The Chemical Client):

We had a client in Southeast Asia making high-transparency shampoo bottles. His factory was very humid, and the local water quality was not good. His old P20 steel moulds were a disaster. The mould surfaces were rusting, leaving marks on the bottles. The cooling channels were clogged with rust, which made his cooling time very slow.

We built him new 2-cavity moulds from S136 Stainless Steel. Five years later, he sent me a photo. The moulds look brand new. The cooling channels are perfectly clean, and the bottle surface is still flawless. For him, S136 was the only correct choice.

Why We Don't Use P20 or S45C Steel Anymore

You might get a very cheap quote from a small workshop. They are almost certainly quoting you P20 or S45C (a basic carbon steel).

We, and most professional factories, no longer use these materials for PET blow moulds for two simple reasons:

- They RUST. The mould surface will rust. The cooling channels will rust. This will destroy your bottle quality (black spots, rough surface) and block your cooling, leading to common PET blow molding defects.

- They Have Bad Cooling. They transfer heat very slowly. Your cycle times will be very long, and your production will be low.

The small amount you save on a P20 mould, you will lose 100 times over in lost production and returned products.

| Material | Best For | Key Advantage | Key Disadvantage |

|---|---|---|---|

| 7075 Aluminum | Water, CSD, Juice (High Speed) | Fastest Cooling (shorter cycles, more output) | Softer than steel (less lifespan for abrasion) |

| S136 Stainless | Cosmetics, High-End Water, Humid Plants | Mirror Polish, 100% Rust-Proof, Long Life | Slower cooling than 7075, higher cost |

| P20 / S45C Steel | (Not Recommended) | Very Cheap | RUSTS easily, very slow cooling, low quality |

Data You Must Provide Before Customizing a 2 Cavity Mould?

You want to order a mould. You send an email: "I need a 2 cavity mould." This is not enough. A factory cannot quote this. Providing the right data first saves weeks of back-and-forth emails.

To get a correct mould, you must provide: 1) The bottle drawing or sample. 2) The preform information (weight and neck size). 3) The bottle's application (water, CSD, or hot-fill). 4) Your blowing machine's exact specs, especially the Cavity Pitch.

A blow bottle mold is a 100% custom-made tool. It is not an off-the-shelf product. To make it right the first time, we need a complete data sheet. As a mould maker, this is the information I must have from you before my engineers can start.

Item 1: The Bottle (Drawing, Sample, or Idea)

This is the most obvious one. We need to know what to make.

- Best: A 3D file (like .stp, .igs, or .x_t) is the best.

- Good: A 2D drawing with all dimensions (height, diameter, volume) is the minimum.

- OK: You can ship us a physical sample. We will 3D scan it to create the drawings.

- We can help: If you only have an idea, our PET bottle mold design team can help. We can create 3D designs for you. We can even provide 3D printed samples for you to hold and check before we make the metal mould.

Item 2: The Preform (Weight and Neck Size)

The mould must be designed to match your preform.

- Preform Weight (in grams): This determines the wall thickness. A 12g preform cannot make a 500ml bottle designed for a 16g preform. The stretch ratio will be too high, and the bottle will be weak or have holes.

- Preform Neck Size: This is critical. Is it PCO 1881? 30/25? 28mm PCO 1810? The mould's neck area (the "neck finish") is machined to match this exact standard. If this is wrong, your caps will not fit or will leak. This is a very common and costly mistake. You must know your preform neck size.

Item 3: The Application (Water, CSD, Hot-Fill)

We must know what will go inside the bottle. A mould for water is different from a mould for Coca-Cola. A mould for 85°C hot-fill juice is completely different. This affects the bottle base design, body design, and cooling system, which we will cover in the next section.

Item 4: The Machine Specs (Especially Cavity Pitch)

This is the one clients miss most often. I need this information, especially for fully-automatic machines.

- Machine Type: Semi-automatic or Fully-automatic?

- Machine Brand and Model: (e.g., "Ribo, 2-cavity linear, Model XYZ")

- Cavity Pitch: This is the most important number for a 2-cavity mould.

What is it? It is the exact distance from the center of cavity 1 to the center of cavity 2.

Why is it vital? Your blowing machine has two stretch rods (the metal rods that pull the preform down). These rods are in a fixed position. Their center-to-center distance is the machine's cavity pitch. Your mould's cavity pitch must match the machine's stretch rod pitch perfectly.

My Case Study (The 0.5mm Disaster):

I had a client who gave us his cavity pitch number from memory. He was off by only 0.5mm.

When he installed the mould in his fully-automatic machine, the stretch rods were not aligned with the center of the preforms. When he started the machine, the rods smashed into the top of the mould.

He destroyed his stretch rods and badly damaged the new mould. It was a disaster, all because of a 0.5mm error.

On a semi-auto machine, the stretch rods can sometimes be adjusted a little. But on a fully-auto linear machine, there is zero room for error.

At iBottler, we help clients double-check this. We have the mounting dimensions for 80% of major machines. We will ask you to measure and confirm before we cut any metal.

Application Matters: Designing for Water, CSD, and Hot-Fill?

You think a 500ml bottle mould is just one mould, right? Wrong. A mould for water will fail if you use it for cola. A mould for juice will deform if not designed correctly.

The bottle's contents change the mould design completely. Water moulds focus on being lightweight. Carbonated (CSD) moulds need a "petaloid" (flower-shaped) base to handle pressure. Hot-fill moulds need special panels to prevent the bottle from collapsing.

-1.jpg)

The design of the mould cavity is not just about looks. It is about physics. The mould must create a bottle that can perform its job safely.

Water Bottle Moulds: Lightweight and Fast

This is the most common application.

- Design Goal: The two goals are light-weighting and speed.

- Light-weighting: PET resin (the plastic) is the biggest cost. The goal is to use the lightest possible preform (e.g., 12g for 500ml) and stretch it perfectly to create a strong bottle. The mould's base design (often a simple "champagne" base) is critical for this.

- Speed: Water is a high-volume, low-margin product. Production must be fast.

- Mould Solution: We use 7075 Aluminum for its fast cooling. We design many efficient cooling channels to shorten the cycle time. The design is simple and robust.

CSD (Carbonated) Bottle Moulds: Strong and Pressurized

This is for products like Coca-Cola, Pepsi, or sparkling water.

- Design Goal: The bottle must withstand high internal pressure (from the CO2 gas) without deforming or bursting, even when it gets warm.

- Mould Solution:

- 1. Petaloid Base: Look at the bottom of a Coke bottle. It has 5 "feet." This is a "petaloid" base. This specific shape is engineered to distribute the pressure evenly. The mould cavity must be machined to create this exact, complex shape.

- 2. Material: Because the blowing pressure for CSD is often higher (up to 40 bar) than for water (25-30 bar), the mould needs to be very strong. We often recommend S136 heat-treated steel for CSD moulds to ensure a very long life under high stress.

- 3. Venting: The mould must have very good, well-placed vent lines to let air escape as the plastic expands rapidly.

Hot-Fill Bottle Moulds: Resisting Vacuum

This is for products like juice or tea that are filled at a high temperature (e.g., 85°C / 185°F).

- Design Goal: This is the most complex. The bottle must withstand two forces:

- The high heat during filling (which tries to soften it).

- The negative pressure (vacuum) that forms as the hot product cools. If not designed correctly, the bottle will suck in on itself and collapse.

- Mould Solution:

- 1. "Panels": The mould is designed with special "flex panels" in the bottle body. These are flat, flexible areas designed to suck in in a controlled way. This absorbs the vacuum, so the rest of the bottle keeps its shape.

- 2. Base: The base is also a special design to help absorb this vacuum.

- 3. Cooling: This is the most critical part. A hot-fill mould needs an extremely efficient and complex cooling channel system. We use S136 steel (which handles high temps well) and run advanced flow analysis to make sure the chiller's water cools the mould cavity perfectly and evenly. This sets the hot plastic quickly and prevents warping.

You cannot use a water bottle mould for hot-fill. The bottle will collapse every time. The application is the most important part of the PET bottle mold design.

2025 Price Guide: Real Cost of a 2 Cavity PET Mould?

You need a price. You get quotes from $300 to $3,000. Why? The cheapest quote is often a trap. You need to know the real cost of a quality mould.

A 2-cavity semi-automatic mould for a 500ml bottle costs around $600 USD. A large 5L mould is around $2,000. A fully-automatic mould will cost 1.2 to 1.4 times more than a semi-auto one. Upgrading from 7075 Aluminum to S136 Steel also increases the price.

Price is always a major question. I believe in being transparent with my clients. A price is not just a number; it is the sum of the material, the machining time, and the service.

Baseline Price: Semi-Automatic Moulds

The simplest way to price a semi-auto mould is by bottle volume. A larger bottle means a larger, heavier mould. It uses more material and takes more time on the CNC machine.

Here is a realistic 2025 price guide for a 2-cavity semi-automatic mould, based on high-quality 7075 Aluminum:

- 2-Cavity (500ml - 1L): ~$600 USD

- 2-Cavity (1.5L - 2L): ~$1,000 - $1,200 USD

- 2-Cavity (5L): ~$2,000 USD

- 2-Cavity (10L): ~$2,800 - $3,000 USD

If you get a quote for a 500ml mould for $300, you must be very careful. It almost certainly means they are using cheap, recycled, or incorrect material like P20 steel, which will rust and give you slow cycles.

The Price Multiplier: Fully-Automatic Moulds

As we discussed, a fully-automatic mould is much more complex. It needs the heavy back plate and precision mounting system.

The price is calculated from the semi-auto base price plus a multiplier.

Full-Auto Mould Price = (Base Semi-Auto Price) x (1.2 to 1.4)

- Example 1:

- A 2-cavity, 500ml semi-auto mould is $600.

- A 2-cavity, 500ml fully-automatic mould for a certain brand of 2-cavity machine would be $600 x 1.3 = $780 USD.

- Example 2:

- A 2-cavity, 5L semi-auto mould is $2,000.

- A 2-cavity, 5L fully-automatic mould would be $2,000 x 1.3 = $2,600 USD.

This extra cost pays for the large, thick back plate and the many hours of high-precision CNC work to make it fit your machine brand perfectly.

The Price Adjuster: Material Choice

The prices above are for our standard, high-quality 7075 Aluminum.

If your application needs S136 Stainless Steel (for mirror polish or 100% rust-proofing), the price will be higher.

Why?

- S136 material itself is more expensive per kg.

- It is much harder, so it takes more time to machine on the CNC.

- It requires a separate, multi-day heat-treatment process.

- It takes much, much longer to polish to a mirror finish.

You can expect a 20% to 40% price increase to upgrade from 7075 to S136. This is a necessary cost for the high-end applications that demand it.

What's Included in a Good Price?

When I give a price, it's not just for the metal. A quote from a professional factory like iBottler includes:

- Guaranteed Material: We provide a material certificate. You are getting real, solid 7075 or S136, not fake P20.

- High-Precision Machining: Our CNC work ensures your mould's parting line (where the halves meet) is smooth. This means no sharp edges or "flash" (extra plastic) on your bottle.

- Lifespan Guarantee: We guarantee our moulds for a minimum number of shots (e.g., 3 million cycles).

- Free Spare Parts: We include a spare parts kit with every mould. This includes high-quality O-rings, seals, and water/air connectors. These small parts wear out, and having them on hand saves you from a shutdown.

The cheap $300 mould includes none of this. It will rust in 6 months, produce bad bottles with defects, and have no after-sales support.

Beyond Manufacturing: iBottler's Custom Design & Service?

You have an idea for a bottle, but no drawing. Or you are new to this and worried about setup. A cheap supplier just ships a box. A good partner helps you succeed.

We are not just a factory. We offer a complete service. We can take your simple idea, create a professional 3D PET bottle mold design in 24 hours, and provide 3D printed samples for you to approve before we make the mould.

Buying a mould can be stressful, especially for a new business. Our goal at iBottler is to remove that stress and become your partner, not just your supplier.

Our Process: From Idea to Production

We have a clear, step-by-step process to ensure you get exactly what you need.

- Step 1: Consultation & Idea. You come to us. Maybe you only have a photo, a competitor's bottle, or just an idea ("I want a 500ml bottle that looks premium and has my logo").

- Step 2: 3D Bottle Design (24 Hours). Our engineering team gets to work. Within 24 hours, we will send you a professional 3D drawing of a proposed bottle shape. We can revise this with you until it is perfect.

- Step 3: 3D Printed Sample (Optional). It can be hard to judge a bottle on a computer screen. We can 3D print a physical 1:1 sample and mail it to you. You can hold it, test the grip, and show it to your local partners.

- Step 4: Mould Structure Design. Once you approve the bottle shape, our mould engineers design the full 2-cavity mould in CAD/CAM software. They design the optimized cooling channels, the mounting system for your machine, and the venting.

- Step 5: Manufacturing. The design goes to our workshop. This involves high-speed CNC machining, precision grinding, hand polishing, and careful assembly.

- Step 6: In-House Testing. This is a key step. We install the finished mould on one of our own test bottle blowing machines in our factory. We connect the chiller and air compressor. We run the mould and produce actual bottles. We check the bottles for any problems and make final adjustments.

- Step 7: Sample & Shipment. We send you the final bottle samples from the test run. Once you approve them, we professionally clean, oil, and pack the mould in a secure wooden box and ship it to you, along with the free spare parts kit.

Case Study 1: The Lightweighting Project

We had a long-term client in Europe who was producing 18-gram water bottles. The bottle was an old design. He asked us, "The price of PET resin is high. Can you help me reduce my costs?"

Our design team took his 18g bottle and ran a computer analysis. We found that by optimizing the strengthening ribs on the bottle body and redesigning the base, we could keep the same strength (top-load) and appearance but use less plastic.

We designed a new 2-cavity mould for a 16.5-gram bottle.

He saved 1.5 grams of PET per bottle.

He produces over 10 million bottles a year.

1.5 grams x 10,000,000 bottles = 15,000,000 grams = 15,000 kg of PET resin saved every year.

He saved tens of thousands of dollars in raw material costs alone. The new mould paid for itself in less than 6 months. This is "design service."

Case Study 2: The New Factory Setup

This is a story I am very proud of. A new entrepreneur in Africa bought a 2-cavity semi-auto machine from a used dealer and ordered his first 2-cavity mould from us.

The machine and mould arrived, but he had no idea how to set them up. He was stuck and stressed.

He called our sales manager, Vivian.

For three straight days, Vivian and our engineering team got on video calls with him. They guided him step-by-step:

- "OK, now connect this high-pressure air pipe to this port."

- "This is the water-in from your chiller. This is the water-out."

- "Now, let's lift the mould and bolt it to the platen. Tighten them in a star pattern."

- "Let's adjust the heating lamp temperature for your preform."

They walked him through installing the mould, setting the blowing parameters, and fixing his first few bottles. After three days, he produced his first batch of perfect, clear bottles. He was so happy he was almost crying.

This is what we mean by service. We don't just sell a product; we sell a solution and a partnership.

Checklist: How to Choose a Reliable PET Mould Supplier in China?

You need a supplier. You search Alibaba and find 100 factories. They all look the same. How do you find a good one? You need a simple checklist to avoid the bad ones.

Ask these questions: 1) Are you a factory or a trading company? (Ask for a live video tour of their CNC machines). 2) What material do you recommend, 7075 or S136, and why? (Test their knowledge). 3) What is your lifespan guarantee? 4) What spare parts are included?

As someone who has been in this industry for many years, I know what separates a good factory from a bad one. Here is the checklist I give to my friends.

Question 1: "Are you a factory or a trading company?"

This is the most important question. A trading company is just a middleman. They add a markup, and they have no control over quality, materials, or delivery time.

How to check: Don't just take their word for it.

Say this: "Can we have a live video call right now? I want you to walk me through your factory."

A real factory (like iBottler) will be happy to do this. I (Vivian) can grab my phone and walk you through our Zhongshan factory right now. I can show you our CNC machines cutting metal. I can show you our polishing workshop and our engineers assembling moulds.

A trading company will make excuses. "Oh, the factory is in another city." "The connection is bad." "Our manager is not here." This is a huge red flag.

Question 2: "What material do you recommend for my water bottle mould and why?"

This is a test of their knowledge.

- Bad Answer: "We use P20 steel. It is very cheap and very good." This is a low-quality workshop. Run away. They are selling you an obsolete, slow, rusting mould.

- Good Answer: "That depends. For a water bottle, you want high speed, so I recommend 7075 Aluminum for its fast cooling. If you are in a very humid area or need a 10-year lifespan, we can discuss S136 Stainless Steel, but for 90% of water bottles, 7075 is the best balance of performance and cost."

This good answer shows they understand the materials. They are asking you questions to find the right solution, not just selling the cheapest thing.

Question 3: "What is the lifespan guarantee for your mould?"

A supplier who trusts their quality will give you a clear, specific number.

- Bad Answer: "It will last a long time. Don't worry." This is not a guarantee.

- Good Answer: "We guarantee our 7075 and S136 moulds for a minimum of 3 million cycles with proper operation and maintenance." A specific number shows confidence in their machining and materials.

Question 4: "What after-sales service and spare parts do you provide?"

The relationship does not end when the mould ships.

- Bad Answer: "Our quality is perfect, you won't need service."

- Good Answer: "We include a free spare parts kit with every mould. This has high-temperature seals, O-rings, and all necessary water/air connectors. These small parts wear out, and this kit will prevent a shutdown. If you have any problems, our engineers are available by video call to help you."

This shows they are planning for your long-term success, not just a one-time sale. Choosing a supplier is choosing a partner. You are not just buying steel; you are buying expertise, reliability, and service.

Conclusion

A 2 cavity PET mould is a precise tool. Your machine, application, and material choice are all critical. Choosing the right partner who understands these details is the key to your success.

Summary of Key Choices

| Aspect | Option 1 | Option 2 | Option 3 | Why it Matters |

|---|---|---|---|---|

| Mould Type | Semi-Automatic | Fully-Automatic Linear | Must match your machine. They are 100% NOT interchangeable. | |

| Material | 7075 Aluminum | S136 Stainless Steel | 7075 = Fast cooling (high speed). S136 = Mirror polish & rust-proof. | |

| Application | Water | CSD (Carbonated) | Hot-Fill | Design is completely different. A water mould cannot handle CSD pressure or Hot-Fill vacuum. |

| Critical Data | Cavity Pitch | Preform Neck Size | A 0.5mm error in pitch can destroy the mould. The wrong neck size means caps won't fit. | |

| Supplier | Trading Company | Real Factory (like iBottler) | A factory controls quality, offers real service, and gives you a better price. |

Frequently Asked Questions (FAQ)

1. Q: What is the price difference between a semi-auto and a fully-auto 2 cavity mould?

A: A fully-automatic linear mould is typically 1.2 to 1.4 times more expensive than a semi-automatic mould for the same bottle size. This is because the fully-automatic mould has a much more complex structure, including a heavy back plate and a precise mounting system (holes or slots) to fit specific machine brands (like certain mainstream brands).

2. Q: Which mould material is better: 7075 Aluminum or S136 Stainless Steel?

A: Neither is "better"; they serve different goals. Both are excellent, mainstream materials.

- 7075 Aluminum is the most common choice for high-speed production (especially for water bottles) because its superior heat dissipation allows for faster cooling and shorter cycle times.

- S136 Stainless Steel is chosen for specialized needs: 1) achieving a perfect mirror-polish (for high-gloss cosmetic bottles), 2) extreme lifespan, or 3) operating in high-humidity/poor water quality environments where its rust-proof quality is essential.

3. Q: What is the lifespan of a 2 cavity PET mould?

A: This depends on the material and maintenance. A high-quality mould from a reputable factory like iBottler, whether it's 7075 Aluminum or S136 Steel, is engineered for a long lifespan. We guarantee at least 3 million shots (cycles) with proper operation and maintenance.

4. Q: What is "Cavity Pitch" and why is it so important for my fully-automatic machine?

A: Cavity Pitch (or center distance) is the exact distance between the centers of the two cavities. For fully-automatic linear machines, this data is critical because the machine's stretch rods are fixed. If your mould's cavity pitch is off by even 0.5mm, the stretch rods will not align with the preforms, potentially crashing into and destroying the mould.

5. Q: Can I use my 2 cavity semi-automatic mould on my new fully-automatic machine?

A: Absolutely not. Their structures are completely incompatible. A semi-automatic mould is simple and relies on the machine's clamps. A fully-automatic mould has a thick, heavy back plate with precision-drilled mounting holes or slots designed to lock perfectly into a specific brand of linear blowing machine.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr