Are you thinking about entering the Thai PET bottle market, but feel confused? You probably see the crowded shelves but don't know where to start. You're worried about investing huge amounts of capital only to pick the wrong lane, ending up in a price war with low profits.

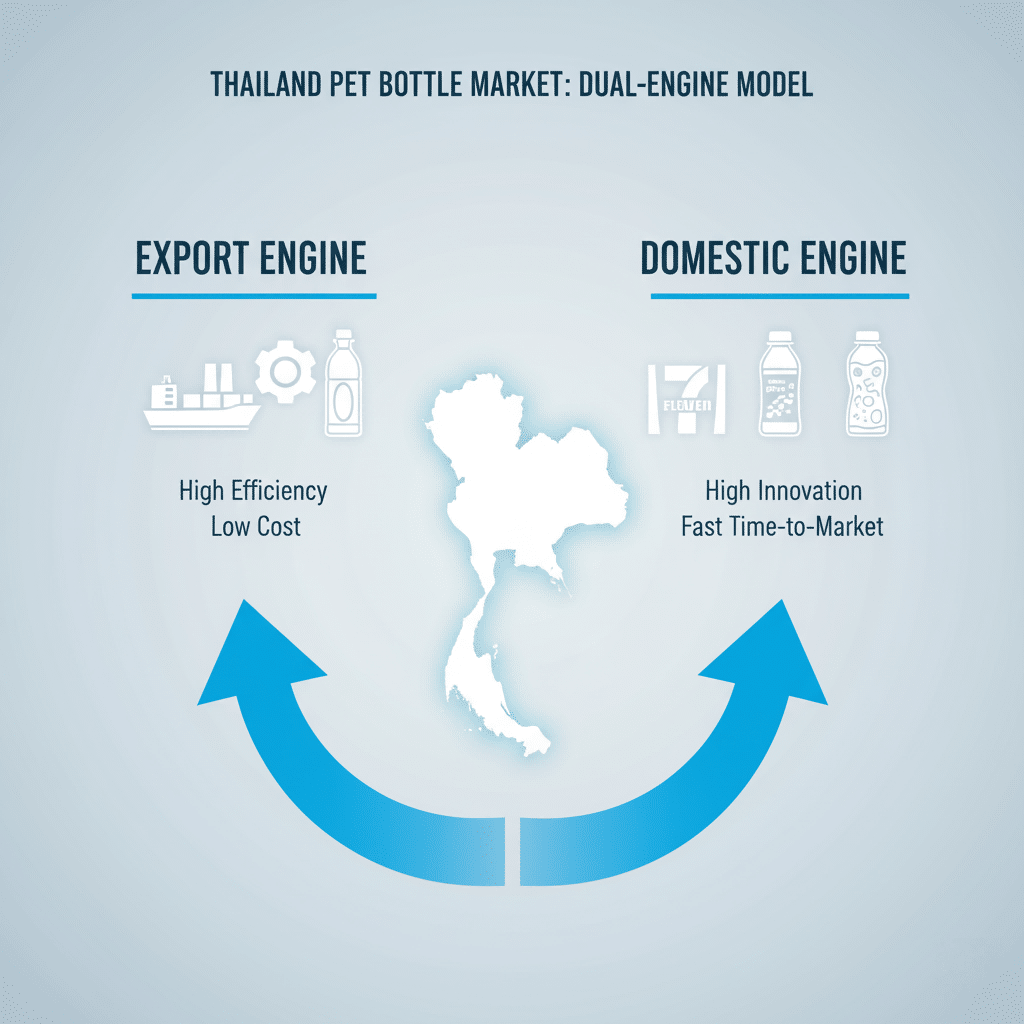

The Thailand PET bottle market is not one single market. It is five separate segments driven by two "engines." The key to success is you must align your entire business model—from capital investment and technology choice to your team's skills—with the specific application you target.

I have spent twenty years deep in this market. I've found the biggest mistake investors make is thinking, "I want to do everything." The truth is, the business model for serving an export cooking oil factory is completely incompatible with the model for supplying functional drinks to 7-Eleven. This article will break down these five major applications and the completely different ways to win in each.

Key Points of This Article

| Market Segment | Core Business Driver | Key Technology System | Primary Risk |

|---|---|---|---|

| Overview | Dual-Drivers (Export vs. Domestic) | Strategy & Tech Alignment | Strategy Mismatch |

| 1. Bottled Water | Volume & Efficiency | High-Speed Rotary Blowing System, Lightweighting | Thin Margins, Cash Flow Failure |

| 2. Functional Drinks | Rapid Innovation (Speed-to-Market) | Rapid Prototyping (3D Printing), Design Engineering | Missing a Market Window |

| 3. RTD Tea/Juice | Product Safety & Shelf Life | Complete Hot-Fill Production Line System | Vacuum Collapse, High CapEx Failure |

| 4. Sauces & Oils | Logistics (Glass-to-PET) | Preform Supply Chain Quality Control | Leaking, Import Rejection |

| 5. Cosmetics | Brand Experience | "Design Engineering" & Concept-to-Reality | Failing to mass-produce a "concept" |

| Key Trend (r-PET) | Supply Chain Mandates | Fine-Tuning of the Blowing Process | High Defect Rates, Losing Key Accounts |

Overview: The Dual-Drivers of Thailand's PET Bottle Market?

You are standing in a crowded Thai supermarket. You see a problem: every shelf is full. How can you possibly compete? You feel anxious that your product will just blend in. The solution is realizing you are in two markets at once, not one.

Thailand's unique PET bottle market is powered by a "dual-engine" system. First is the high-efficiency food export engine. Second is the high-innovation domestic consumer engine. A successful supplier must know which engine they are building parts for.

Let me explain this in more detail. I call this the "Dual-Driver" theory, and it's the most important concept for any investor to understand.

The First Engine: The "World's Kitchen" Export Hub

This engine is all about high-volume, low-cost, and extreme efficiency. Thailand is a global food exporting powerhouse. Think of massive factories producing edible oils, fish sauce, sweet chili sauce, and coconut milk. Their customers are not Thai consumers. Their customers are Walmart in the US, Tesco in the UK, and Carrefour in Europe.

What do these export factories care about?

- Cost Control: Their margins are thin and set by global commodity prices. Every fraction of a cent matters. They must control costs on raw materials (resin), energy, and logistics.

- Efficiency: Their lines run 24/7. "Overall Equipment Effectiveness" (OEE) is their key metric. A machine-down situation is a disaster. They need reliability.

- Logistics: The bottle is just a container to move liquid from Thailand to another continent. The bottle's main job is to be light and strong.

When I visit these factories, the conversation is all about numbers. Their focus is purely on manufacturing and logistics. Their business model is operational efficiency.

The Second Engine: The "7-Eleven" Domestic Market

This engine is the complete opposite. It is driven by innovation, brand, and speed. The battlefield here is the local convenience store (C-store), dominated by 7-Eleven (CP All).

CP All's strategy is to be a "food and beverage destination." They demand a constant stream of new products from brands.

What do these domestic brands (like Sappe, Ichitan, or Oishi) care about?

- Innovation: They must launch new flavors, new ingredients (like collagen or vitamins), and new brand collaborations every quarter to keep their shelf space.

- Brand Appeal: The bottle is the marketing. A unique shape, a bright color, or a special cap is what makes a customer pick it up.

- Speed-to-Market: Their biggest fear is missing a trend. If "butterfly pea" is the hot new flavor, they need a bottle now, not in six months.

When I visit these factories, the conversation is all about ideas. Their business model is marketing.

Why This Matters for You

You cannot serve both engines with the same strategy. The technology, team, and mindset are different. A factory built for high-speed, high-efficiency production (focused on OEE) simply cannot (and will not want to) serve the "low-volume, high-mix, fast-changeover" design needs of the functional drink market.

As an investor, you must choose. Are you in the business of efficiency or the business of innovation? Your answer will determine your entire factory layout, your choice of machinery, and the type of partners you need.

Application 1: Bottled Water (The "Volume & Efficiency" Market)?

You see the massive demand for bottled water in Thailand's hot climate. But you are worried about the tiny profit on each bottle. How can you possibly build a business when the margins are almost zero?

The bottled water market is a game of pure efficiency. Profit does not come from the single bottle. It comes from 24/7 production, extreme lightweighting, and shaving fractions of a second off your cycle time. This is a "scale game" defined by your entire production system.

This is the largest segment by volume in Thailand. But it is also the hardest to make money in. The market pressure comes from:

- Retailer Squeeze: Giants like 7-Eleven and Big C have immense bargaining power and drive purchase prices to the floor.

- Price Wars: This is a highly commoditized market. Your only weapon against competitors is price.

- Rising Costs: The cost of PET resin (a petroleum product) and electricity is constantly fluctuating and rising.

Therefore, the only path to profit in this market is extreme operational efficiency. You must be better than your competition at every single step.

1. Strategic Investment: High-Speed Production Systems

In this field, you cannot use slow, linear blowing machines. You must invest in high-speed rotary blowing systems. This is a high-capital game. These machines are engineered for extremely short cycle times.

For a modern, fully automatic rotary blowing machine, let's say your cycle time is 3.0 seconds. If you can reduce it to 2.8 seconds, that is a ~7% increase in your total factory output for the same time and energy cost.

Where does this 0.2 second come from? It comes from an efficient system.

- Fast Machine Cycle: The mechanical design of the machine itself.

- Optimized Heating: Precise heating lamps and reflectors that heat the preform evenly and quickly.

- High-Efficiency Cooling: This isn't just about the mold material (whether steel or aluminum). It is critical that you have an extremely powerful chiller. The chiller pumps low-temperature coolant to efficiently pull heat out of the mold.

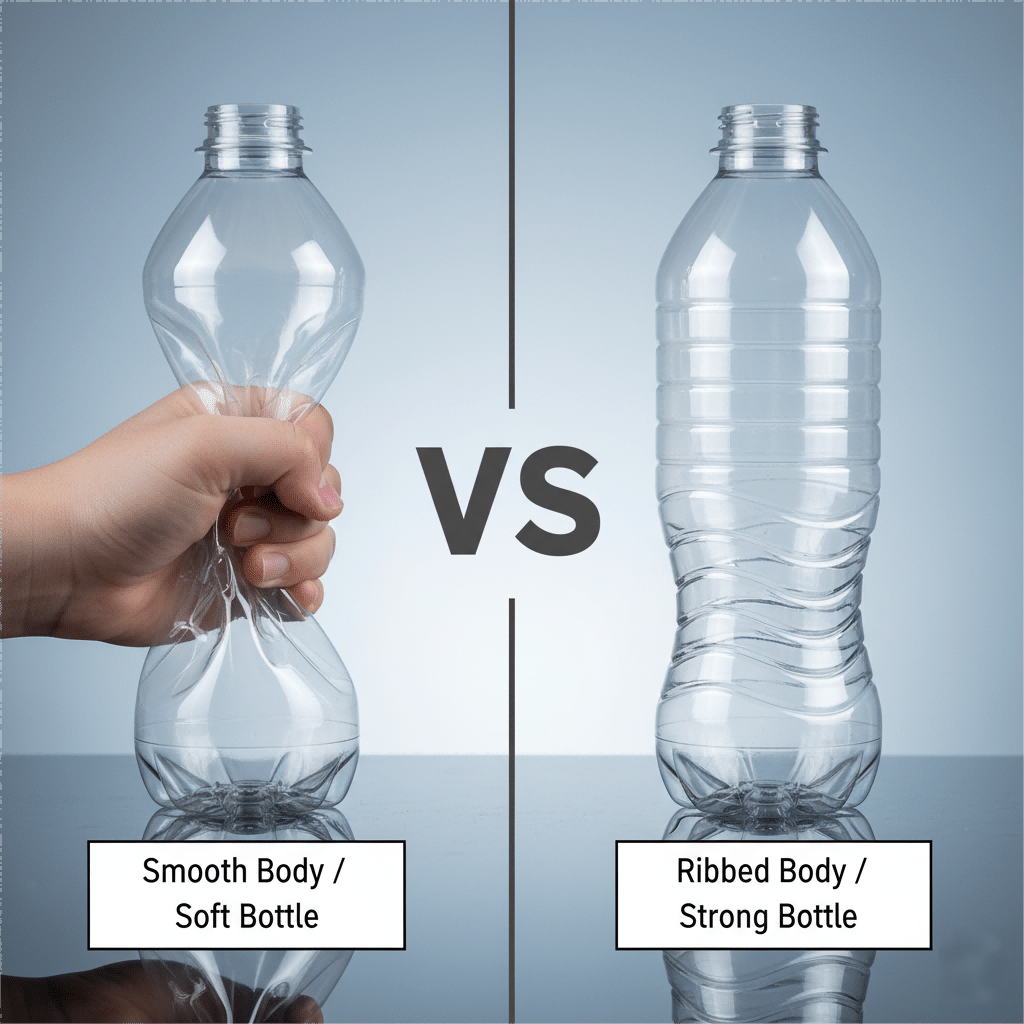

2. Core Competency: Lightweighting Engineering

Your second source of profit is "grams." Lightweighting is the process of reducing the amount of plastic (grams) in each bottle.

But this is a technical challenge. You cannot just make the walls thinner. If you do, the bottles will fail. They will be too weak to be stacked on a pallet. This is a common and costly PET blow molding defect.

True lightweighting is an engineering design problem. I once helped a large export factory whose original bottle was 20 grams. By re-engineering the bottle's structure (especially the ribs in the base and shoulder) and optimizing the preform's stretch profile, we cut the weight to 18 grams. We saved a full 2 grams, and through structural mechanics, the bottle's vertical stacking strength and hand-feel were even better than before. This saved them millions in resin costs every year.

In this market, you are not selling water. You are selling your manufacturing efficiency. Your profit is "squeezed" from fractions of a second and fractions of a gram.

| Operation Model | Typical Equipment | Core Technology Focus |

|---|---|---|

| Small-Scale / Local Brand | Semi-auto or Linear Blow Molder | Flexibility, Initial Mold Cost |

| Large-Scale / National Brand | High-Speed Rotary Blow Molder | Extreme Cycle Time, Gram-Weight Control, Energy Efficiency |

Application 2: Functional Drinks (The "Rapid Innovation" Market)?

Your marketing team has a brilliant idea for a new vitamin drink. You know it will be a hit. But you are worried. By the time you design it, order molds, and start production, will the trend be over?

In the functional drink market, speed is everything. Your biggest competitor is not another brand; it is the calendar. The winner is the one who gets their new product on 7-Eleven's shelves first. This is a race of "service and prototyping."

This market is the perfect example of the "Second Engine." It is fast, creative, and brutal. The Thai consumer is always looking for what is new. This creates a huge market for:

- Vitamin-infused waters

- Collagen and beauty drinks

- Herbal and traditional "healthy" drinks

Brand managers are under constant pressure to innovate. A successful new product might have a life cycle of only 9-12 months before it is replaced.

Core Competency: Speed-to-Market

As a factory owner, your value is not in "low cost." Your value is in "rapid response."

The traditional process is broken for this market:

- Traditional Process: 2D drawing -> 3-week review -> 3D modeling -> 2-week review -> 6 weeks for mold production = 3+ months.

- The Market Window: 8 weeks.

To win here, you need a new process based on "Design Engineering" and "Rapid Prototyping."

- Day 1: The Idea. The brand manager comes in with a sketch.

- Day 2: 3D Concept. Our engineer turns that idea into a 3D model.

- Day 3: 3D Printing. We don't talk about molds. We 3D print a physical sample.

- Day 4: The "Feel" Test. We give the 3D printed sample to the brand manager. This is the most important step. They can hold it, check the label fit, and feel the grip.

We might go through 3 or 4 printed samples in a week. Once the brand manager says "This is the one," then we start production. This model requires your team to have strong front-end design skills and fast mold-making capabilities, often delivering a production blow bottle mold in 3-4 weeks.

Here, the brand manager is not buying a mold. They are buying time. They are buying the service that gets their product on the shelf before the trend dies.

| Supplier Type | "The Old Way" (Cost-Focused) | "The New Way" (Speed-Focused) |

|---|---|---|

| Main Product | Steel Molds | "Speed-to-Market" (A Service) |

| First Question | "What is your budget?" | "What is your launch date?" |

| Prototyping | 2D Drawings, 3D Renders | 3D Printed Physical Samples |

| Key Skill | CNC Machining | Design Engineering, Communication |

| Lead Time | 8-12 Weeks | 3-4 Weeks |

Application 3: RTD Tea, Coffee & Juices (The "High-Tech" Hot-Fill Market)?

You want to sell a premium, all-natural mango juice. Your marketing says "No Preservatives." But you are worried. How can you guarantee a 12-month shelf life without chemicals, and without the bottle collapsing?

The answer is Hot-Fill processing. But this is a high-technology, high-capital market. It requires a complete system of specialized bottles, molds, and filling equipment designed to withstand 85-92°C heat and the powerful vacuum that follows.

Thailand has a massive market for "shelf-stable" drinks. Think of Oishi Green Tea, Ichitan herbal drinks, and tropical fruit juices. The consumer demand for "natural" and "preservative-free" is very strong.

This creates a business challenge: how do you get a 6-12 month ambient shelf life without chemical preservatives?

The answer is hot-fill technology.

- The product (tea, juice) is heated to 85-92°C (185-198°F).

- It is poured hot into the PET bottle.

- The bottle is capped immediately.

- The bottle is cooled (usually in a "cooling tunnel").

Here is the problem. It's simple physics. When the hot liquid cools to room temperature, it shrinks. This shrinkage creates a very powerful vacuum. A standard PET water bottle cannot handle this; it will panel and collapse.

The Solution: An Engineered System

To solve this, you don't just need a mold. You need a complete, high-capital-investment system.

- Specialized Preforms: The preform neck must be "crystallized" (turning it white and opaque) to increase its heat resistance. This requires a special preform mold or preform supplier.

- Specialized Bottle Design: The bottle body must be engineered with "vacuum panels" to absorb the pressure as it cools. This is a complex PET bottle design challenge.

- Specialized Blow Molder: The blowing machine may need a "heat-set" function, which treats the bottle inside the mold at a high temperature to raise its heat resistance.

- Expensive Filling Line: You must buy the expensive hot-filler machine, warmers, and cooling tunnel.

This is a high-barrier-to-entry market. You cannot "try" hot-fill. You must commit. It requires much higher upfront capital, but the reward is a higher-priced product and a longer shelf life that smaller players cannot compete with.

| Process | Standard (Cold-Fill) | Hot-Fill | Aseptic-Fill |

|---|---|---|---|

| Capital Cost | Low | High (Hot-fill line, cooler) | Very High (Clean-room, sterile line) |

| Bottle Requirement | Standard, lightweight. | Heavy, paneled, crystallized neck. | Can be lightweight, but must be sterilized. |

| My Analysis | Good for CSD, water. | Good for Thai RTD tea, juice. High barrier to entry, but high margin. | The "future," but very high cost. |

Application 4: Sauces, Oils & Spices (The "Glass-to-PET" Export Market)?

Your family business has exported fish sauce in glass bottles for 30 years. Now, your European buyer is complaining about shipping costs and breakage. He is asking about plastic. But you are worried. Will it leak?

This is the "Glass-to-PET" trend. It is driven 100% by logistics. PET is lighter and unbreakable, saving exporters thousands. The single biggest technical challenge is preventing leaks. And the solution is not in the bottle; it is in the preform.

This is the "First Engine" export market. Thailand's "World's Kitchen" exports massive amounts of fish sauce, soy sauce, oyster sauce, and cooking oils.

For decades, the standard was glass. But it has two huge problems.

- Weight: A 500ml glass bottle might weigh 250g. A 500ml PET bottle weighs 25g. Most of the freight cost you pay is to ship glass, not sauce.

- Breakage: A single broken bottle in a case can ruin the entire case. This "damage rate" is a constant cost.

PET solves both problems. The switch from glass to PET is not a "nice to have"; it is a "must-do" to stay competitive.

Core Competency: Supply Chain Quality Control

The biggest nightmare for this market is leaking. A container arrives in Hamburg. The importer opens it and finds a sticky, leaking mess. They reject the entire shipment.

Why does it happen? Oils are very "thin" liquids. They can "creep" through microscopic gaps.

The leak almost never happens through the wall of the bottle. It happens at the cap.

More specifically, it happens at the "sealing surface." This is the very top, flat ring of the preform neck. The seal is made when this flat surface is pressed hard against the liner inside the cap.

If that sealing surface is not perfectly flat, perfectly level, and perfectly smooth, a leak channel is created.

You cannot fix this problem in the blowing machine. This is a problem that is created before the bottle even exists. It is created in the preform mold.

- If the preform mold is old or low-quality, the sealing surface can be uneven.

- If the mold's "gate" (where the plastic is injected) is not perfect, the neck can be out-of-round.

I had a large fish sauce exporter as a client. They were getting 5% leak complaints. They were desperate. I went in and ignored the blowing line. I asked to see their preform supplier. I took their preforms and put them under a microscope. The sealing surface was rough.

We did not change their bottle, their cap, or their machine. We changed their preform supplier to one who used high-precision, valve-gated preform molds. The leak complaints dropped to zero.

In this market, you must be obsessed with your preform neck size and quality. A high-quality preform is the cheapest insurance you can buy.

Application 5: Cosmetics & Personal Care (The "High-Margin" Design Market)?

You are launching a new luxury body lotion. Your brand designer gives you a beautiful sketch. It is a non-symmetrical, curved bottle. It looks like art. But your factory manager says it is "impossible" to make.

In the cosmetics market, the bottle is the product. The customer is buying the "experience," not just the lotion. The key skill is not manufacturing. It is "Design Engineering": the art of turning a beautiful, complex concept into a stable, manufacturable product.

This is a high-margin market, driven by Thailand's growing middle class and its massive tourism and hotel industry. In this segment, the bottle's function is to communicate "luxury," "natural," or "premium."

This creates a conflict. Brand designers are artists. They draw sharp corners, "glass-like" heavy bases, and complex curves. As an engineer, I can tell you: these are a nightmare to manufacture.

- Sharp corners: PET plastic does not like to flow into sharp corners. They will be thin, weak, and brittle.

- Asymmetric shapes: The plastic will stretch unevenly. One side will be thick, the other will be paper-thin. This is a very common PET blow molding defect.

Core Competency: "Design Engineering"

This is where my team and I add the most value. Our job is to be the bridge between the designer's concept and the factory's reality. We call this "Design Engineering."

Here is the process:

- Receive the Concept: The designer gives us the 2D sketch or 3D art file. We never say "no."

- Run Simulation: We immediately run a blow-molding simulation. This shows us exactly where the problems will be.

- Engineer the Solution: Now, we become problem-solvers.

- "This sharp corner is a problem. But if we change it from a 0.1mm radius to a 1.5mm radius, the plastic will flow, and the design will still look sharp."

- "This wall is thin. We must change the preform's heating profile."

- Prototype and Approve: We make a 3D printed sample of the engineered design. The designer can hold it and approve the small changes.

I had a client from a high-end spa. Their designer wanted a "twisted square" lotion bottle. Our simulation showed the four sharp, twisted corners would be paper-thin.

Our solution was twofold:

- Design: We modified the 3D model, adding a tiny, almost invisible "fillet" to the corners to help the plastic flow.

- Process: We designed the production mold with special venting in the corners.

We delivered a bottle that looked 99% like the designer's "impossible" art, but was 100% strong and stable. In this market, you are not selling plastic. You are selling your engineering expertise.

Key Market Trend: The r-PET Mandate & Process Optimization?

Your biggest export customer, a global brand in Europe, just sent you a new requirement. Starting next year, all bottles must contain 50% r-PET. You find a supplier, but when you run the r-PET preforms, your defect rate explodes. What is happening?

The move to r-PET (recycled PET) is the biggest trend facing the Thai market. It is not a "material" problem. It is a "process" problem. r-PET behaves differently than virgin plastic, and you must re-optimize your entire blowing machine process, not your mold.

This is not a choice. This is a mandate. Global brands like Coca-Cola, Nestle, and Unilever have made public pledges to use r-PET. They are forcing this requirement down to their entire supply chain. If you are a Thai exporter, you must comply, or you will lose your contract.

Why is r-PET so Difficult?

I get this call every week. A factory manager is furious. He says, "This r-PET preform is junk! My bottles are hazy, brittle, and the walls are uneven!"

The problem is not the r-PET. The problem is his machine settings.

He is using the same settings he has used for 10 years with virgin PET. But r-PET is a different material.

- Different IV (Viscosity): r-PET has a lower and less consistent viscosity, meaning it stretches differently.

- Different Heating Profile: r-PET absorbs infrared heat in the oven differently than virgin PET. It often heats up faster and less evenly.

If you use virgin PET settings, the r-PET preform gets overheated in the oven. This causes all kinds of PET blow molding defects.

The Solution: Process Optimization

You do not need a new mold. You do need to retrain your operators and re-optimize your blowing machine.

This is a service I provide. I go into factories and we "re-tune" the machine for r-PET.

- Heating: This is the big one. We must change the oven's heating profile. We usually have to turn down the power on the lamps.

- Blowing: We may need to adjust the pre-blow time and the high-pressure blowing profile.

- Air System: r-PET can be more sensitive to moisture. A clean, dry air compressor system becomes even more critical.

I was at a large juice exporter's plant. Their defect rate on 100% r-PET was 30%. I flew to his factory. We did not touch his mold. We spent one full day only adjusting the settings on his blowing machine's oven. By the end of the day, we were running 100% r-PET with a defect rate of less than 1%.

All he needed was the knowledge of how the new material behaved.

| Process Parameter | Virgin PET Setting (Example) | r-PET Setting (Example) | Why it Changes |

|---|---|---|---|

| Oven Heat (Zone 1) | 80% Power | 70% Power | r-PET heats faster, needs "gentler" heat. |

| Oven Heat (Zone 4) | 60% Power | 65% Power | We may need to force heat to specific areas. |

| Pre-Blow Pressure | 8 Bar | 9 Bar | May need to stretch the material earlier. |

| Blowing Time | 0.8 seconds | 0.7 seconds | A hotter preform may fill faster. |

| Operator Mindset | "Set it and forget it." | "Active, constant optimization." | r-PET requires a more skilled operator. |

Conclusion: How to Choose a Partner for the Demanding Thai Market?

You have now seen that the Thai market is not one market, but a complex ecosystem of five different business models. How do you choose a supplier to help you win?

Your success is not in buying a machine or a mold. It is in aligning your entire operation—capital, technology, and team skills—with the specific application you choose. You need a technical partner whose skills match your target application.

| Your Market (Application) | The Wrong Partner | The Right Partner (Ask Them This...) |

|---|---|---|

| 2. Functional Drinks | A factory that only talks mold price. | "How fast can you get me a 3D-printed sample?" |

| 3. RTD Hot-Fill Tea | A "general purpose" mold maker. | "Show me three hot-fill bottle projects you have engineered. Explain the vacuum panel design." |

| 4. Export Sauces (Leaking) | A partner who only talks about bottles. | "What is your quality control process for your preform mold sealing surface?" |

| 5. Cosmetics | A "low price, high volume" factory. | "What is your 'Design Engineering' process? How do you simulate and fix my designer's 'impossible' shape?" |

| 7. r-PET Trend | A supplier who "just sells you a mold." | "My r-PET defect rate is high. Will you send an engineer to my factory to help me optimize my process?" |

This is where my company, iBottler, has built its 20-year reputation.

Our core value is not in being the cheapest. Our value is in our in-house engineering team and technical expertise.

- We are experts in Hot-Fill Technology (for Application 3).

- We are experts in Design Engineering (for Application 5).

- We are experts in Process Optimization (for Application 7).

- We have a world-class Rapid Prototyping system (for Application 2).

I had a customer in Thailand who bought a mold. It arrived. It did not fit his blowing machine. The mounting plates were wrong. His line was down. He called us. We have the mounting dimensions for 80% of blow molding machines worldwide in our database. We built him a new, correct mold. Our value was not just making the mold; it was making the mold right, the first time.

Conclusion

Thailand's PET market is diverse and full of opportunity. Success means matching your strategy to one of its specific segments. You need a partner who has the deep engineering skills for that exact application.

Summary of Thai PET Bottle Market Applications

| Application | Market Driver | Key Technology Challenge | What You Need in a Partner |

|---|---|---|---|

| 1. Bottled Water | Efficiency & Cost | Cycle Time & Lightweighting | High-Speed Production System & Process Expert |

| 2. Functional Drinks | Speed-to-Market | Rapid Prototyping | Fast Design & Mold-Making Partner |

| 3. RTD Tea/Juice | Shelf-Life (Preservative-Free) | Hot-Fill System & Vacuum Collapse | Proven Hot-Fill Engineering Expert |

| 4. Sauces & Oils | Logistics (Glass-to-PET) | Preform Neck Sealing (Leaking) | Quality Control (Preform) Expert |

| 5. Cosmetics | Brand & Design | Turning "Concepts" into Reality | "Design Engineering" Team |

| 7. Key Trend (r-PET) | Brand Mandates | Process Optimization | Technical Consultant & Trainer |

Frequently Asked Questions (FAQs)

1. Q: What is the biggest difference between Thailand's water bottle market and its RTD tea market?

A: The business model. The water market is a high-volume, low-margin game won by production efficiency (lightweighting, fast cycle times). The RTD tea/juice market is a high-tech, high-margin game won by preservation technology (hot-fill processing) and brand appeal.

2. Q: What is the "Glass-to-PET" trend in Thailand's food industry?

A: This is a logistics-driven trend where sauce, oil, and spice exporters are replacing heavy, breakable glass bottles with lightweight, durable PET bottles. This significantly reduces their shipping costs and product damage during transit.

3. Q: Why is using 100% r-PET so difficult for my factory?

A: The problem is not your mold; it's your process parameters. r-PET resin behaves differently than virgin plastic when heated. You must re-optimize your blowing machine's heating curves (often needing more, gentler heat) and blowing pressure to match r-PET's properties, otherwise you will see high defect rates.

4. Q: For cosmetic bottles, what is "Design Engineering"?

A: "Design Engineering" is the skill of taking a brand designer's creative "concept" (which may be complex or non-symmetrical) and turning it into a 3D model that is technically stable and efficient to manufacture. It is the bridge between a beautiful idea and a perfect final product.

5. Q: What is the fastest-growing PET bottle segment in Thailand?

A: While water is the largest by volume, the fastest-growing and most dynamic segments are functional/premium drinks (like vitamin water, collagen drinks) and RTD tea/coffee. This is driven by strong domestic consumer demand for innovation and new flavors.

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr