Producing 5L water bottles is a game of thin margins where every gram of resin counts. You face a tough choice: reduce weight to save money or add weight to prevent damage during transport.

The most effective way to optimize a 5L PET bottle is not simply changing the weight, but re-engineering the structural geometry. By implementing strategic ribbing to prevent vacuum collapse, selecting the precise 45mm preform standard, and refining the base for conveyor stability, you can reduce raw material usage while actually increasing the bottle's load-bearing capacity.

Many manufacturers struggle with the balance between a bottle that looks premium and one that is profitable. If you reduce the weight too much without changing the design, the bottle feels cheap and "squishy" in the customer's hand. If you keep the weight high, your profit evaporates. The solution lies in engineering, not just in the settings of your machine. In the following sections, I will break down exactly how we approach this engineering challenge to give you a competitive edge.

The Geometry of Strength: Preventing "Vacuum Collapse" in Thin-Wall Water Bottles

Thin-walled 5L bottles often suck inward or deform when the user pours water or when the temperature drops. This "vacuum collapse" makes the product look defective and cheap.

You can prevent this collapse by adding specific structural ribs that act like the skeleton of the bottle. These ribs break up large, flat surfaces and resist the negative pressure generated inside the bottle, allowing you to use less plastic while maintaining a rigid feel.

When we design a 5L bottle, we must deal with the physics of negative pressure. When a customer pours water out of a large bottle, air must rush in to replace the liquid. If the neck design restricts airflow (glugging), a temporary vacuum forms inside. Additionally, if you fill the bottle with water that is slightly warmer than the storage environment, the cooling liquid creates an internal vacuum. In a bottle with large, smooth panels, this vacuum pulls the walls inward. This is called "paneling" or "vacuum collapse."

The instinctive reaction of many producers is to increase the weight of the preform to make the wall thicker. This is the wrong approach. It increases your costs permanently. Instead, we use geometry. A flat surface has very little structural integrity against forces perpendicular to it. By introducing horizontal ribs or a "diamond" texture, we increase the moment of inertia of the wall section. This means the wall resists bending much more effectively without adding a single gram of material.

I worked with a client recently who wanted a completely smooth, "minimalist" 5L bottle. It looked beautiful in the 3D rendering. However, when we produced it at 85g, it felt like a plastic bag filled with water. It had no rigidity. We modified the PET bottle mold design guide to include three subtle horizontal ribs in the grip area and a reinforced shoulder. We kept the weight exactly the same at 85g. The result was a bottle that felt significantly harder. The ribs acted as "hoops" that prevented the barrel of the bottle from collapsing.

In 5L design, the "waist" or grip area is critical. This is where the user grabs the heavy bottle. If this area is weak, the water level rises when squeezed, potentially spilling. We often design deep, ergonomic ribs here. These ribs serve a dual purpose: they guide the user's hand and they provide the strongest structural point in the bottle body. Do not rely on thickness for strength. Rely on shape.

Preform Selection: 45mm Neck Standards and Weight Precision Strategies

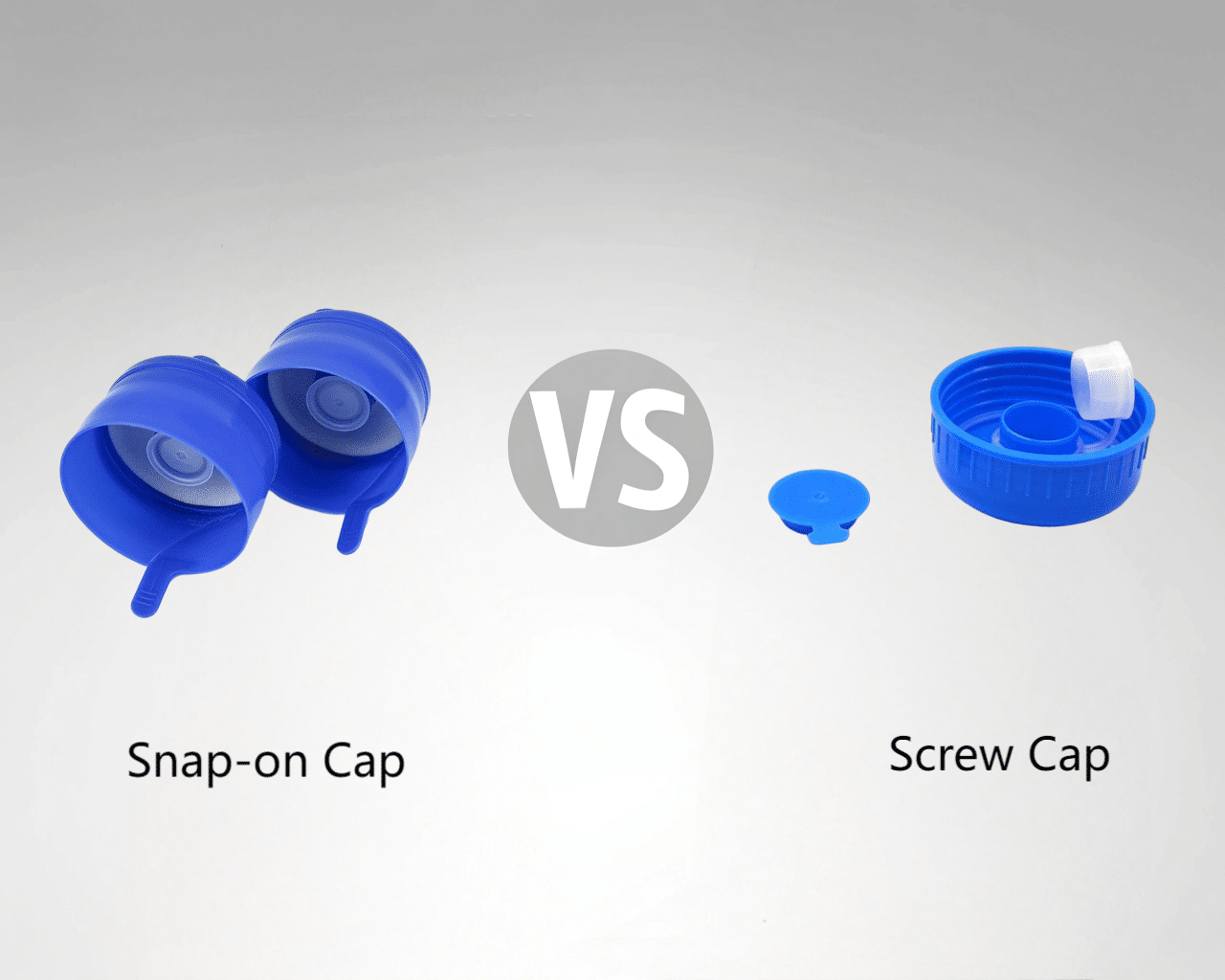

Choosing the right neck finish is the first step in cost control because it dictates the cap type and the minimum weight of the preform. You must choose between the screw cap and the press cap based on your end-user.

For the 5L market, the 45mm neck is the industry standard, but optimizing it requires strict weight control. A screw cap (threaded) offers resealability for home users, while a press cap (snap-on) is standard for water coolers, and choosing the lighter option can save grams per unit.

The 45mm neck finish is the battleground for cost efficiency in large-format water bottles. Unlike small water bottles that use 29/25 or 30/25 finishes, the 5L bottle needs a wider opening to manage the flow of a large volume of liquid. There are two primary distinct categories here: the threaded screw neck and the press-on neck. Your choice depends entirely on how your customer uses the product, but the manufacturing implications are huge.

The screw neck is mandatory if your bottle is sold in supermarkets for direct consumption. Customers need to open, pour, and seal the bottle repeatedly. The press neck is used almost exclusively for bottles that go onto a dispenser or cooler. The press neck is generally simpler to mold, but the caps can be harder to apply for a standard user without a dispenser.

Here is where the precision comes in. I had a client producing pure water with a daily output of 8,000 bottles. He was using a generic 90g preform with a 45mm neck. He felt this was the "safe" weight to avoid complaints. We conducted a full audit of his preform mold and blowing process. We realized that his material distribution was poor. The bottom of the bottle was excessively thick, while the shoulder was thin. This is a common issue when the preform design does not match the bottle shape perfectly.

We proposed a new strategy. We moved him to an optimized 86g preform. We did this by redesigning the preform geometry to stretch more evenly. We thickened the transition area at the base (the gate) and thinned out the straight wall section of the preform. On paper, 4 grams seems like nothing. But let’s do the math. 4 grams times 8,000 bottles a day is 32 kilograms of resin saved daily. Over a production year, that is nearly 12 tons of PET material. In the commoditized water market, saving 12 tons of resin without changing the price of the product is pure profit.

You must also consider the "locking ring" area of the neck. Some older mold designs have excessive plastic in the support ledge (the ring used to transport the preform). Modern designs minimize this ledge to the bare minimum required for the bottle blowing machine grippers to hold it. Every milligram you shave off the neck is a milligram you can put into the body of the bottle for strength, or simply remove to save money. If you are unsure which geometry fits your market, you should consult a guide on how to choose the right preform neck size.

Base Design Engineering: Stability on Conveyors and Shelves

A 5L bottle is tall and heavy, making it prone to tipping over during high-speed production if the base is not engineered correctly. Stability is not just about standing on a table; it is about surviving the movement of the filling line.

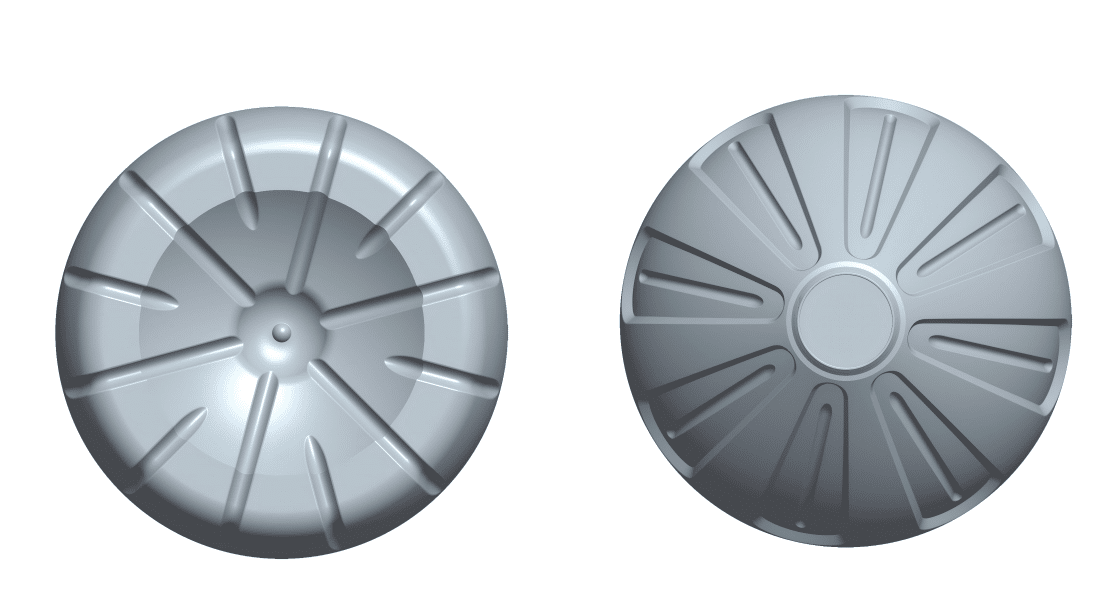

The base design must balance the center of gravity and provide a wide enough contact surface to prevent the "bowling pin" effect. A petaloid or modified flat base ensures the bottle remains upright during the rapid starts and stops of the conveyor belt.

When we discuss base design, most people think about the bottle sitting on a kitchen counter. However, the most dangerous time for a 5L water bottle is the few seconds after it is filled and before it is capped. At this stage, the bottle is full of water, heavy, and moving at high speed on a conveyor. If the base design is poor, the inertia of the water will cause the bottle to wobble. If one bottle falls, it creates a domino effect—the "bowling pin" disaster—that can shut down your line for twenty minutes while operators clean up the mess.

I see many factories that focus only on the static stability of the empty bottle. This is a mistake. You must design for dynamic stability. The contact diameter of the base must be large enough to counter the high center of gravity. For a 5L bottle, a simple flat base is often not enough because the internal pressure of the water will bulge the bottom out, making it a "rocker." The bottle becomes a sphere on the bottom and spins.

To solve this, we use a "petaloid" design or a reinforced "push-up" base. The petaloid base uses feet (usually 5 or 6) to create separate contact points. This structure is incredibly strong and resistant to internal pressure. It allows the bottle to stand firm even if there is slight internal expansion. For 5L bottles, we often use a hybrid design: a high push-up in the center to resist pressure, with a wide, flat outer rim that has small venting channels.

The venting channels are crucial. When the bottle is blown, air can get trapped between the mold metal and the plastic in the base corners. If this air cannot escape, the plastic cannot touch the mold wall, and the base will be soft and undefined. The blow bottle mold must have adequate venting in the base to ensure sharp, crisp definition of the feet.

Another critical factor is the clearance between the injection gate (the nub in the center of the bottom) and the ground. If the push-up is not deep enough, the gate nub might touch the conveyor. This causes the bottle to spin and slide unpredictably. I always check the "gate clearance" on my client's designs. We need at least 2mm to 3mm of clearance to ensure the bottle sits on its outer rim, not on the injection point. If you are seeing bottles wobble on the line, look at the bottom. The solution is almost always in the geometry of the base.

Handle Solutions: Product Positioning Determines the Choice (Side Insert vs. Neck Ring)

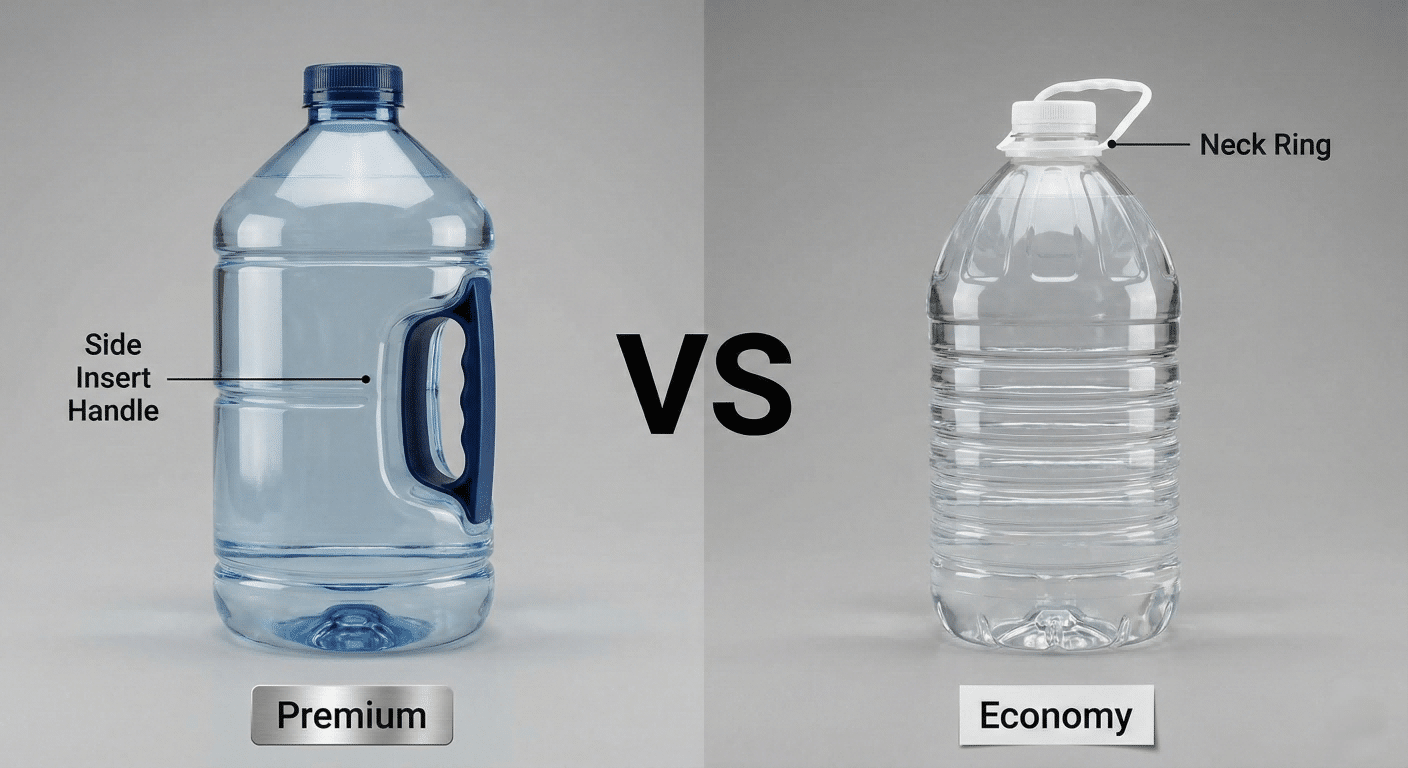

Adding a handle to a 5L bottle is critical for user experience, but you must decide between a Side Insert Handle and a Neck Handle based on your product positioning (Premium vs. Mass Market). This is not just a cost decision; it is a branding decision.

Major market leaders (like Watsons) utilize Side Insert Handles for their premium lines to offer superior ergonomics and stacking capabilities, while budget-focused brands prefer the cost-efficiency of the Neck Ring.

In the 5L water sector, the handle is the first point of contact for the consumer. Carrying 5kg of water by pinching a wide body is uncomfortable, making the handle indispensable. As a manufacturer, you need to weigh two options against your target market:

1. Side Insert Handle: Premium Experience & Differentiation

This involves a separately molded handle that is "clicked" or inserted into a deep recess on the side of the bottle.

- Advantages: It offers excellent ergonomics, allowing the wrist to sit naturally while carrying. It gives the bottle a professional, durable look similar to rigid polycarbonate jugs. Furthermore, side handles usually sit flush, allowing for stable vertical stacking of finished bottles.

- Challenges: This requires a higher investment. Your blow bottle mold needs complex deep recesses (often requiring moving sliders) and you need a dedicated handle insertion machine (or manual labor). However, if you are competing with top-tier brands, this investment differentiates your product on the shelf.

2. Neck Ring Handle (Carry Loop): Extreme Cost-Efficiency

This is a separate plastic ring applied to the bottle neck after filling.

- Advantages: The cost structure is unbeatable. The mold is simple (standard round bottle), blowing speeds are faster (no complex side geometry to cool), and you don't need extra wall thickness to support a handle slot.

- Challenges: It can be uncomfortable ("finger cutting") when carrying heavy loads for long distances, and the loop can interfere with stacking stability.

My Advice: If your goal is to build a premium family-water brand like Watsons, the Side Insert Handle is a worthy investment for customer retention. If your goal is the catering channel or the ultra-low-cost market, the Neck Ring is the smarter financial choice.

Labeling Area Design: Optimizing for OPP, Self-Adhesive, and Shrink Sleeves

The labeling strategy for 5L bottles generally falls into three categories: OPP Roll-fed, Pressure Sensitive (Self-Adhesive), and Shrink Sleeves. You must define your labeling strategy during the mold design phase, as each requires a different geometric approach.

If you choose OPP, the bottle must be a perfect cylinder; if you choose Self-Adhesive, the surface must be mirror-smooth; if you choose Shrink Sleeves, you have the ultimate freedom in bottle shaping.

Before cutting steel for your mold, ensure you optimize the design for your specific label type:

1. Optimization for OPP Roll-fed Labels

This is the most cost-effective method for mass production. Since OPP labels have zero elasticity, they demand an "Absolute Cylinder."

- Design Requirement: The label panel cannot have a draft angle (or a very minimal one). If the bottle is tapered, the label will spiral up or down at the overlap.

- Bumpers: I strongly recommend 0.5mm high protection ridges (bumpers) above and below the label area. These protect the label during transport and act as physical guides for the labeling machine.

2. Optimization for Pressure Sensitive (Self-Adhesive) Labels

Common in mid-to-high-end water or "no-label look" clear labels. These stick directly to the bottle surface.

- Design Requirement: This is the most "honest" label. Any defect on the bottle surface (ripples, uneven parting lines, orange peel effect) will show through, especially with clear stickers. The mold surface in the label area must be Mirror Polished.

- Rigidity: Like OPP, the applicator head applies pressure. If the bottle is too soft under the label area, it will depress, causing bubbles or wrinkles. We must never place textured ribs under a self-adhesive label area.

3. Optimization for Shrink Sleeves

Sleeves shrink with heat to wrap around the bottle, accommodating complex shapes (like curves or spheres).

- Design Requirement: You don't need a cylinder, but you need to consider uniform shrinkage rates. If the diameter changes too drastically, the artwork on the sleeve might distort.

- Cost: While visually stunning, the unit cost per label and the energy cost for the steam tunnel are higher than the other two options.

Summary: Regardless of the type, the Mold Parting Line is critical. If the parting line is misaligned, OPP labels will "tent" and Self-Adhesive labels will trap air lines. Ensure high-precision alignment in the labeling zone.

Blow Molding Process: Ensuring Clarity in Thick Preforms

5L preforms have thick walls which hold heat, often resulting in a hazy or white bottle if not processed correctly. You need to master the cooling and heating balance to achieve glass-like transparency.

To avoid haze, you must use a blow bottle mold with a high-performance cooling system and an oven profile that penetrates deep into the preform wall. Rapid cooling stops crystallization, keeping the PET clear and amorphous.

Consumers buy water with their eyes. They equate clarity with purity. If your 5L bottle looks milky, foggy, or pearlescent, consumers subconsciously think the water is dirty or stale. This haze is rarely a material defect; it is almost always a process defect known as crystallization or "cold stretching."

The 5L preform is much thicker than a standard 500ml preform. This thickness creates a thermal challenge. When you heat the preform in the oven, the outside heats up quickly, but the heat takes time to soak into the inner layers. If you blow the bottle while the inside is still cold, the plastic will stretch unevenly and turn white (pearlscence). This is stress whitening. To fix this, you need "soaking time" in your oven or lower power lamps to allow the heat to penetrate without burning the surface.

On the other hand, if the preform is too hot, or if the blown bottle cools too slowly, the PET molecules will try to organize themselves into crystals. This creates a milky thermal haze. This usually happens in the thickest parts of the bottle—the neck and the base.

The solution lies in the mold cooling. You cannot rely on ambient air or standard tower water. You absolutely need to connect your mold to a chiller. The water running through the mold channels should be around 8°C to 10°C. For 5L bottles, the base is the thickest part and holds the most heat. If your mold base cooling is blocked or poorly designed, the bottom of the bottle will be opaque.

I worked with a factory in a tropical region. They were using 25°C tower water to cool their molds. Their bottles were constantly slightly hazy. They thought it was the humidity. I told them to install a dedicated chiller for the blow mold. Within an hour of turning on the chiller, the bottles came out crystal clear. The rapid cooling "froze" the molecular structure in its transparent state. It is a simple rule: Hot preform + Cold mold = Clear bottle.

Also, do not ignore the air circulation inside the bottle. High-pressure air is used to blow the bottle. This air also helps cool the plastic from the inside. We often recommend high-performance air recovery systems or optimizing the exhaust time to ensure the internal heat is flushed out quickly.

Shape Selection: Why Round Bottles are the Standard for Water Over Square Shapes

While square bottles are efficient for shipping, round bottles are structurally superior for holding non-carbonated water. The round shape distributes stress evenly, allowing for lighter weights.

You should choose round bottles if your priority is raw material cost reduction. Square bottles require more plastic to maintain their shape because the corners act as stress concentrators and the flat sides bulge easily under load.

| Feature | Round Bottle | Square Bottle |

|---|---|---|

| Material Efficiency | High (Best volume-to-surface ratio) | Medium (Corners require thickness) |

| Structural Strength | Excellent (Hoop strength) | Weak (Sides bulge easily) |

| Logistics | Poor (Lost space between bottles) | Excellent (Dense packing) |

| Labeling | Easy (Roll-fed/Adhesive) | Difficult (Panel orientation needed) |

The debate between round and square is a battle between logistics and physics. Logistics managers love square bottles. You can stack them on a pallet with almost zero wasted air space. You can fit 20% more water in a truck. This is a valid argument. However, as a production expert, I must advocate for the round bottle.

A cylinder is the most efficient shape for a pressure vessel. Even though water is not carbonated, the hydrostatic pressure of 5kg of water pushing down is significant. In a round bottle, this force is distributed perfectly evenly along the circumference (hoop stress).

In a square bottle, the forces attack the flat sides. The flat side wants to become round. It bulges out. To prevent this "bloating," you have to add significant thickness to the walls. You also have to reinforce the corners because stress concentrates there. If you drop a square bottle, it will almost always crack at the corner. A round bottle tends to bounce or dent.

I often explain to clients: "You can make a square bottle, but you will pay for it in resin." A round 5L bottle might work perfectly at 85g. A square bottle of the same volume and height might need 100g or 105g to pass the same drop test and top-load test. You have to calculate if the savings in shipping fuel outweigh the extra cost of 15g or 20g of PET per bottle. For most local water distribution, the resin cost is the dominant factor, which is why the round bottle remains the king of the industry.

Additionally, blowing a square bottle is harder. The plastic has to travel further to reach the corners of the mold. This can lead to thin corners and thick sides (bad distribution). Round bottles blow naturally and evenly. If you are starting a new line, start with round. It is the path of least resistance.

Why Should iBottler Be Your Partner for 5L Projects?

You need a partner who understands not just the machinery, but the economics of the water business. iBottler brings decades of expertise in optimizing molds and machines specifically for large-format containers.

We provide more than just steel; we provide the engineering insights to run lighter, faster, and cheaper. From 3D printed samples to full production line integration, we are with you at every step.

At iBottler, we don't just sell molds; we sell solutions to the problems I have described in this article. We understand that a 5L bottle is a commodity product where a fraction of a cent matters.

When you work with us, we start by analyzing your preform. Can we lightweight it? We look at your bottle blowing machine. Do you have the right mounting dimensions? We check your auxiliary systems. Is your compressor efficient enough?

We have a library of proven 5L designs that maximize strength-to-weight ratios. We don't guess. We verify. If you are worried about how a new design will look or feel, we can move from 3D printed samples to production rapidly. This allows you to hold the bottle in your hand before cutting steel.

Our goal is to ensure that when you turn on your machine, you are producing sellable, profitable bottles from day one. We have seen every defect, every haziness issue, and every wobbly base, and we know how to fix them. Let us bring that experience to your factory floor.

Conclusion

Optimizing a 5L PET water bottle requires a holistic approach that balances weight reduction with structural integrity. By leveraging geometric ribs, selecting precise preforms, and ensuring proper mold cooling, you can produce a durable, premium-looking bottle that maximizes your profit margins.

FAQ

Q1: What is the ideal weight for a 5L PET water bottle?

A: For standard non-carbonated water, the weight typically ranges from 80g to 95g. Through advanced rib design and high-quality molds, some manufacturers can optimize it down to 80-85g without compromising drop-test performance.

Q2: Which machine is best for producing 5L water bottles?

A: You need a semi-automatic or fully automatic blow molding machine specifically designed for large cavities. Standard machines often lack the heating oven length required to evenly heat the thick 5L preforms, leading to white/hazy bottles.

Q3: Should I choose a side insert handle for my 5L bottle?

A: It depends on your product positioning. Top-tier brands like Watsons use side insert handles to enhance user experience and convey a premium feel. While this requires more complex molds and slightly higher production costs, the investment is valuable if you are competing in the high-end market. If your focus is extreme cost-efficiency, the neck ring is more economical.

Q4: Can I use Pressure Sensitive (Self-Adhesive) labels instead of OPP?

A: Yes, self-adhesive labels are often used for premium products or small batches requiring flexibility. However, note that these labels demand a high degree of surface smoothness. The labeling area must be mirror-polished and free of texture, and the bottle wall must be rigid enough to withstand the applicator pressure.

Q5: Why is my 5L bottle base uneven (wobbly)?

A: This is usually a cooling issue. The base of a 5L bottle is the thickest part. If the mold base cooling is insufficient, the plastic shrinks unevenly after demolding. Upgrading the mold's cooling channels or checking the chiller connection is the solution.

Summary of Optimization Strategies

| Aspect | Optimization Strategy | Benefit |

|---|---|---|

| Wall Structure | Add horizontal ribs / diamond texture | Prevents vacuum collapse; increases rigidity without weight. |

| Handle Choice | Position-based: Side Insert (Premium) vs. Neck Ring (Budget) | Side Insert offers superior ergonomics; Neck Ring offers lowest cost. |

| Labeling Area | Adapt to Process: OPP, Self-Adhesive, or Sleeve | OPP needs cylinder; Adhesive needs mirror polish; Sleeve offers flexibility. |

| Base Design | Petaloid or High Push-up | Ensures stability on high-speed conveyors; prevents "rocking". |

| Cooling | Use 8-10°C Chilled Water | Eliminates haze; ensures crystal clear transparency. |

| Shape | Round Cylinder | Best strength-to-weight ratio; prevents corner cracking. |

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr