Is your production line plagued by hazy jars, oval necks, or bottoms that rock like a cradle? Producing wide-mouth containers is not just "scaling up" a standard bottle process; it requires a completely different engineering approach and precise physical calculations.

Successful wide-mouth PET jar production requires specialized machinery with wider heating pitch, tailored "low-power" heating profiles for thick preforms, and rigorous neck cooling systems. This guide details the engineering solutions to ensure clarity and dimensional stability, moving beyond standard capacity metrics to focus on physical diameter limits.

Many manufacturers lose time and money by ignoring these specific physics. They buy a machine based on volume, only to find the preforms crash in the oven. Let’s dive into the production floor reality and analyze the technical details that separate premium jars from scrap.

1. The Physical Limit: Does Your Machine Pitch Match the Preform Diameter?

Do you choose your machine based solely on the volume of the container? This is the most common and expensive mistake in wide-mouth production. Many factory owners and procurement managers look at the spec sheet, see "Max Volume," and ignore the parameter that determines life or death: the Pitch.

The fundamental difference between a standard water bottle machine and a specialized wide-mouth machine is the Pitch (center-to-center distance). If your preform diameter exceeds the machine pitch, the preforms will physically collide in the heating oven. You must select equipment based on "Maximum Preform Diameter," not just "Maximum Volume."

When we discuss the "Pitch" of a bottle blowing machine, we are referring to the physical distance between the centers of two adjacent mandrels on the heating chain. The global standard for water bottle machines is typically set at 76.2mm (3 inches). This is designed for standard 600ml water bottles.

Here is the insurmountable physical obstacle: The Machine Pitch must be greater than the Preform Body Diameter.

If you attempt to run a 90mm diameter preform on a standard machine with a 76.2mm pitch, it is absolutely impossible. It is not a matter of risk; it is a matter of geometry. A 90mm object cannot fit into a 76.2mm space. Even if your preform diameter is 75mm, which technically fits within 76.2mm, you are left with only 1.2mm of clearance. This tight spacing causes severe airflow blockage, and any slight vibration in the chain will cause the high-speed rotating preforms to smash into each other, potentially jamming the entire drive system.

Vivian's Insight (Professional Analysis):

I once met a client who was misled by an unprofessional salesperson into buying a "5-Liter" oil machine (76.2mm pitch) to produce a 1.5-liter wide-mouth dried fruit jar (90mm preform diameter). The client thought, "A 5L machine can surely handle 1.5L." But when the preforms arrived, they discovered they couldn't even load them onto the heating mandrels—the preforms were wider than the gap between holders! This was a painful lesson: Physics does not negotiate. If your preform is 90mm, you need a machine with a pitch of at least 110mm-120mm. Do not count on luck; standard machines cannot make wide-mouth jars.

Machine Pitch vs. Preform Compatibility Table

| Machine Type | Typical Pitch (mm) | Compatible Preform Diameter (mm) | Feasibility Analysis |

|---|---|---|---|

| Standard Water Bottle | 76.2 (3 inches) | < 70mm | Impossible: >70mm wide-mouth preforms will crash or block airflow. |

| Edible Oil Machine | 76.2 - 101.6 | 60 - 90mm | Limited: Only for small-to-medium necks; large necks lack cooling. |

| iBottler Wide-Mouth | 120.0 - 150.0 | 90 - 135mm | Optimal: Designed for large diameters with ample clearance and cooling. |

2. Preform Design Strategy: How Do You Balance Wall Thickness and Heating Efficiency?

Does your jar feel soft like cheap plastic, despite having a heavy weight? The problem likely lies in the preform geometry and stretch ratios. Often, to increase the tactile quality ("hand feel"), clients blindly increase weight but ignore the science of preform design.

Wide-mouth preforms require a wall thickness of 3.5mm to 5.0mm to maintain structural rigidity, which is significantly thicker than standard preforms. The challenge is balancing this thickness with the ability to heat the material through without burning the surface. You must optimize the Length-to-Diameter (L/D) ratio and address transparency issues during the mold design phase.

Designing a preform for a wide-mouth jar requires a completely different engineering mindset than designing for a water bottle. In standard water bottle applications, we rely heavily on the Axial Stretch Ratio (stretching the preform length significantly) to align the PET molecule chains and gain strength. However, in jar design, the container is usually "short and fat," so the axial stretch space is very limited.

If we design the preform to be too short to accommodate the required weight, the wall thickness is forced to increase (often exceeding 6mm). PET is a poor conductor of heat. When the wall thickness exceeds 5mm, it acts as a thick insulator. In the heating oven, the infrared energy cannot conduct to the inner core before the outer skin overheats and crystallizes (turns white). This state of "cooked outside, raw inside" leads to severe haze in the finished bottle, and the jar becomes extremely brittle. Conversely, if the preform is designed too long and thin, while heating becomes easier, the final container wall becomes too thin, lacking the premium "glass-like" feel consumers expect.

Therefore, the core of the design lies in utilizing Hoop Stretch (Radial Stretch). We need to force the preform to expand more in the diameter direction rather than the length direction.

Vivian's Insight (Professional Analysis):

Do not simply copy the "stretch ratio" parameters from a water bottle data sheet; it will not work. I advise my clients to keep the preform length close to 1/2 or 2/3 of the final jar length. I recently participated in the design of a preform mold for a 1kg honey jar. The initial design was very short and thick, with a wall thickness of 6.5mm. During production, to heat this "thick chunk" thoroughly, the cycle time exceeded 20 seconds, and electricity costs were astronomical. We redesigned the preform to be taller and slightly thinner (4.2mm). The result? The cycle time dropped to 14 seconds, and because heat absorption was more uniform, the bottle's clarity transformed from a "frosted look" to a "crystal look." When designing, you must simulate the stretching process on the preform mold drawings to ensure every gram of material goes exactly where it is needed.

Key Preform Design Parameters & Failure Correlations

| Parameter | Recommended Range | Consequence (Too Low) | Consequence (Too High) |

|---|---|---|---|

| Single Wall Thickness | 3.5mm - 4.5mm | Soft body, poor quality feel | Difficult heating, surface whitening, stress whitening |

| Axial Stretch Ratio | 1.4 - 1.8 | Heavy accumulation in base | Base too thin, easy to rupture |

| Hoop Stretch Ratio | 3.0 - 3.8 | Insufficient rigidity, deformation | Explosion risk, requires high pressure |

When selecting the preform neck size, remember that a wider neck means less stretching at the shoulder. The shoulder design of the preform must slope gently to ensure material flows effectively into the jar's shoulder without thinning out.

3. Heating Process: Why Is the "Low Power, Long Soak" Strategy Crucial?

Are you seeing a white haze on your finished jars, or do they shatter like glass during drop tests? This is usually not a raw material issue, but rather "thermal damage" caused by aggressive heating of thick-walled preforms.

To solve the issue of "burnt surface, cold core," you must implement a "Low Power, Long Soak" strategy. This involves significantly reducing the lamp output percentage while slowing down the heating chain speed. This allows infrared radiation to penetrate deep into the thick PET wall without overheating the outer skin.

The thermal conductivity characteristics of PET make it extremely difficult to heat when walls are thick. When you blast a thick preform with high-intensity infrared energy (e.g., 95% power), the energy accumulates primarily on the surface layer. The outer surface quickly reaches the crystallization temperature of around 140°C, instantly turning opaque white (thermal crystallization). Meanwhile, the inner core temperature may still be stuck at 80°C, below the optimal glass transition temperature.

When you send this "brittle outside, raw inside" preform into the mold for blowing, the outer layer has already aged and become brittle, while the inner layer is too cold to stretch uniformly. The result is a defective product filled with internal stress, high haze, and extreme fragility.

The engineering solution is to completely modify the thermal gradient. We need to lower the energy density but drastically increase the exposure time. It is like slow-cooking a stew; you cannot rush it with a high flame.

Steps to Implement this Strategy:

- Lower Voltage: Reduce the power of the IR lamps from the standard 85% down to 60% - 70%.

- Reduce RPM: This is painful because it means lower output, but you must reduce the heating chain speed to let the preform stay in the oven for an extra 5-10 seconds.

- Aggressive Ventilation: Increase the surface ventilation in the oven to constantly strip hot air off the preform skin, preventing surface overheating while allowing IR energy to continue penetrating inward.

Vivian's Insight (Case Study):

I helped a well-known protein powder factory solve a severe haze issue. Their production manager was very anxious because their jars always looked grey and lacked a premium feel. To meet production quotas, the operators had cranked the lamps to 90% for a "flash bake," trying to shorten heating time. The first thing I did upon arrival was force them to slow the machine down by 15% and drop all lamp power below 65%. The production manager was initially resistant, thinking I was destroying efficiency. But when the first batch of adjusted jars came out, he fell silent—the jars were crystal clear, like acrylic. More importantly, the previous drop test pass rate was only 70%; after adjustment, it hit 100%. For wide-mouth thick-walled products, transparency is achieved by "soaking" in time; haste creates waste.

Heating Zone Control Strategy

| Heating Zone | Power Suggestion | Physical Function |

|---|---|---|

| Zone 1 (Below Neck) | 50% - 55% | Protection Zone: Prevents heat from conducting up to the neck, requiring only mild heat. |

| Zone 2-4 (Body) | 60% - 70% | Soak Zone: Low power maintains long exposure, ensuring minimal temp difference between inside/outside. |

| Zone 5-6 (Base) | 75% - 85% | Intensify Zone: The base is thickest and travels furthest, requiring higher heat for flow. |

4. Neck Protection: How Can You Prevent Ovality in Large Finishes?

Do your caps fail to seal tightly after a few days? Or does the capping machine feel uneven resistance? Large diameter necks are massive heat sinks that distort easily during the heating process.

Wide-mouth finishes (80mm - 120mm) collect significant radiant heat in the oven. Without dedicated cooling, the neck softens and becomes oval, leading to leakage. Your machine must be equipped with aggressive neck cooling ventilation or water-cooled shields to maintain the dimensional stability of the finish.

The "Neck Finish" is the only part of the preform that should not change shape; it is the foundation of the entire package's seal. However, in wide-mouth production, this principle faces a huge challenge. Because wide-mouth preforms are usually short, the neck sits very close to the heating lamps. Heat naturally rises, and the stray "waste heat" in the oven naturally bakes the neck.

For a small 28mm water bottle, this thermal impact is negligible. But for a 100mm large-diameter neck, the surface area absorbing heat is multiplied. Once the thread area temperature exceeds 60°C, PET molecules begin to mobilize. Subsequently, during blowing, high-pressure gas exerts radial tension on the neck; or after cooling, internal stress release causes the neck to twist into an oval shape (Ovality). Even an ovality of just 0.5mm is fatal for sealing caps, leading to product oxidation or moisture ingress.

Engineering Solutions for Neck Stability:

- Physical Shielding: You must verify that your heating oven has intact metal Shielding Plates installed between the first layer of lamps and the preform neck.

- Active Cold Air: Standard machines use ambient air for cooling. For wide-mouth jars, you must introduce a "Cold Source." I recommend ducting air-conditioned cold air or air from a heat exchanger directly onto the neck rails via dedicated piping.

- Water-Cooled Mandrels: This is a high-end configuration. It involves circulating cooling water internally through the mandrels that hold the preforms, directly conducting heat away from the neck from the inside out.

Vivian's Insight (Professional Analysis):

If you find your jars leaking, don't just blame the cap. Take a high-precision digital caliper and measure the "Ovality" of the neck. Measure the diameter at 0°, 45°, 90°, and 135°. I often find clients ignoring the oven protection plates; some plates are even bent or missing, allowing heat to leak directly onto the neck. I recall a client with a 120mm pickle jar that couldn't hold a vacuum and always leaked oil. We troubleshot on-site and found the exhaust fan on top of the oven was broken, causing hot air to accumulate at the top and bake the necks. After fixing the fan and adding a compressed air nozzle aimed at the neck, the neck temperature dropped by 15°C instantly, and the leakage stopped. This is the most easily overlooked blind spot when troubleshooting common PET blow molding defects.

5. Base Forming: What Ensures Stability and Thickness in Flat Bottoms?

Does your jar wobble when placed on a flat table? This "rocker bottom" phenomenon not only affects shelf display but also causes bottles to tip over on the filling line. The core reason lies in uneven material distribution and insufficient cooling.

Most wide-mouth jars utilize a flat base design for aesthetics and stacking requirements. However, if the material at the base is too thin, it bulges outward due to internal pressure or residual heat, creating a curved bottom. You must drive enough material thickness into the base to create a rigid, flat foundation.

From a structural mechanics perspective, a flat plane is the weakest geometry for resisting internal pressure. Carbonated beverage bottles use a "petaloid" base precisely to utilize the arch structure for pressure resistance. Wide-mouth jars, however, usually pursue a flat aesthetic. The problem is that even slight residual pressure after blowing, or the temperature from hot-filling, can easily push a thin flat center outward. Once the bottom becomes convex, the jar becomes a "weeble-wobble."

To fix this, we need to accumulate "Mass" in the base. We must ensure that a significant portion of the preform material (often 25%-30% of total weight) lands precisely in the bottom area of the blow bottle mold, forming a thick disc.

Three Critical Factors for Base Stability:

- Excessive Pre-blow Pressure: If pre-blow pressure is too high or timing is too early, the preform expands too much in the middle of the mold and sticks to the side walls, leaving insufficient material for the bottom.

- Insufficient Gate Cooling: The injection Gate is the thickest and hottest part of the preform. If it isn't "frozen" instantly upon touching the mold base, it will continue to soften and deform after the mold opens due to retained heat.

- Mold Compensation Design: Smart mold design never makes an absolute flat surface. We typically design a 1.5mm - 2.5mm concave "Push-up" in the mold base. This way, even if the plastic springs back slightly after cooling, the base remains flat or slightly concave, ensuring stable standing.

Vivian's Insight (Professional Analysis):

Many people mistakenly think flat-bottom jars are the easiest to blow. In reality, "flat" hates being "thin." I have seen countless jars acting like wobbling toys, while the client frantically increased blow pressure trying to "flatten it out," which only made it thinner and more convex. The real solution is in timing. I significantly delay the Pre-blow (Pre-blow Delay), letting the stretch rod physically carry that thick mass of material all the way to the mold bottom before turning on the high-pressure air. It’s like laying a thick floor tile at the bottom. It is better to have a slightly thicker base and thinner walls than a wobbly jar.

Furthermore, connecting the mold to a high-capacity chiller is non-negotiable. For flat-bottom wide-mouth jars, the mold base water channel must be independent, and water temperature should be controlled at an aggressive 8°C - 10°C to achieve "instant setting."

6. Axial Stretch Management: How Do You Compensate for Low Stretch Ratios?

Do the bottom corners of your jar rupture during drop tests? This structural weakness occurs when the stretch rod fails to guide material into the corners. The "short and fat" nature of wide-mouth jars makes this a precision game of material allocation.

Because wide-mouth jars have low axial stretch ratios, the stretch rod has a short stroke. It cannot naturally "pull" the material into the bottom corners (the chime area) like it does in long water bottles. You must manipulate the pre-blow delay and pressure to force the material into these corners pneumatically, rather than mechanically.

When producing slender mineral water bottles, the stretch rod travels a long distance, physically stretching and orienting the PET crystals to make them tough. But when producing a 100mm tall squat jar, the rod might move less than 100mm. This low movement means we lose mechanical control over where the material lands.

The "Chime"—the radius where the side wall meets the bottom—is the stress concentration point for the entire container. If this area is too thin, or hasn't undergone sufficient Bi-axial Stretch, impact force will tear it apart immediately upon dropping.

Process Adjustments for Strong Corners:

- Extremely Late Pre-Blow: Delay the pre-blow activation until the stretch rod has almost touched the bottom of the mold (e.g., 5mm from the bottom). This ensures the bulk of the material stays gathered at the tip of the rod until the very last moment before being released into the corners.

- Explosive High Pressure: Wide-mouth jar corners are often sharp. You need higher main blow pressure (30-35 bar) to force the material to conform tightly to the mold wall. This may require a stronger high pressure compressor.

- Mold Venting: Venting in the mold corners is critical. If air is trapped in the corner, it forms an air cushion, preventing the plastic from touching the metal mold, resulting in undefined corners and insufficient cooling.

Vivian's Insight (Professional Analysis):

I often describe this as a battle between "Pushing" and "Blowing." For wide-mouth jars, we are mostly "Pushing." If you trigger the pre-blow air too soon, the balloon expands in the middle of the mold and sticks to the mold walls early; friction then prevents the material from sliding down, starving the bottom corners. By delaying the pre-blow, I force the "bubble" to start expanding from the bottom upwards. This packs more material into the corners, creating a sturdy crash bumper. If your jars always break, don't suspect the raw material; first, check your pre-blow delay time and whether the mold corner vents are clogged.

For more expert guidance on optimizing these geometries, refer to our PET bottle mold design guide.

7. Demolding Challenges: How Do You Overcome Vacuum Resistance?

Is your machine making a loud "popping" sound when the mold opens? Or are the mechanical arms deforming the jars? This is a physical side effect of flat-bottom designs: Vacuum Lock.

Wide-mouth jars with flat bottoms create a massive vacuum seal against the mold metal. This resistance can be strong enough to pull the jar out of shape during ejection or even damage the robotic arms. You must combat this via mold surface treatment and strategic venting.

Let's do a simple physics calculation: The force required to pull a jar off the mold is $Force = Vacuum \times Area$. A 120mm diameter flat bottom has a huge surface area. When hot plastic makes intimate contact with cold, smooth metal, all air is squeezed out, creating a near-perfect seal. When the mold tries to open, a vacuum forms, holding the jar bottom dead against the mold base.

At this moment, if the machine tries to pull the jar up by the neck, there are only two outcomes: the jar stretches and deforms, or the robot arm overloads and alarms.

Engineering Solutions for Smooth Demolding:

- Mold Surface Texture: Absolutely do not polish the bottom of a wide-mouth mold to a mirror finish. We recommend a VDI 3400 standard sandblast (matte) texture. This microscopic roughness breaks surface tension, preventing the plastic from sealing perfectly against the metal, effectively reducing vacuum adhesion.

- Base Venting Slots: The mold base must be designed with micro-vents (0.03mm - 0.05mm deep slits) cut directly into the base plate. These allow air to rush in under the bottle the instant the mold begins to open, equalizing the pressure.

- Draft Angles: Ensure the side walls near the base have a sufficient draft angle (taper) to facilitate release. Vertical walls on wide containers increase friction significantly.

Vivian's Insight (Professional Analysis):

This is a detail that is easy to miss until you hear it. I’ve heard machines that sound like huge suction cups popping—THUMP!—every cycle. This shockwave, over time, loosens machine screws and damages expensive servo motors. In my experience, simply sandblasting the mold base can reduce ejection force by 50%. On a particularly stubborn project, we added extra venting slits in a "star" pattern across the base. The result was immediate: the "thump" disappeared, and the robot arms could remove the bottles smoothly without any distortion. Before finalizing your mold, check the mounting dimensions to ensure proper venting paths are available.

8. Why iBottler is Your Strategic Partner for Wide-Mouth Projects

Are you looking for a vendor who understands that a wide-mouth machine is more than just a standard machine with a bigger hole?

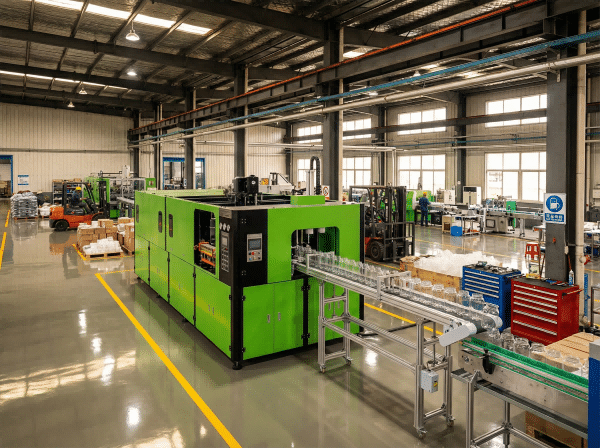

Producing wide-mouth jars is a balancing act of thermal management, mechanical precision, and mold engineering. At iBottler, we provide dedicated Wide-Mouth Series machines featuring extended heating pitches, specialized cooling channels, and high-torque clamping systems designed specifically for large-diameter production.

We don't just ship equipment; we transfer a complete production process. When you order a wide-mouth line from us, we analyze your 3D printed samples and preform designs before the metal is even cut.

iBottler's Full-Process Technical Commitment:

- Precision Pitch Matching: We do not sell "universal" machines. We recommend models with 120mm, 140mm, or larger pitches based on your largest preform diameter, completely eliminating collision risks in the oven.

- Process Window Preset: We understand the heating difficulties of thick-walled jars. Before shipment, we pre-configure the "Low Power, Long Soak" heating profiles in the PLC based on your wall thickness, ensuring you start with 80% yield immediately.

- Complex Mold Engineering: Our mold design team includes proper venting strategies and deep cooling channels as standard, ensuring your jars are not only clear but also flat.

Vivian's Insight (Service Commitment):

Producing wide-mouth jars is like walking a tightrope. You need to balance heat (preventing haze) and cooling (preventing deformation), balance wall thickness (tactile feel) and efficiency (cost). With 20 years of frontline experience, I have seen every defect and accident imaginable. When you partner with iBottler, you aren't just buying steel and wires; you are buying the experience library of myself and our engineering team. We ensure that when you press "Start," you get crystal-clear, saleable product, not bins of melted plastic scrap.

Conclusion

Wide-mouth jar production is a challenge against physical limits, requiring specific engineering attention to machine pitch, heating penetration depth, and base formation control. By respecting these physical constraints rather than just chasing speed, you can produce premium containers that are both crystal clear and structurally durable.

FAQ

Q1: Why are my wide-mouth jars turning white/hazy during production?

A1: This is usually due to the "Cold Core, Burnt Skin" effect. Your preform walls are thick. If you use high power for fast heating, the surface crystallizes (whitens) before the inside gets hot. The solution is to lower lamp power (to 60%-70%) and simultaneously slow down the machine to increase heating time, allowing heat to soak through gently.

Q2: Can I use my standard water bottle machine for wide-mouth jars?

A2: Absolutely not. Standard machines usually have a center-to-center pitch of 76.2mm (3 inches). If your wide-mouth preform diameter (e.g., 90mm) exceeds the machine pitch, it will physically collide in the oven and simply cannot be loaded or run. This is not just a quality issue; it is a fundamental equipment mismatch. Always check the mandrel "Center-to-Center" distance first.

Q3: Why do the jar bottoms rock and not sit flat (Rocker Bottom)?

A3: This is the "Rocker Bottom" defect. When base material is too thin or too hot, it bulges outward under pressure. The solution is to significantly delay the pre-blow time to push more material to the bottom, and ensure the chiller provides 8-10°C water to the mold base for aggressive cooling.

Q4: How do I stop the large necks from becoming oval?

A4: Large necks absorb massive amounts of heat and deform easily. You must install intact metal shielding plates in the oven to block IR rays from the neck, and we strongly recommend using an active cold air system blowing directly onto the neck rails.

Q5: What is the ideal wall thickness for a wide-mouth preform?

A5: For most applications, 3.5mm to 4.5mm is the ideal range. This provides enough structural rigidity (tactile feel) for the jar without being so thick that it becomes impossible to heat efficiently or creates haze.

Summary of Wide-Mouth Technical Challenges & Solutions

| Challenge | Root Technical Cause | Engineering Solution | Cost Impact |

|---|---|---|---|

| Preform Collision | Preform Diameter > Machine Pitch | Select machine based on Pitch (e.g., 120mm+) not Volume. | Requires specialized machine purchase; higher initial investment but prevents stoppages. |

| White/Hazy Wall | Thick wall causes surface overheating | Implement Low Power (60%), Long Soak strategy. | Reduces output by 10%-15%, but increases yield rate significantly. |

| Oval Neck/Leakage | Radiant heat softens large finish | Install oven shields and active air cooling system. | Increases cooling energy usage, but eliminates return risks. |

| Wobbly/Uneven Base | Base material too thin / bulging | Delay pre-blow to push material to base; enhance base cooling. | Requires high-precision compressor coordination. |

| Corner Rupture | Low axial stretch, starved corners | Increase main blow pressure; optimize pre-blow timing; improve venting. | Increases high-pressure air consumption. |

| Loud Demolding | Vacuum lock on flat bottom | Sandblast mold base (Texture) and add venting slits. | Minimal cost; protects robotic arms and product shape. |

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr