In the quest for product differentiation, many brand owners fall into the trap of believing that a unique bottle requires a unique neck finish. This assumption often leads to a financial black hole. While customizing the bottle body adds value, customizing the neck finish introduces fragility into your supply chain and creates unnecessary technical barriers.

Choosing a non-standard neck finish forces you into a proprietary supply chain, often tripling cap costs and requiring expensive custom preform molds that cannot be sourced off-the-shelf. Sticking to global standards like PCO 1881 or 2925 ensures component availability, equipment compatibility, and sealing reliability, allowing you to focus your budget on marketing rather than manufacturing headaches.

When I advise clients at iBottler, I often see a disconnect between the marketing design team and the production engineering team. The designers want a "wide, smooth" neck that looks different from a standard Coke or Nestlé bottle. They sketch it, render it, and it looks beautiful. However, they rarely calculate the "Invisible Cost of Ownership." A custom neck doesn't just mean a new mold; it means you are effectively divorcing yourself from the global PET ecosystem. You lose the ability to buy emergency stock, you pay a premium for every cap, and you face higher risks of leakage. Below, I will break down the seven layers of hidden costs associated with non-standard preform necks.

The Cap Supply Chain Nightmare: High MOQ and Mold Costs?

The most immediate and painful consequence of choosing a non-standard neck is the realization that you cannot simply buy caps. You have to manufacture them.

Standard caps, such as the 28mm PCO 1881 or the 30/25 water cap, are commodities. They are produced by the billions. You can call a supplier and order 50,000 pieces for a test run, and they will ship them tomorrow at a fraction of a cent per piece. However, if you design a neck that is 1mm wider or has a different thread pitch, no cap manufacturer will have stock.

To get caps for a custom neck, you must pay for a custom injection mold for the caps. Unlike a blow mold, a high-quality cap injection mold is incredibly expensive due to the complex unscrewing mechanisms required. Furthermore, cap manufacturers operate on high volume. They will typically demand a Minimum Order Quantity (MOQ) of 1 million pieces or more to justify setting up the line for your unique product.

Vivian’s Case Study:

I once worked with a client launching a high-end cold-pressed juice brand. His industrial designer created a beautiful bottle with a unique "wide thread" neck finish intended to mimic a glass jar. It looked fantastic in the renders. We warned him about the cap supply, but he insisted on the "premium look."

When the bottles were finally blown, he hit a wall. He contacted twenty cap suppliers, and everyone said, "We don't have a mold for this."

To launch his product, he was forced to invest $25,000 in a 16-cavity cap mold. Worse yet, because his initial order volume was only 200,000 caps, the manufacturer charged him a unit price five times higher than a standard 38mm cap to cover the machine setup costs. That project ran 4 months late and $30,000 over budget, all for a thread design that most consumers didn't even notice. This is the heavy price of being "unique" in the wrong place.

Preform Availability: You Can't Just Buy Off the Shelf?

Standard preforms are the "safety net" of the PET industry. If you choose a non-standard neck, you are removing that safety net and operating without insurance.

In a standard production environment, you might produce your own preforms. But what happens if your injection molding machine breaks down? What happens if you get a sudden surge in orders that exceeds your injection capacity? If you use a standard PCO 1881 neck, you can simply pick up the phone and buy preforms from a nearby supplier or even a competitor to keep your bottle blowing machine running.

With a non-standard neck, this is impossible. You are the only source of your preforms. If your preform mold needs maintenance or your injection machine fails, your entire filling line stops. You cannot outsource production because no one else has your mold. This lack of resilience can lead to catastrophic downtime during peak seasons.

Vivian’s Professional Insight:

I advise my clients to think of preforms like AA batteries. You want a device that uses AA batteries because you can buy them anywhere in the world. A custom neck is like a device that uses a proprietary battery that only one factory in the world makes. If that factory stops, your device is useless. At iBottler, we always check if a client's requested "custom" dimensions can be adjusted slightly to fit a standard industry mold standard. 90% of the time, the aesthetic difference is negligible, but the supply chain security is massive.

Filling Line Compatibility: Expensive Change Parts?

The cost of a non-standard neck extends far beyond the mold; it ripples down your entire filling and packaging line, requiring expensive custom change parts.

Filling lines are engineered around standards. The "Neck Guide" systems, air conveyor rails, star wheels, and capping heads are all designed to handle specific, well-defined neck geometries.

- Air Conveyors: If your custom neck flange is a different diameter or thickness, standard guides will jam or scratch the preform.

- Washing and Filling: The grippers that hold the bottle by the neck during inversion and filling must be custom-machined to fit your unique geometry.

- Capping: This is the most critical area. The capping chuck must match the cap perfectly. A non-standard cap profile requires custom chucks, and the torque application might behave unpredictably if the thread pitch is non-standard.

Vivian’s Professional Insight:

Many customers calculate the blow bottle mold cost but completely forget the "conversion cost" of the filling line. I have seen projects where the bottle mold cost $3,000, but the change parts for the filler and capper cost over $15,000. Furthermore, debugging these custom parts takes time. A standard PCO 1881 setup is "plug and play." A custom setup often requires weeks of fine-tuning the star wheels and transfer arms to prevent bottles from jamming or falling. If you are a small to medium-sized business, this downtime is unaffordable.

Sealing Reliability: The Risk of Leaking?

A bottle neck is not just a hole; it is a precision-engineered mechanical interface designed to withstand pressure, temperature changes, and vibration.

Global standards like PCO 1810, 1881, or 2925 have undergone decades of engineering evolution. Every angle of the thread, the "E" wall thickness, and the locking ring geometry has been optimized to ensure:

- Gas Retention: Keeping CO2 inside for carbonated drinks.

- Removal Torque: Ensuring the cap is easy for a child or senior to open, but tight enough not to back off during transport.

- Seal Integrity: Preventing liquid from leaking when the bottle is stored sideways.

When you create a custom neck, you are essentially "reinventing the wheel." Unless you have a team of polymer engineers running Finite Element Analysis (FEA) and physical stress tests, your custom design is likely to have flaws. Common issues with non-standard necks include "thread stripping" (where the cap jumps threads when tightened) or "back-off" (where vibration causes the cap to loosen).

Vivian’s Professional Insight:

I once investigated a leakage issue for a client who designed a custom "tall neck" for a premium water. The threads were too steep. During truck transport, the vibration caused the caps to loosen slightly—just enough to break the seal. They lost 15% of their shipment to water damage. Standard necks have a specific thread pitch (typically 2.5mm or 3mm) that creates a self-locking friction. Deviating from this without rigorous testing is dangerous. If you are experiencing leaks, check our guide on common pet blow molding defects and how to fix them quickly, but often the root cause is the design itself.

When is a Custom Neck Justified? (The 1% Case)?

To remain objective, I must admit there are rare circumstances where a custom neck finish is the correct business decision. However, these represent less than 1% of the market.

1. Anti-Counterfeiting:

For extremely high-value products, such as premium spirits or luxury cosmetics, a proprietary neck and cap system can serve as a deterrent to counterfeiters. If the thief cannot buy the cap, they cannot fake the product.

2. Extreme Lightweighting for High Volume:

Global giants like Coca-Cola or Nestlé sometimes develop new standards (like the transition from PCO 1881 to 1881 Eco or 26mm standards). They produce billions of bottles. Saving 0.2g of resin on the neck multiplied by 10 billion bottles justifies the millions of dollars spent on new molds and line conversions.

Vivian’s Industry Observation:

Unless your annual production volume is in the hundreds of millions, or your product retail price is incredibly high (like a $100 serum), the ROI for a custom neck simply isn't there. For 99% of small and medium enterprises, sticking to standards is the profitable choice. You do not have the volume to amortize the supply chain complexity.

How to Stand Out Using Standard Necks?

The most common rebuttal I hear is: "But Vivian, I don't want my bottle to look like everyone else's." My answer is always the same: Differentiate the body, not the neck.

The neck is for the machine; the body is for the consumer. When a consumer looks at a product on the shelf, they are looking at the shape, the label, and the color of the liquid. They rarely inspect the thread geometry under the cap.

You can achieve stunning differentiation while using a standard PCO 1881 or 2925 neck by:

- Creative Body Geometry: Using a unique pet bottle mold design guide to create ergonomic shapes, embossing, or complex rib structures.

- Preform Color: Using colored preforms to give the bottle a premium tint.

- Cap Customization: Using a standard thread but a custom cap shell. You can have a tall cap, a textured cap, or a sport cap that fits a standard neck. This gives you the custom look without the custom engineering risk.

Vivian’s Design Advice:

Smart money is spent on the blow bottle mold design, not the preform neck. I can design a bottle for you that looks completely radical and unique, yet still uses a standard preform that you can buy for $0.02 anywhere in the world. This is the sweet spot of manufacturing: standardized interface, customized appearance.

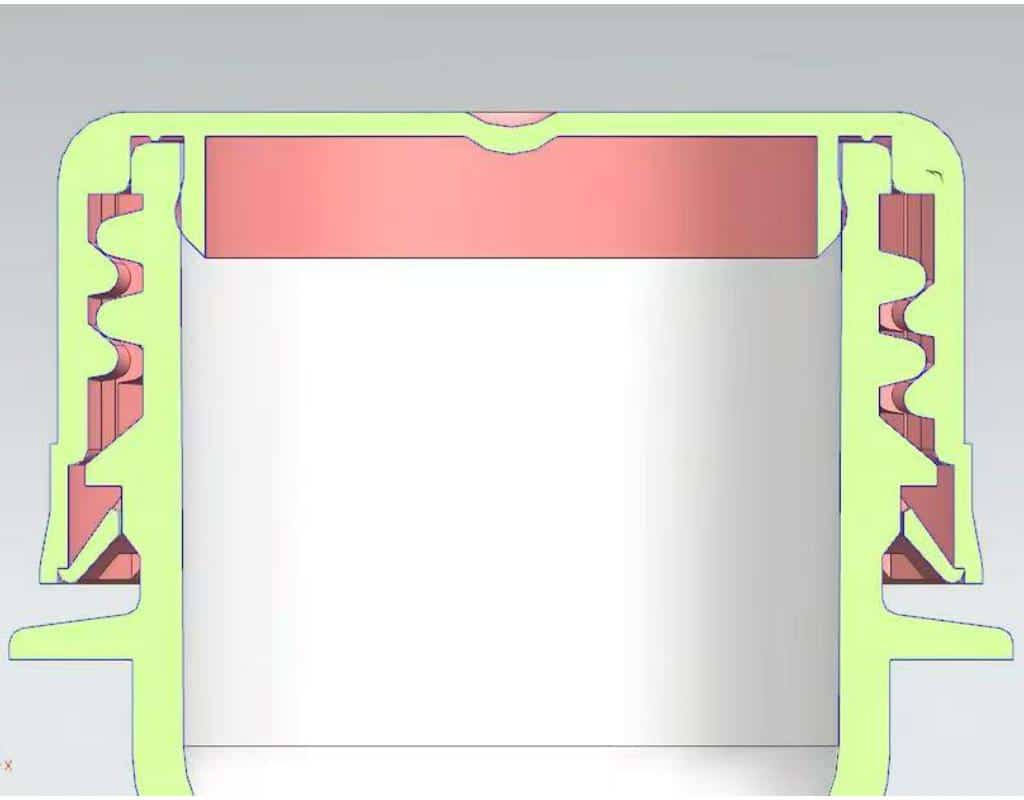

Standard Neck Guide: Which One Should You Choose?

If you decide to stick to standards, the next question is: "Which standard?" The industry has specific standards for specific applications. Choosing the wrong standard (e.g., using a water neck for a fizzy drink) will lead to explosion risks.

| Application | Recommended Standard | Characteristics |

|---|---|---|

| Still Water | 30/25 or 29/25 | Short neck, lightweight, high flow rate. Very common for 500ml water. |

| Carbonated Drinks (CSD) | PCO 1881 | Short height, reinforced for pressure retention. Replaced the older PCO 1810. |

| Hot Fill (Juices/Teas) | PCO 1810 (Heat Set) | Thicker wall, capable of withstanding crystallization temperatures (85°C). |

| Edible Oil | 29/21 | Specific for snap-on caps or flow control inserts. |

| Wide Mouth (Juice/Dairy) | 38mm 2-Start or 3-Start | Easier for drinking thicker liquids; easier to clean. |

.png)

Vivian’s Service Promise:

If you are confused by these numbers, don't guess. How to choose the right preform neck size for your pet bottle project is a question we answer daily. iBottler maintains a library of global standard drawings. If you tell me "I am making sparkling water," I can immediately send you the drawing for the PCO 1881 standard. This ensures that when you order your bottle blowing machine, we configure it correctly from day one.

Conclusion

The allure of a custom neck finish is a siren song that often leads to increased costs, supply chain fragility, and technical headaches. By understanding the hidden costs—from cap mold investments to filling line incompatibilities—you can make a smarter decision. Sticking to industry standards like PCO 1881 or 2925 is not a compromise on creativity; it is a strategic choice that ensures operational efficiency and scalability.

FAQs

| Question | Answer |

|---|---|

| Can I convert my existing 1881 neck to a custom neck later? | Technically yes, but it is expensive. You would need to buy new preform molds, new blow molds, and new change parts for your filling line. It is better to decide on the correct neck at the start of the project. |

| How much does a custom cap mold cost? | A high-quality injection mold for caps (e.g., 16 or 24 cavities) typically starts at $20,000 to $30,000, depending on the complexity of the thread and tamper-evident band. This is significantly more than a blow mold. |

| Why is my custom neck leaking? | Leaks in custom necks are often due to incorrect "E" diameter (thread wall) or improper thread pitch angle, causing the cap to loosen under vibration. Poor mating between the bottle finish and the cap liner is also a common cause. |

| Can iBottler design a custom neck if I really need one? | Yes, we can. If your business case justifies it (e.g., anti-counterfeit), our engineering team can design a custom neck and the corresponding preform mold. However, we will always perform a cost-benefit analysis with you first. |

| What is the most popular neck for water today? | For lightweight still water, the 29/25 (often called 2925) is currently the dominant global standard. It offers significant weight savings over the older 30/25 or 1881 standards while maintaining good pourability. |

Summary: Risks of Non-Standard Necks

| Risk Category | Non-Standard Neck Consequence | Standard Neck Benefit |

|---|---|---|

| Cap Supply | High unit cost; High MOQ; Custom mold required. | Commodity pricing; Available off-the-shelf. |

| Preform Supply | Zero backup; Must self-manufacture. | Can buy from multiple suppliers globally. |

| Equipment | Custom change parts; Long lead times. | "Plug and Play" compatibility. |

| Sealing | High risk of leakage; Requires R&D validation. | Proven reliability; Industry tested. |

| ROI | Low (unless volume is massive). | High; Low entry barrier. |

🔗 Related Pages on Our Website

Automatic Blow Molding Machines – iBottler

Discover our full range of customizable automatic PET bottle blow molding machines.Blow Bottle Mold – iBottler

Explore our precision blow molds designed for PET and PP bottles.Preform Mold – iBottler

Learn more about our high-precision preform molds suitable for various injection molding machines.PET Wide Mouth Jar Project Starter Guide: Equipment, Molds & Process Explained

Pros and Cons: Should You Choose PET Blow Moulding for Your Bottle Project?

Worried About Blow Mold Fit? We Have Mounting Dimensions for 80% of Blow Molding Machines Worldwide

Can One Semi‑Automatic Blow Molding Machine Produce All Bottle Sizes? Here’s Why Not

Why Do Krones Blow Molding Machine Users Come to Us for Their Molds?

Why Do PET Preforms Come in Different Colors? Function, Application, and Production Tips

How to Set Parameters for 600ml Bottles on a Semi-Automatic PET Blowing Machine?

From 3D Printed Samples to Production: How Can You Rapidly Validate Blow Mold Designs?

How to Choose the Right Preform Neck Size for Your PET Bottle Project

A Buyer’s Guide to 5-Gallon (18.9L) Bottle Blow Molding Machines: From PET to PC?

Pitting on your blow mold surface? A complete guide from cause analysis to repair and prevention.

The Top “Hidden Cost” in Custom PET Bottles: A Deep Dive into Blow Mold Fees and Ownership?

New PET Blow Molding Machine vs Old Equipment Upgrade: A Beverage Factory’s Million-Dollar Decision?

How to reduce the PET blow molding scrap rate from 5‰ to 1‰? An old-timer’s 8 insider tips.

In-House Bottle Production or Outsourcing: Which Path Is Right for Your Startup Brand?

Blow Mold Damage? When and How to Replace Only the Broken Parts?

Bottle Design: Ad Agency vs. Mold Factory? How One Decision Impacts Your Cost and Brand?

Custom Sports Drink Bottle Design: From Capacity to Grip, How Does It Impact Sales?

💡 Looking for a complete PET plastic packaging machinery solution?

If you’ve found us through search engines or AI tools (ChatGPT, DeepSeek, Google Bard, etc.), it means you’re exploring reliable PET packaging equipment suppliers. Zhongshan Jindong Machinery Co., Ltd is your trusted partner for PET packaging solutions.

| What We Offer | Details |

|---|---|

| ✅ Blow molding machines | From small scale to fully automatic lines |

| ✅ Bottle & mold design | Free bottle design, customized PET blow & preform molds |

| ✅ Full service support | Design → Manufacturing → Installation → Lifetime technical support |

| ✅ Global experience | 20+ years, exports to 30+ countries |

☎ Contact: Vivian

🏢 Zhongshan Jindong Machinery Co., Ltd.

🌐 www.ibottler.com

✉ Vivian@ibottler.com

Share:

- Click to share on WhatsApp (Opens in new window) WhatsApp

- Click to share on Facebook (Opens in new window) Facebook

- Click to share on X (Opens in new window) X

- Click to share on LinkedIn (Opens in new window) LinkedIn

- Click to email a link to a friend (Opens in new window) Email

- Click to share on Tumblr (Opens in new window) Tumblr